Patents

Literature

35 results about "P-tert-Butyltoluene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation technology of p-tert-butyl benzoic acid

ActiveCN101648866ASimple preparation processReduce manufacturing costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidOrganic synthesis

The invention discloses a preparation technology of p-tert-butyl benzoic acid, comprising the following steps: firstly, adding toluene, isobutene and concentrated sulfuric acid into a reaction kettle, carrying out alkylation reaction to obtain coarse p-tert-butyl toluene, and rectifying to obtain fine p-tert-butyl toluene; secondly, adding a composite catalyst containing the p-tert-butyl toluene,cobalt acetate and bromide into the reaction kettle, heating and introducing oxygen to obtain coarse p-tert-butyl benzoic acid, decoloring by activated carbon and diatomite , crystallizing and dryingto obtain fine p-tert-butyl benzoic acid. The prepared p-tert-butyl benzoic acid is an organic synthesis intermediate, can be used for the fields of additives, antioxidants, alkyd resin modifying agents, soldering fluid, dye, and the like of polypropylene nucleating agents, polyvinyl chloride heat stabilizers, metal machining and lubricating oil and has excellent performance. The p-tert-butyl benzoic acid has low energy consumption, high yield, simple separation, and the like and can satisfy ever-increasing market demands of the p-tert-butyl benzoic acid.

Owner:JIANGXI YONGTONG TECH

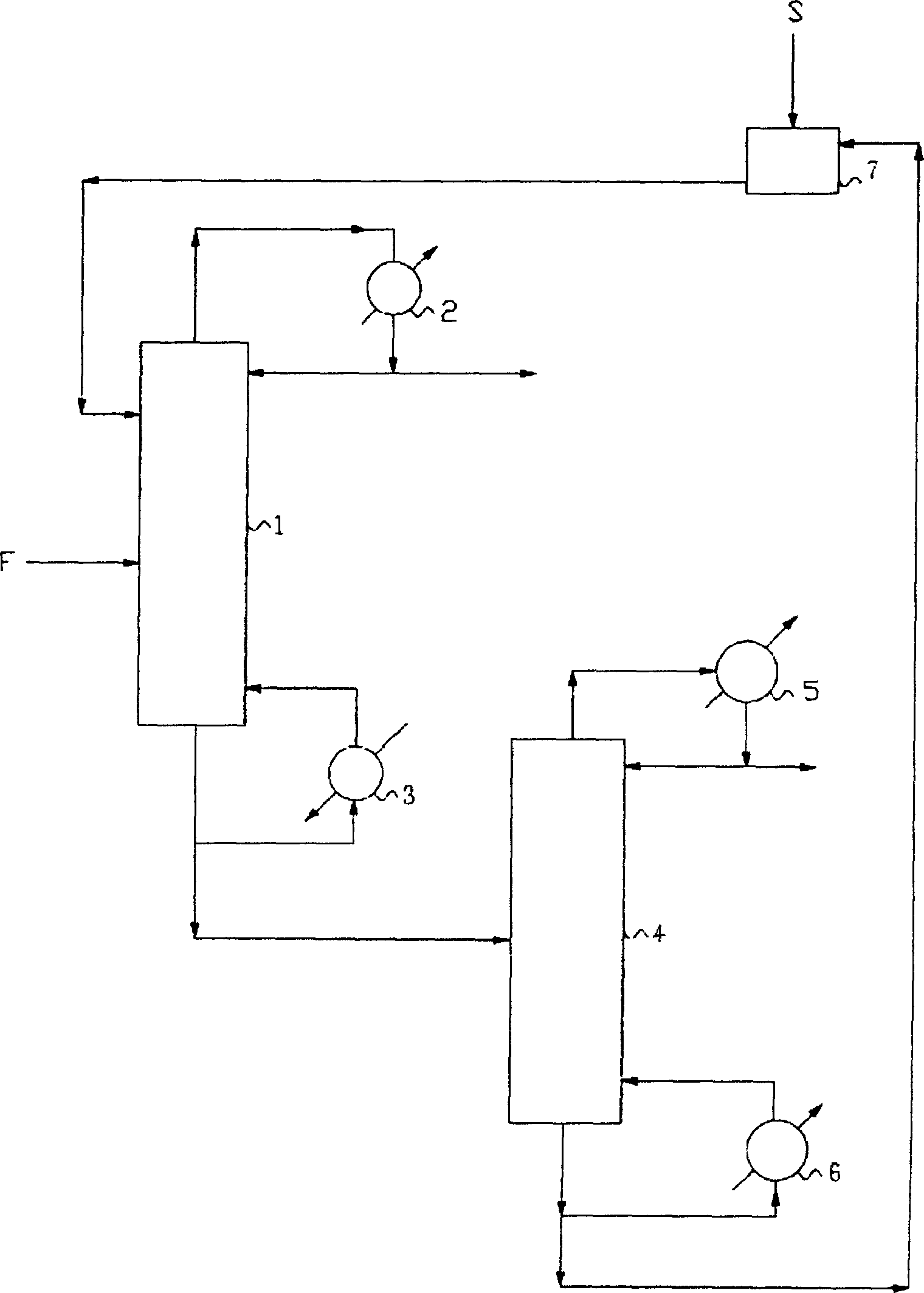

Method for separating acetonitrile-methylbenzene azeotropic mixture by continuous extractive distillation

InactiveCN1736530AEasy to realize automatic controlScale upExtractive distillationRefluxExtractive distillation

The invention discloses a method for continuous extraction and distillation and separation of acetonitrile- toluene azeotrope. The method is described as the following: using propyl benzene, butylbenzene, isobutylbenzene, sec- butylbenzene, tertiarybutyl phenol, mesitylene, p- diethyl benzene or tertiary-butyl toluene as the extractant, operating in a extracting- fractionating tower at a normal pressure or reduced pressure with a mass ratio of extractant in extracting- fractionating tower to overhead being 2: 1- 10: 1 and a feeding temperature of extractant of 25- 80 Deg. C, the acetonitrile- toluene azeotrope entering from the middle of extracting- fractionating tower, picking the qualified content of acetonitrile from the head of tower with a reflux ratio of 1: 1- 5: 1, toluene and solvent from the bottom of the tower flowing into the middle of the extractant recovery tower, the toluene being picked from the head of extractant recovery tower with a reflux ratio of 2: 1- 10: 1, and the high-purity extractant which can be circularly used being picked from the bottom of the extractant recovery tower. The merit of the invention is that using extractant to destroy acetonitrile- toluene azeotrope,the high purity acetonitrile and toluene are prepared.

Owner:TIANJIN UNIV

Method for producing p-tert-butyltoluene

InactiveCN102199068AAvoid disadvantagesPromote regenerationMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationP-tert-ButyltolueneToluene

The invention discloses a method for producing p-tert-butyltoluene, which comprises the following steps of: putting toluene and tert-butyl alcohol in a molar ratio of 1:(2-6) and a catalyst in an amount which is 5 to 30 percent based on the total weight of the toluene serving as a reactant into a reaction kettle under the action of the mesoporous / microporous composite molecular sieve catalyst consisting of a beta zeolite (Hbeta) microporous molecular sieve and an MCM-41 mesoporous molecular sieve, and reacting at the temperature of between 160 and 240 DEG C for 2 to 8 hours to obtain the p-tert-butyltoluene. The preparation process is simple, the catalyst is easy to separate and is reusable, production cost is low, the method is environment-friendly, and safe production is realized.

Owner:NANJING UNIV OF TECH

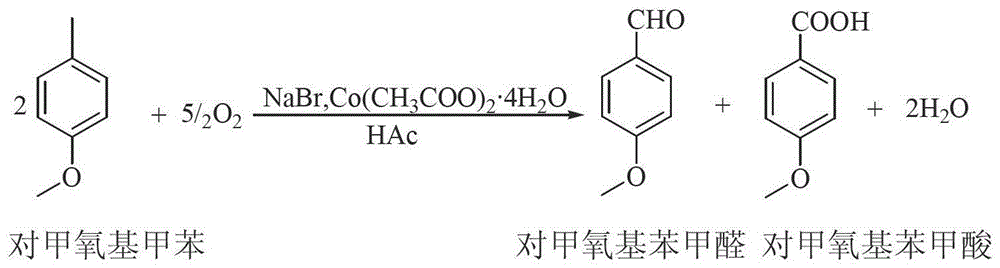

Process for synthesizing p-tertiary butyl benzaldehyde

ActiveCN101440028AEasy to separateConvenient and quick escapeMolecular sieve catalystsOrganic compound preparationBenzaldehydeManganese

The invention discloses a method for synthesizing p-tert-butylbenzaldehyde. The method comprises the following steps: a normal atmosphere heterogeneous catalytic oxidation method is adopted; p-tert-butyltoluene as a raw material, sufficient oxygen as an oxygen source and n-hydroxyphthalimide as a free radical evocating agent in an acetonitrile solution react for 4 to 7 hours at a temperature between 50 and 70 DEG C under the condition of a catalyst to directly synthesize the p-tert-butylbenzaldehyde; and the catalyst is a cobalt-loaded mesoporous molecular sieve or a cobalt- and manganese-loaded mesoporous molecular sieve. The method use the cobalt-loaded mesoporous molecular sieve or the cobalt- and manganese-loaded mesoporous molecular sieve as the solid-phase catalyst; compared with the prior liquid-phase catalyst, the target product is easier to separate after reaction; a reactant can rapidly contact catalytic activity center; product molecules rapidly escape from a pore canal, thereby avoiding deep oxidation and improving the selectivity of aldehyde; in addition, micro n-hydroxyphthalimide as the free radical evocating agent is added to the system to trigger the chain transmission reaction of free radicals.

Owner:格林生物科技股份有限公司

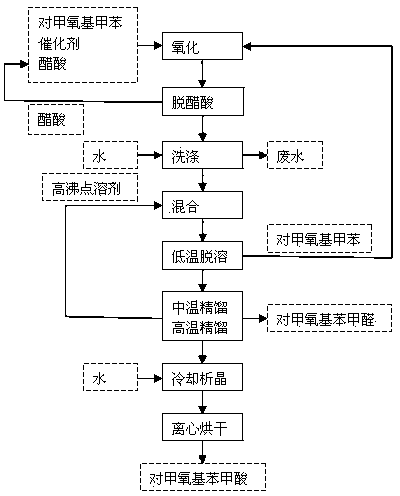

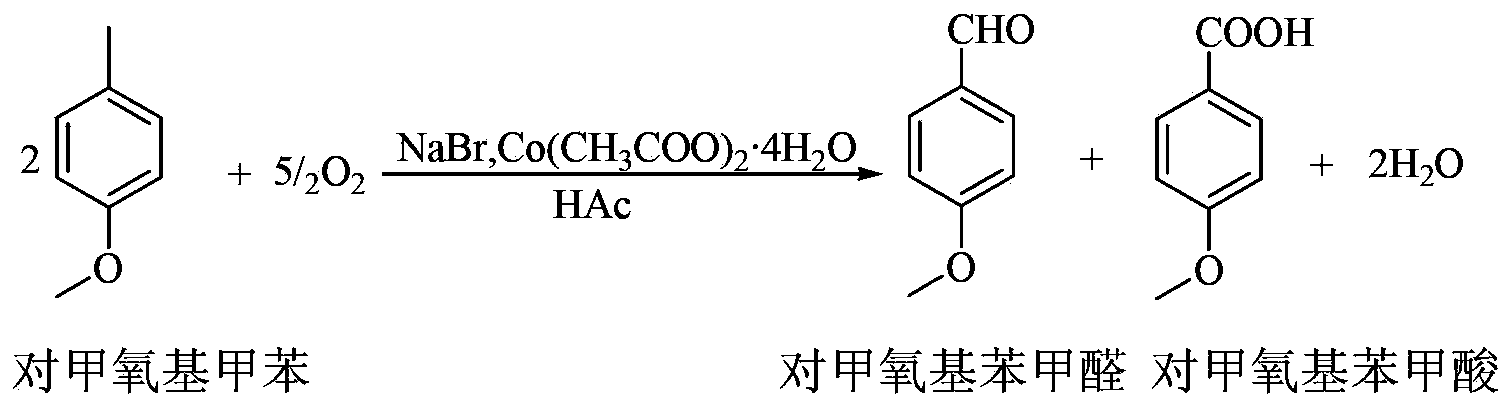

Process for synthesizing p-methoxy benzaldehyde or p-tertbutyl benzaldehyde

InactiveCN103145527AEmission reductionReduce pollutionOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationBenzoic acidBenzaldehyde

