Method for preparing cement kiln synergistic desulfurization and denitrification agent through resource utilization of hazardous waste and solid waste

A desulfurization, denitrification and resource utilization technology is applied in the field of preparing cement kiln synergistic desulfurization and denitrification agent, which can solve the problems of system impact, high cost and difficult disposal, and achieve the effects of simple process operation, elimination of fugitive ammonia, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The background emission concentration of nitrogen oxides at the C1 outlet is 280mg / Nm 3 , SO 2 The background emission concentration is 230mg / Nm 3 , according to the mass ratio of 1:2:2, mix the waste SCR denitration catalyst (block size less than 80mm), electrolytic manganese slag and calcium carbide slag crushed by the hammer crusher; coarsely grind the mixed materials until the size is smaller than 2mm particles; in the coarsely ground material, 1% of fly ash and 0.1% of white mud by mass are respectively added, and finely ground to particles smaller than 80 μm in size to obtain desulfurization and denitrification agent.

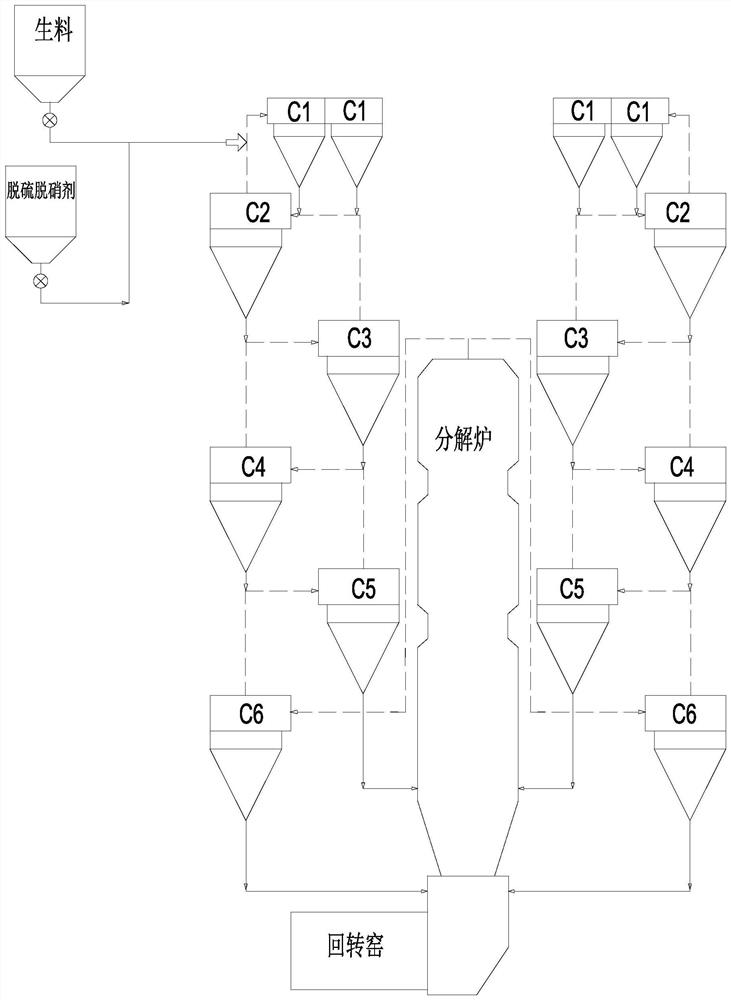

[0037] like figure 1 As shown in the figure, the desulfurization and denitrification agent and the cement raw meal are mixed at a ratio of 1:1000, and then enter the kiln elevator through the chute, and then add it from the air duct connecting the C1 and C2 cyclones at the kiln end to achieve desulfurization and denitrification. After adding nitr...

Embodiment 2

[0039] The background emission concentration of nitrogen oxides at the C1 outlet is 260mg / Nm 3 , SO 2 The background emission concentration is 350mg / Nm 3 , according to the mass ratio of 2:2:5, mix the waste SCR denitration catalyst (block size less than 100mm), electrolytic manganese slag and calcium carbide slag crushed by the hammer crusher; coarsely grind the mixed materials to a size smaller than 2mm particles; in the coarsely ground material, respectively add fly ash and 0.2% cerium oxide, which account for 2% by mass, and finely grind to particles smaller than 80 μm to obtain desulfurization and denitrification agent.

