Preparation method of catalyst for synergistic removal of hydrogen sulfide and elemental mercury in garbage gasification pollutants

A technology for catalysts and pollutants, applied in the field of catalyst preparation, can solve the problems of poor dispersion and obvious aggregation, particles cannot enter the pores, etc., to avoid deactivation when encountering water, be beneficial to adsorption capacity, and prevent growth and aggregation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The first step, passivation: choose MCM-41 molecular sieve with a mass of 3g, dissolve it in 80mL of n-hexane and perform ultrasonic dispersion for 15min in an ultrasonic disperser, and gradually add 7g of trimethylsilane dropwise under the condition of ultrasonic dispersion To modify, continue ultrasonic dispersion for 20min. The molecular sieve solution was condensed and refluxed at a temperature of 70°C for 12 hours, washed several times with n-hexane, and dried in an oven at a temperature of 80°C for 12 hours;

[0044] The second step, removing the template: choose the above-mentioned molecular sieve with a mass of 3g, dissolve it in 200mL of absolute ethanol, and condense and reflux for 12h at a temperature of 80°C, wash it several times with absolute ethanol, and heat it in an oven at a temperature of Drying is performed at 80°C for 12 hours, and the second step is repeated twice.

[0045] The third step, activation: select the above-mentioned molecular sieve wit...

Embodiment 2

[0050] The difference from Example 1 is:

[0051] The La, Ce, Fe metal molar ratio controlled in the 4th step is the molecular sieve of 1:1:1,

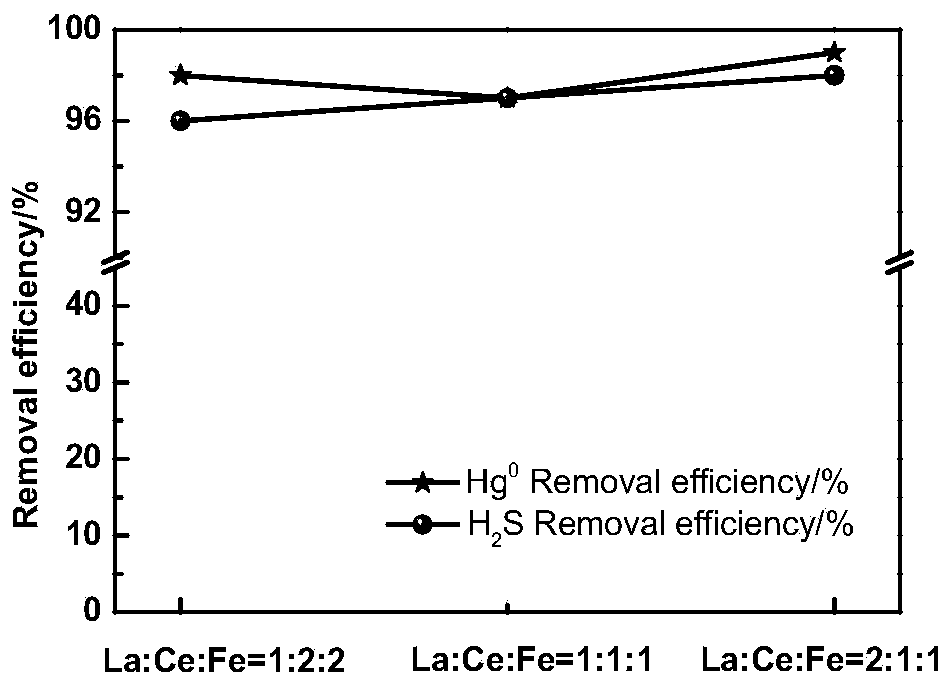

[0052] The simulated garbage pyrolysis gasification synthesis gas was selected for mercury and desulfurization experiments. H during the experiment 2 S concentration is 100mL / min, carrier gas N 2 The flow rate is 900mL / min, and the mercury and desulfurization experiment is carried out. The experimental results show that the mercury removal efficiency is about 97%, and the desulfurization efficiency is about 97%.

Embodiment 3

[0054] The difference from Example 1 is:

[0055] In the 4th step, control La, Ce, the molecular sieve that Fe metal molar ratio is 2:1:1,

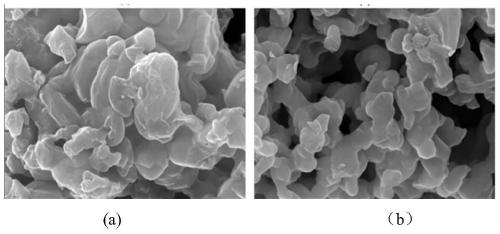

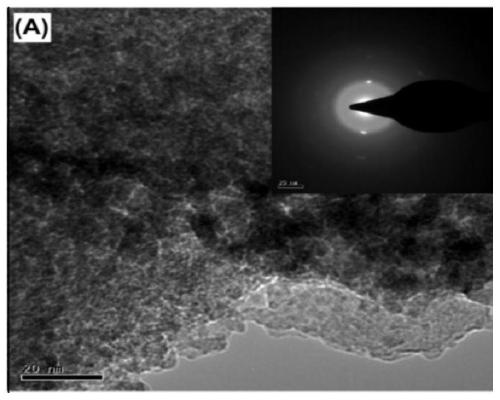

[0056] The simulated garbage pyrolysis gasification synthesis gas was selected for mercury and desulfurization experiments. H during the experiment 2 S concentration is 100mL / min, carrier gas N 2 The flow rate is 900mL / min, and the mercury and desulfurization experiment is carried out. The experimental results show that the mercury removal efficiency is about 99%, and the desulfurization efficiency is about 98%. The HRTEM of the molecular sieve with a metal molar ratio of 2:1:1 finally prepared is as follows: figure 2 shown.

[0057] It can be seen from the above-mentioned Examples 1-Example 3 that the most preferred catalyst of the present invention is a molecular sieve with a metal molar ratio of La, Ce, and Fe of 2:1:1. For specific data, see image 3 shown.

[0058] Different contents of water vapor have little effect on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com