Owner:NANJING UNIV

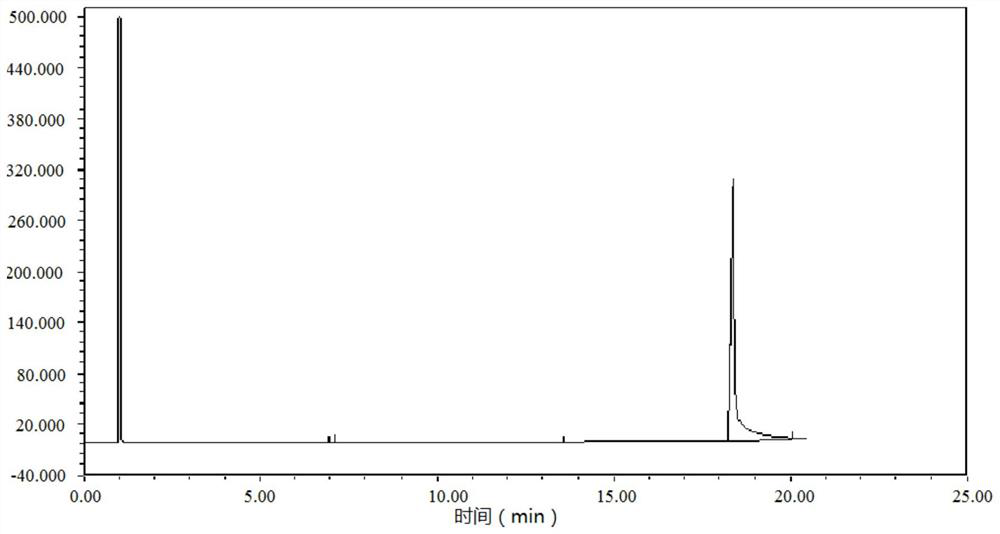

Process for synthesizing p-tert-butylbenzoic acid

ActiveCN102617335AReduce usageReduce recycling stepsOrganic compound preparationCarboxylic compound separation/purificationOxygenMoisture

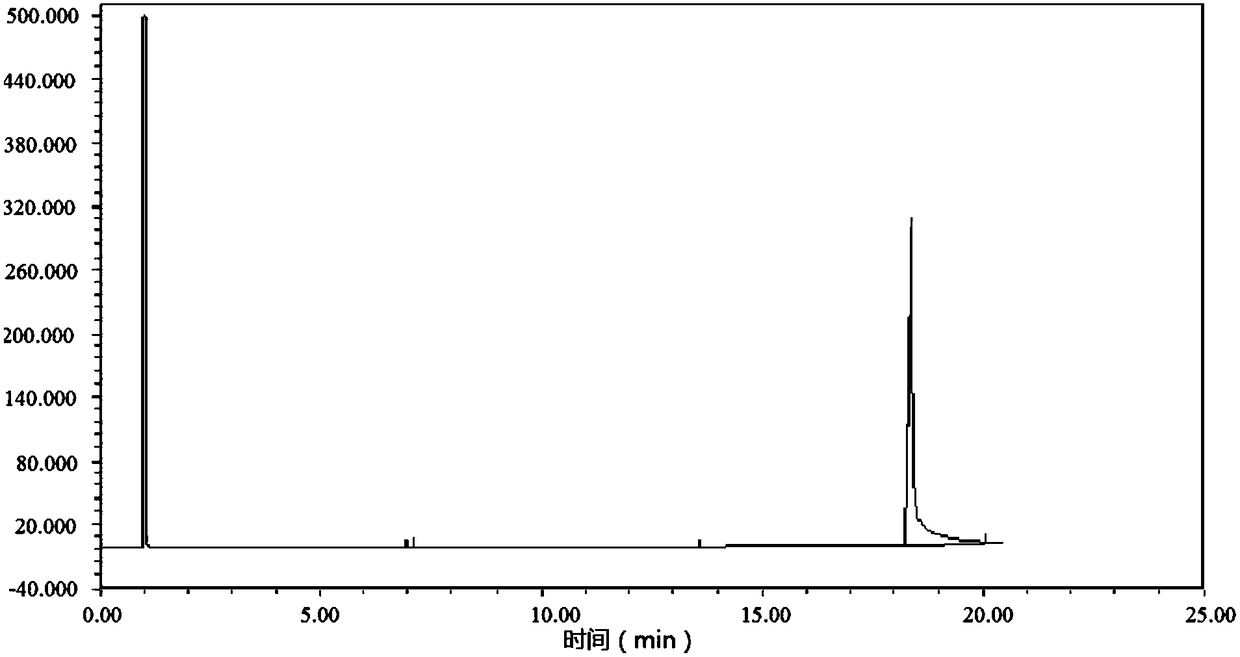

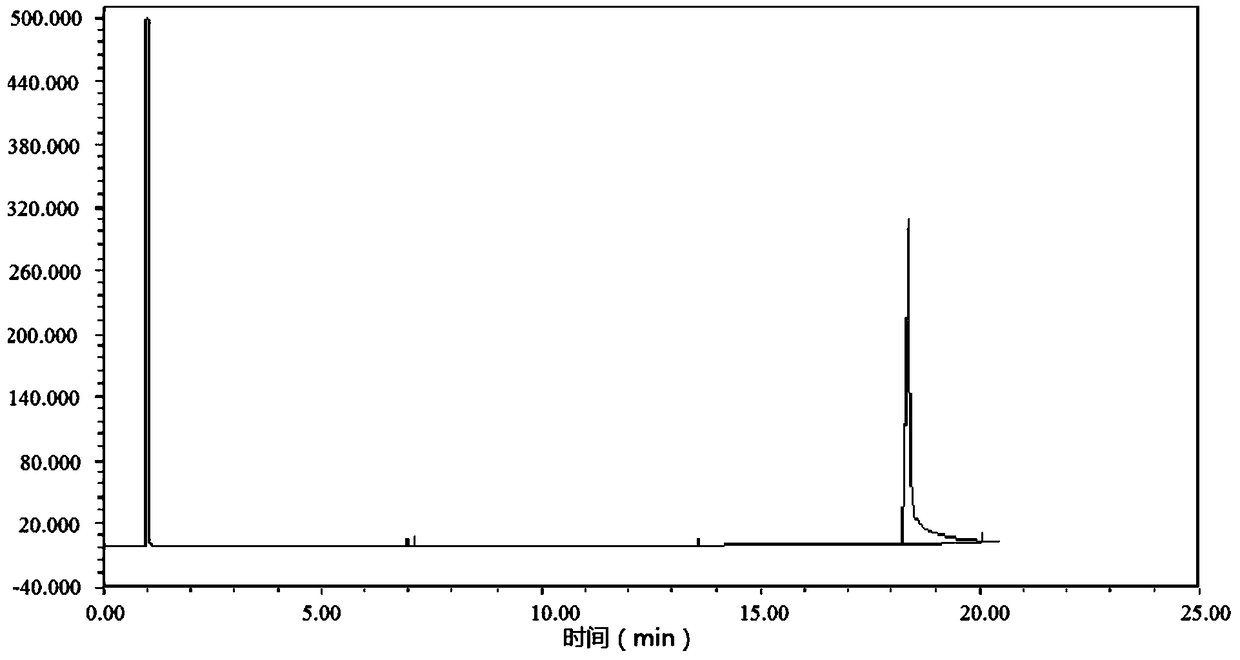

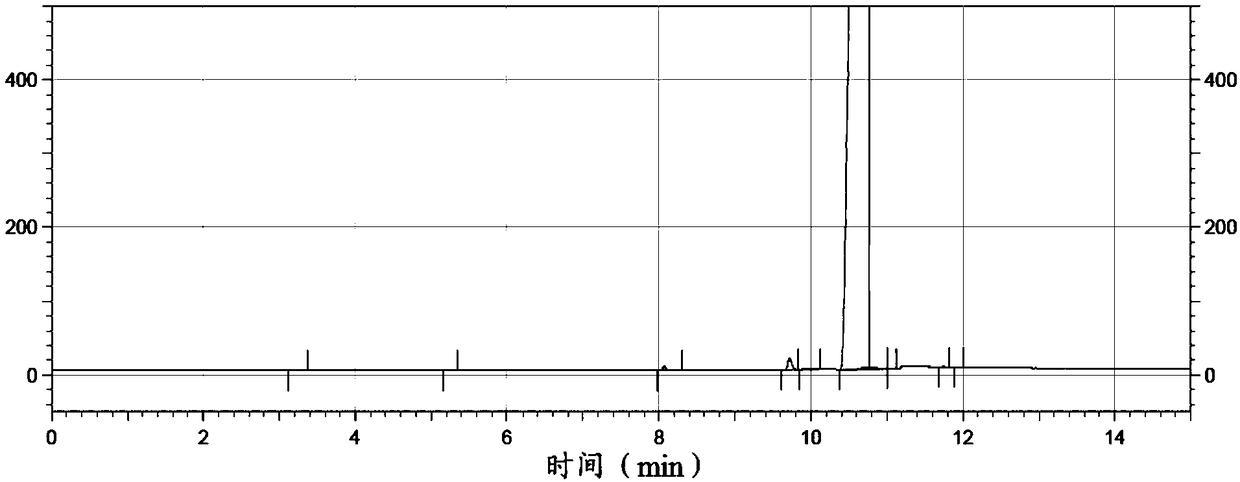

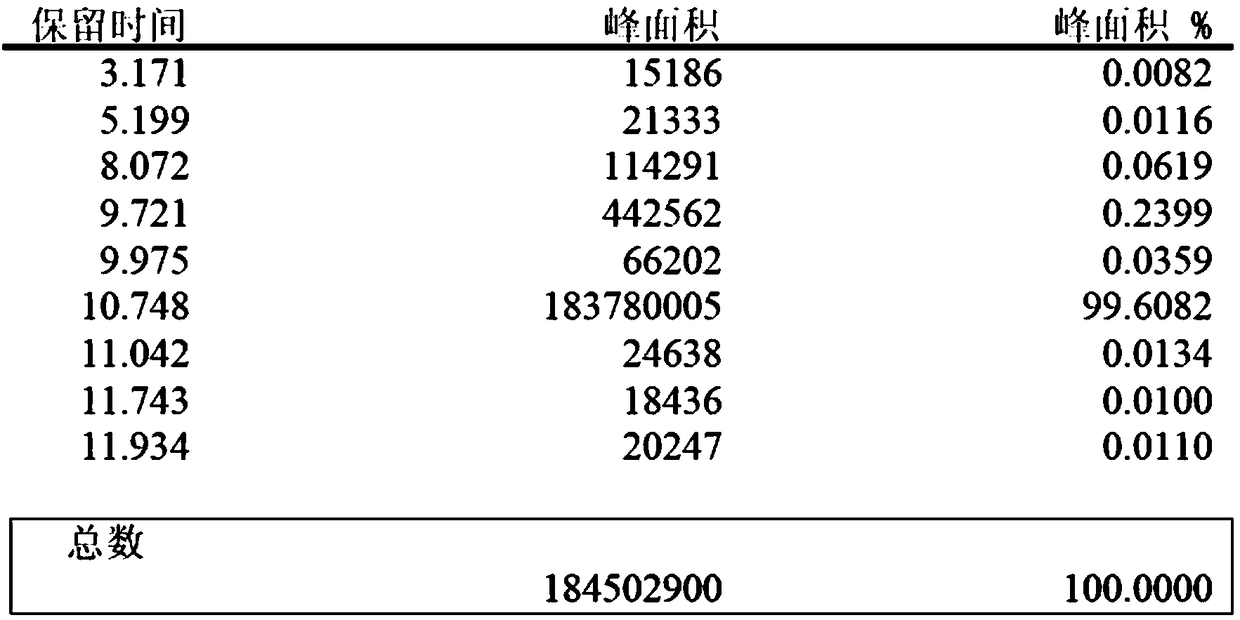

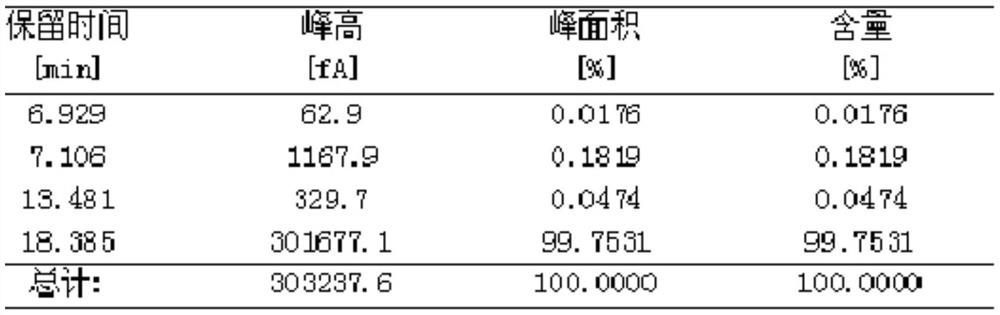

The invention relates to a process for synthesizing p-tert-butylbenzoic acid. The process comprises the following steps of: adding p-tert-butyltoluene and cobalt acetate into a reaction kettle, introducing oxygen-containing gas, triggering at the temperature of between 150 and 155 DEG C, performing oxidation reaction for 0.5 to 1 hour, and continuously reacting at the temperature of between 135 and 145 DEG C for more than 5 hours to obtain a p-tert-butylbenzoic acid crude product; cooling the p-tert-butylbenzoic acid crude product to crystallize, performing centrifuge dripping, and striking and washing by using p-tert-butyltoluene to obtain a centrifugation crude product; and adding the centrifugation crude product into a dissolution kettle, adding methylbenzene, raising temperature and dissolving, filtering when a mixture is hot to remove impurities, adding water to wash, transferring materials to a recrystallization kettle, cooling to crystallize, centrifuging, striking and washing by using methylbenzene, and drying to obtain a p-tert-butylbenzoic acid finished product. The prepared p-tert-butylbenzoic acid is white crystals and does not contain mechanical impurities; and the melting point is 164.0 to 167.0 DEG C, the acid value is 312 to 316mgKOH / g, high performance liquid chromatography (HPLC) purity is more than or equal to 99.2 percent, moisture is less than or equal to 0.08 percent, and methylbenzene is less than or equal to 0.05 percent.

