Device for absorbing and purifying SO2 in diesel engine tail gas by utilizing seawater and absorption method

A diesel engine and seawater technology, applied in the field of environmental pollution control, can solve the problems of no obvious improvement in gas-liquid mass transfer efficiency, no substantial improvement in desulfurization efficiency, complex device structure, etc., to meet space requirements, high absorption efficiency, and economical cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

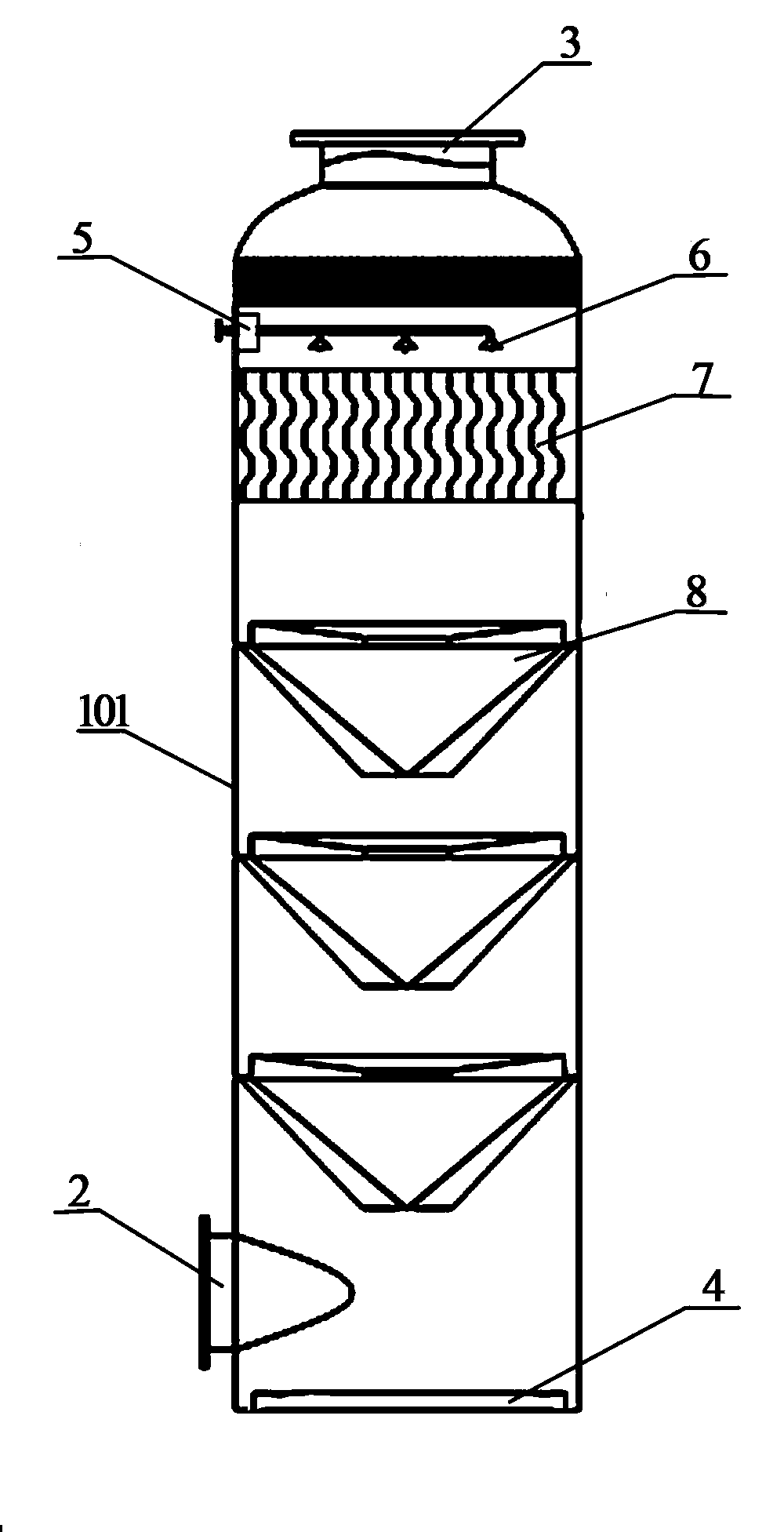

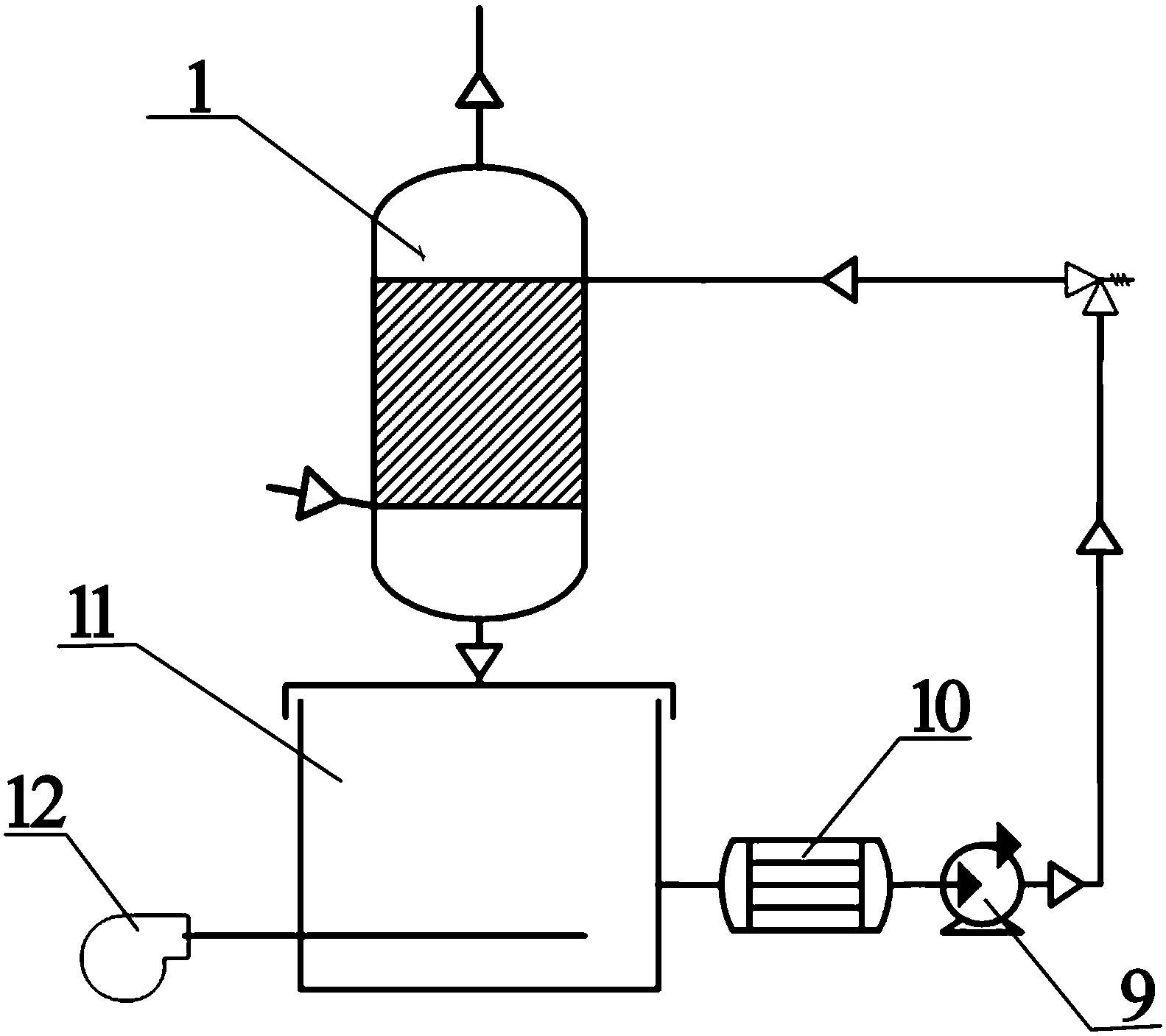

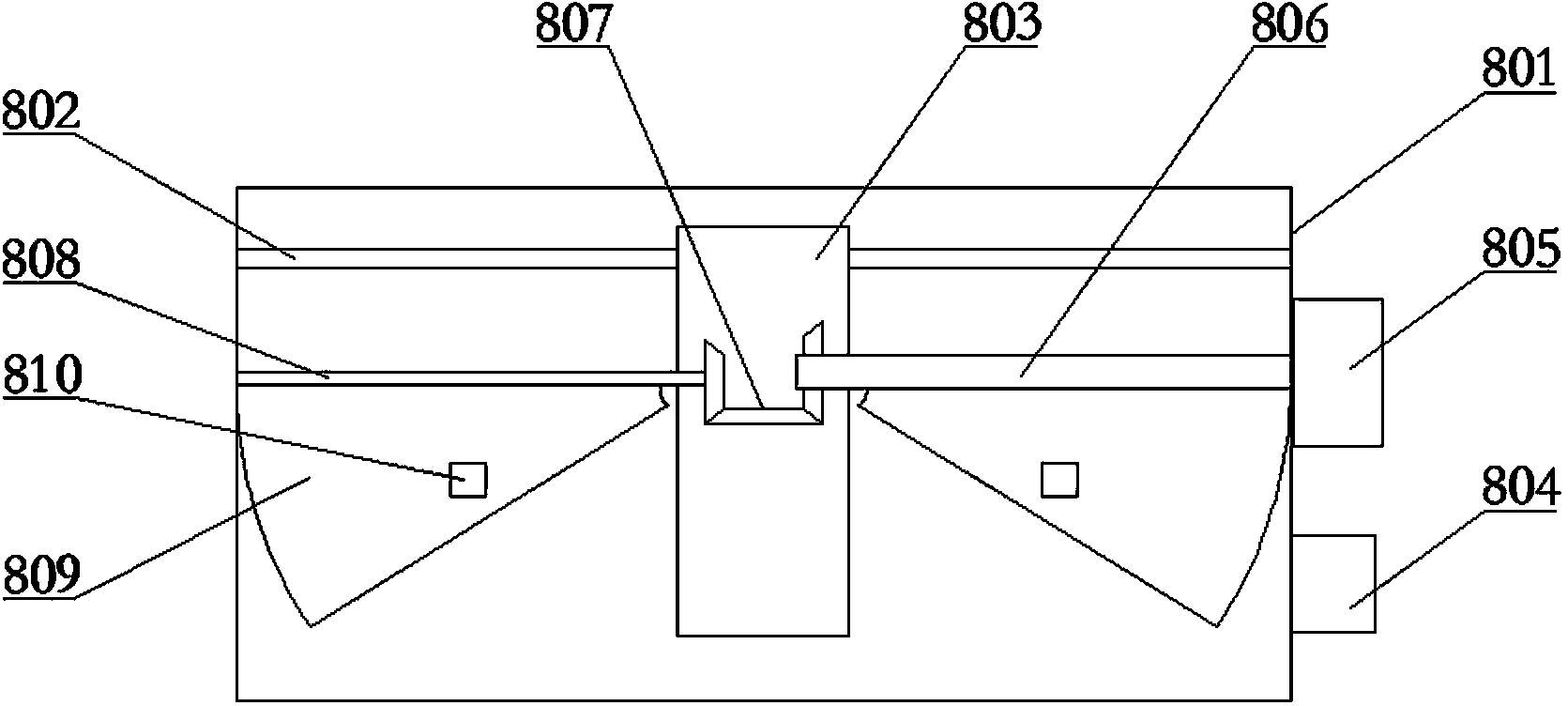

[0028] Figure 1-3 As shown, a kind of using seawater to absorb and purify SO in diesel engine exhaust 2The device includes flue gas scrubber 1, air inlet 2, air outlet 3, water outlet 4, liquid flow meter 5, circulating liquid nozzle 6, defogging plate 7, gas-liquid cyclone contactor 8, liquid circulation pump 9, Heat pipe heat exchanger 10, seawater regeneration tank 11 and aeration fan 12. The stainless steel shell 101 of the flue gas scrubber 1 is provided with a liquid flow meter 5, a circulating liquid nozzle 6, a defogging plate 7 and a three-stage gas-liquid cyclone contactor 8 from top to bottom, and the bottom of the stainless steel shell 101 is set There is an air inlet 2, the bottom of the stainless steel housing 101 is provided with a water outlet 4, the top of the stainless steel housing 101 is provided with an air outlet 3, the air inlet 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com