Batch extractive distillation separating method of acetonitrile-methylbenzene azeotropic mixtrue

An azeotropic mixture and extractive distillation technology, applied in the direction of extractive distillation, etc., can solve the problems such as unseen data, and achieve the effect of flexible operation and low equipment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

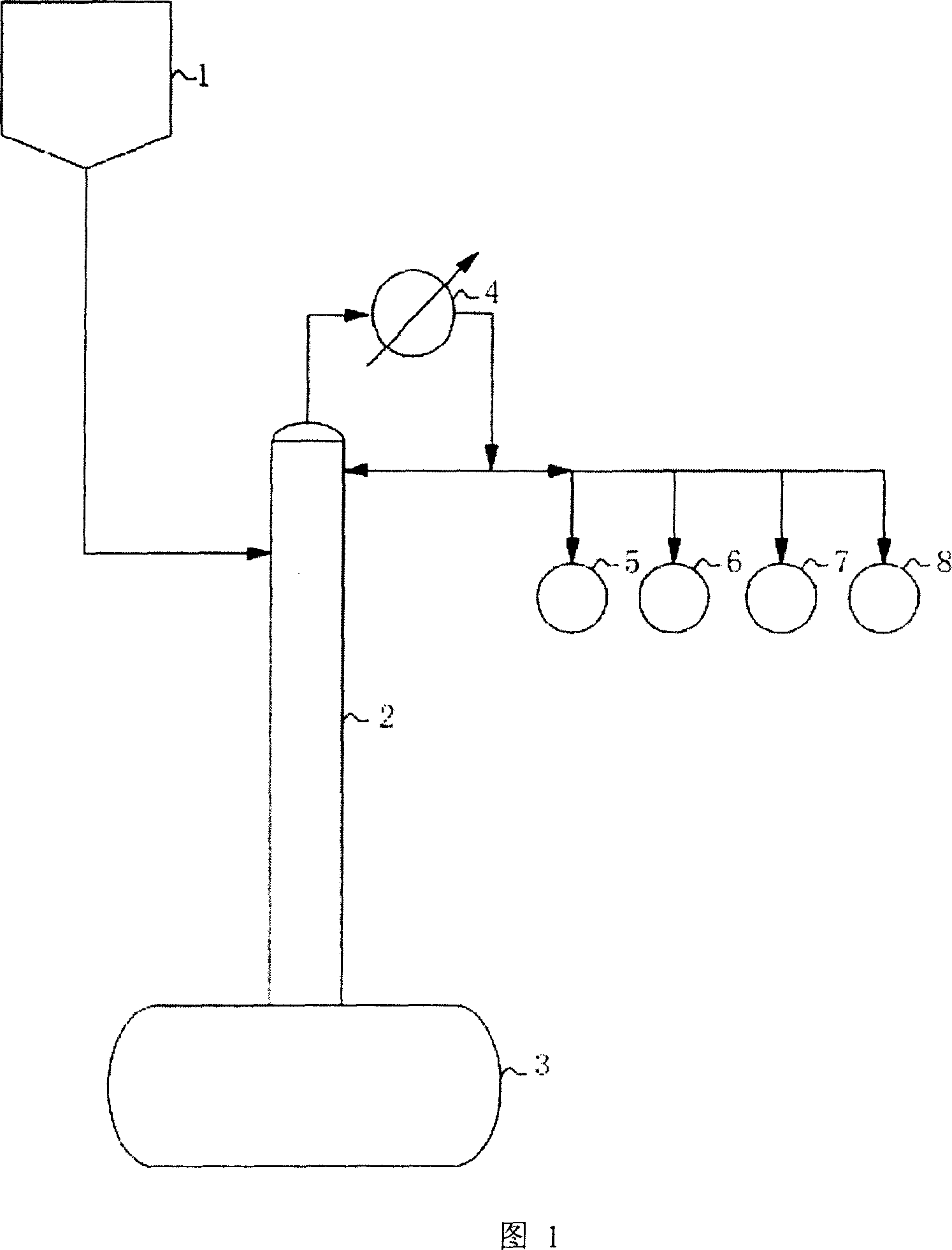

Image

Examples

Embodiment 1

[0011] Adopt intermittent extraction rectification device, drop into 500ml acetonitrile-toluene azeotropic mixture (wherein acetonitrile 73%, toluene 27%, all are mass percentages) in heating kettle, the selected extraction agent of test is propylbenzene, open heating kettle heat source and condenser When the cooling source is used, the extractive distillation tower starts to run. When there is reflux at the top of the extractive distillation tower, add the extractant. The feed position of the extractant is near the top of the tower. Control the addition rate of the extractant to 800ml / h. When the temperature at the top of the rectification tower is 81.5-82° C., the acetonitrile content in the distillate is ≥ 99%, and the material starts to be discharged, the reflux ratio is 3:1, and the discharge rate is 200 ml / h. When the temperature at the top of the extractive distillation tower is 83-110°C, the acetonitrile-toluene transition section is extracted, and the addition of the e...

Embodiment 2

[0013] Adopt intermittent extraction and rectification device, drop 500ml acetonitrile-toluene azeotropic mixture (wherein acetonitrile 73%, toluene 27%, all are mass percent) in heating kettle, the extraction agent selected for test is p-tert-butyl toluene, open heating kettle heat source and the cold source of the condenser, the rectification tower starts to run. When there is reflux at the top of the extractive rectification tower, the extractant is added. The feed position of the extractant is near the top of the tower. When the temperature at the top of the extractive distillation tower is 81.5-82° C., the acetonitrile content in the top distillate is ≥ 99%, and the discharge starts, the reflux ratio is 2:1, and the discharge speed is 150 ml / h. When the temperature at the top of the extractive distillation tower is 83-110°C, the acetonitrile-toluene transition section is extracted, and the addition of the extractant is stopped, and the reflux ratio is 10:1. When the temper...

Embodiment 3

[0015] Experimental device and operation method are the same as embodiment one, and extractant adopts mesitylene

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com