Patents

Literature

59results about How to "Avoid oversupply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

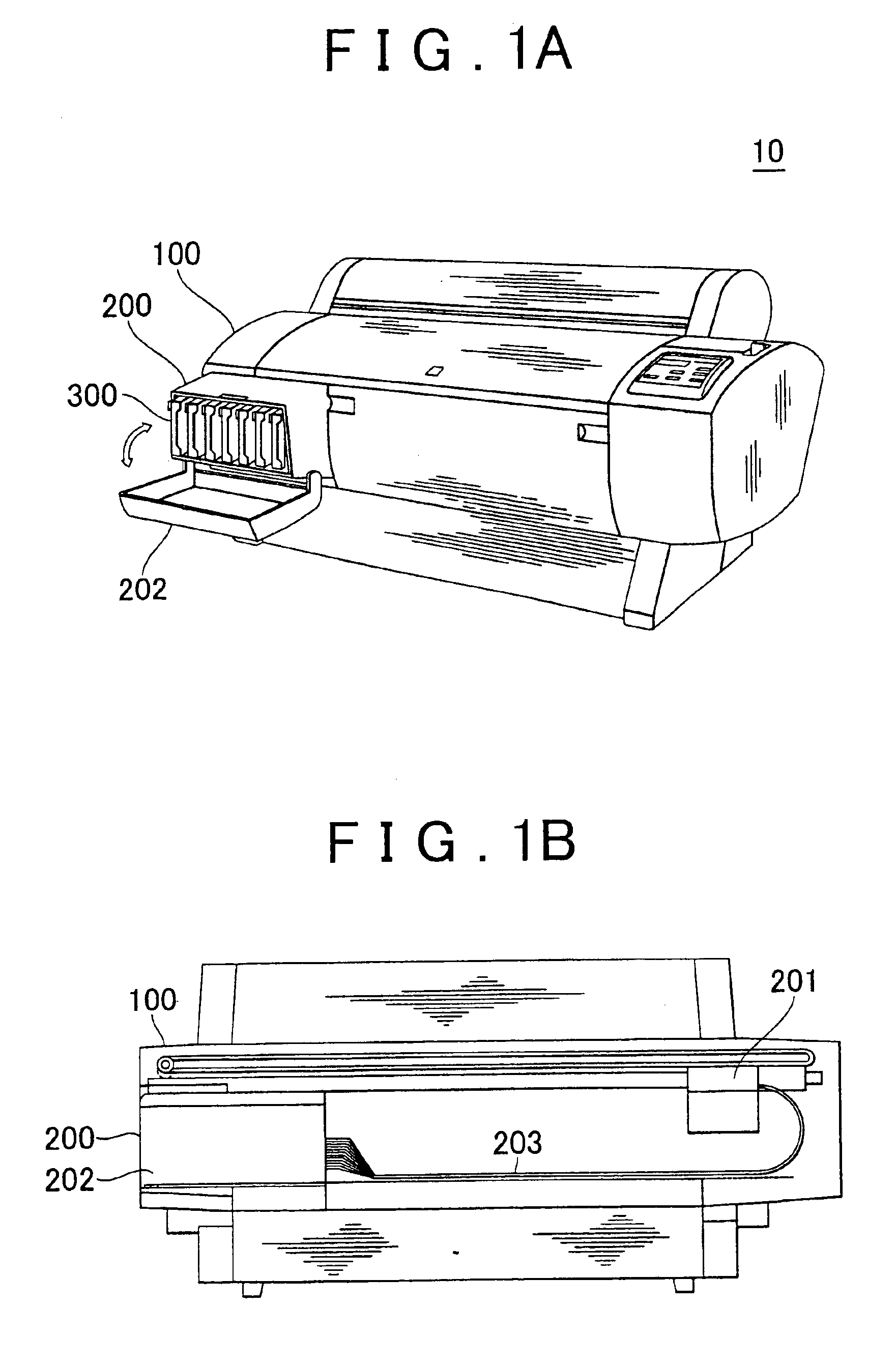

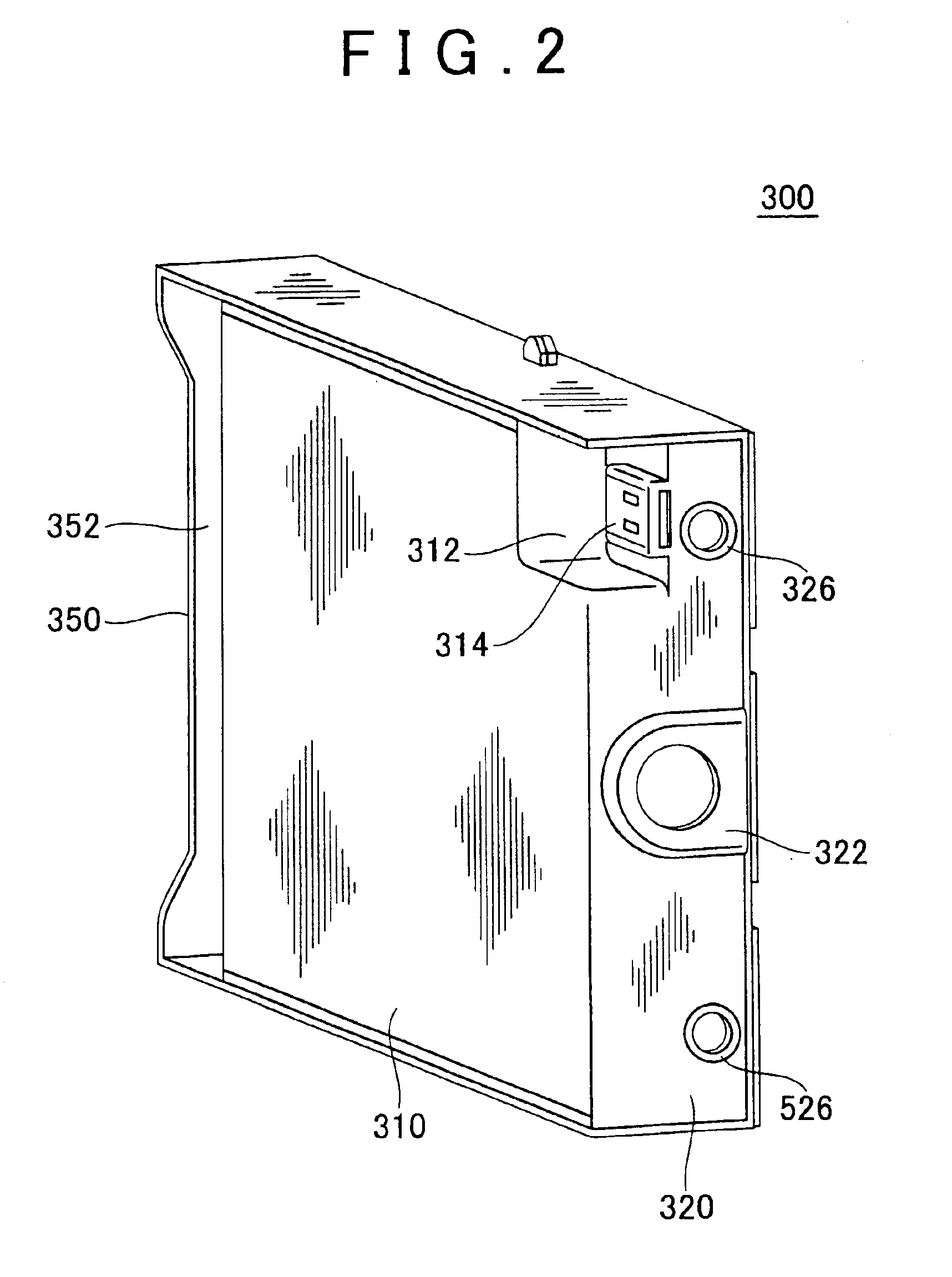

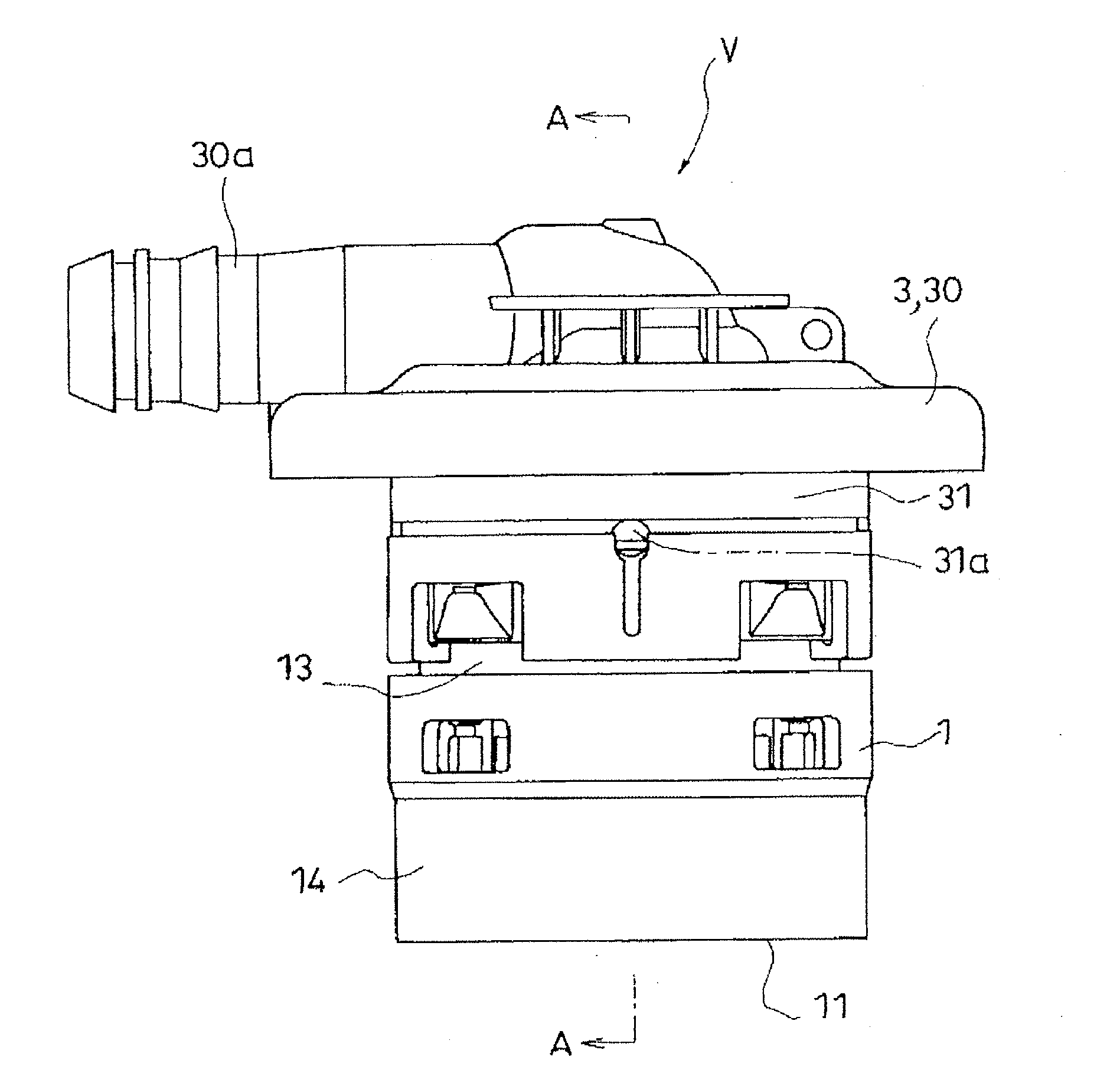

Liquid cartridge and liquid accommodating member

A liquid cartridge for supplying liquid to a liquid ejecting apparatus, includes: a liquid accommodating part for holding the liquid; a channel for allowing the liquid in the liquid accommodating part to flow to the outside of the liquid accommodating part; and a check valve for preventing air from getting into the liquid accommodating part via the channel in a case where the channel is opened to the atmosphere with the channel faced upward and allowing backward flow of liquid from the liquid ejecting apparatus to the liquid accommodating part while the channel is connected to the liquid ejecting apparatus.

