Flow guide filler

A technology of packing sheets and diversion holes, which is applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of increasing flow resistance between broken lines, reducing the liquid film area of corrugated sheets, Affecting mass transfer efficiency and other issues, to achieve the effect of strengthening disturbance, realizing liquid film renewal, and improving mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A diversion filler of the present invention will be further described in detail below in conjunction with the accompanying drawings.

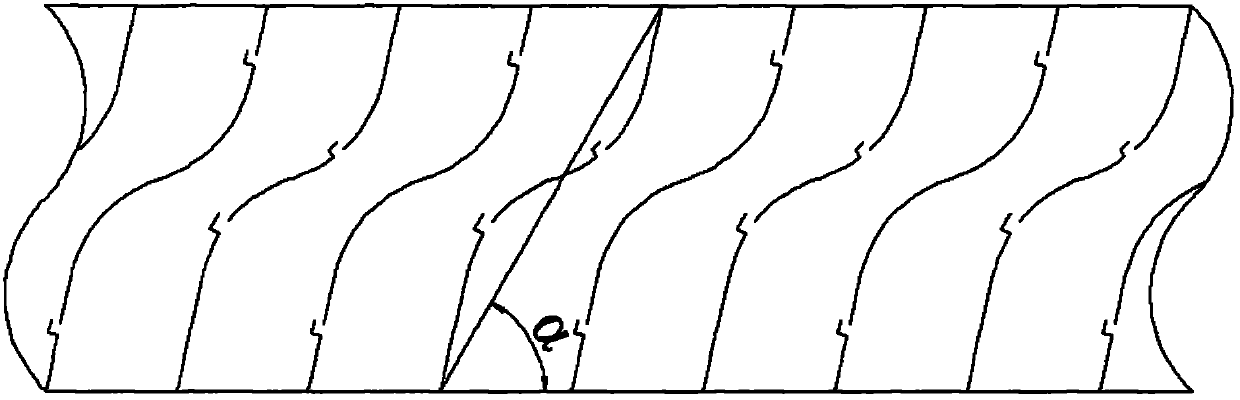

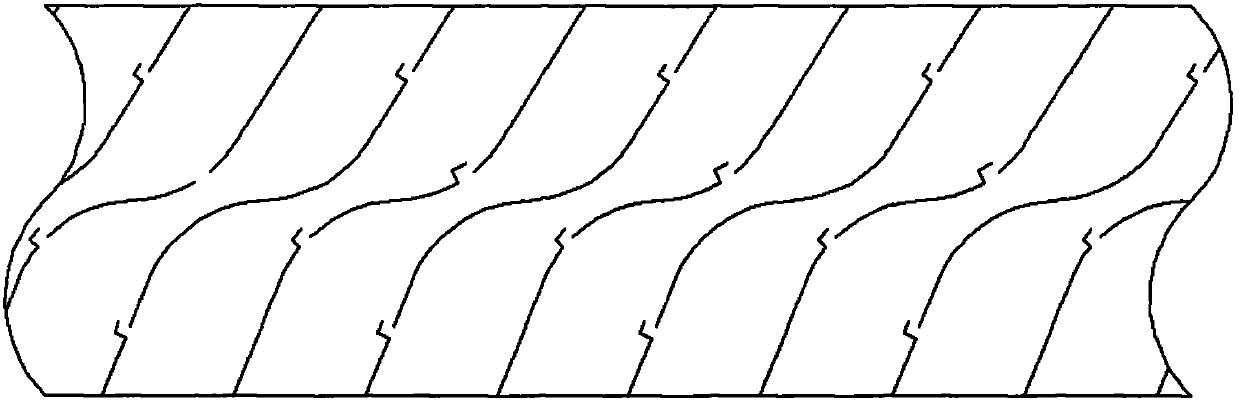

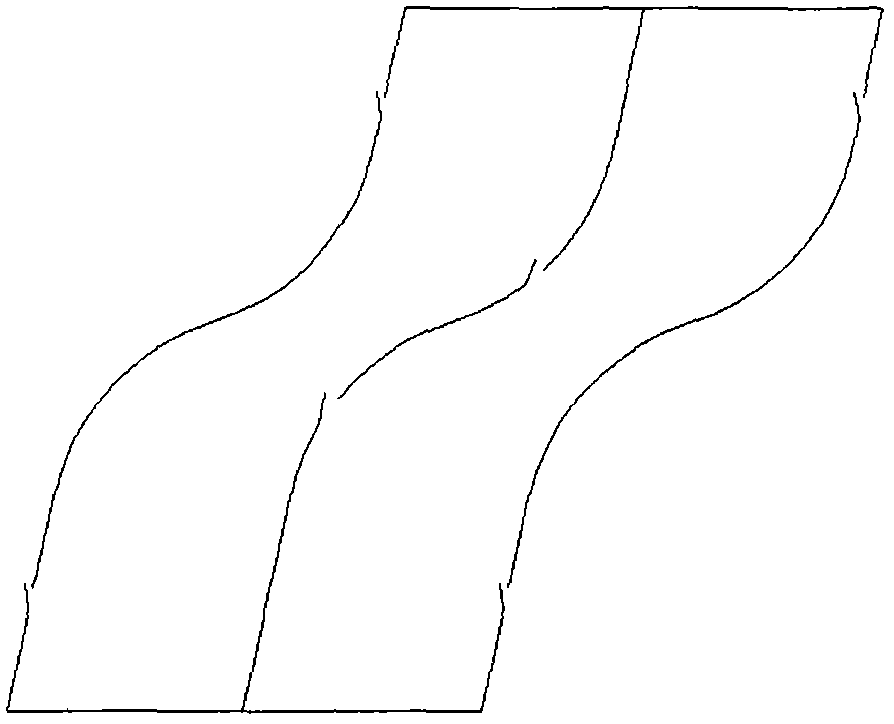

[0024] The structure of diversion packing is as figure 1 As shown, the surface of the filler sheet of the diversion filler is firstly treated with regular diamond particles, and the surface is roughened according to the regular vibration and rubbing in the direction of the liquid flow, so that the surface wettability of the filler sheet is increased. Then, according to the different specific surface area of the filler, according to the requirements of peak height, corrugation inclination and tooth profile angle, the corrugated sheet is punched on a precision punching machine with a special abrasive tool. The middle of the corrugated ridgeline of the packing sheet is two symmetrically inverted curves The upper and lower ends are straight lines, the two curves are tangent, and the upper curve is tangent to the straight line of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com