76-degree phase change energy storage material and preparation method thereof

A technology of phase change energy storage material and host material, applied in the field of 76-degree phase change energy storage material and its preparation, can solve the problems of easy phase separation, low cost, limited application site and scale, etc., to overcome toxicity, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] High-purity urea and ammonium bromide blend crystal 360g, nitrogen-rich porous carbon material 8g, carboxymethyl cellulose 8g, hydrophilic nano titanium dioxide 2g, expanded graphite 40g.

[0040] Weigh 360g of high-purity urea and ammonium bromide blended crystals at a ratio of 9:1, mix and melt under heating at 90 degrees; add 8g of nitrogen-rich porous carbon material, 8g of carboxymethyl cellulose, and hydrophilic nano-titanium dioxide in sequence 2g, 40g of expanded graphite, fully stirred.

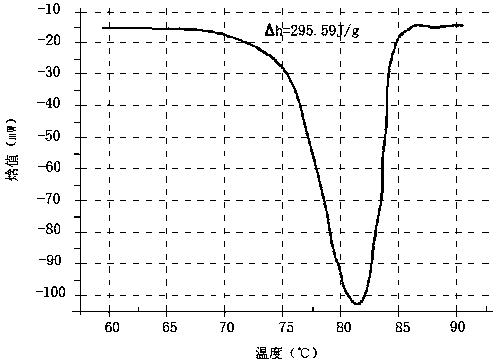

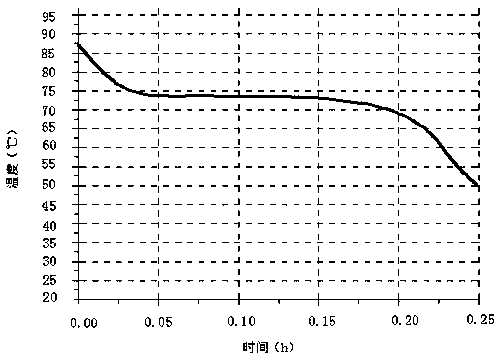

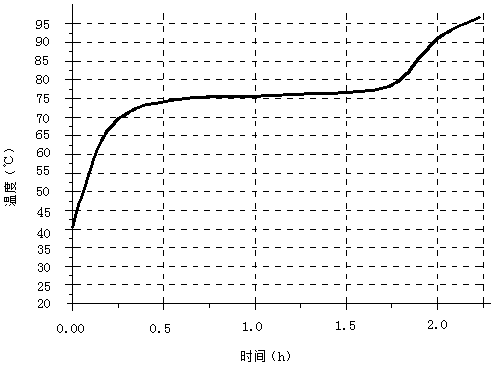

[0041] After testing, the phase transition temperature of the material is 76~77°C, and the phase transition enthalpy is 293.4~295.6KJ / kg; the thermal performance decays by 4.7% after 10000 cycles.

Embodiment 2

[0043] High-purity urea and ammonium bromide blend crystal 320g, nitrogen-rich porous carbon material 4g, carboxymethyl cellulose 8g, hydrophilic nano titanium dioxide 2g, expanded graphite 40g.

[0044] Weigh 320g of high-purity urea and ammonium bromide blended crystals in a ratio of 5:1, mix and melt under heating at 90 degrees; add 4g of nitrogen-rich porous carbon material, 8g of carboxymethyl cellulose, and hydrophilic nano-titanium dioxide in sequence 2g, 40g of expanded graphite, fully stirred.

[0045] After testing, the phase transition temperature point of the material is 76~77℃, and the phase transition enthalpy value is 277.8~278.2KJ / kg; the thermal performance decays by 5.2% after 10000 cycles.

Embodiment 3

[0047] High-purity urea and ammonium bromide blend crystal 320g, nitrogen-rich porous carbon material 4g, carboxymethyl cellulose 8g, hydrophilic nano titanium dioxide 2g, expanded graphite 20g.

[0048] Weigh 320g of high-purity urea and ammonium bromide blended crystals in a ratio of 5:1, mix and melt under heating at 90 degrees; add 4g of nitrogen-rich porous carbon material, 8g of carboxymethyl cellulose, and hydrophilic nano-titanium dioxide in sequence 2g, expanded graphite 20g, fully stirred.

[0049] After testing, the phase transition temperature point of the material is 76~77°C, and the phase transition enthalpy value is 278.0~278.4KJ / kg.

[0050] It can be seen from the test results that the thermal stability of the material can be greatly improved and the enthalpy value of the material can be significantly improved by adding additives into the mixture of the main material.

[0051] It can be seen from Example 2 and Example 3 that after using a specific proportion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com