Owner:SUQIAN COSMOS CHEM +1

Continuous production process of p-tert-butyl toluene

ActiveCN103274890AHigh activityImprove thermal stabilityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveAcid catalysis

The invention relates to a continuous production process of p-tert-butyl toluene, and in particular relates to a method for synthetizing the p-tert-butyl toluene through catalyzing toluene and tert butyl alcohol by using a metallic oxide-supported molecular sieve catalyst. The invention aims to overcome the shortcomings that catalysts corrode equipment, pollute the environment and are difficult to separate and incapable of being recycled and the like in traditional methods for synthetizing the p-tert-butyl toluene through liquid acid catalysis. The continuous production process of the p-tert-butyl toluene comprises the following steps of (1) preparation of the metallic oxide-supported molecular sieve catalyst and (2) synthetic reaction of the p-tert-butyl toluene. The process disclosed by the invention has the advantages of simpleness, environmental friendliness, low labour intensity and low production cost; by adopting the homemade metallic oxide-supported molecular sieve catalyst, the problems that the liquid acid catalysts corrode equipment and pollute the environment in the traditional production methods are solved; and in the meantime, the homemade catalyst is high in activity, good in heat stability, high in mechanical strength and capable of meeting the requirements of long-period operation in the continuous production process of fixed beds.

Owner:FAREAST KINGSTAR CHEM

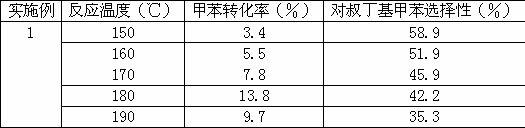

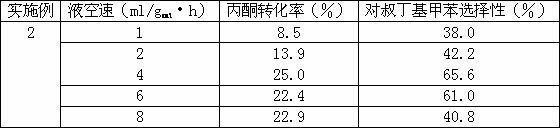

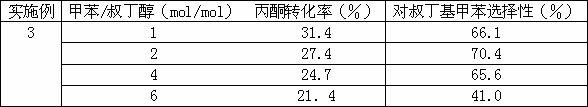

Method for producing p-tert-Butyltoluene by using mordenite for catalyzing toluene and tertiary butanol

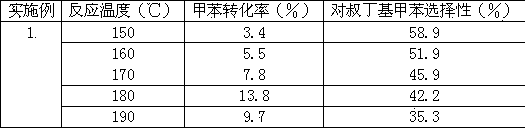

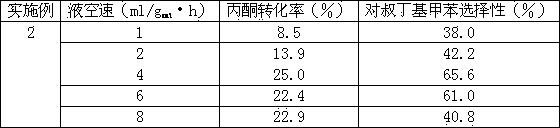

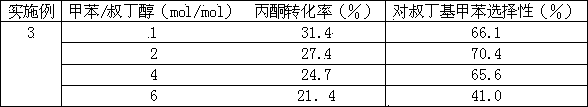

InactiveCN102557858ASuitable for large-scale continuous productionHydrocarbon by hydrocarbon and non-hydrocarbon condensationReaction temperatureP-tert-Butyltoluene

The invention discloses a method for producing p-tert-Butyltoluene by using mordenite for catalyzing toluene and tertiary butanol, which uses a mordenite catalyst, n(SiO2) / n(Al2O3)=30, the catalyst is conducted activating treatment for 3 hours at 550 DEG C, or the catalyst is conducted treatment for 4 hours at 100 DEG C in 0.2mol / L NaOH solution, then the p-tert-Butyltoluene is obtained after roasting at 550 DEG C. At the reaction temperature of 150-190 DEG C, liquid space velocity is 1-8ml / gcatXh, and mole ratio of the toluene / the tertiary butanol is 1:1-1:6. In a fixed bed reactor, toluene percent conversion is 10-33%, and selectivity of the p-tert-Butyltoluene achieves 35-75%. The method can continuously produce the p-tert-Butyltoluene under soft reaction conditions, and overcomes the shortcoming that in the traditional production method, liquid acid catalysts corrode equipment, environmental contamination is caused, interval liquid phase reaction is big in production strength, and production rate is low.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Synthetic method of p-tert-butylbenzaldehyde

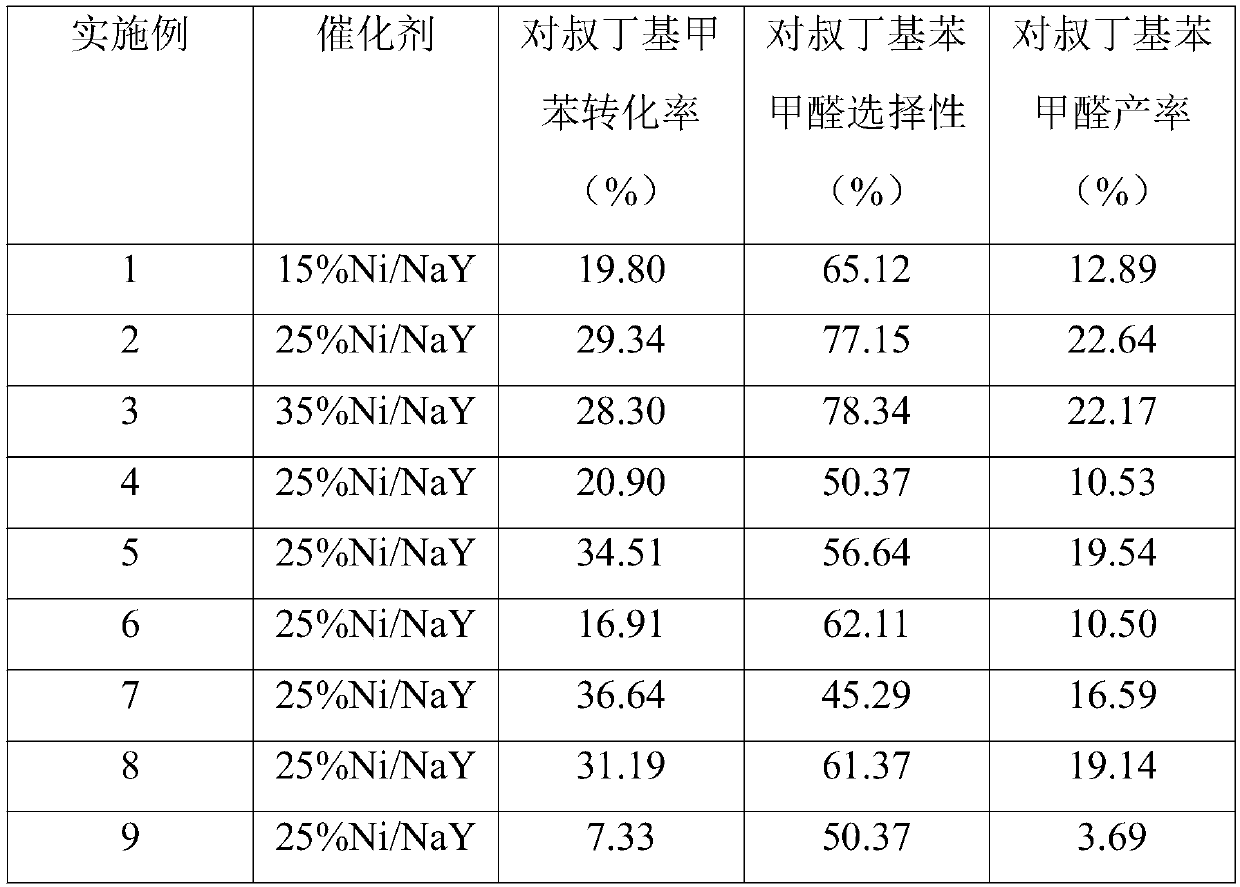

InactiveCN109608315AEasy to separateMany cyclesMolecular sieve catalystsOrganic compound preparationNickel saltSolvent

The invention provides a synthetic method of p-tert-butylbenzaldehyde. A liquid-phase oxidation method is used, p-tert-butyltoluene as a raw material, oxygen as an oxidizing agent, N-hydroxyl phthalimide as an initiator and acetonitrile as a solvent are used under the action of a catalyst for reacting for 7 hours at the temperature of 70 DEG c under the magnetic stirring rotating speed of 200r / minso as to obtain the p-tert-butylbenzaldehyde. The selected catalyst is a Ni-loaded microporous molecular sieve, and preparation raw materials comprise a nickel salt, a molecular sieve and deionized water; the microporous molecular sieve is used as a carrier for loading of an active component by an impregnation method to prepare the catalyst containing the active component nickel, the catalyst hasrelatively high selectivity and activity, the conversion rate of the raw material in the reaction for preparing the p-tert-butylbenzaldehyde by the liquid-phase oxidation reaches 30.6%, the selectivity of the target product reaches 77.2%. Compared with other catalysts in the prior art, the catalyst has the advantages that the selectivity is obviously improved.

