Synthetic method of p-tert-butylbenzaldehyde

A technology of p-tert-butyltoluene and p-tert-butyl, which is applied in the field of highly selective synthesis of p-tert-butylbenzaldehyde by catalytic oxidation of p-tert-butyltoluene, which can solve the problems of expensive template agent, complex process and low conversion rate , to achieve the effect of avoiding deep oxidation, good selectivity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

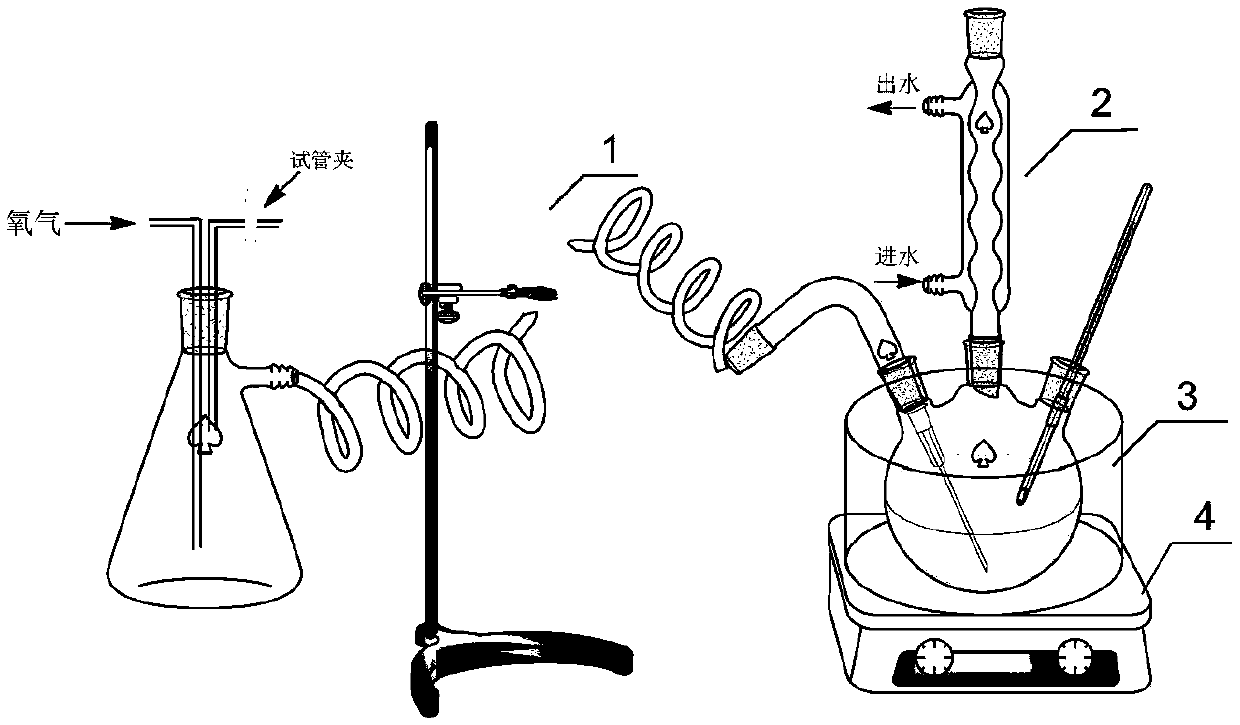

Method used

Image

Examples

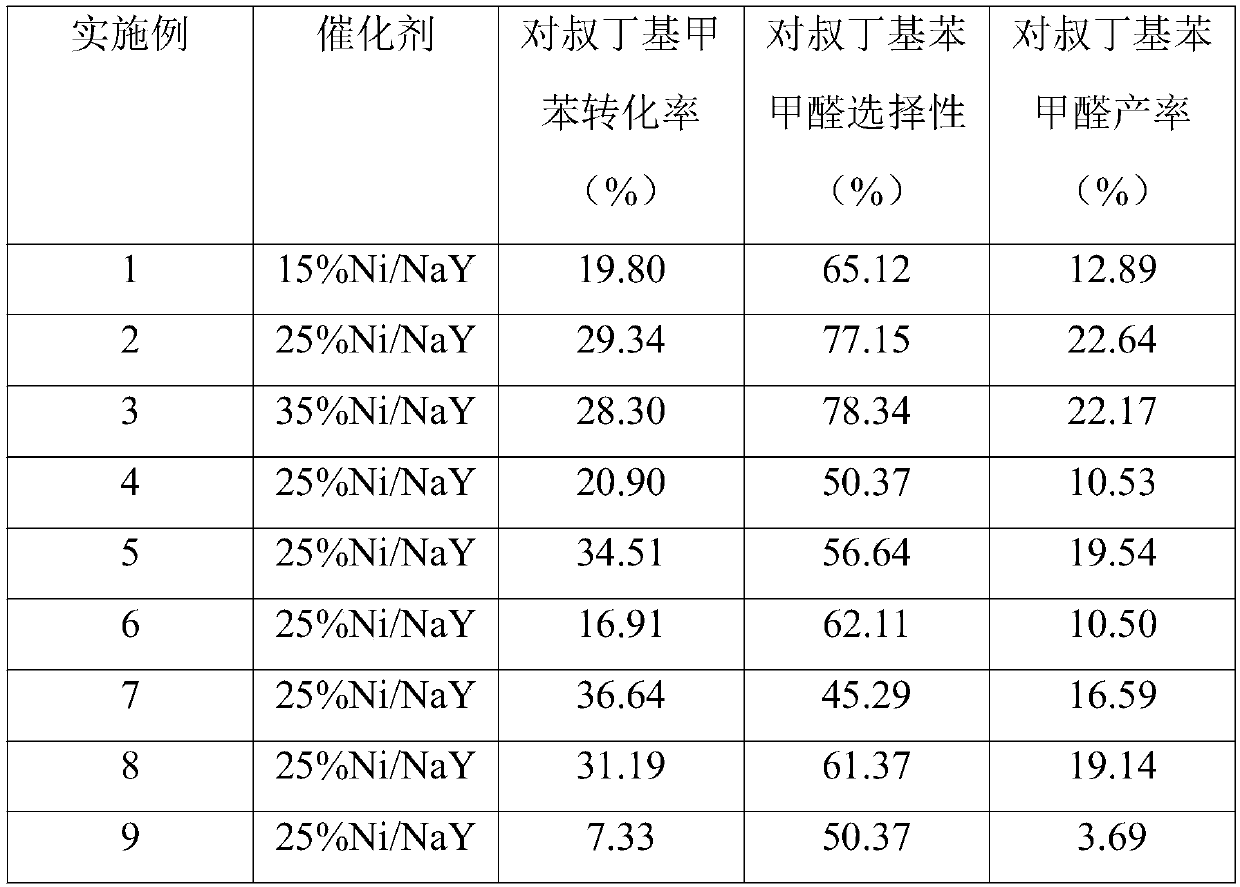

Embodiment 1

[0024] The preparation of 15%Ni / NaY: Adopt equal volume impregnation method, can know that the specific pore volume of NaY molecular sieve is 0.36ml / g by BET detection, then when the required active component content (calculated as oxide) is 15%, can Knowing that the required impregnating solution concentration is 0.5mol / L, it is deduced that Ni(NO 3 ) 2 ·6H 2 O 7.25g. 7.25g Ni(NO 3 ) 2 ·6H 2 Dissolve O in 50 mL of deionized water to obtain impregnating solution No. 1, add 5 g of NaY molecular sieves to magnetically stir for 3 h, let stand for 12 h to age overnight, filter with suction, dry at 80°C for 12 h, and roast at 450°C for 4 h to obtain 15% Ni / NaY catalyst .

[0025] Oxidation reaction: Add 6mL p-tert-butyltoluene and 18mL acetonitrile (1:3 volume ratio) into a 25mL three-necked flask, heat in an oil bath at 70°C, condense and reflux, and magnetically stir at 200r / min. When the temperature reaches 70°C, add 0.2g15%Ni / NaY and 0.1gN-hydroxyphthalimide (mass ratio ...

Embodiment 2

