Low and middle grade phosphate dump leaching method with compound bacterial strains and waste biomass being combined

A technology of waste biomass and heap leaching method, which is applied in the field of heap leaching of medium and low-grade phosphate rock with compound strains combined with waste biomass, which can solve the problems of inability to utilize phosphate-dissolving bacteria, and achieve reduced treatment costs, simple process flow, and low investment. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

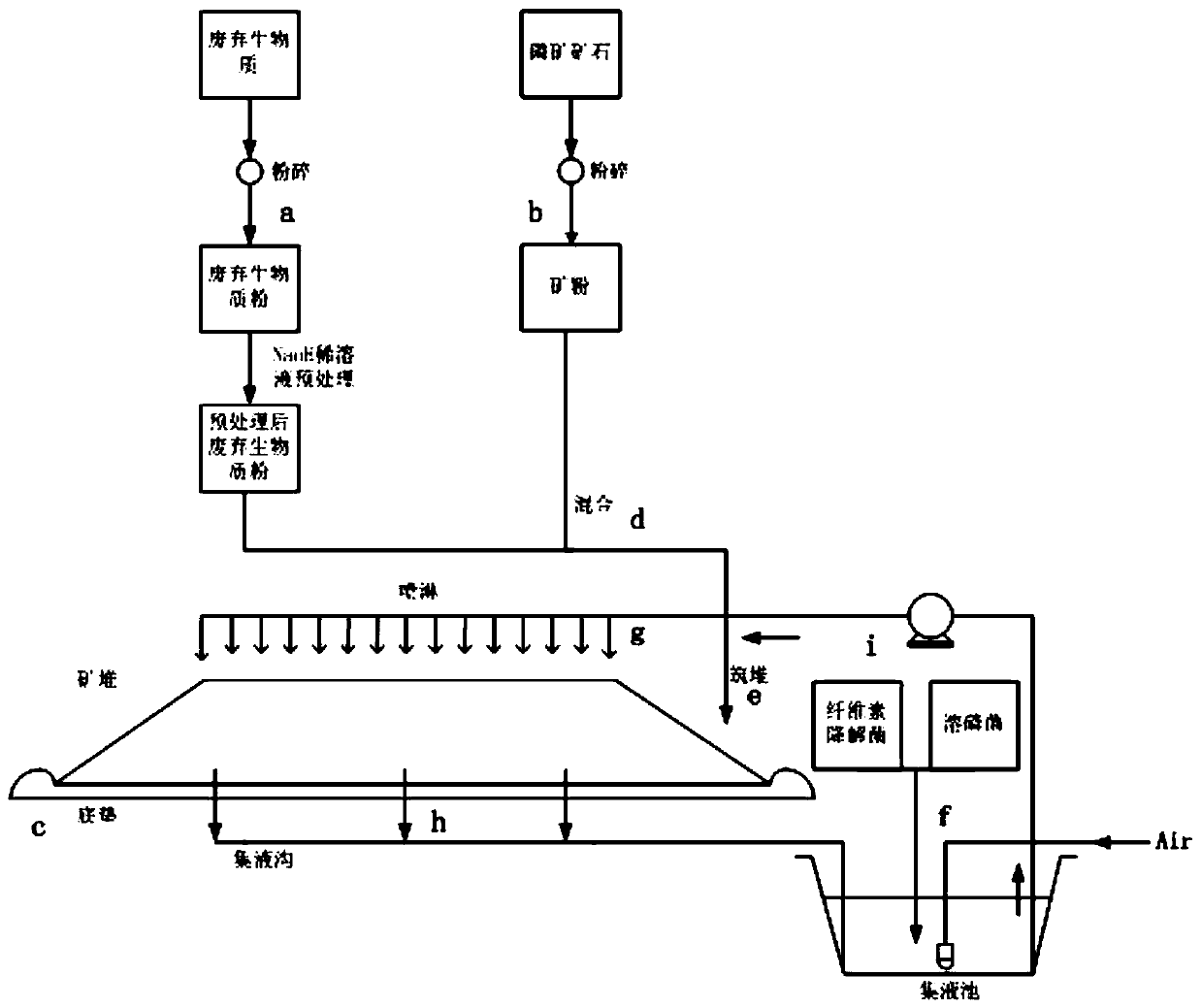

Method used

Image

Examples

Embodiment 1

[0033] a) Biomass preparation: Weigh 0.05 kg of rice straw and crush it into 0.5 mm particles. Add rice straw granules to 2% NaOH aqueous solution and soak for 8 days, filter and wash with double-layer gauze after the time is up, until the pH of the supernatant is neutral, and dry the filter residue at 50°C to constant weight for later use .

[0034] b) Preparation of ore: Weigh 1 kg of phosphate rock (the mass content of phosphorus pentoxide is 23.75%), and crush it to 1mm to obtain phosphate rock powder.

[0035] c) Laying bottom mat: Lay high-strength polyethylene sheet at the selected leaching heap position as the heap leaching bottom mat, and at the same time dig a liquid collection ditch and a liquid collection pool at the bottom of the heap and its surroundings. The leaching heap should be selected in a flat area, and the site is required to have a certain slope (longitudinal inclination of 3%) so that the leachate can be collected and flowed out, but the slope should ...

Embodiment 2

[0044]a) Biomass preparation: 0.1 kg of rice straw was weighed and crushed into 0.1 mm particles. Add rice straw granules to 2% NaOH aqueous solution and soak for 8 days, filter and wash with double-layer gauze after the time is up, until the pH of the supernatant is neutral, and dry the filter residue at 50°C to constant weight for later use .

[0045] b) Preparation of ore: Weigh 2kg of phosphate rock (the mass content of phosphorus pentoxide is 23.75%), and crush it to 1mm to obtain phosphate rock powder.

[0046] c) Laying bottom mat: Lay high-strength polyethylene sheet at the selected leaching heap position as the heap leaching bottom mat, and at the same time dig a liquid collection ditch and a liquid collection pool at the bottom of the heap and its surroundings. The selection and setting requirements of the heap leaching site are the same as those in Example 1.

[0047] d) Mixing: uniformly mixing the phosphate rock powder in step b) and the pretreated rice straw pa...

Embodiment 3

[0055] a) Biomass preparation: 0.15 kg of rice straw was weighed and crushed into 1 mm particles. Add rice straw granules to 2% NaOH aqueous solution and soak for 8 days, filter and wash with double-layer gauze after the time is up, until the pH of the supernatant is neutral, and dry the filter residue at 50°C to constant weight for later use .

[0056] b) Preparation of ore: Weigh 3kg of phosphate rock (the mass content of phosphorus pentoxide is 23.75%), and crush it to 1mm to obtain phosphate rock powder.

[0057] c) Laying bottom mat: Lay high-strength polyethylene sheet at the selected leaching heap position as the heap leaching bottom mat, and at the same time dig a liquid collection ditch and a liquid collection pool at the bottom of the heap and its surroundings. The selection and setting requirements of the heap leaching site are the same as those in Example 1.

[0058] d) Mixing: uniformly mixing the phosphate rock powder in step b) and the pretreated rice straw pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com