High-voltage narrow-pulse discharge and semi-dry process type cooperative pollutant control method and high-voltage narrow-pulse discharge and semi-dry process type cooperative pollutant control device

A collaborative control, narrow pulse technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of unsatisfactory removal efficiency, large floor space, single function, etc., and achieve high practical environmental protection benefits , Small footprint, simple system effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

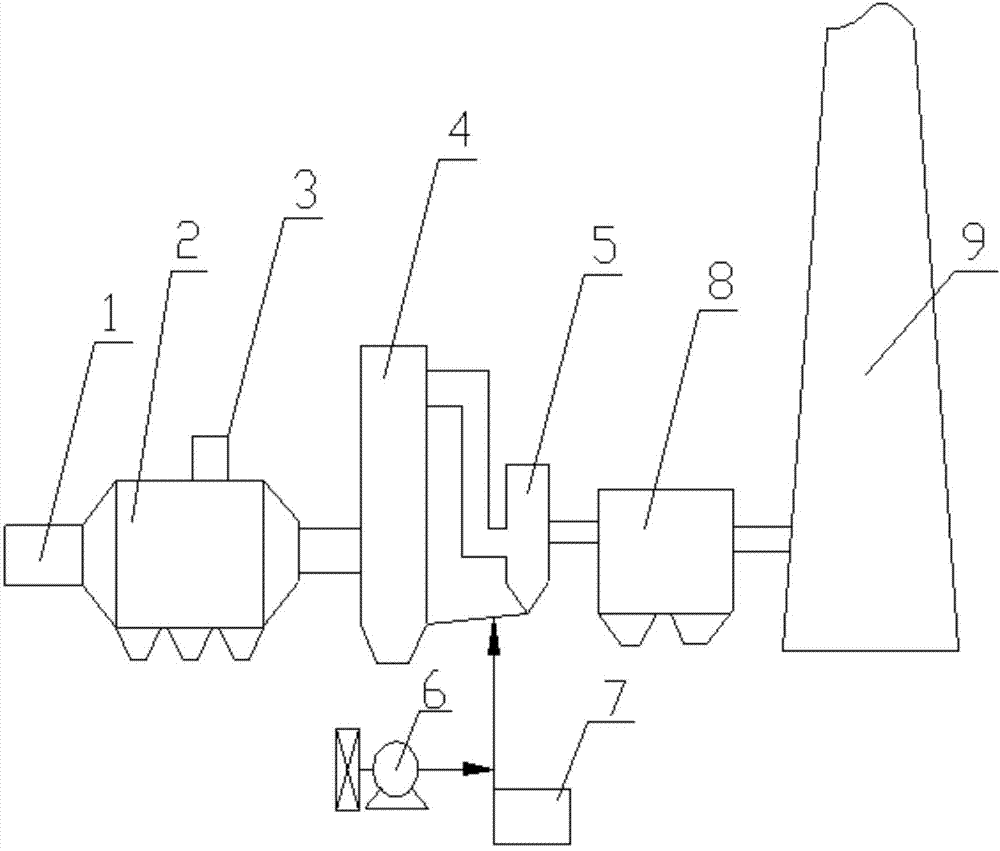

[0034] Such as figure 1 As shown, a high-voltage narrow pulse discharge combined with a semi-dry pollutant collaborative control method includes the following steps:

[0035] Step 1: Transport the dedusted flue gas to the high-voltage narrow pulse discharge reactor through the flue gas inlet 1, and monitor the concentrations of sulfur dioxide and nitrogen monoxide at the flue gas inlet 1;

[0036] Step 2: Set the energy input value of the high-voltage narrow-pulse discharge reactor 2 according to the concentration of sulfur dioxide and nitric oxide, and the flue gas after dust removal is oxidized and degraded in the high-voltage narrow-pulse discharge reactor 2;

[0037] Step 3: The oxidized and degraded flue gas enters the semi-dry desulfurization system, and the quicklime or slaked lime absorbs or adsorbs the original and newly generated pollutants.

[0038] In the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com