Medium/low temperature mesoporous nitrogen oxide and dioxin removal catalyst and preparation method thereof

A technology for removing dioxins and catalysts, which is used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. and other problems, to achieve the effect of highly ordered pores, multiple active sites, and uniform pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

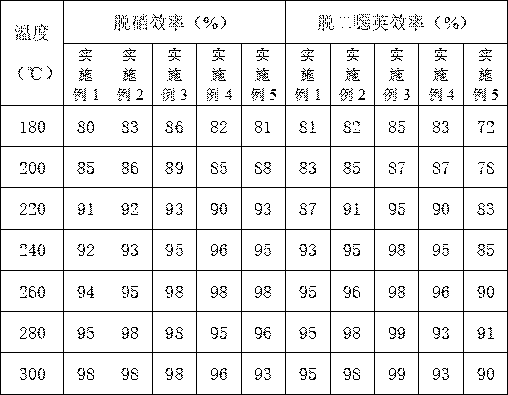

Examples

Embodiment 1

[0018] 1) Dissolve 6gP123 in 25g ethanol, add dropwise 0.5g dilute hydrochloric acid with a concentration of 0.2 mol / L, and stir in a constant temperature tank at 40ºC for 15-20 minutes to obtain solution A; meanwhile, mix 9.36g ethyl orthosilicate and 1. 49g of octadecyldimethyl[3-(trimethoxysilyl)propyl]ammonium chloride was dissolved in ethanol, stirred at 40°C for 30-50 minutes in a constant temperature tank to obtain solution B;

[0019] 2) Mix solution A and solution B obtained in step 1), add 25g of resole phenolic resin ethanol solution, continue to react at 40°C for 2 hours, and evenly coat the obtained reaction solution on the surface of the glass dish. The dish is placed in an oven at 40°C for 6-8 hours to volatilize, then thermally polymerized in an oven at 100°C for 24 hours, and then cool down naturally;

[0020] 3) Take the cooled glass dish out of the oven, scrape off the surface coating, and calcinate the scraped coating at 275°C for 5 hours in a nitrogen atmo...

Embodiment 2

[0023] 1) Dissolve 6gP123 in 25g ethanol, add dropwise 0.5g dilute hydrochloric acid with a concentration of 0.2 mol / L, and stir in a constant temperature tank at 40ºC for 15-20 minutes to obtain solution A; meanwhile, mix 9.36g ethyl orthosilicate and 1. Dissolve 49g of 3-aminopropyltrimethoxysilane in 25g of ethanol, stir in a constant temperature tank at 40ºC for 30-50 minutes to obtain solution B;

[0024] 2) Mix solution A and solution B obtained in step 1), add 25g of resole phenolic resin ethanol solution, continue to react at 40°C for 2 hours, and evenly coat the obtained reaction solution on the surface of the glass dish. The dish is placed in an oven at 40°C for 6-8 hours to volatilize, then thermally polymerized in an oven at 100°C for 24 hours, and then cool down naturally;

[0025] 3) Take the cooled glass dish out of the oven, scrape off the surface coating, and calcinate the scraped coating at 275°C for 5 hours in a nitrogen atmosphere, and then grind it into po...

Embodiment 3

[0028] 1) Dissolve 6gP123 in 25g ethanol, add dropwise 0.5g dilute hydrochloric acid with a concentration of 0.2 mol / L, and stir in a constant temperature tank at 40ºC for 15-20 minutes to obtain solution A; meanwhile, mix 9.36g ethyl orthosilicate and 4. Dissolve 13g of octadecyldimethyl[3-(trimethoxysilyl)propyl]ammonium chloride in 25g of ethanol, stir in a constant temperature bath at 40°C for 30-50 minutes to obtain solution B;

[0029] 2) Mix solution A and solution B obtained in step 1), add 25g of resole phenolic resin ethanol solution, continue to react at 40°C for 2 hours, and evenly coat the obtained reaction solution on the surface of the glass dish. The dish is placed in an oven at 40°C for 6-8 hours to volatilize, then thermally polymerized in an oven at 100°C for 24 hours, and then cool down naturally;

[0030] 3) Take the cooled glass dish out of the oven, scrape off the surface coating, and calcinate the scraped coating at 275°C for 5 hours in a nitrogen atmos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com