Owner:SEIKO EPSON CORP

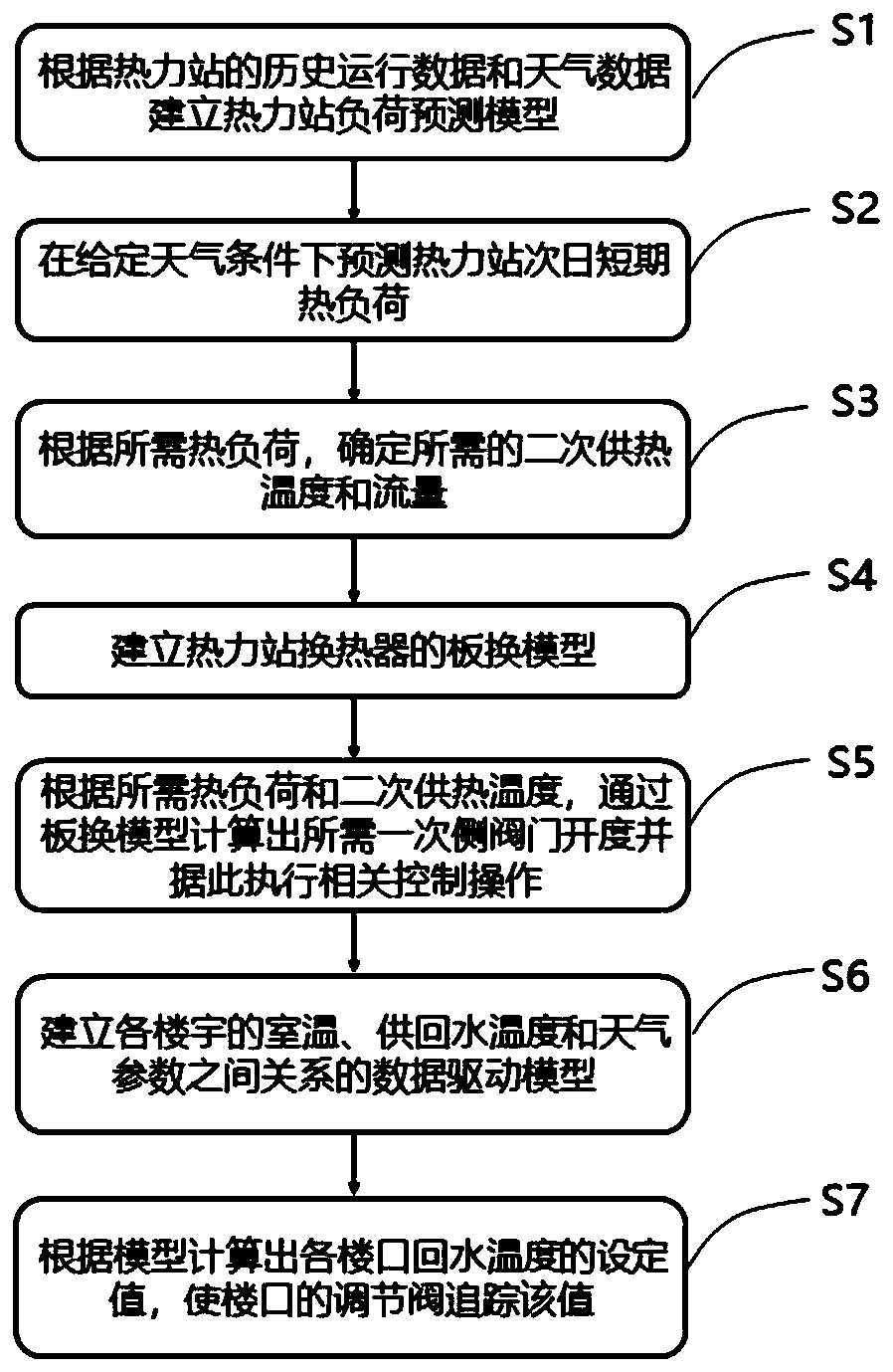

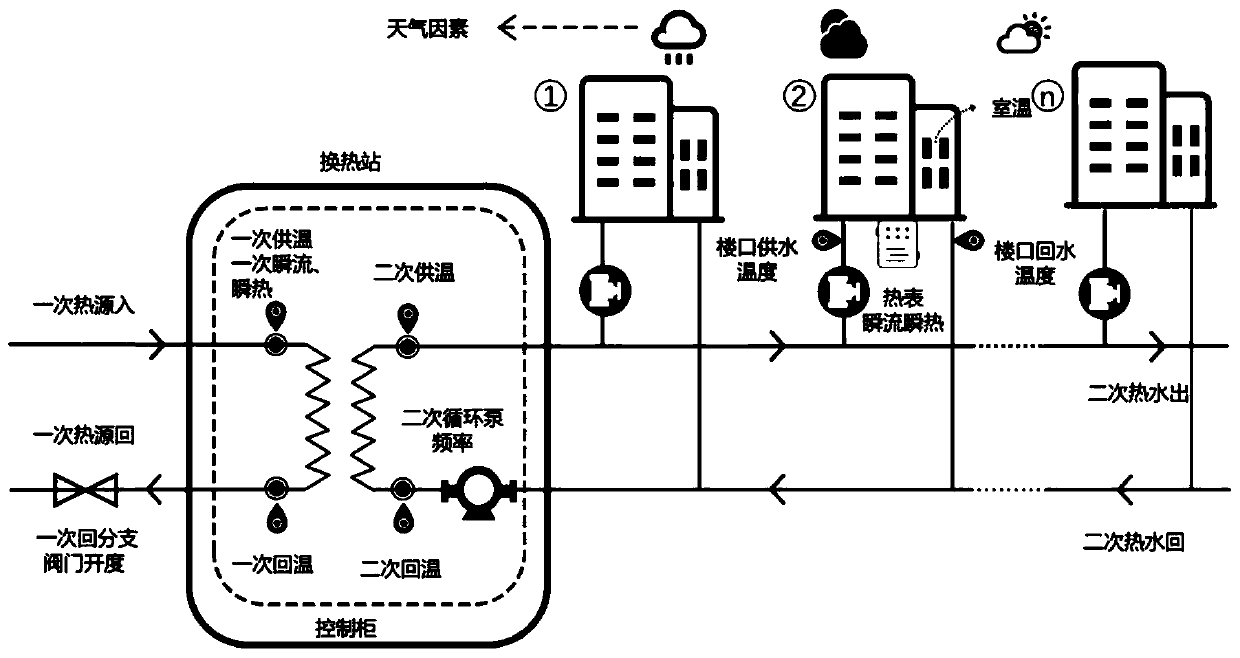

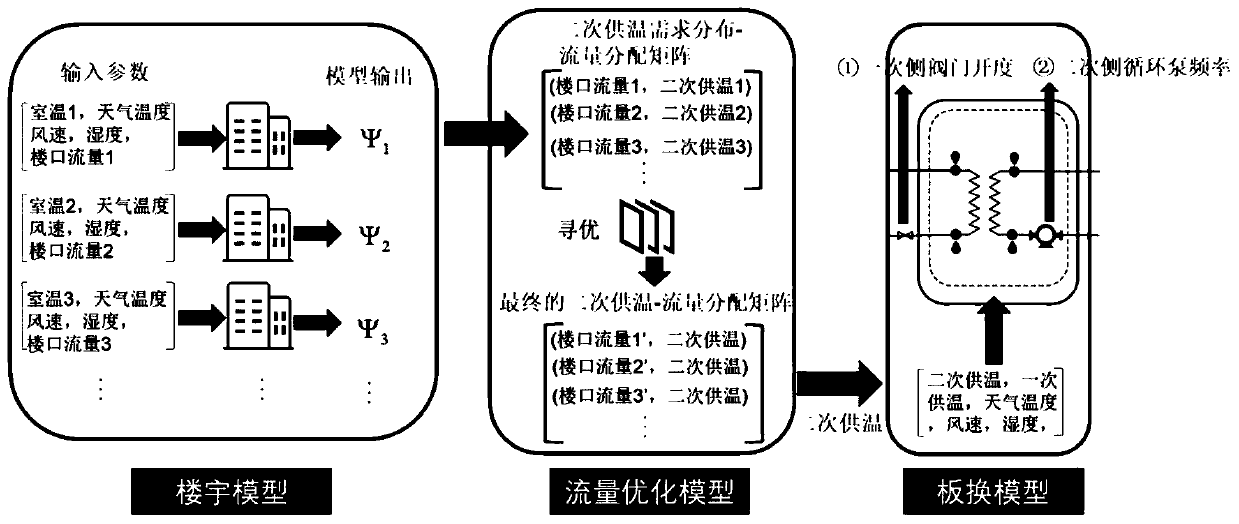

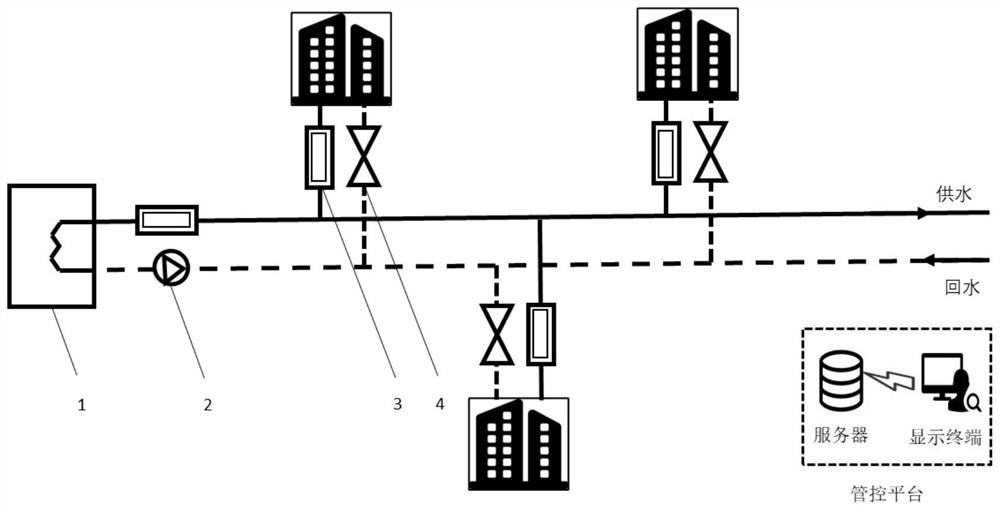

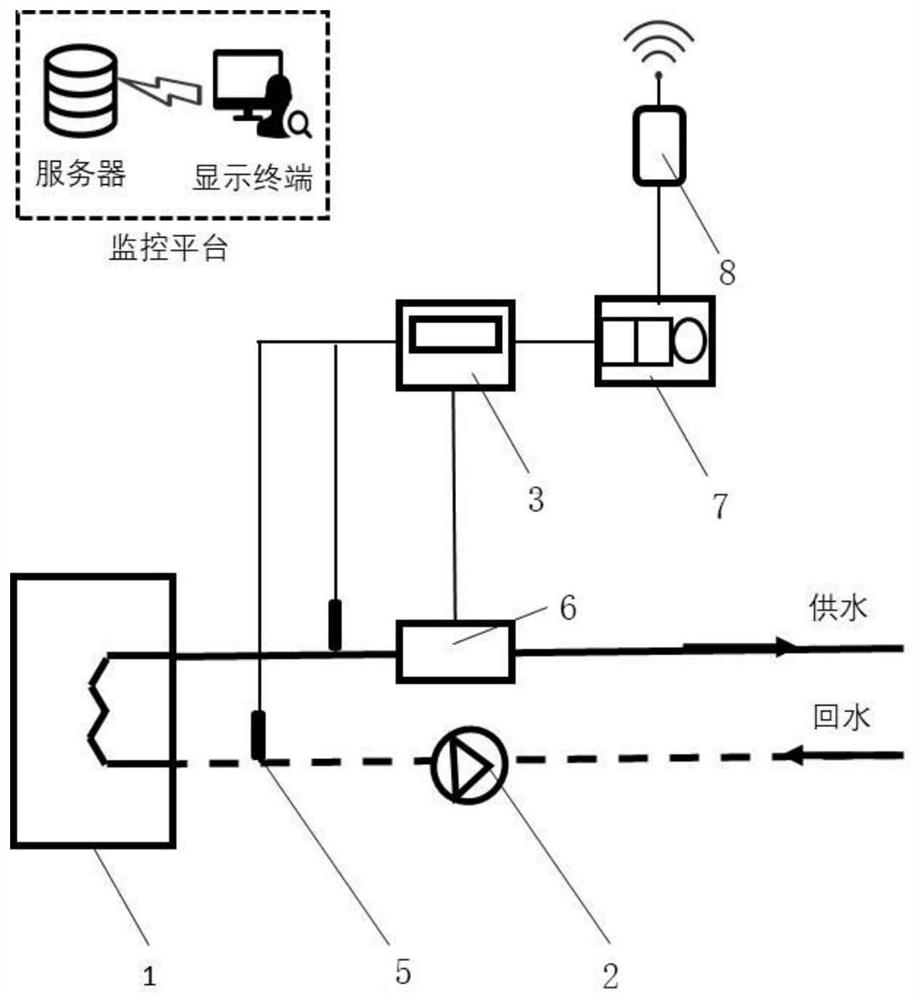

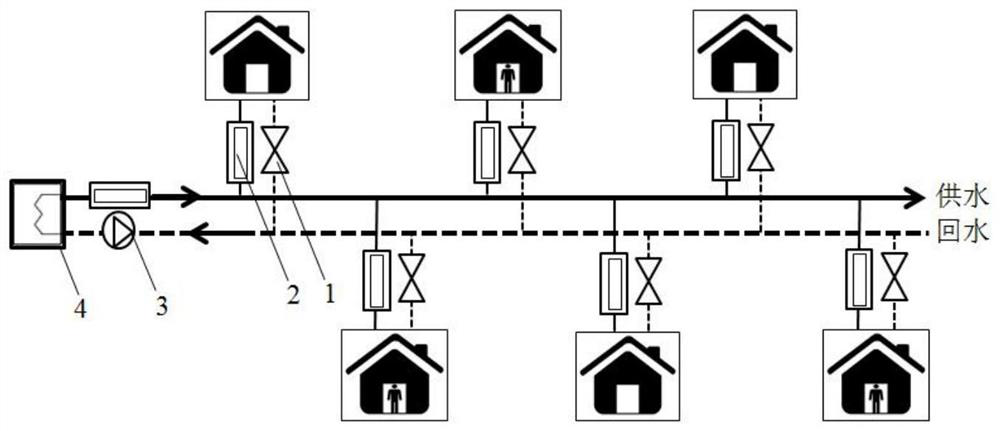

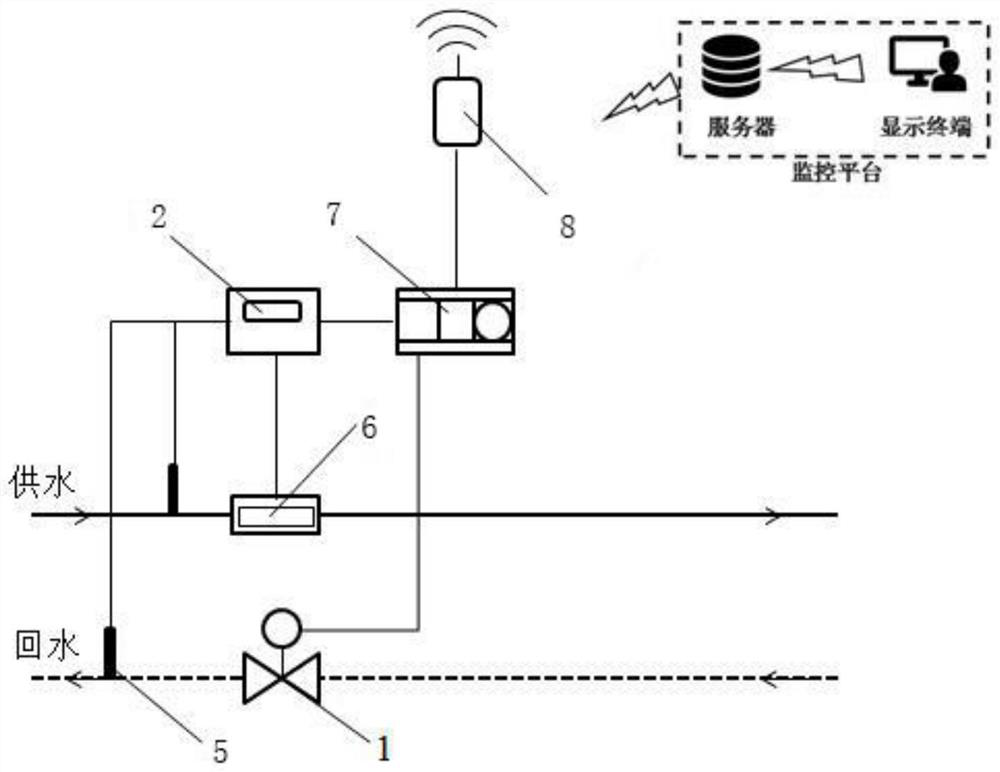

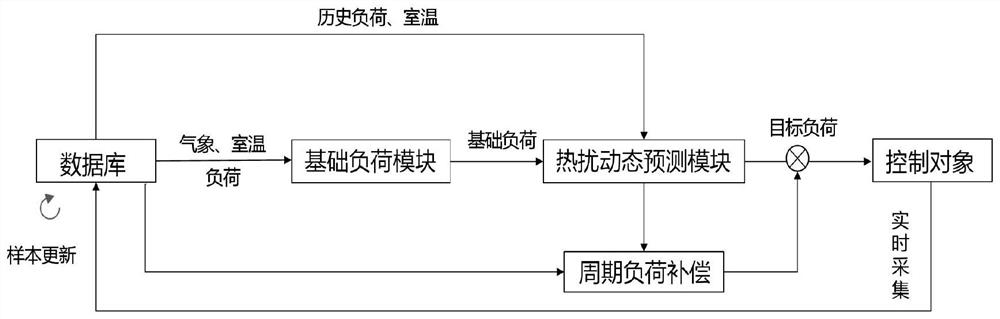

Central heating system on-demand precise regulation and control method based on models

ActiveCN111473407AAvoid oversupplyMeet heat load demandsLighting and heating apparatusForecastingWeather parameterWeather condition

The invention discloses a central heating system on-demand precise regulation and control method based on models. The method comprises the following steps that S1, a heating station load predicting model is built according to the historical operation data of a heating station and weather data; S2, the next-day short-term heat load of the heating station is predicted under the given weather condition; S3, needed secondary side heat supply and flow are determined according to the needed heat load; S4, a plate exchange model of a heating station heat exchanger is built; S5, the needed primary side valve opening degree is calculated through the plate exchange model according to the needed heat load and secondary side heat supply temperature, and related control operation is executed accordingly; S6, a data driving model of the relation among the room temperature, return water temperature and weather parameters of all buildings is built; and S7, the set value of the return water temperatureof all building openings is calculated according to the models, so that adjusting valves of the building openings track the value. According to the method, the situation of excessive supply of the heating station can be effectively avoided, heat energy loss can be reduced, and the utilization efficiency of the heating station on energy is improved.

