Fluid bed reactor for producing trichlorosilane and gas distributor thereof

A technology for fluidized bed reactors and gas distributors, which is applied in the direction of silicon halides, halosilanes, etc., and can solve problems such as low production capacity and poor fluidization quality of small fluidized bed reactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described more specifically through examples below, but the present invention is not limited to the described examples.

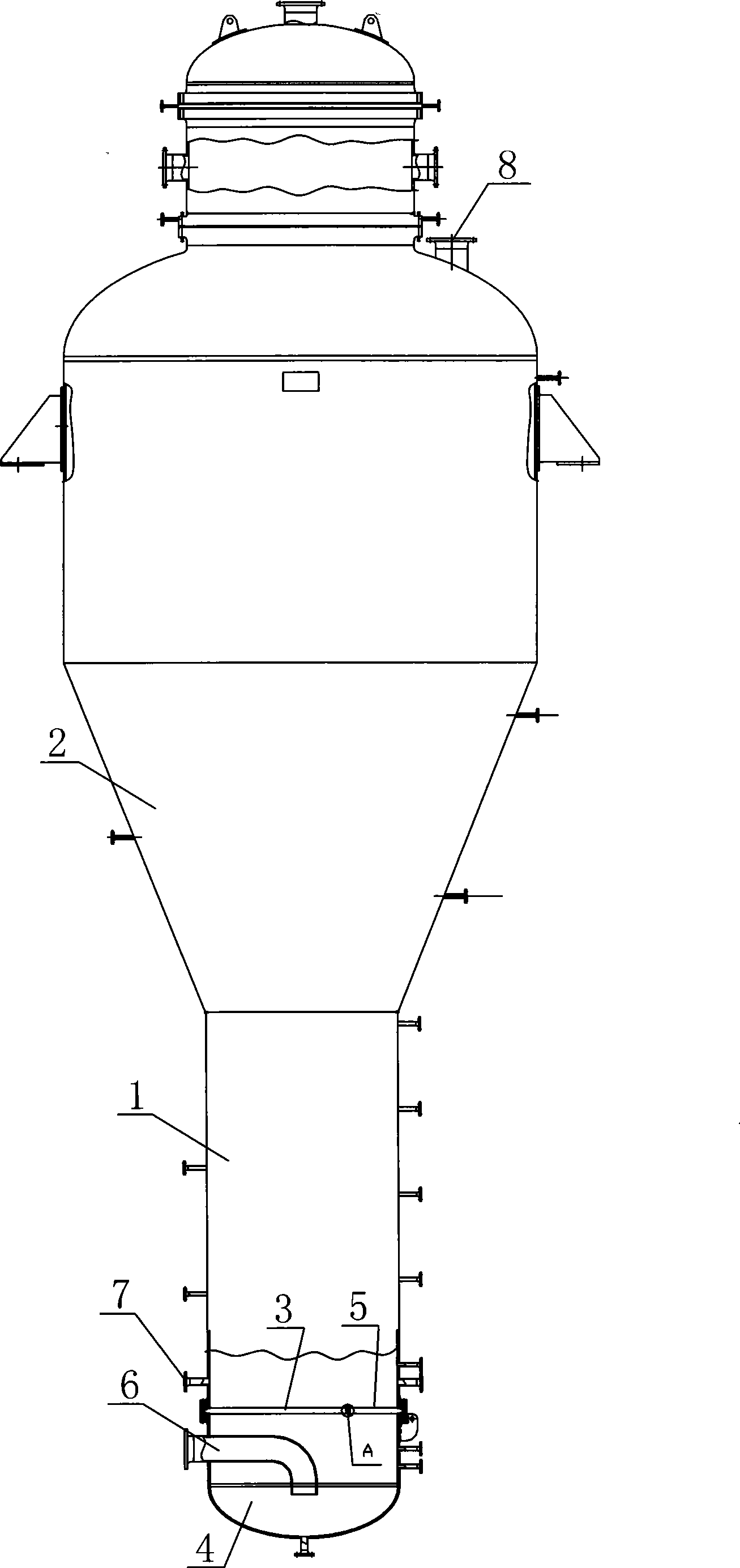

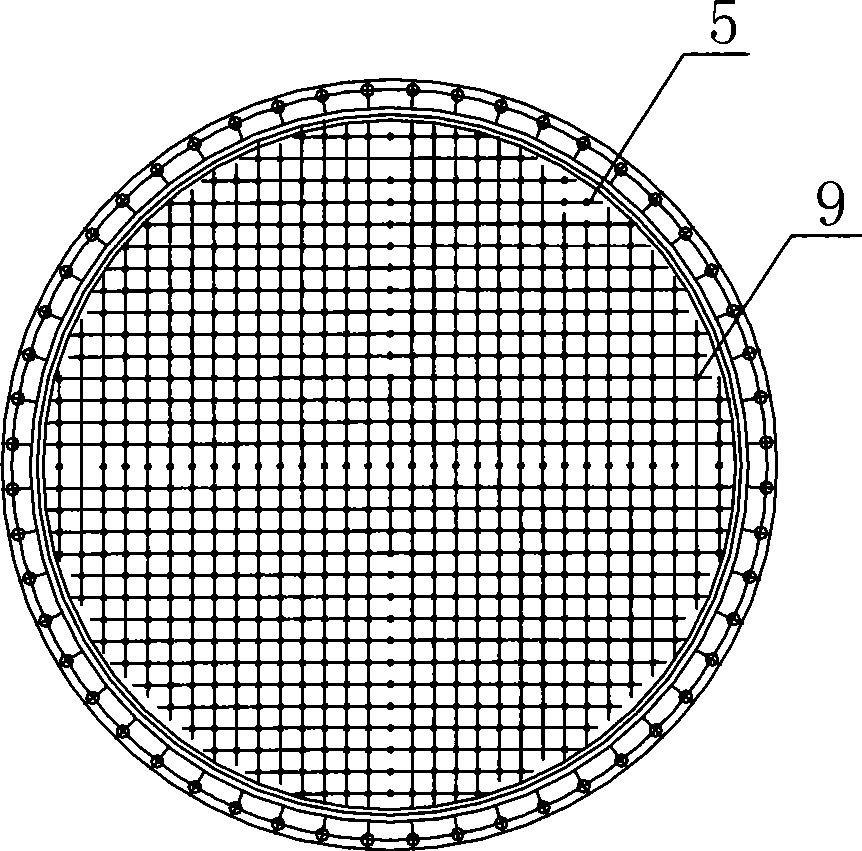

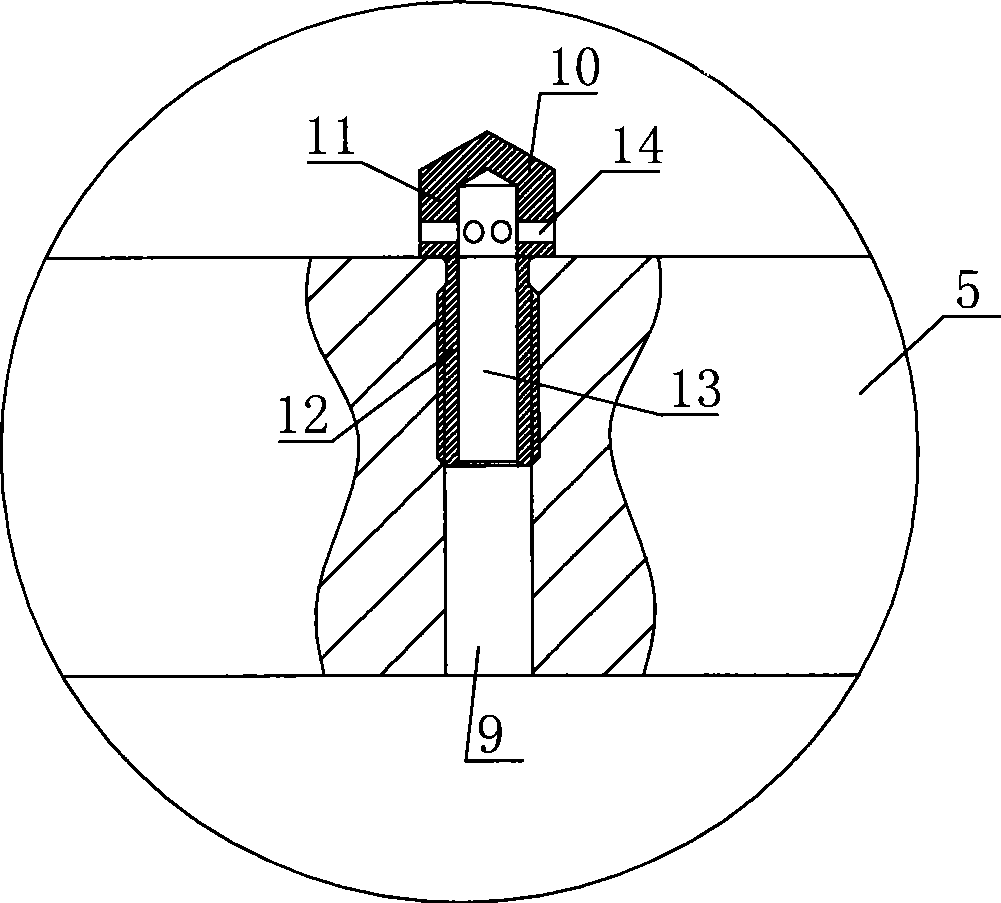

[0020] Such as figure 1 A fluidized bed reactor for the production of trichlorosilane is shown, the fluidized bed reactor includes a lower reaction section 1 and an upper expansion section 2, the diameter of the reaction section 1 is 1500 mm to 3000 mm, and the expansion section 2 The diameter is 3700mm-8000mm; the diameter ratio of the expansion section 2 to the reaction section 1 is 2.5-2.8; the height of the reaction section 1 is 2500mm-5000mm, and the height of the expansion section 2 is 4000mm-8000mm. The lower part of the reaction section 1 is provided with a silicon powder feed port 7, the lower part of the reactor is provided with an inspection head 4, the inspection head 4 is provided with a hydrogen chloride inlet 6 and a slag discharge port, and the upper part of the expansion section 2 is provided with a synt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com