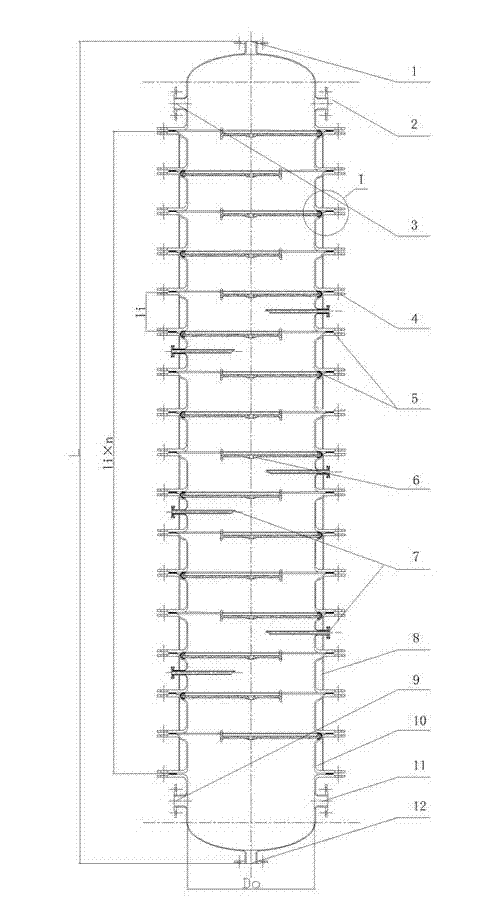

Gas absorption apparatus

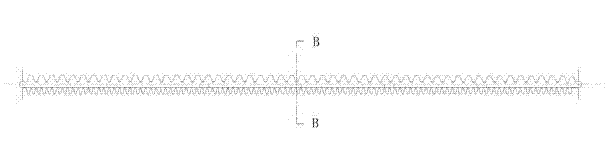

A technology of gas absorption and gas outlet, which is applied in the case of gas-liquid phase reaction or absorption contact, in the field of chemical production equipment, can solve the problems of small liquid holding capacity, insufficient liquid holding capacity, blocked channels, etc., and achieve the improvement of mass transfer efficiency , The gas-liquid contact area is increased, and the effect of occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

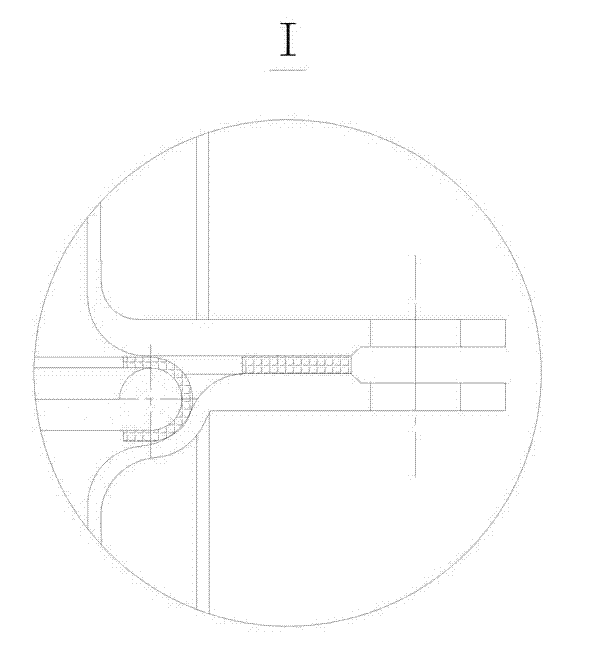

Method used

Image

Examples

Embodiment 1

[0023] Combined production of thionyl chloride (SOCl 2 ) and phosphorus oxychloride (POCl 3 ) process, from the top phosphorus oxychloride (PCl 3 ) enters, chlorine gas (Cl 2 ) and sulfur dioxide (SO 2 ) into the reaction tower system from the bottom of the tower to adjust the ratio of gas and liquid, and the reaction completed liquid enters the intermediate tank from the tower kettle for buffering to obtain thionyl chloride (SOCl 2 ) and phosphorus oxychloride (POCl 3 ) product mixture, rectification in the rectification tower after heating, and at the same time obtain the product thionyl chloride (SOCl 2 ) and phosphorus oxychloride (POCl 3 ), the product quality reaches the specified standard, and the yield is greater than or equal to 90%.

Embodiment 2

[0025] A carbon dioxide (CO 2 ) In the absorption device, the absorption liquid containing sodium carbonate enters the tower from the liquid inlet at the top of the tower, and the gas rich in carbon dioxide enters the tower from the gas inlet at the bottom of the tower. The gas-liquid two-phase cross-flow contacts through the trapezoidal plate-shaped liquid curtain in the tower to carry out phase transfer, and the carbon dioxide gas is transferred from the gas to the liquid phase. Adjust the ratio of gas and liquid, the reaction completed liquid enters the intermediate tank from the tower kettle for buffering, obtains the absorption complete liquid, and then decomposes pure carbon dioxide after heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com