Novel plastic filler

A technology of packing sheets and hydrophilic materials, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as slag dropping, shrinkage of packing sheets, floating liquid, etc., and increase gas Liquid contact area, air-liquid contact area, and the effect of improving mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

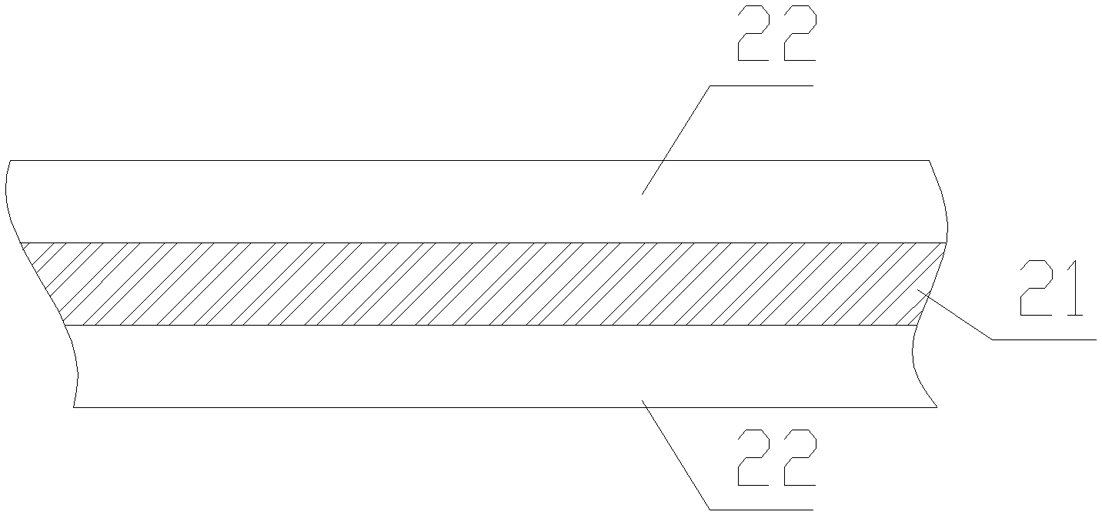

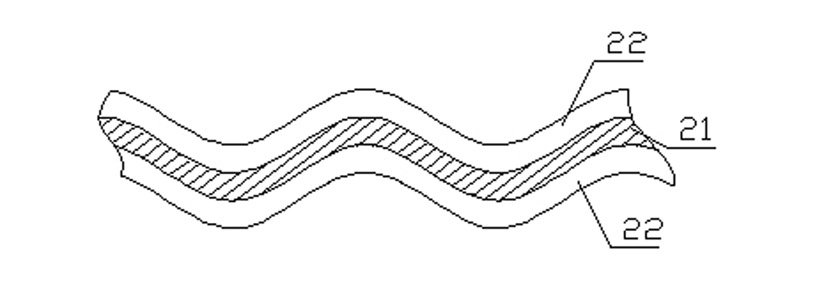

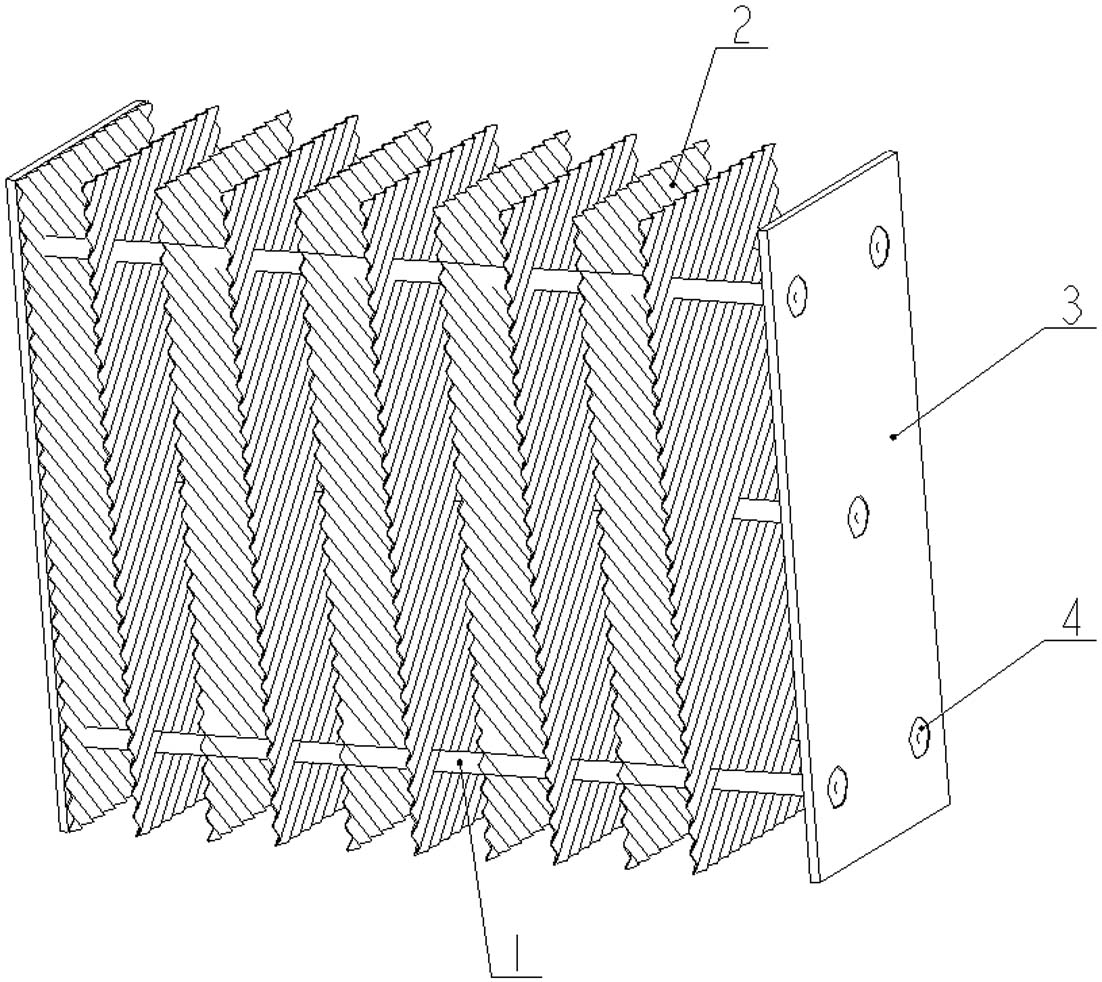

[0042] like figure 1 As shown, the hydrophilic non-woven fabric is pasted on the plastic alloy (30%PE+70%PP), and then rolled and thermoformed to form a corrugated shape with a wave height of 7mm. like image 3 As shown, the packing sheets are connected in series, the assembled packing size is 1200mm×600mm×300mm, and the windward side is 1200mm×600mm.

Embodiment 2

[0044] like figure 1 As shown, the plastic alloy (30%PE+70%PP) is laminated with hydrophilic weaving cloth by laminating method, and then rolled and thermoformed to form a corrugated shape with a wave height of 7mm. like image 3 As shown, the packing sheets are connected in series, the assembled packing size is 1200mm×600mm×300mm, and the windward side is 1200mm×600mm.

Embodiment 3

[0050] The packing efficiency test was carried out under the same conditions for the packings prepared in the above-mentioned Examples 1-2 and Comparative Examples 1-2. The efficiency test adopts the test method commonly used in the HVAC field. Wet the filler with cold water from top to bottom, and the wind blows through the filler from the front, measure the temperature and humidity before and after the wind passes through the filler and the temperature and humidity of the filler surface, and calculate the heat transfer efficiency of the filler. The test results are shown in Table 1.

[0051] Table 1 Packing efficiency test results

[0052] Example

[0053] According to the results in Table 1, it can be seen that the mass transfer efficiency of Example 1-2 implemented according to the technical solution of the present invention is obviously higher than that of the prior art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com