Owner:CHANGZHOU UNIV

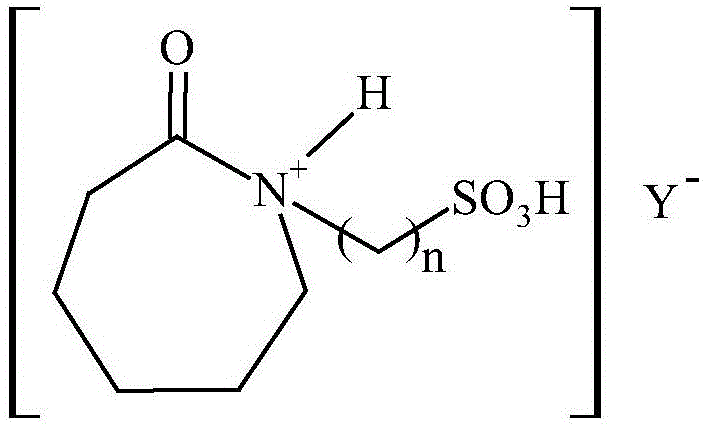

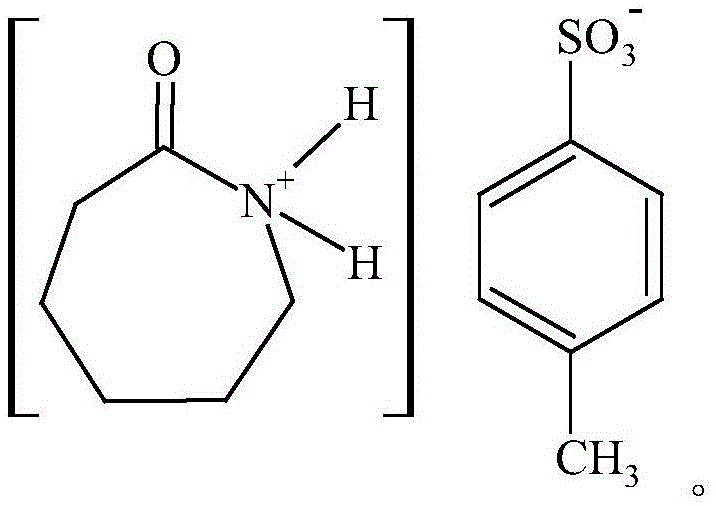

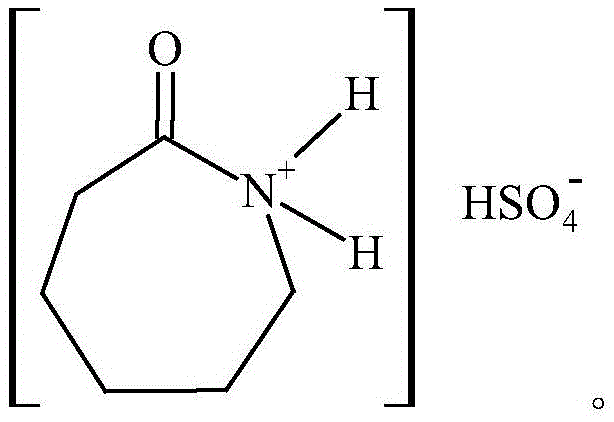

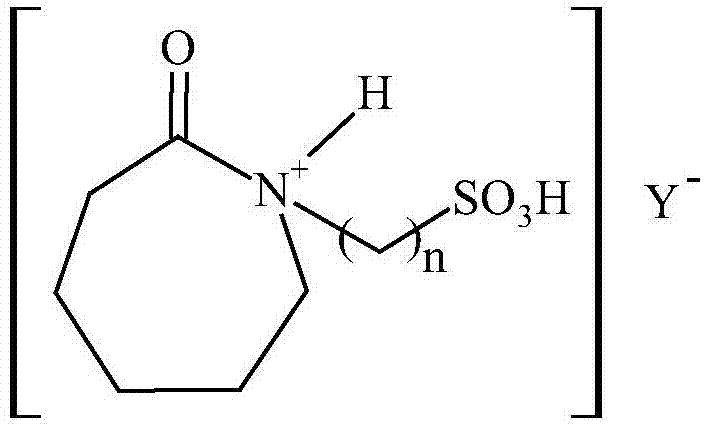

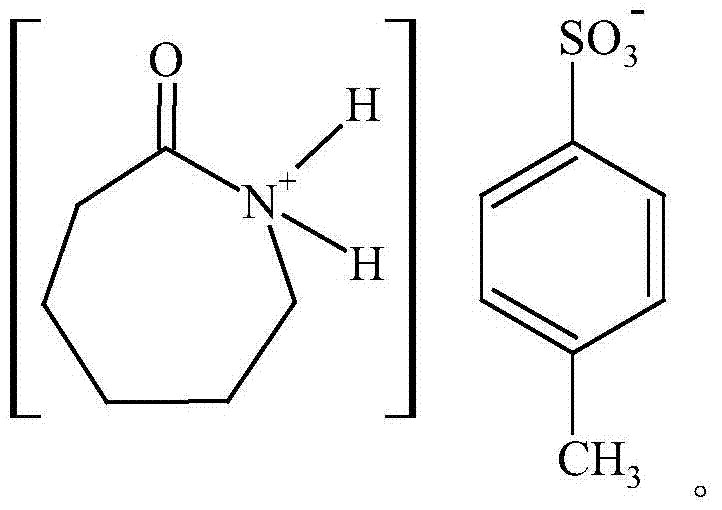

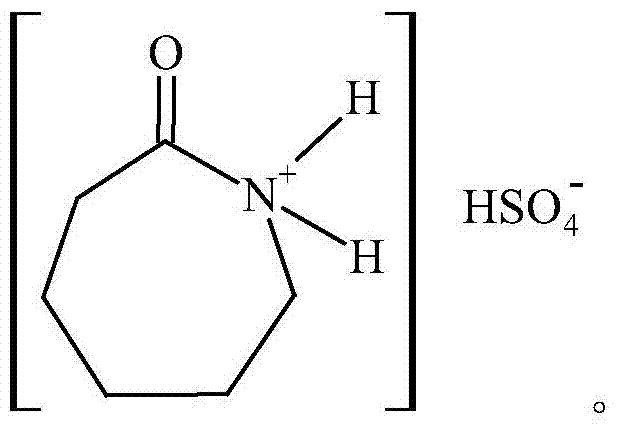

Method of synthesizing p-tert-butyl toluene with caprolactam ionic liquid as catalyst

ActiveCN105669342ALow costEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsAfter treatmentReaction temperature

The invention discloses a method of synthesizing p-tert-butyl toluene with a caprolactam ionic liquid as a catalyst. The method comprises the following steps: (1) adding methylbenzene into a reaction kettle, and adding the caprolactam ionic liquid, and adding isobutylene or tert-butyl alcohol; (2) regulating and controlling reaction temperature and time; (3) allowing the mixture to stand for layering, separating a supernatant, and rectifying the supernatant to prepare a product p-tert-butyl toluene; and (4) washing a subnatant in methylbenzene and performing vacuum-drying to remove the methylbenzene to obtain recyclable caprolactam ionic liquid. In the method, the caprolactam ionic liquid is low in cost, is mild in synthetic conditions and can be used for large-scale industrial production. Separation and after-treatment on the product are very simple so that an alkali-washing process in the prior art can be omitted, thereby simplifying the process and increasing production efficiency without generation of waste water. The caprolactam ionic liquid can be recycled for the next reaction just through simple treatment, thereby effectively reducing production cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

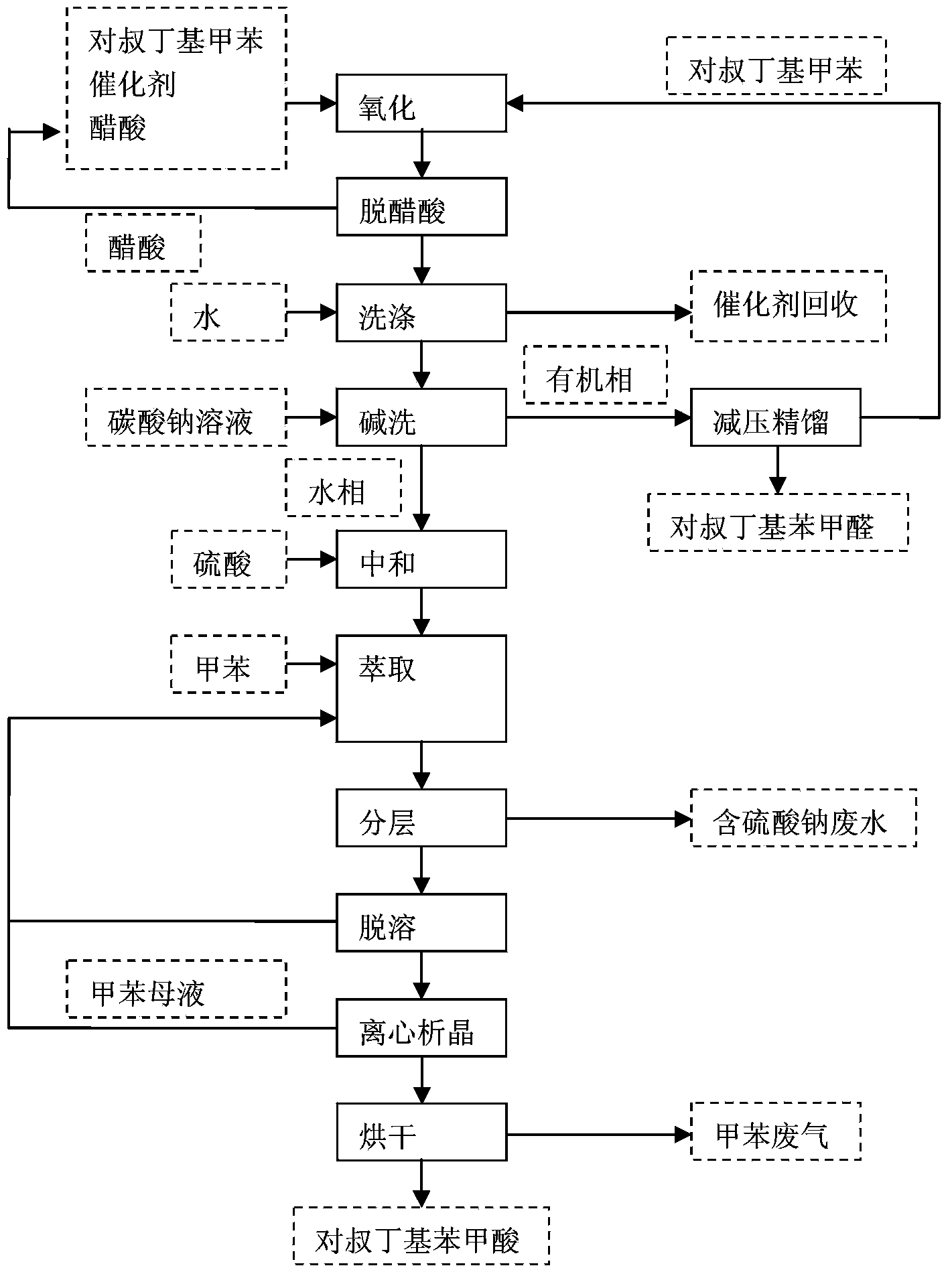

Preparation and after-treatment method of p-tert-butylbenzoic acid

ActiveCN108530285AHigh yieldEmission reductionOrganic compound preparationHydrocarbon from saturated and unsaturated hydrocarbon additionAfter treatmentP-tert-Butyltoluene

The invention discloses a preparation and after-treatment method of p-tert-butylbenzoic acid. The preparation method of the p-tert-butylbenzoic acid includes the steps: firstly, performing tert-butylation on toluene to obtain p-tert-butyl toluene; secondly, oxidizing the p-tert-butyl toluene; finally, performing crystallization to obtain the p-tert-butylbenzoic acid. Crystallization mother liquidis retreated after crystallization, p-tert-butylbenzoic acid remained in the mother liquid is further acquired, the yield of the p-tert-butylbenzoic acid is improved, waste sodium sulfate in the mother liquid is after-treated to obtain industrial-grade sodium sulfate, waste emission in the preparation process is reduced, the waste sodium sulfate is converted into recyclable industrial-grade sodiumsulfate, a certain economic benefit is achieved, and environment-friendly significance is remarkable.

