Ultrafine particle based on high-temperature-resistance titanium-based adsorbent and heavy-metal combined removal method

An ultra-fine particle, combined removal technology, applied in separation methods, chemical instruments and methods, fuel additives, etc., can solve the problems of not fully meeting the requirements of use, small operating temperature range, limited emission reduction effect, etc. Large-scale industrial production, low price, and the effect of reducing particulate emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

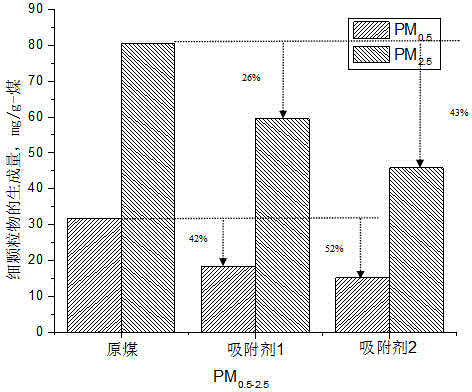

[0028] Select industrial titanium dioxide products, TiO 2 The mass content is 95%, and the impurity component is mainly Al 2 o 3 . The particle size is concentrated at 15 μm. According to the mass ratio of 3%, it is fully mixed with pulverized coal (particle size 60 μm), and the combustion experiment is carried out at 1500 ° C in the laboratory settling furnace (DTF) to simulate the combustion process of the pulverized coal boiler. The low-pressure impact particle sampler (LPI) and load-bearing particle sampler (DGI) were used to collect and analyze the generation of fine particles PM2.5 and ultrafine particles PM0.5 and the content of heavy metals. removal effect such as figure 1 As shown, the generation of fine particulate matter PM2.5 was reduced by 26%, and the generation of ultrafine particulate matter was reduced by 42%.

Embodiment 2

[0030] The titanium dioxide product described in Example 1 and the kaolin powder reagent were mixed in a mass ratio of 6:4 and mechanically mixed uniformly to prepare a titanium-based particulate adsorbent added with clay minerals. An appropriate amount of the prepared titanium-based particulate adsorbent was fully mixed with coal powder (particle size 60 μm) at a mass ratio of 3%, and a combustion experiment was carried out in a laboratory settling furnace (DTF) at 1500 °C to simulate the combustion process of a pulverized coal boiler. The low-pressure impact particle sampler (LPI) and load-bearing particle sampler (DGI) were used to collect and analyze the generation of fine particles PM2.5 and ultrafine particles PM0.5 and the content of heavy metals. removal effect such as figure 1 As shown, the generation of fine particulate matter PM2.5 was reduced by 43%, and the generation of ultrafine particulate matter was reduced by 52%.

Embodiment 3

[0032] The titanium dioxide described in Example 1 was used to carry out the control experiment of particulate matter added in the furnace on the industrial pulverized coal boiler. A titanium-based particulate adsorbent is added to the furnace through the primary air duct, and the ratio of the adsorbent to the pulverized coal (particle size: 60 μm) is 3% by mass. Compared with the operating condition without adding adsorbents, the concentration of particulate matter at the furnace outlet is reduced after adding Ti-based adsorbents. With the combined effect of the tail electrostatic precipitator, the concentration of particulate matter emissions has dropped significantly, meeting the national emission standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com