Owner:ZHEJIANG UNIV

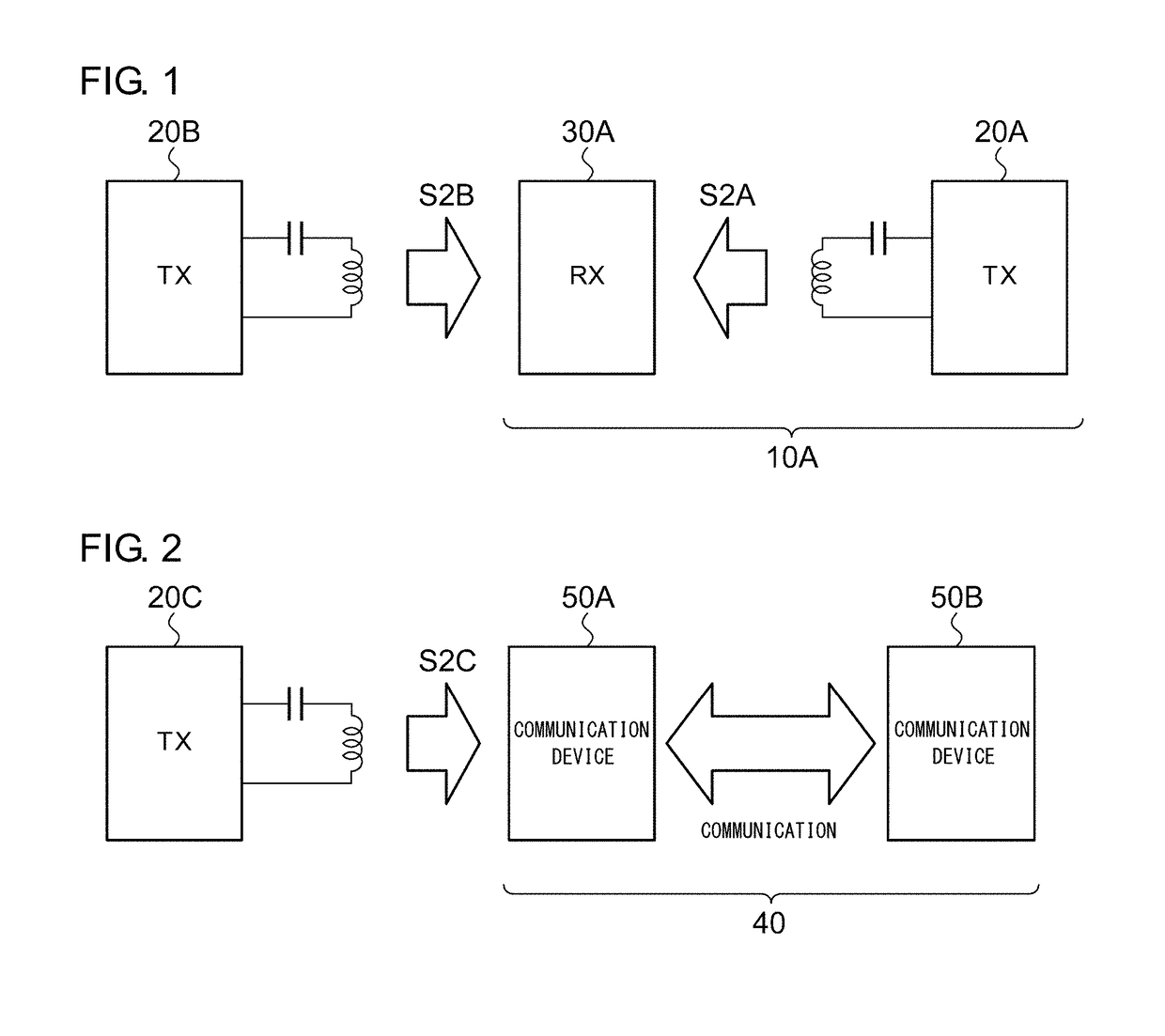