Owner:SUQIAN COSMOS CHEM

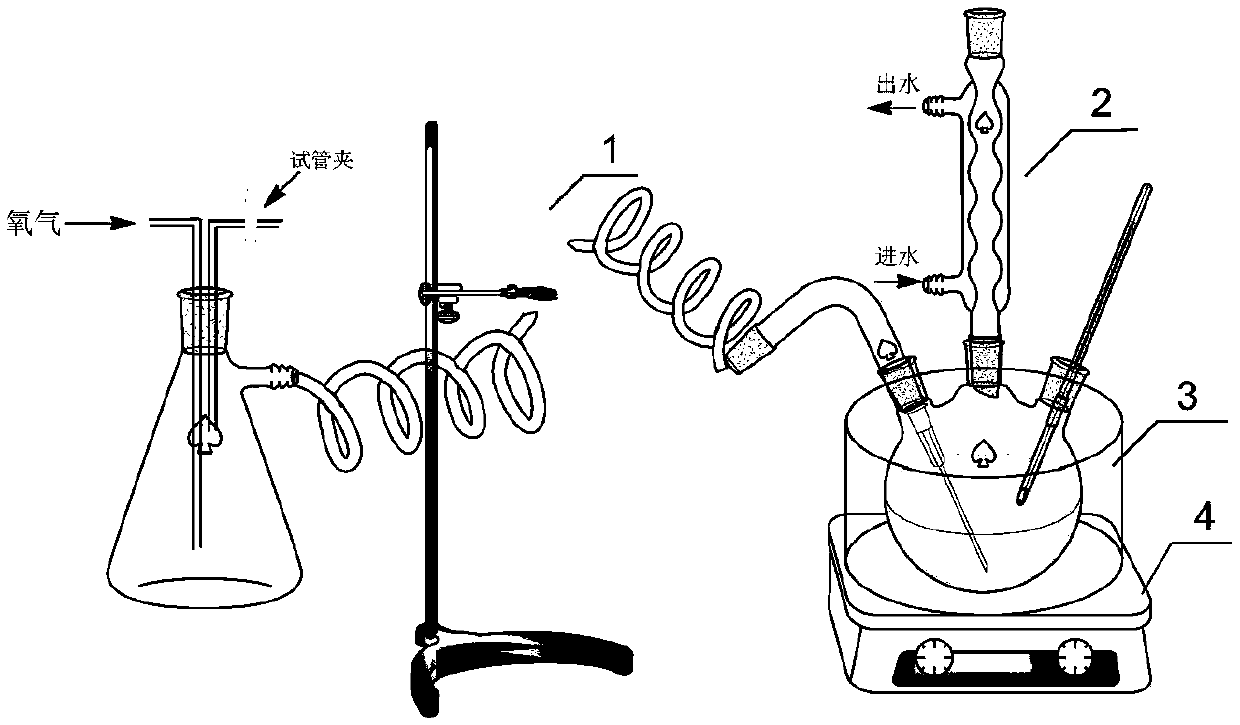

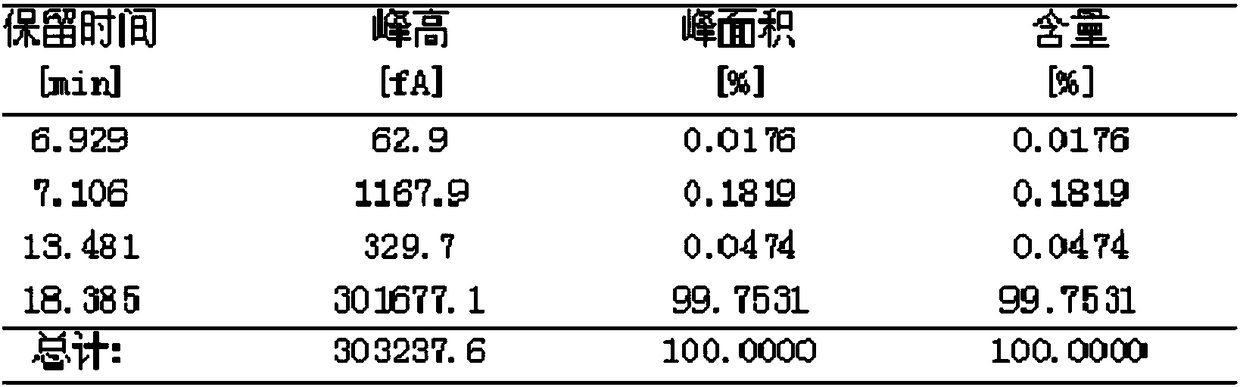

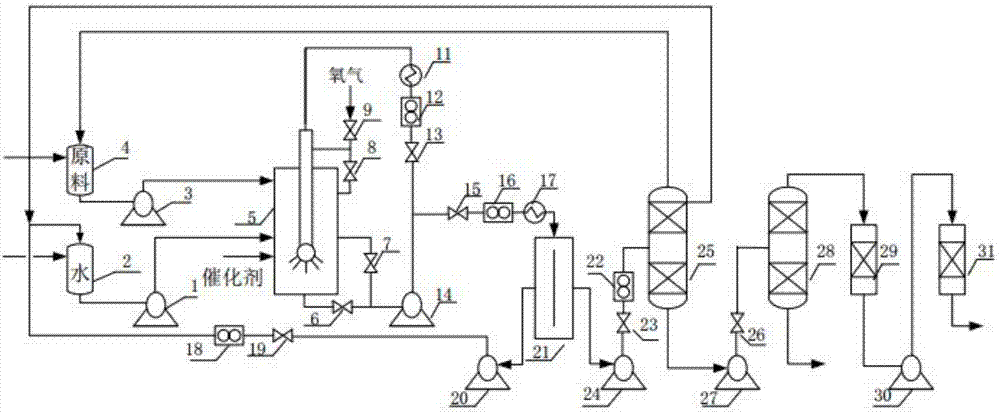

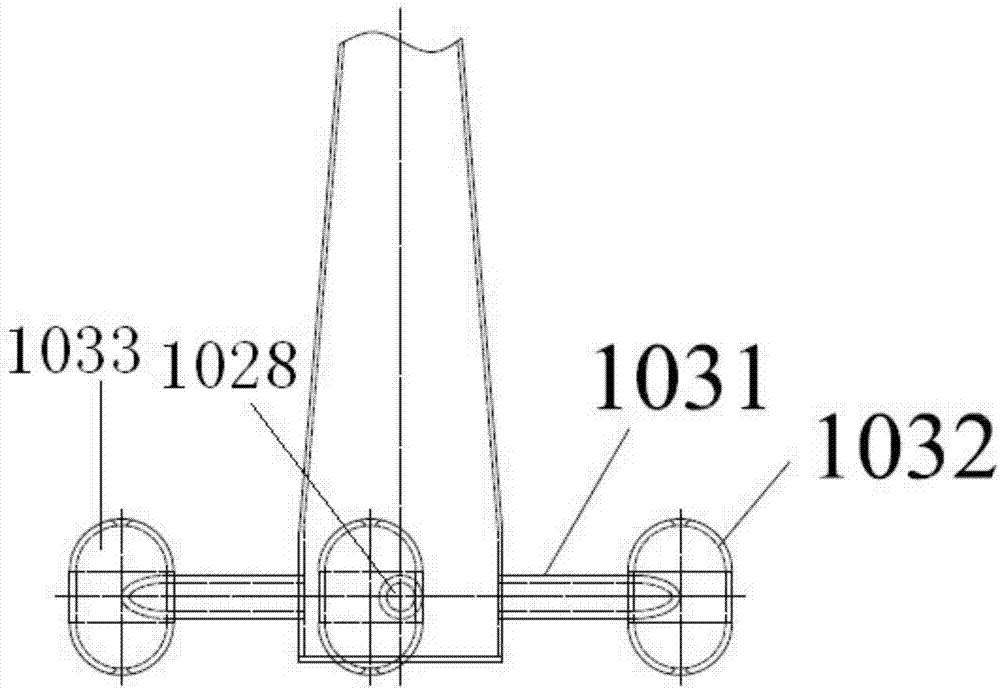

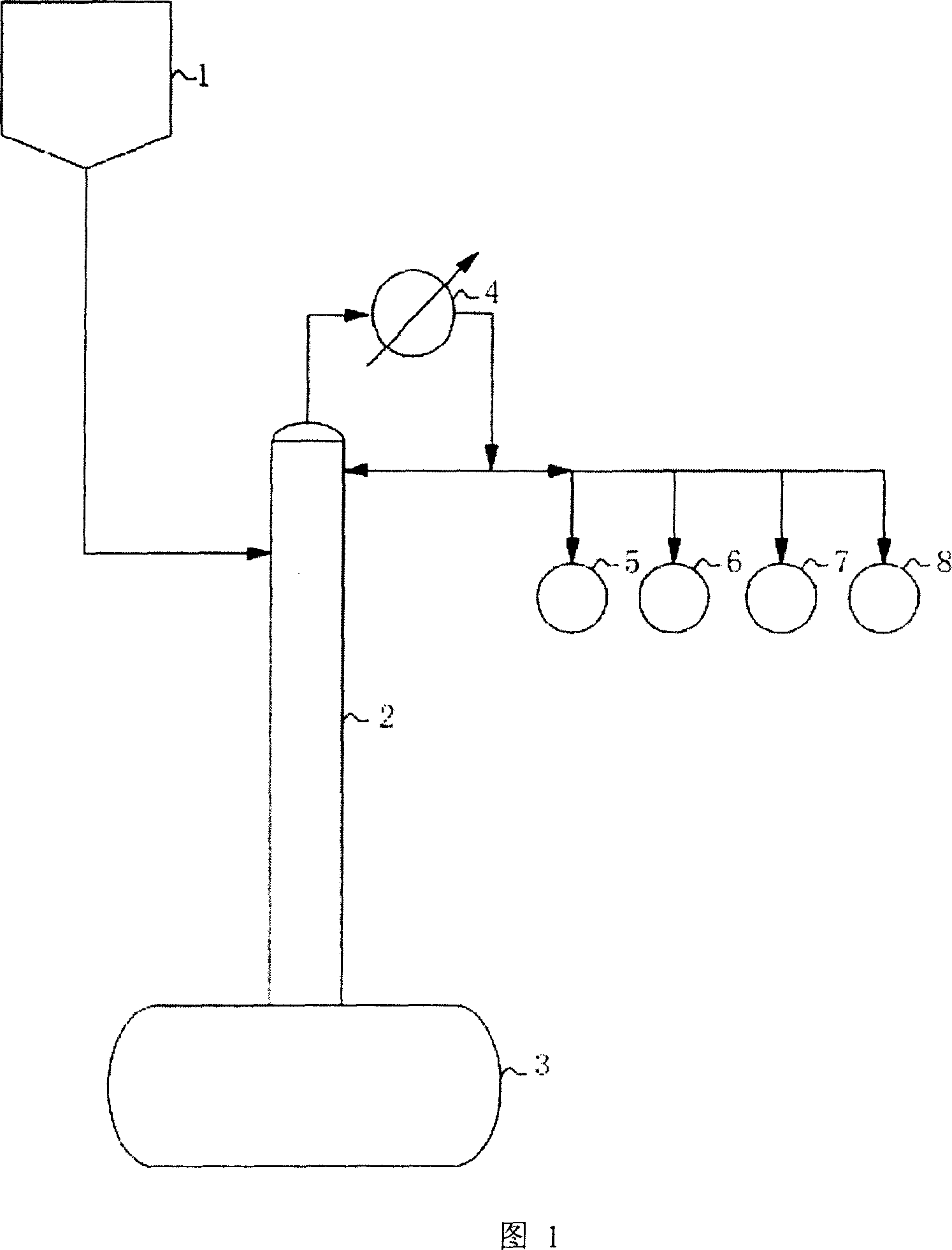

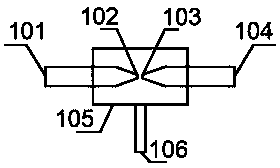

Preparation method and preparation apparatus of high-grade 4-tert-butylbenzaldehyde

PendingCN106977379AIncrease profitIncrease the gas-liquid contact areaOrganic compound preparationCarbonyl compound preparationHalogenP-tert-Butyltoluene

The invention discloses a preparation method of high-grade 4-tert-butylbenzaldehyde and a preparation apparatus of high-grade 4-tert-butylbenzaldehyde. The preparation method of high-grade 4-tert-butylbenzaldehyde comprises the following steps: A) 4-tert-butylbenzaldehyde, water and a catalyst without halogen are mixed in a micrometer bubble reactor for carrying out an oxidation reaction, in order to obtain reaction feed liquid; B) oil-water separation is carried out for reaction feed liquid in order to obtain water phase and oil phase, water phase contains the catalyst, and the oil phase contains 4-tert-butylbenzaldehyde and impurities; and C) 4-tert-butylbenzaldehyde and the impurities are separated in order to obtain high-grade 4-tert-butylbenzaldehyde. 4-tert-butylbenzaldehyde prepared by the preparation method of high-grade 4-tert-butylbenzaldehyde according to an embodiment does not contain halogen, and can be applied to the fields of foodstuff, medicine, perfume and the like.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

Method for producing p-tert-butyltoluene

InactiveCN102199068BAvoid disadvantagesPromote regenerationMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationP-tert-ButyltolueneToluene

The invention discloses a method for producing p-tert-butyltoluene, which comprises the following steps of: putting toluene and tert-butyl alcohol in a molar ratio of 1:(2-6) and a catalyst in an amount which is 5 to 30 percent based on the total weight of the toluene serving as a reactant into a reaction kettle under the action of the mesoporous / microporous composite molecular sieve catalyst consisting of a beta zeolite (Hbeta) microporous molecular sieve and an MCM-41 mesoporous molecular sieve, and reacting at the temperature of between 160 and 240 DEG C for 2 to 8 hours to obtain the p-tert-butyltoluene. The preparation process is simple, the catalyst is easy to separate and is reusable, production cost is low, the method is environment-friendly, and safe production is realized.