[0027] The preparation of 25%Ni / NaY: adopt equal volume impregnation method, can know that the specific pore volume of NaY molecular sieve is 0.36ml / g by BET detection, then when the required active component content (calculated as oxide) is 25%, can Knowing that the required impregnating solution concentration is 1.0mol / L, it is deduced that Ni(NO 3 ) 2 ·6H 2 O 14.50g. 14.50g Ni(NO 3 ) 2 ·6H 2 Dissolve O in 50mL of deionized water to obtain impregnating solution No. 2, add 5g NaY molecular sieve to magnetically stir for 3h, let stand for 12h to age overnight, filter with suction, dry at 80°C for 12h, and roast at 450°C for 4h to obtain 25% Ni / NaY catalyst .

[0028] Oxidation reaction: Add 6mL p-tert-butyltoluene and 18mL acetonitrile (1:3 volume ratio) into a 25mL three-necked flask, heat in an oil bath at 70°C, condense and reflux, and magnetically stir at 200r / min. When the temperature reaches 70°C, add 0.2g 25% Ni / NaY and 0.1g N-hydroxyphthalimide (mass ratio is 2:...

Embodiment 3

[0030] The preparation of 35%Ni / NaY: adopt equal volume impregnation method, can know that the specific pore volume of NaY molecular sieve is 0.36ml / g by BET detection, then when the required active component content (calculated as oxide) is 35%, can Knowing that the required impregnation solution concentration is 1.5mol / L, it is deduced that Ni(NO 3 ) 2 ·6H 2 O 21.75g. 21.75g Ni(NO 3 ) 2 ·6H 2 O was dissolved in 50mL of deionized water to obtain impregnation solution No. 3, and 5g NaY molecular sieve was added to magnetically stir for 3h, left to stand for 12h to age overnight, filtered with suction, dried at 80°C for 12h, and calcined at 450°C for 4h to obtain 35% Ni / NaY catalyst .

[0031] Oxidation reaction: Add 6mL p-tert-butyltoluene and 18mL acetonitrile (1:3 volume ratio) into a 25mL three-necked flask, heat in an oil bath at 70°C, condense and reflux, and magnetically stir at 200r / min. When the temperature reaches 70°C, add 0.2g35%Ni / NaY and 0.1gN-hydroxyphth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com