A kind of method for preparing p-tert-butyltoluene

A technology of p-tert-butyltoluene and toluene, which is applied in the field of continuous liquid-liquid two-phase alkylation reaction to synthesize p-tert-butyltoluene, which can solve the problem of low mass transfer efficiency, long reaction time and unfavorable mass transfer in multiphase reaction phase interface To achieve the effect of improving the yield of the target product, high yield of the target product, and promoting heat transfer and mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

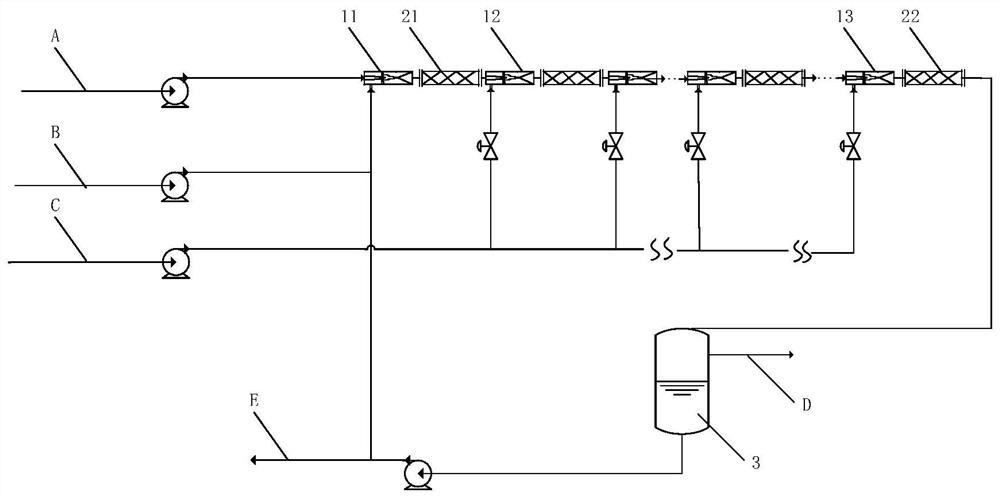

[0057] The venturi mixer and the tubular reactor with SV internals are alternately connected as a new reactor group. The single tube length of the tubular reactor is 3m, and the inner diameter of the tube is 12mm. The length of all tubular reactors with internals The sum is 6m, and it consists of two Venturi mixers and two tubular reactors with SV internals connected alternately in sequence.

[0058] The single feed of toluene enters from the main inlet of the first Venturi mixer 11, and the single feed of concentrated sulfuric acid enters from the side inlet of the first Venturi mixer 11. After the toluene and concentrated sulfuric acid are mixed in the first Venturi mixer 11 Enter the first tubular reactor 21 with internals for pre-mixing, and the first liquid-phase isobutene enters the new reactor group from the side inlet of the second Venturi mixer 12 .

[0059] The molar flow rate of toluene is 2 kmol / h, the molar flow rate of sulfuric acid is 0.25 kmol / h, and the total ...

Embodiment 2

[0063] The venturi mixer and the tubular reactor with SX internals are alternately connected as a new reactor group. The length of the tubular reactor is 2m, the inner diameter of the tube is 25mm, and the sum of the length of all tubular reactors with internals is 14m. , consisting of seven Venturi mixers and seven tubular reactors connected alternately in sequence.

[0064] The single feed of toluene enters from the main inlet of the first Venturi mixer 11, and the single feed of concentrated sulfuric acid enters from the side inlet of the first Venturi mixer 11. After the toluene and concentrated sulfuric acid are mixed in the first Venturi mixer 11 Enter the first tubular reactor 21 with internals for pre-mixing, and the liquid-phase isobutene is fed in 6 streams, which enter the new reactor group from the side inlets of the second to seventh Venturi mixers respectively.

[0065] The total molar flow rate of toluene is 4.06kmol / h, the total molar flow rate of sulfuric acid...

Embodiment 3

[0069] The venturi mixer and the tubular reactor with SV internals are alternately connected as a new reactor group. The length of the tubular reactor is 1.8m, and the inner diameter of the tube is 11mm. The sum of the lengths of all tubular reactors with internals is 19.8m, composed of eleven Venturi mixers and eleven tubular reactors connected alternately in sequence.

[0070] The single feed of toluene enters from the main inlet of the first Venturi mixer 11, and the single feed of concentrated sulfuric acid enters from the side inlet of the first Venturi mixer 11. After the toluene and concentrated sulfuric acid are mixed in the first Venturi mixer 11 Enter the first tubular reactor 21 with internals for pre-mixing, and the liquid-phase isobutene is divided into 10 feeds, which enter the new reactor group from the second to eleventh Venturi mixer side inlets respectively.

[0071] The total molar flow of toluene is 5.6kmol / h, the total molar flow of sulfuric acid is 0.4kmo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com