Owner:NANJING TECH UNIV

Preparation of methyl p-tert-butylbenzoate

InactiveCN108658761AHigh yieldEmission reductionOrganic compound preparationCarboxylic acid esters separation/purificationP-tert-ButyltolueneEsterification reaction

The invention discloses preparation of methyl p-tert-butylbenzoate. The preparation of the methyl p-tert-butylbenzoate comprises the steps of oxidizing tert-butyltoluene in air by using a composite catalyst to obtain p-tert-butylbenzoic acid; and then replacing traditional concentrated sulfuric acid by using p-toluenesulfonic acid, and carrying out esterification reaction to obtain the methyl p-tert-butylbenzoate. Meanwhile, a special treatment process is used for preparation of the methyl p-tert-butylbenzoate, the yield and the purity of products are increased by repeated water carrying of methanol, meanwhile, after being treated, evaporated methanol, an extracted water phase and a catalyst are reused, the cost for raw materials is greatly reduced, and moreover, the preparation of the methyl p-tert-butylbenzoate also has important environmental protection significance.

Owner:SUQIAN COSMOS CHEM

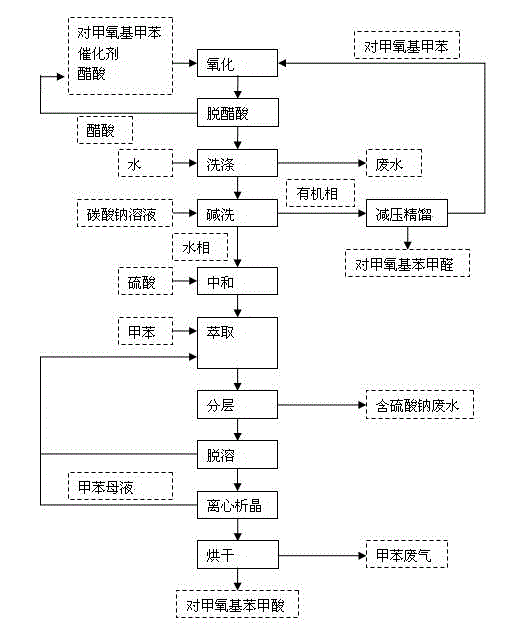

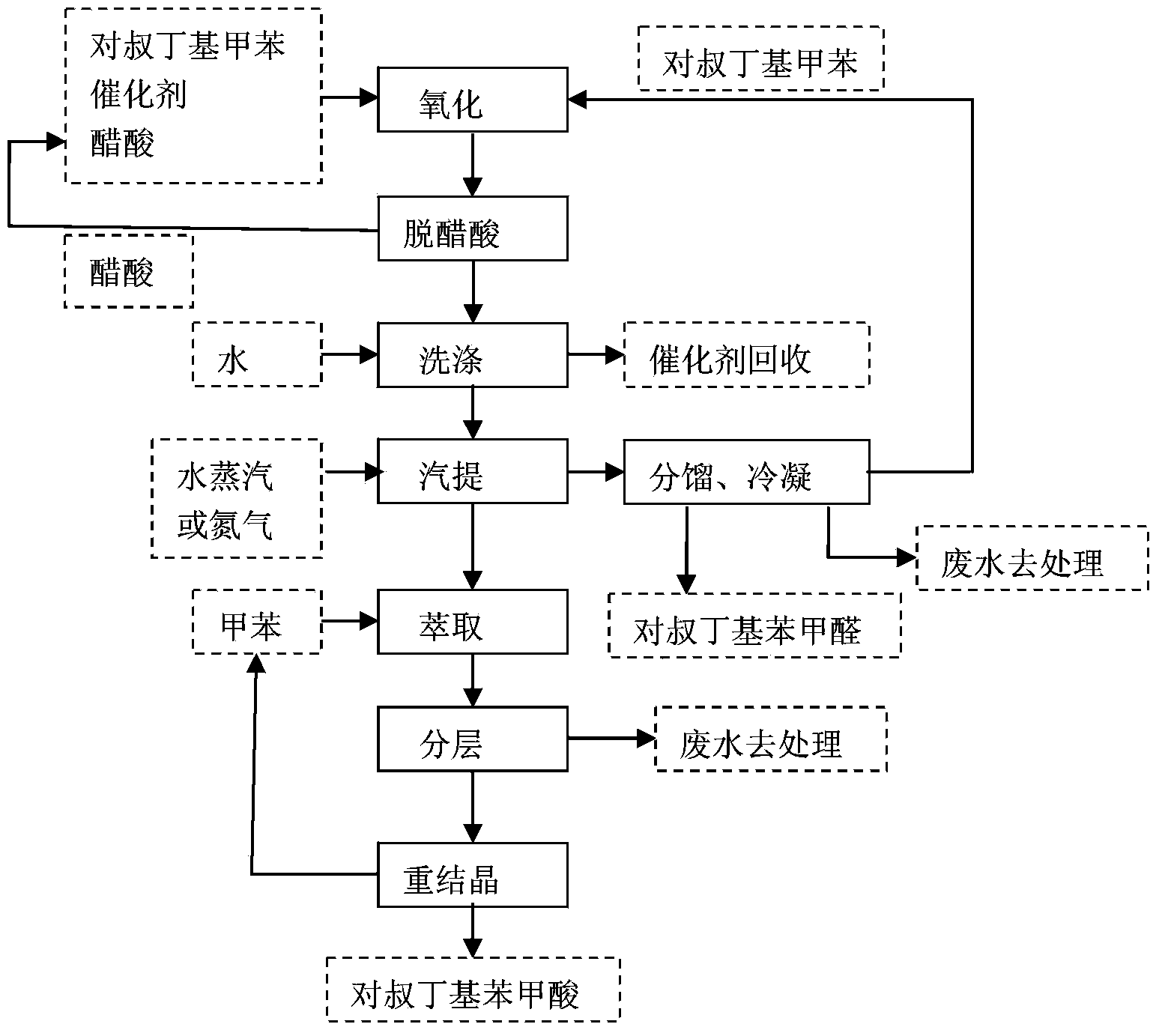

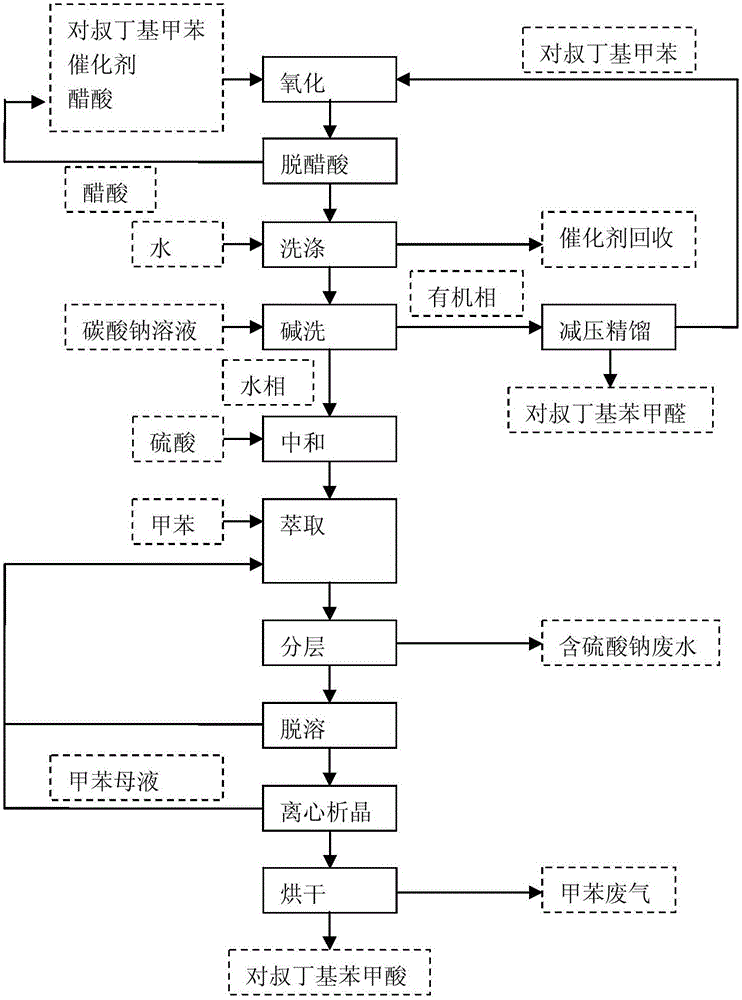

Separation process of substituted benzaldehyde co-produced products

InactiveCN103408412AAvoid it happening againSimple separation processCarbonyl compound separation/purificationCarboxylic compound separation/purificationAcetic acidBenzaldehyde

The invention discloses a separation process after synthesis of p-tertbutyl benzaldehyde (co-produced p-tertbutyl benzaldehyde). The separation process comprises the steps: rectifying an oxidization feed liquid to remove acetic acid, and washing with water to remove a catalyst; heating a washed organic phase to 95-100 DEG C, introducing saturated vapor or nitrogen, stripping, carrying out fractionation under reduced pressure, for separating vapor or nitrogen, p-tertbutyl benzaldehyde and p-tert-butyltoluene, cooling stripped residual liquid and then extracting by using methylbenzene, distilling the p-tertbutyl benzaldehyde after the methylbenzene is recovered, and then recrystallizing the methylbenzene. According to the separation process, the process step is reduced, and sodium sulfate-containing wastewater is prevented from producing.

Owner:NANJING UNIV

Batch extractive distillation separating method of acetonitrile-methylbenzene azeotropic mixtrue

InactiveCN1317049CFlexible operationReduce cost inputExtractive distillationExtractive distillationDiethyl benzene

The invention discloses a method for intermittent extraction and distillation and separation of acetonitrile- toluene azeotrope, belonging to the separation technique of acetonitrile- toluene. The method is described as the following: using propyl benzene, butylbenzene, isobutylbenzene, sec- butylbenzene, tertiarybutyl phenol, p- diethyl benzene or tertiary-butyl toluene as the extractant, operating in a extracting- fractionating tower at a normal pressure or reduced pressure with a mass ratio of extractant to overhead of 2: 1- 10: 1 and a feeding temperature of extractant of 25- 80 Deg. C, picking separately acetonitrile, the transition section I of a low rate of acetonitrile, and transition section II of toluene and toluene- extractant from the extracting- fractionating tower by controlling the temperature and reflux ratio of the head of extracting- fractionating tower; when the constitute of extractant in heating kettle approaches to the requirement, pumping the extractant into elevated container and feeding material to prepare for the intermittent extraction and distillation and separation of next batch. The merit of the invention is that using extractant to destroy acetonitrile- toluene azeotrope,the high purity acetonitrile and toluene are prepared, and the operation is flexible with a single towel.

Owner:TIANJIN UNIV

Process for synthesizing p-tert-butylbenzoic acid

ActiveCN102617335BReduce usageReduce recycling stepsOrganic compound preparationCarboxylic compound separation/purificationMoistureImpurity

The invention relates to a process for synthesizing p-tert-butylbenzoic acid. The process comprises the following steps of: adding p-tert-butyltoluene and cobalt acetate into a reaction kettle, introducing oxygen-containing gas, triggering at the temperature of between 150 and 155 DEG C, performing oxidation reaction for 0.5 to 1 hour, and continuously reacting at the temperature of between 135 and 145 DEG C for more than 5 hours to obtain a p-tert-butylbenzoic acid crude product; cooling the p-tert-butylbenzoic acid crude product to crystallize, performing centrifuge dripping, and striking and washing by using p-tert-butyltoluene to obtain a centrifugation crude product; and adding the centrifugation crude product into a dissolution kettle, adding methylbenzene, raising temperature and dissolving, filtering when a mixture is hot to remove impurities, adding water to wash, transferring materials to a recrystallization kettle, cooling to crystallize, centrifuging, striking and washing by using methylbenzene, and drying to obtain a p-tert-butylbenzoic acid finished product. The prepared p-tert-butylbenzoic acid is white crystals and does not contain mechanical impurities; and the melting point is 164.0 to 167.0 DEG C, the acid value is 312 to 316mgKOH / g, high performance liquid chromatography (HPLC) purity is more than or equal to 99.2 percent, moisture is less than or equal to 0.08 percent, and methylbenzene is less than or equal to 0.05 percent.

