Shape-stabilized phase change material taking alumina hollow spheres as carrier and preparation method thereof

An alumina hollow sphere, shape-setting phase change material technology, applied in heat exchange materials, chemical instruments and methods, chemical industry and other directions, can solve the problems of low strength, poor thermal performance, and high manufacturing cost of matrix materials, and achieve high strength , The effect of fast thermal response and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

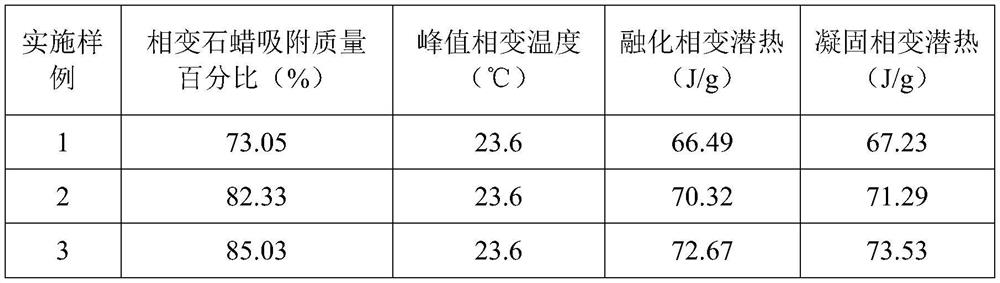

Examples

Embodiment 1

[0041] The present invention also provides a preparation method of a shape-fixed phase-change material using alumina hollow spheres as a carrier, which is specifically implemented according to the following steps:

[0042] Step 1, weighing the following raw material components by mass percentage: 38.39% paraffin wax, 46.67% aluminum oxide hollow ball, 14.94% styrene-acrylic emulsion, the sum of the mass percentages of the above components is 100%;

[0043] Step 2, put the aluminum oxide hollow ball and paraffin into the container and put it into the vacuum reactor, fasten the vacuum reactor, start the vacuum pump, and vacuumize the vacuum reactor. The relative vacuum pressure reaches -0.1MPa, and the holding time is 30min;

[0044] Step 3, after step 2 is vacuumed, open the pressure relief valve to restore the pressure in the vacuum reactor to normal pressure, take out the paraffin-absorbed aluminum oxide hollow ball and put it in a refrigerator not higher than 5°C for refrige...

Embodiment 2

[0048] The present invention also provides a preparation method of a shape-fixed phase-change material using alumina hollow spheres as a carrier, which is specifically implemented according to the following steps:

[0049] Step 1, weighing the following raw material components by mass percentage: 39.18% paraffin wax, 46.07% aluminum oxide hollow ball, 14.74% styrene-acrylic emulsion, the sum of the mass percentages of the above components is 100%;

[0050] Step 2, put the aluminum oxide hollow ball and paraffin into the container and put it into the vacuum reactor, fasten the vacuum reactor, start the vacuum pump, and vacuumize the vacuum reactor, so that the relative vacuum pressure in the vacuum reactor is -0.1MPa, holding time 60min;

[0051] Step 3, after step 2 vacuum treatment, open the pressure relief valve to restore the pressure in the vacuum reactor to normal pressure, take out the paraffin-absorbed aluminum oxide hollow ball and put it in a refrigerator not higher t...

Embodiment 3

[0055] The present invention also provides a preparation method of a shape-fixed phase-change material using alumina hollow spheres as a carrier, which is specifically implemented according to the following steps:

[0056] Step 1, weighing the following raw material components by mass percentage: 38.75% of paraffin wax, 46.40% of aluminum oxide hollow balls, 14.85% of styrene-acrylic emulsion, the sum of the mass percentages of the above components is 100%;

[0057] Step 2, put the aluminum oxide hollow ball and paraffin into the container and put it into the vacuum reactor, fasten the vacuum reactor, start the vacuum pump, and vacuumize the vacuum reactor. The relative vacuum pressure reaches -0.1MPa, and the holding time is 120min;

[0058] Step 3, after step 2 vacuum treatment, open the pressure relief valve to restore the pressure in the vacuum reactor to normal pressure, take out the paraffin-absorbed aluminum oxide hollow ball and put it in a refrigerator not higher than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com