Ultrasonic exciting hydrogenation reactor

A hydrogenation reactor, ultrasonic technology, applied in chemical/physical/physical-chemical mobile reactors, chemical/physical/physical-chemical processes using energy, etc., can solve the problem of inaccurate metering, poor sealing, and low mass transfer efficiency and other problems to achieve the effect of speeding up the reaction speed, increasing the reaction pressure, and increasing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described below in conjunction with specific accompanying drawing:

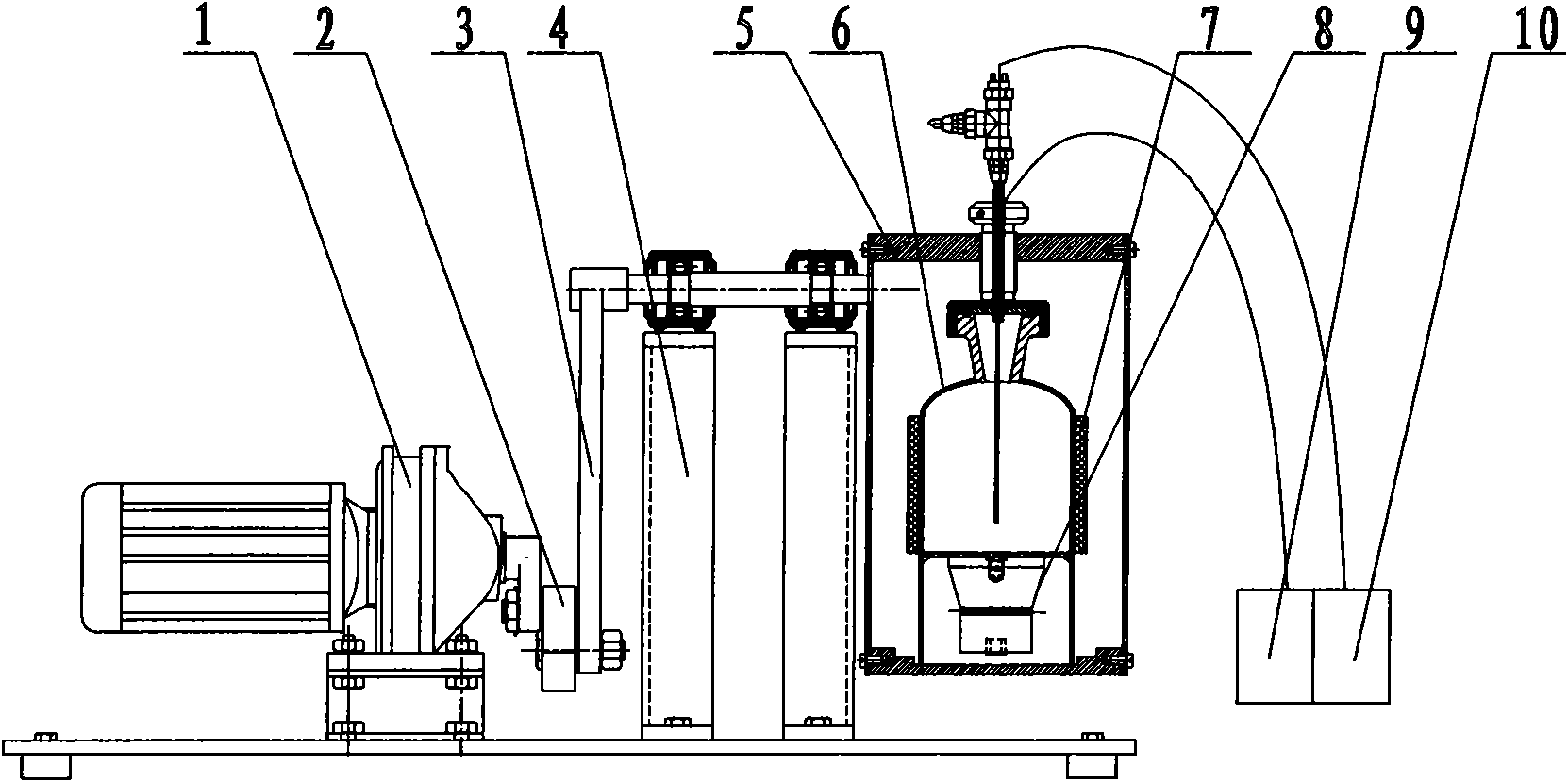

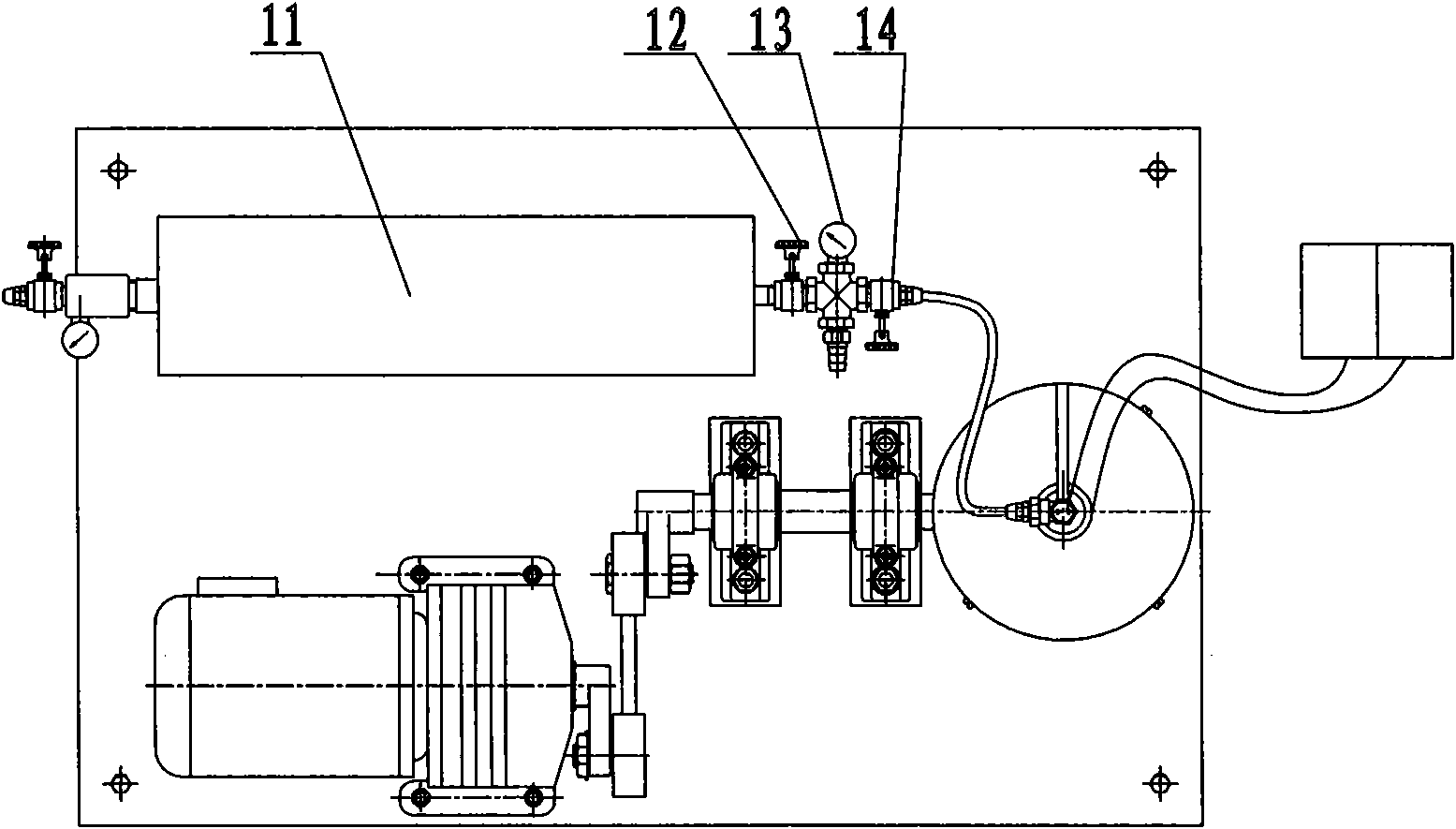

[0014] refer to Figure 1-2 : An ultrasonic excitation hydrogenation reactor, comprising a reaction vessel 6 and a hydrogen storage tank 11, the reaction vessel 6 is arranged in a swing cover 5, the swing cover 5 is connected with a swing mechanism 2, and the swing mechanism 2 is connected to the swing cover 5 through the swing rod 3, the swing cover 5 is supported on the support 4, the power of the swing mechanism 2 comes from the motor, and the reduction box 1 is connected between the two. A regulating valve with a pressure gauge 13 is connected between the reaction vessel 6 and the hydrogen storage tank 11, and the regulating valve is connected with the hydrogen storage tank 11, the reaction vessel 6 and the pressure gauge 13 respectively. The air inlet, working port, and exhaust port communicated with the outside world, the pressure gauge 13 communicates with the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com