Owner:SUQIAN COSMOS CHEM +1

A kind of continuous production process of p-tert-butyltoluene

ActiveCN103274890BHigh activityImprove thermal stabilityMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationFixed bedTert butyl

The invention relates to a continuous production process of p-tert-butyl toluene, and in particular relates to a method for synthetizing the p-tert-butyl toluene through catalyzing toluene and tert butyl alcohol by using a metallic oxide-supported molecular sieve catalyst. The invention aims to overcome the shortcomings that catalysts corrode equipment, pollute the environment and are difficult to separate and incapable of being recycled and the like in traditional methods for synthetizing the p-tert-butyl toluene through liquid acid catalysis. The continuous production process of the p-tert-butyl toluene comprises the following steps of (1) preparation of the metallic oxide-supported molecular sieve catalyst and (2) synthetic reaction of the p-tert-butyl toluene. The process disclosed by the invention has the advantages of simpleness, environmental friendliness, low labour intensity and low production cost; by adopting the homemade metallic oxide-supported molecular sieve catalyst, the problems that the liquid acid catalysts corrode equipment and pollute the environment in the traditional production methods are solved; and in the meantime, the homemade catalyst is high in activity, good in heat stability, high in mechanical strength and capable of meeting the requirements of long-period operation in the continuous production process of fixed beds.

Owner:FAREAST KINGSTAR CHEM

Preparation method for 2,6-dihydroxytoluene

ActiveCN103508850BGood reaction selectivityHigh yieldOrganic compound preparationAmino compound preparationNitrationP-tert-Butyltoluene

The invention relates to a preparation method for 2,6-dihydroxytoluene. The preparation method adopts p-tert-butyltoluene as a raw material which is subjected to nitration, reduction and hydrolytic tert-butyl elimination reactions to obtain 2,6-dihydroxytoluene. The preparation method has the characteristics of high selectivity and product purity, low cost, environmental friendliness and the like, and is a route with an industrialization prospect.

Owner:ZHEJIANG DINGLONG TECH

Method for preparing p-tert-butylbenzaldehyde by carrying out liquid phase oxidation on p-tert-butyltoluene

ActiveCN108440263ALow investment costImprove qualityOrganic compound preparationCarbonyl compound preparationP-tert-ButyltolueneOil phase

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

A kind of separation process of substituted benzaldehyde co-production product

InactiveCN103408412BAvoid it happening againSimple separation processCarbonyl compound separation/purificationCarboxylic compound separation/purificationAcetic acidBenzaldehyde

Owner:NANJING UNIV

A kind of preparation and aftertreatment method of p-tert-butylbenzoic acid

ActiveCN108530285BHigh yieldEmission reductionOrganic compound preparationHydrocarbon from saturated and unsaturated hydrocarbon additionBenzoic acidP-tert-Butyltoluene

The invention discloses a preparation and post-treatment method of p-tert-butylbenzoic acid. During the preparation, p-tert-butyltoluene is obtained by tert-butylation of toluene, and then p-tert-butyltoluene is oxidized, and then analyzed crystallization treatment to obtain p-tert-butylbenzoic acid; wherein, after the crystallization treatment, the crystallization mother liquor is reprocessed to further obtain the residual p-tert-butylbenzoic acid in the mother liquor, which improves its productivity, and, in the mother liquor The waste product sodium sulfate is post-treated to obtain industrial grade sodium sulfate. In this way, the discharge of waste materials in the preparation process is reduced, and the waste product sodium sulfate is converted into reusable industrial grade sodium sulfate. In this way, it not only brings certain economic benefits , and the significance of environmental protection is more prominent.

Owner:SUQIAN COSMOS CHEM

Method for producing p-tert-Butyltoluene by using mordenite for catalyzing toluene and tertiary butanol

InactiveCN102557858BSuitable for large-scale continuous productionHydrocarbon by hydrocarbon and non-hydrocarbon condensationProduction rateFixed bed

The invention discloses a method for producing p-tert-Butyltoluene by using mordenite for catalyzing toluene and tertiary butanol, which uses a mordenite catalyst, n(SiO2) / n(Al2O3)=30, the catalyst is conducted activating treatment for 3 hours at 550 DEG C, or the catalyst is conducted treatment for 4 hours at 100 DEG C in 0.2mol / L NaOH solution, then the p-tert-Butyltoluene is obtained after roasting at 550 DEG C. At the reaction temperature of 150-190 DEG C, liquid space velocity is 1-8ml / gcatXh, and mole ratio of the toluene / the tertiary butanol is 1:1-1:6. In a fixed bed reactor, toluene percent conversion is 10-33%, and selectivity of the p-tert-Butyltoluene achieves 35-75%. The method can continuously produce the p-tert-Butyltoluene under soft reaction conditions, and overcomes the shortcoming that in the traditional production method, liquid acid catalysts corrode equipment, environmental contamination is caused, interval liquid phase reaction is big in production strength, and production rate is low.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Refining method of p-tert-butylbenzoic acid

InactiveCN113105320AReduce manufacturing costEliminate corrosionMolecular sieve catalystsOrganic compound preparationBenzoic acidPtru catalyst

The invention provides a refining method of p-tert-butylbenzoic acid. The refining method comprises the following steps: 1, obtaining p-tert-butyltoluene; 2, adding the p-tert-butyltoluene obtained in the step 1 and a supported composite catalyst into a reaction kettle, introducing oxygen, and carrying out an oxidation reaction at a certain temperature to obtain a p-tert-butylbenzoic acid crude product; 3, cooling and crystallizing the p-tert-butylbenzoic acid crude product obtained in the step 2, performing centrifugal spin-drying, and washing with p-tert-butyltoluene to obtain a centrifuged crude product; and 4, adding the centrifuged crude product into a dissolving kettle, centrifuging, and drying to obtain a p-tert-butylbenzoic acid finished product. The method has the beneficial effects that the high-quality product can be obtained by simply washing the crude product with water, the post-treatment process is simplified, the quality of the product can be improved, and the production cost can be reduced.

Owner:天津鼎晟新化科技有限公司

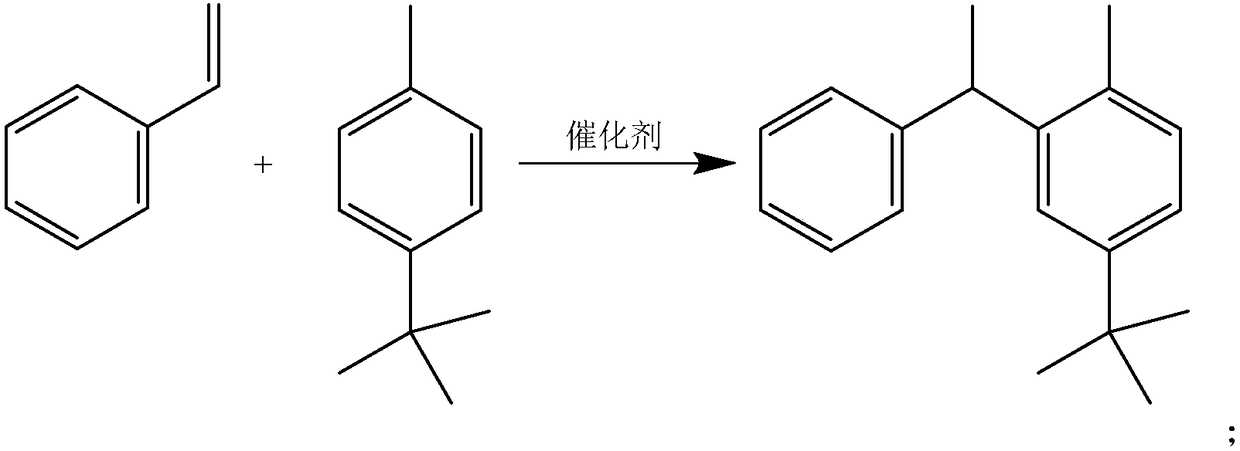

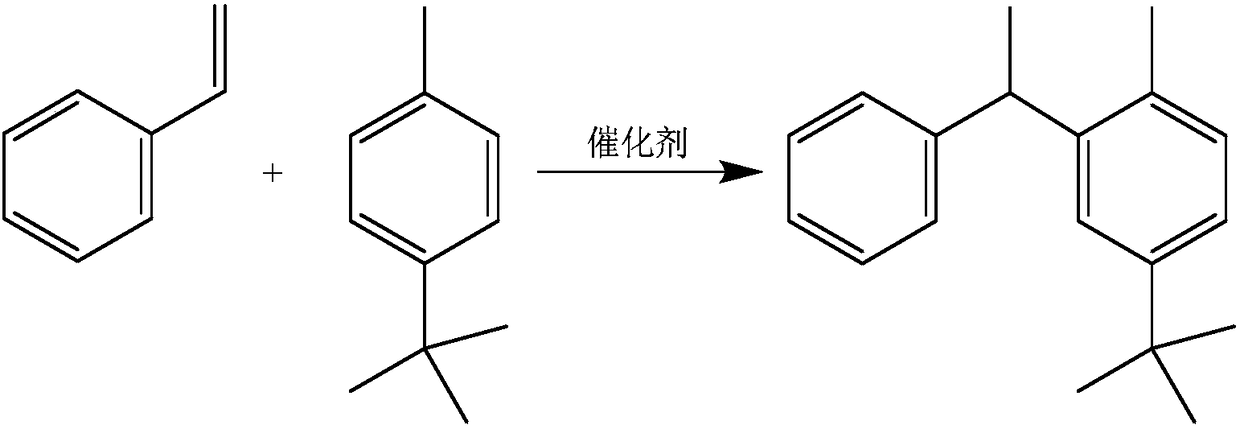

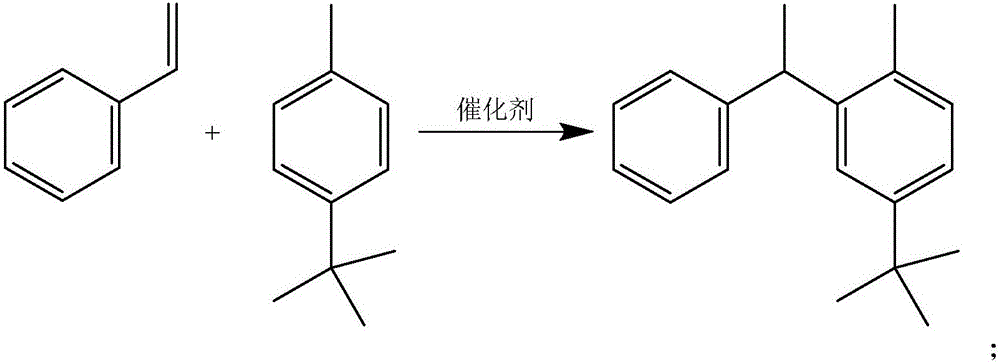

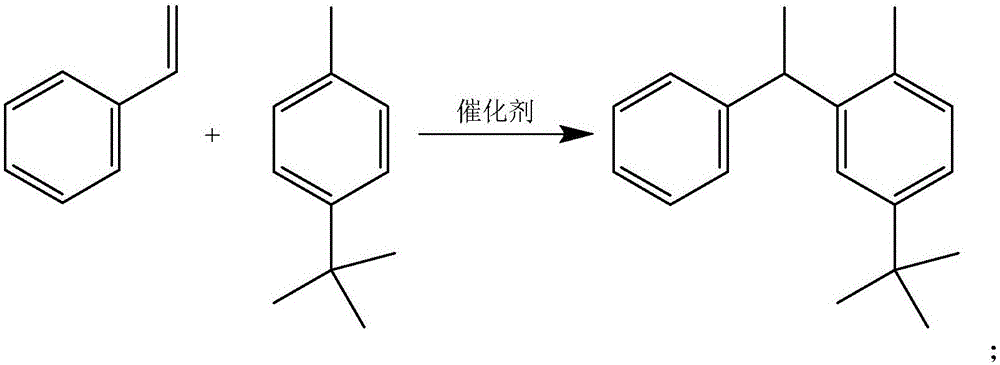

1-phenyl-1-(p-tert-butyltolyl)ethane and its synthesis method

ActiveCN105820021BNo pollutionLow yieldHydrocarbons from unsaturated hydrocarbon additionChemical recyclingFiltrationSynthesis methods

The invention discloses a kind of 1-phenyl-1-(p-tert-butyltolyl)ethane and a synthesis method thereof, the steps are as follows: 1) using styrene and p-tert-butyltoluene as raw materials, in the presence of a solid acid catalyst Under the action, through the alkylation reaction, the reaction formula is as follows: 2) After the reaction is completed, the solid acid catalyst needs to be separated, and the solid material composed of activated clay and magnesium oxide with a mass ratio of 10:1 is used for further adsorption and neutralization And decolorize and filter, recover excess p-tert-butyltoluene through water pump vacuum distillation, and then vacuum pump vacuum distillation to obtain. The catalyst selected in the invention can be recycled, does not pollute the environment, and simultaneously avoids the use of catalysts such as sulfuric acid, aluminum trichloride and the like which are volatile, poisonous and difficult to handle. The preparation process has the characteristics of mild and controllable, few by-products and high yield.