[0040] The desulfurization and denitrification agent is mixed with the cement raw meal at a ratio of 2:500, and then enters the kiln hoist through the chute and is added from the air duct connecting the C1 and C2 cyclones at the kiln end to achieve desulfurization and denitrification. After adding, the nitrogen oxides in the exhaust gas are reduced. to...

Embodiment 3

[0042] The background emission concentration of nitrogen oxides at the C1 outlet is 400mg / Nm 3 , SO2 The background emission concentration is 500mg / Nm 3 , according to the mass ratio of 3:1:5, mix the waste SCR denitration catalyst (block size less than 60mm), electrolytic manganese slag and calcium carbide slag crushed by the hammer crusher; coarsely grind the mixed materials until the size is smaller than 2mm particles; in the coarsely ground material, add fly ash, 0.2% cerium oxide, 0.2% zirconia, which account for 2% of its mass ratio, and finely grind it to less than 80μm particles to obtain desulfurization and denitrification. agent.

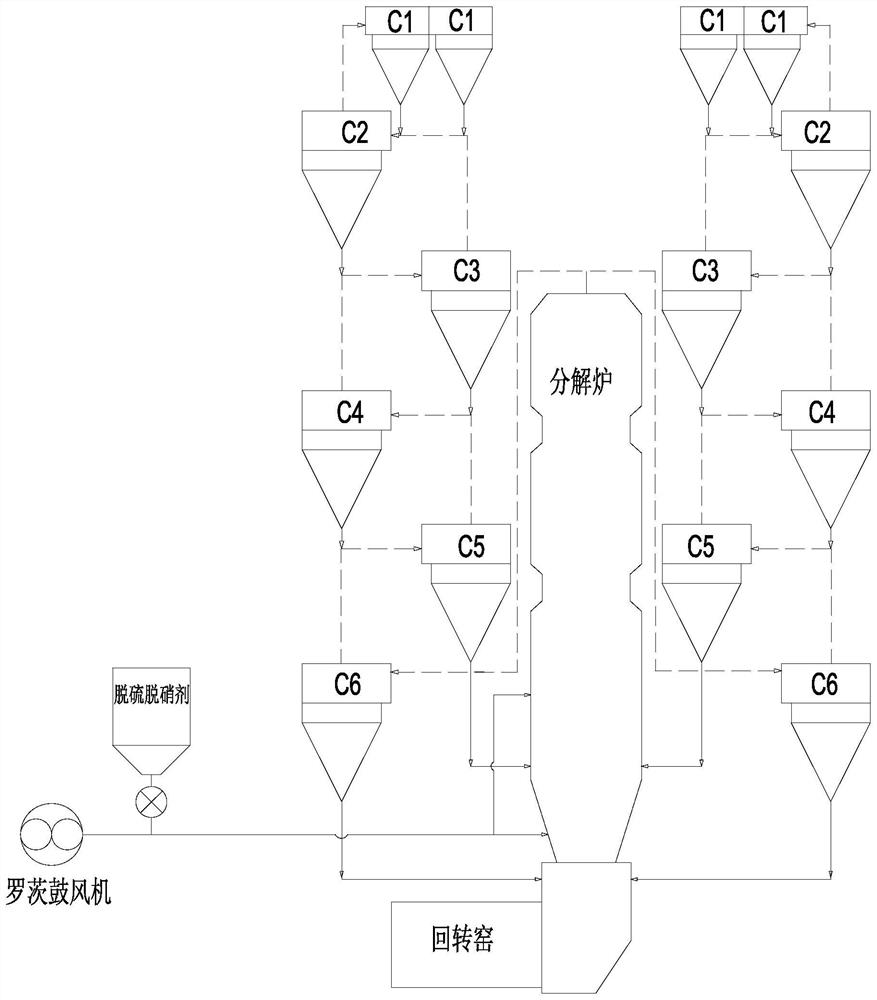

[0043] like figure 2 As shown in the figure, the desulfurization and denitrification agent, which accounts for 5‰ of the cement raw meal mass, is sent to the decomposition furnace through the Roots fan through the metering pump to achieve desulfurization and denitrification. After adding, the nitrogen oxides in the exhaust gas are reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com