Electrostatic cooperative pollutant removing method and device

A technology of pollutants and electrostatic precipitators, which is applied in the field of electrostatic collaborative pollutant removal methods and devices, can solve the problems of single removal equipment capacity, small investment and operation costs, and small floor space, and achieve compact structure and low operating costs. Low cost and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

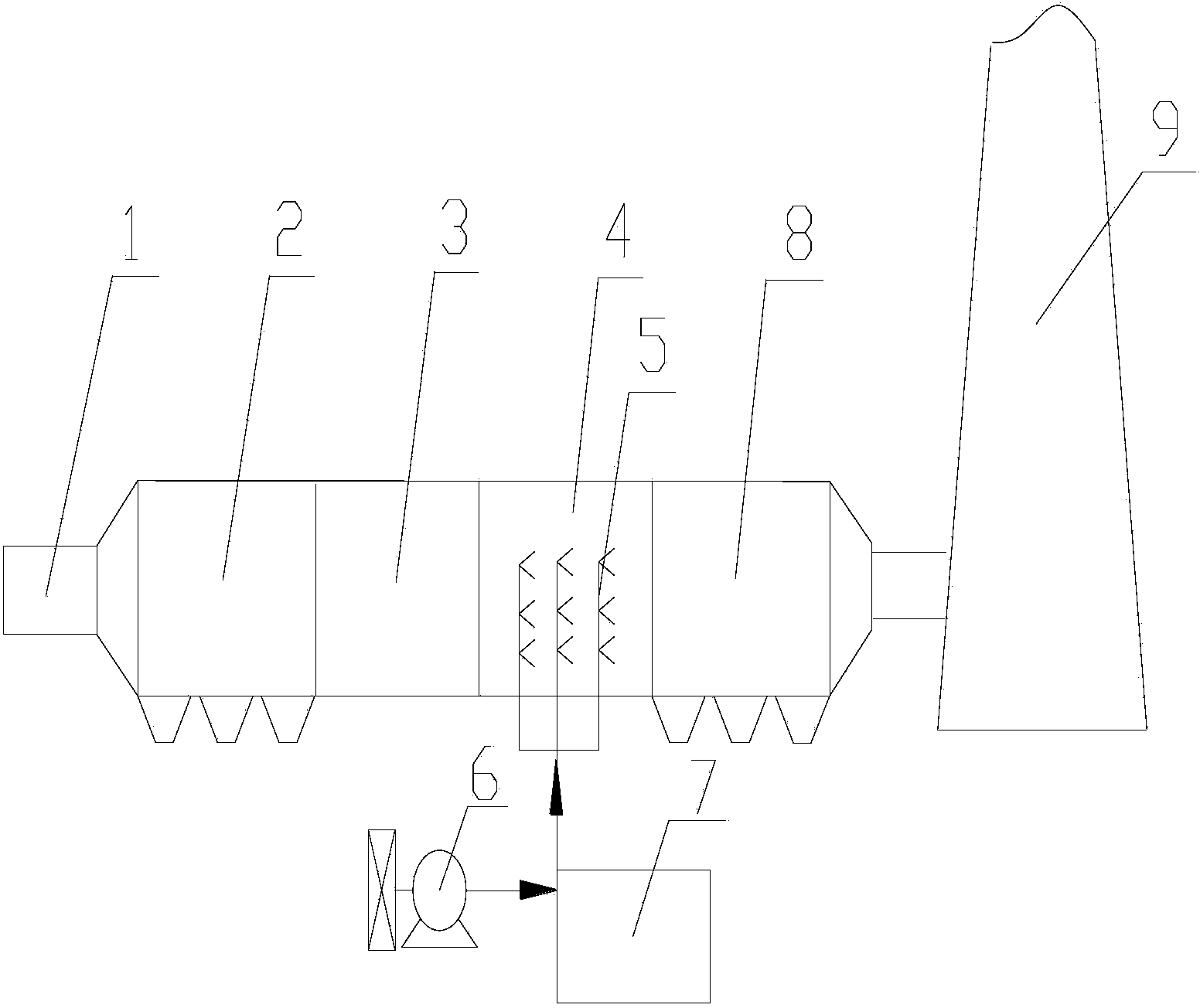

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

[0033] Such as figure 1 Shown, a kind of electrostatic cooperative pollutant removal method comprises the following steps:

[0034] Step 1: transport the flue gas to the electrostatic precipitator 2 for pre-dust removal, and remove more than 90% of the particulate matter in the flue gas;

[0035] Step 2: The low-temperature plasma generation system generates low-temperature plasma to oxidize and degrade the pollutants in the flue gas after pre-dust removal;

[0036] Step 3: Absorb or absorb the flue gas treated in Step 2 by means of calcium oxide powder injection;

[0037] Step 4: Transport the flue gas treated in Step 3 and the used calcium oxide powder to the electrostatic precipitator 8 powered by high-frequency pulse power.

[0038] In the first step, the electrostatic precipitator 2 is a conventional DC electrostatic precipitator with two electric fields or three elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com