Coal-fired flue gas semi-dry method combined desulfurization and denitrification system and method

A technology for coal-fired flue gas, desulfurization and denitrification, applied in the field of flue gas purification, can solve the problems of inability to meet NOx emission requirements, low absorption efficiency of semi-dry desulfurization system, limited oxidation efficiency, etc., so as to avoid ineffective decomposition and achieve stable content. , improve the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

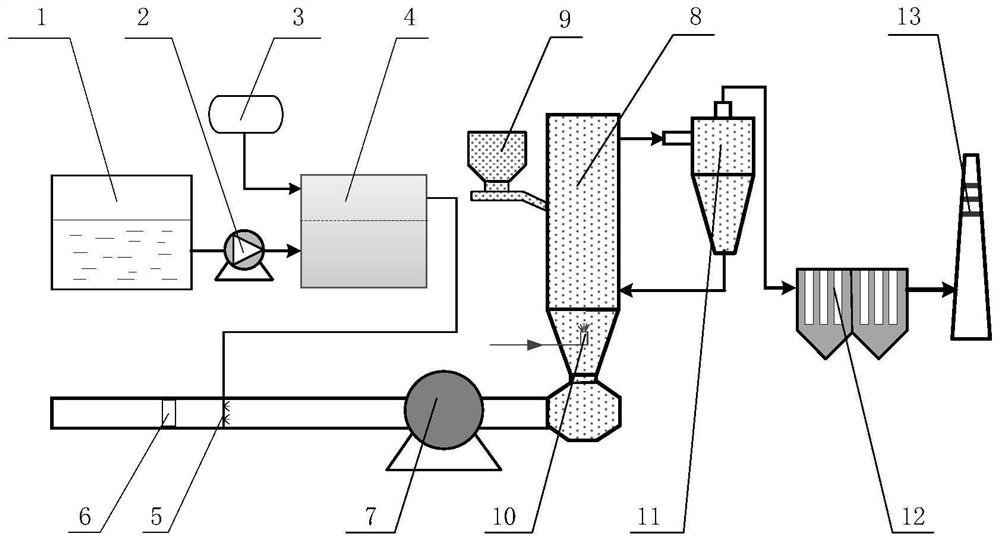

[0034] The coal-fired flue gas semi-dry method combined desulfurization and denitrification system of the present invention, such as figure 1 As shown, it includes four parts: pre-oxidation system, absorption system, dust removal system and chimney. The oxidation system consists of sequentially linked H 2 o 2 Storage tank 1, delivery pump 2, ultrasonic nebulizer 4, atomized H 2 o 2 Carried by compressed gas, the inlet of the ultrasonic atomizer 4 is connected to the compressed gas tank 3, and the outlet is connected to the spray grid 5, and a section mixer 6 is set in front of the spray grid 5 for H 2 o 2 Mix well with flue gas. h 2 o 2 Inject into the flue to oxidize NO to NO 2 , containing SO 2 and NO 2 The flue gas of the gas enters the absorption tower 8 through the induced dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com