Owner:JIANGSU ZHONGNENG CHEM TECH CO LTD

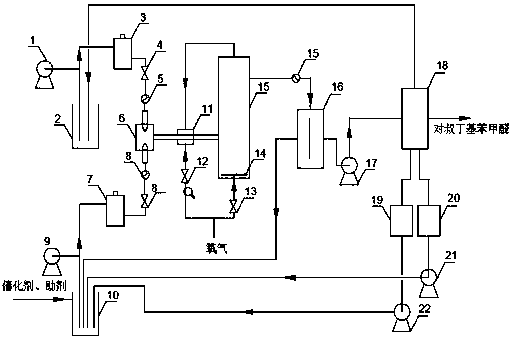

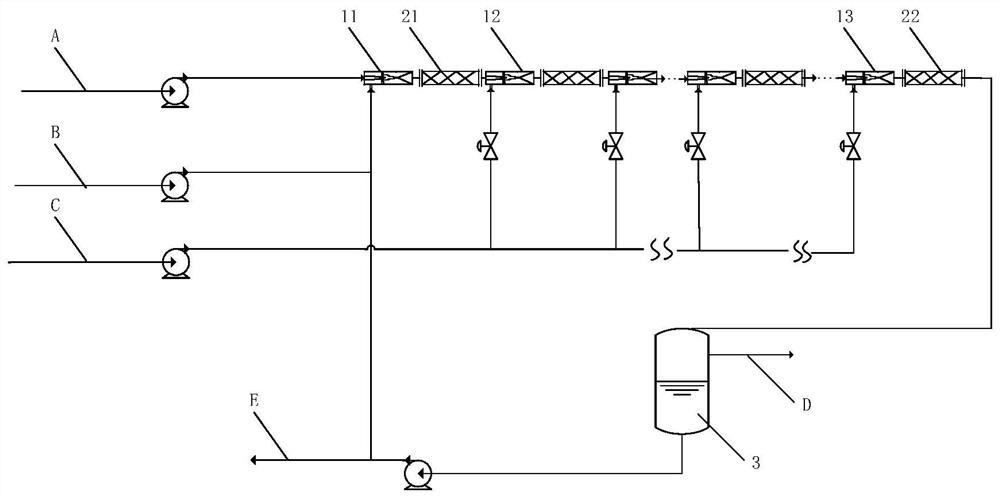

A kind of method for preparing p-tert-butyltoluene

ActiveCN111408319BWell mixedHigh yieldHydrocarbon from saturated and unsaturated hydrocarbon additionChemical/physical processesPtru catalystReaction temperature

The invention provides a method for preparing p-tert-butyltoluene, wherein the novel reactor includes a plurality of Venturi mixers connected alternately in sequence and a tubular reactor with internals, and the tubular reaction with internals The outer wall of the device is provided with a jacket. It also relates to a method for combining p-tert-butyltoluene with a novel reactor, using isobutylene and toluene as raw materials, under the catalysis of concentrated sulfuric acid, toluene is fed in a single strand, concentrated sulfuric acid is fed in a single strand, and isobutylene is fed in multiple strands. Synthesis of p-tert-butyltoluene by continuous liquid-liquid two-phase alkylation reaction through a novel reactor group. The invention creates the novel reactor group for synthesizing p-tert-butyltoluene and its use method. The novel reactor group is applied to the continuous liquid-liquid two-phase alkylation reaction process of toluene and isobutylene, which not only has the advantages of uniform material mixing , the reaction temperature is controllable, the target product yield is high, the catalyst consumption is small, etc., and it can realize efficient, low-cost and continuous production of p-tert-butyltoluene.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

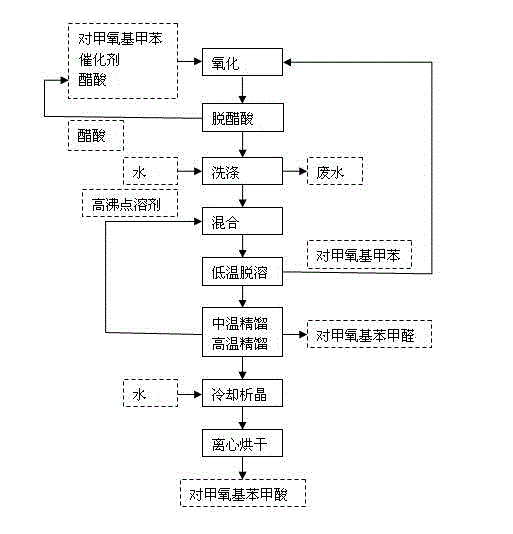

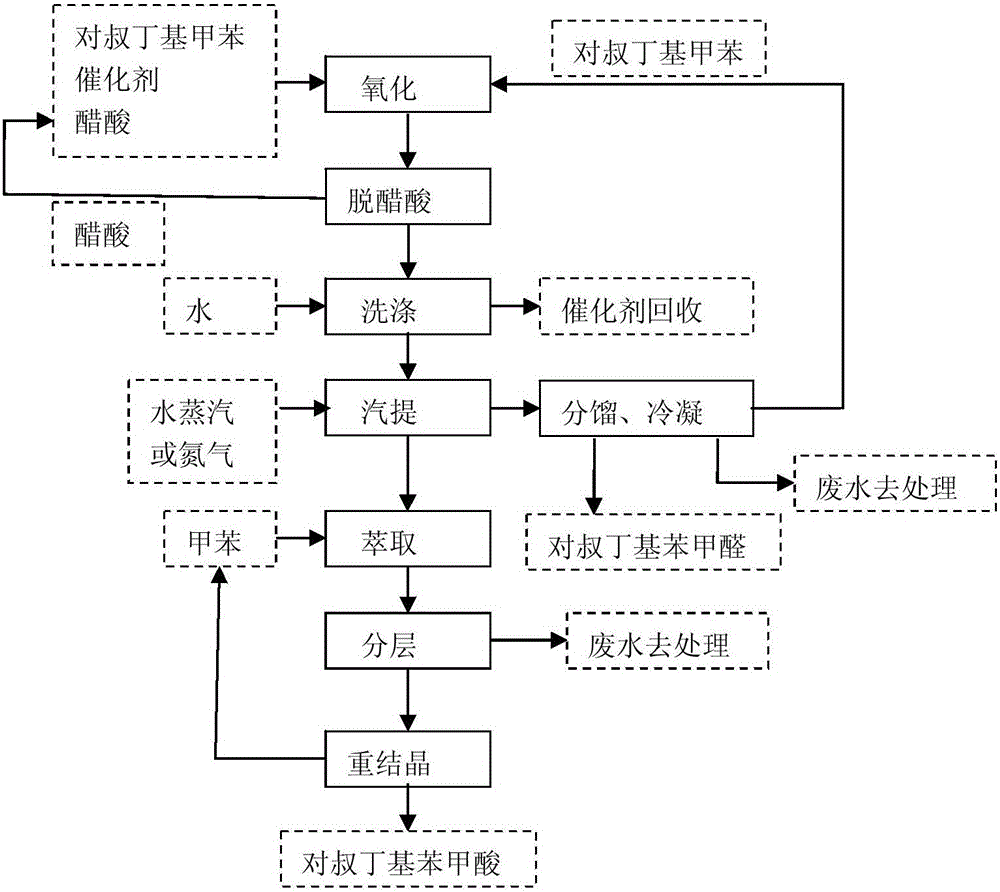

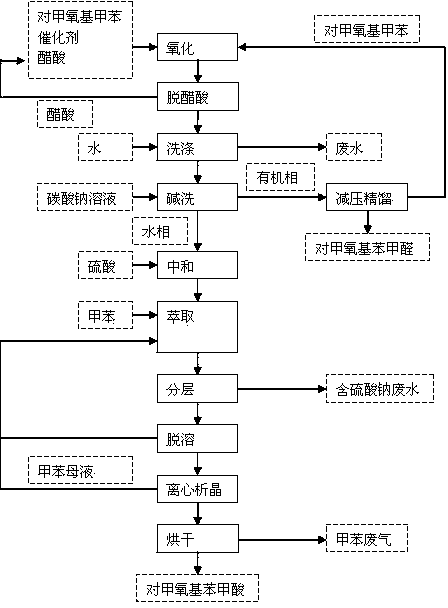

Process for synthesizing p-methoxy benzaldehyde or p-tertbutyl benzaldehyde

InactiveCN103145527BEmission reductionReduce pollutionOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationBenzoic acidBenzaldehyde

The invention provides a process for synthesizing p-methoxy benzaldehyde or p-tertbutyl benzaldehyde. The process comprises the following steps of: adding an acidifying agent glacial acetic acid and catalysts cobalt acetate and sodium bromide into p-methoxy methylbenzene or p-tertbutyl methylbenzene, introducing oxygen to perform oxidation reaction under a heating condition, and after the reaction, washing feed liquid with water for twice to remove the catalysts and the acetic acid; adding an oil phase after washing into a high-boiling-point solvent, and then performing rectification under vacuum step by step; unmixing and steaming out excessive p-methoxy methylbenzene or p-tertbutyl methylbenzene, then increasing the vacuum degree and the temperature, and collecting a gas-phase condensate to obtain the p-methoxy benzaldehyde or p-tertbutyl benzaldehyde; and continuously raising the rectification temperature, and receiving the gas-phase condensate with water, and performing recrystallization for twice to obtain p-methoxy benzoic acid or p-tertbutyl benzoic acid. According to the process, the discharge of waste water is reduced, the generation of the waste water containing sodium sulfate is avoided, and meanwhile, methylbenzene is not used for extracting the p-methoxy benzoic acid or p-tertbutyl benzoic acid, so that the pollution of the methylbenzene to the environment is reduced.

Owner:NANJING UNIV

Method for separating acetonitrile-methylbenzene azeotropic mixture by continuous extractive distillation

The invention discloses a method for continuous extraction and distillation and separation of acetonitrile- toluene azeotrope. The method is described as the following: using propyl benzene, butylbenzene, isobutylbenzene, sec- butylbenzene, tertiarybutyl phenol, mesitylene, p- diethyl benzene or tertiary-butyl toluene as the extractant, operating in a extracting- fractionating tower at a normal pressure or reduced pressure with a mass ratio of extractant in extracting- fractionating tower to overhead being 2: 1- 10: 1 and a feeding temperature of extractant of 25- 80 Deg. C, the acetonitrile- toluene azeotrope entering from the middle of extracting- fractionating tower, picking the qualified content of acetonitrile from the head of tower with a reflux ratio of 1: 1- 5: 1, toluene and solvent from the bottom of the tower flowing into the middle of the extractant recovery tower, the toluene being picked from the head of extractant recovery tower with a reflux ratio of 2: 1- 10: 1, and the high-purity extractant which can be circularly used being picked from the bottom of the extractant recovery tower. The merit of the invention is that using extractant to destroy acetonitrile- toluene azeotrope,the high purity acetonitrile and toluene are prepared.

Owner:TIANJIN UNIV

1-phenyl-1-(p-tert-butyl methylphenyl)ethane and synthesis method thereof

ActiveCN105820021ANo pollutionLow yieldHydrocarbons from unsaturated hydrocarbon additionCatalystsDistillationFiltration

The invention discloses 1-phenyl-1-(p-tert-butyl methylphenyl)ethane and a synthesis method thereof. The synthesis method comprises the following steps: 1) with styrene and p-tert-butyl toluene as raw materials and under the effect of a solid acid catalyst, performing an alkylation reaction, wherein the reaction formula is shown in the specification; and 2) after the reaction, separating the solid acid catalyst; performing further adsorption, neutralization and decoloration filtration using a solid material consisting of activated clay and magnesium oxide in a mass ratio of 10:1; performing reduced-pressure distillation through a water pump to recycle excess p-tert-butyl toluene; and performing reduced-pressure distillation through a vacuum pump to obtain 1-phenyl-1-(p-tert-butyl methylphenyl)ethane. In the invention, the adopted catalyst can be recycled to avoid environmental pollution; and meanwhile, the use of volatile, toxic and hard-to-treat catalysts such as sulfuric acid and aluminum trichloride is avoided. The preparation technology has the characteristics of mildness and controllability, few byproducts and high yield.

Owner:JIANGSU ZHONGNENG CHEM TECH CO LTD

A method for synthesizing p-tert-butyltoluene with caprolactam ionic liquid as catalyst

ActiveCN105669342BLow costEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsAfter treatmentReaction temperature

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com