Production-transportation integrated continuous reaction device for hydrate

A reaction device and hydrate technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of retardation, shorten the induction period, low gas storage rate, etc., to increase the conversion rate, increase the gas-liquid contact area, improve the The effect of gas storage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

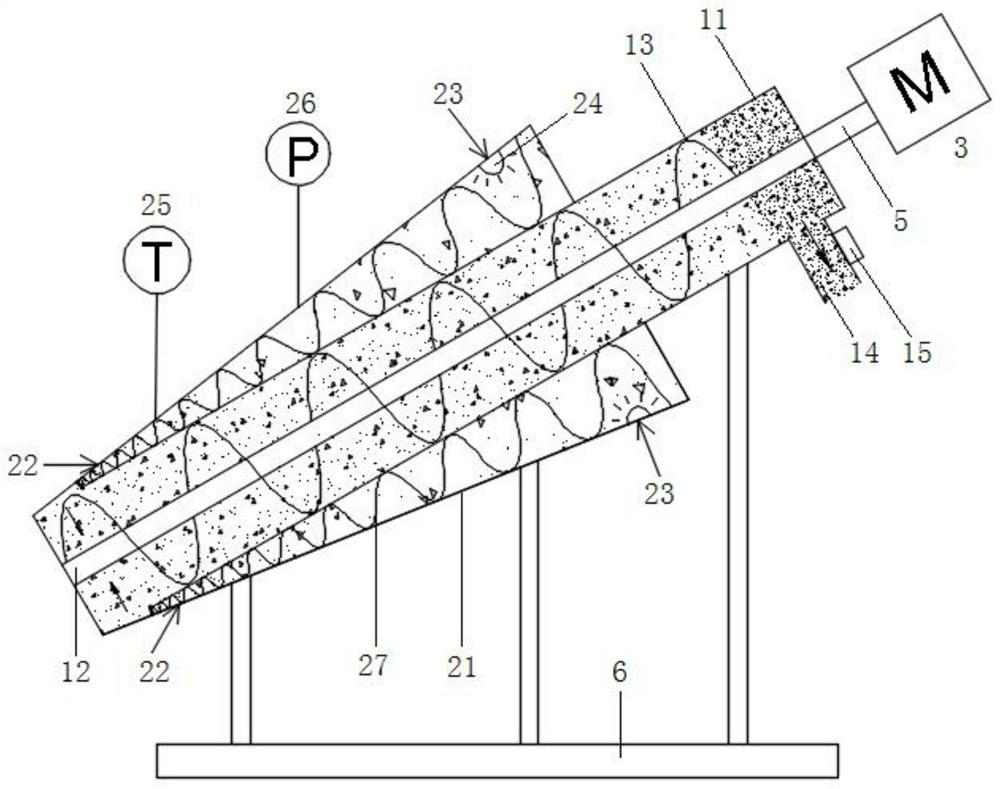

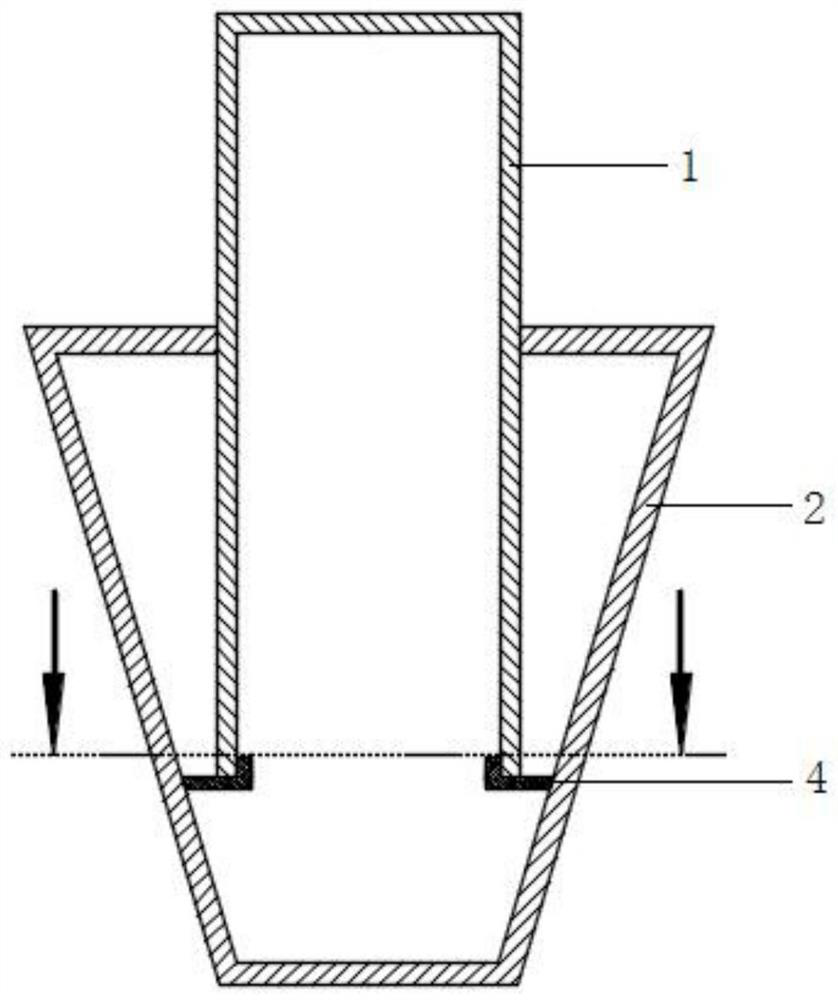

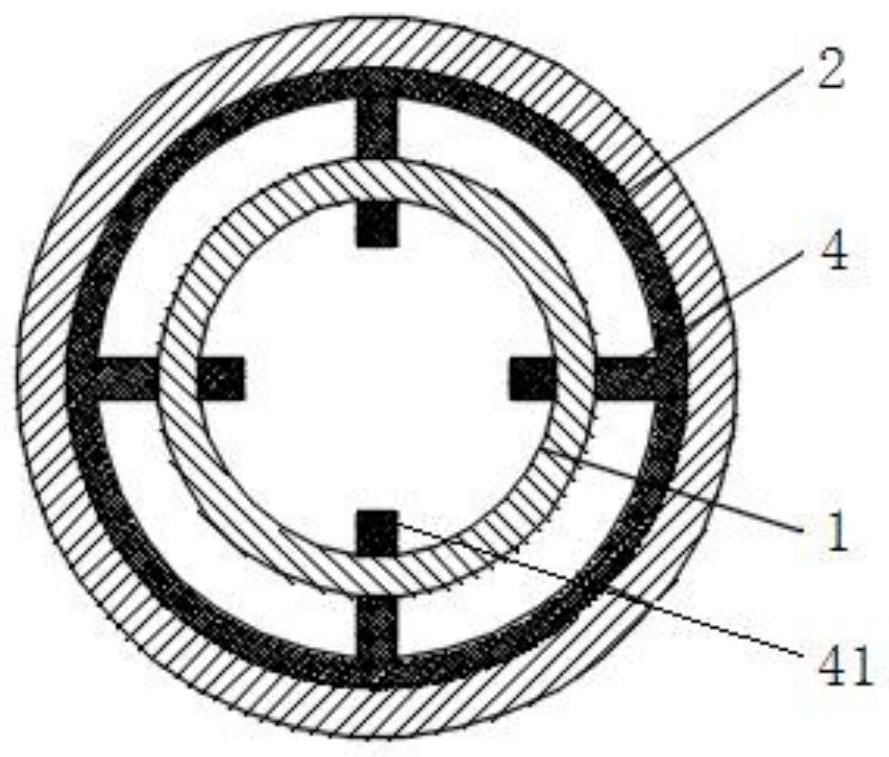

[0019] The main structure of the hydrate production-transport integrated continuous reaction device involved in this embodiment includes an inner screw reactor 1, an outer screw reactor 2, a motor 3, a clasp 4 and a magnetic transmission rod 5; One end of the spiral reactor 1 extends into the interior of the outer spiral reactor 2 with an inverted trapezoidal cross section, and the other end of the inner spiral reactor 1 is connected to the motor 3; the inner spiral reactor 1 and the outer spiral reactor 2 pass through the clasp 4 connection, the central axis of the inner spiral reactor 1 and the outer spiral reactor 2 coincide, and the inner spiral reactor 1 and the motor 3 are connected through a magnetic transmission rod 5 .

[0020] The main structure of the internal spiral reactor 1 involved in this embodiment includes an inner cylinder 11, a stirring rod 12, an internal spiral blade 13, a discharge port 14 and a ball valve 15; the inner cylinder 11 with a rectangular cros...

Embodiment 2

[0025] When the hydrate production-transport integrated continuous reaction device involved in this embodiment is used, the upper part of the inner cylinder 11, the 1 / 3 length of the outer cylinder 21 and the 2 / 3 length of the outer cylinder 21 are respectively connected to the support 6, and the support 6 While supporting the inner spiral reactor 1 and the outer spiral reactor 2, it has an angle adjustment function, and the inclination angle of the inner spiral reactor 1 and the outer spiral reactor 2 is adjusted to 30° (the adjustment range of the support 6 is 0°~ 90 °); send gas through the air inlet 22 to sweep the inner spiral reactor 1 and the outer spiral reactor 2, get rid of air, when the internal temperature of the inner spiral reactor 1 and the outer spiral reactor 2 reaches the set When the reaction temperature is reached, gas is sent in again through the air inlet 22, so that the internal pressure of the inner screw reactor 1 and the outer screw reactor 2 reaches 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com