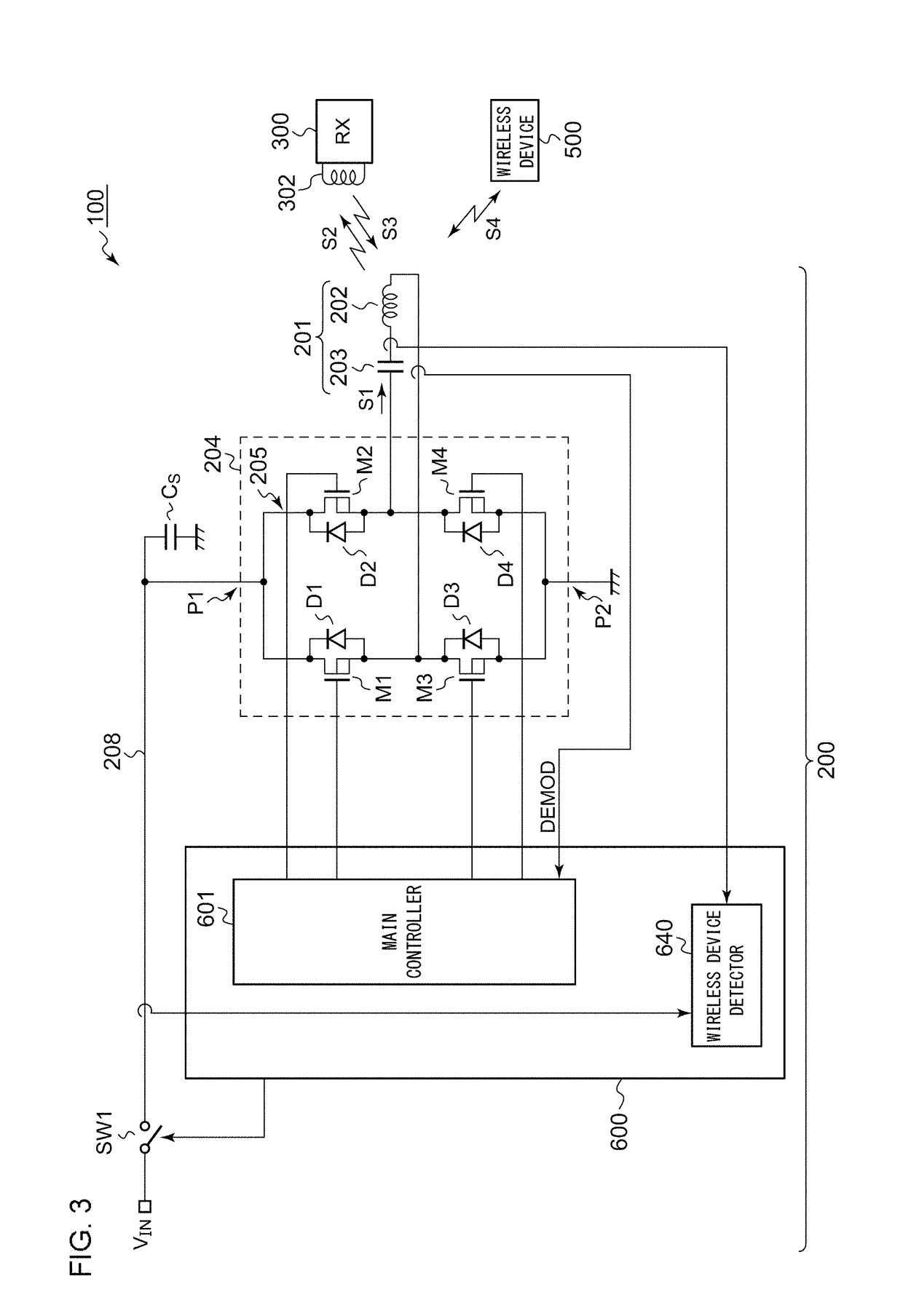

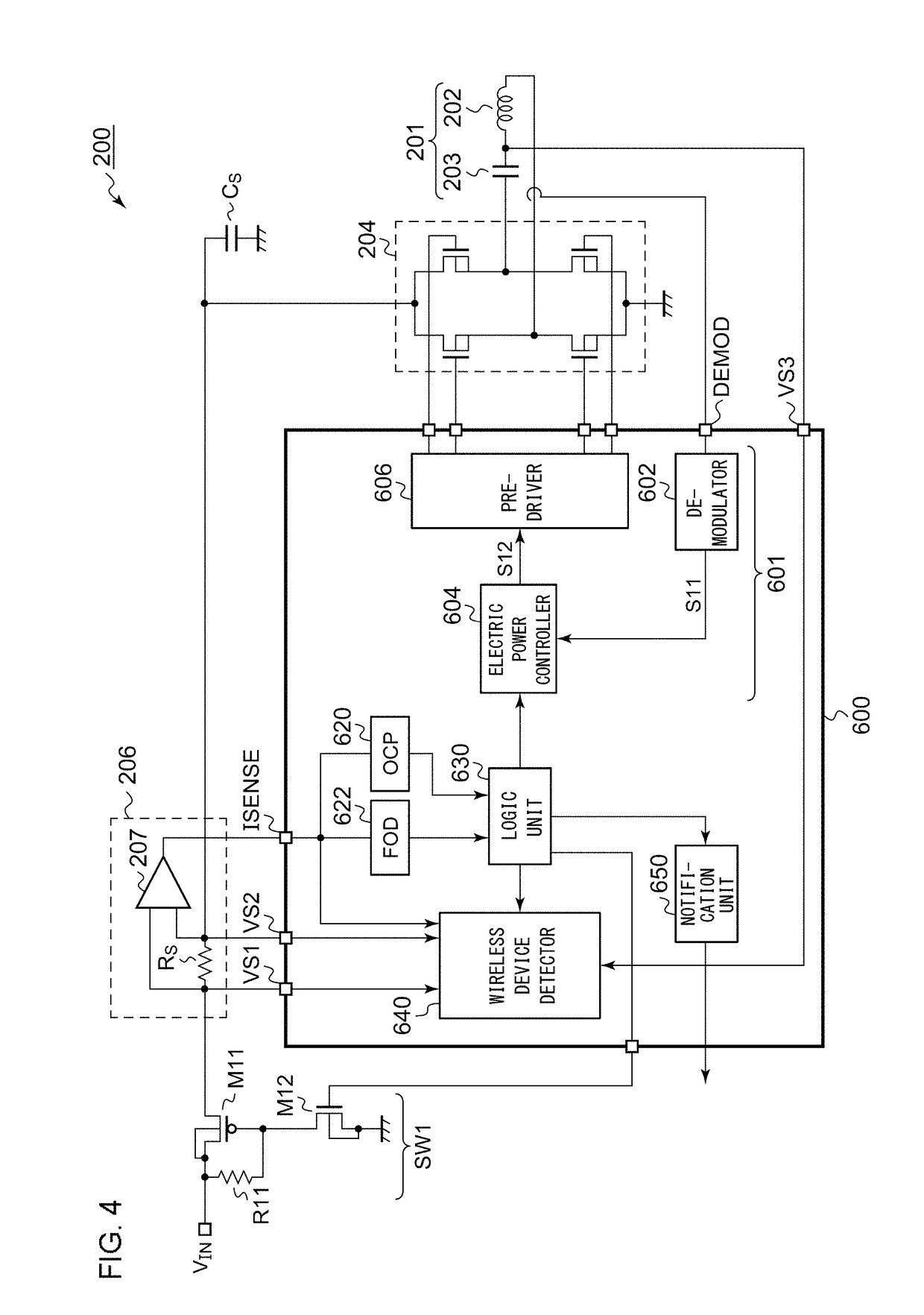

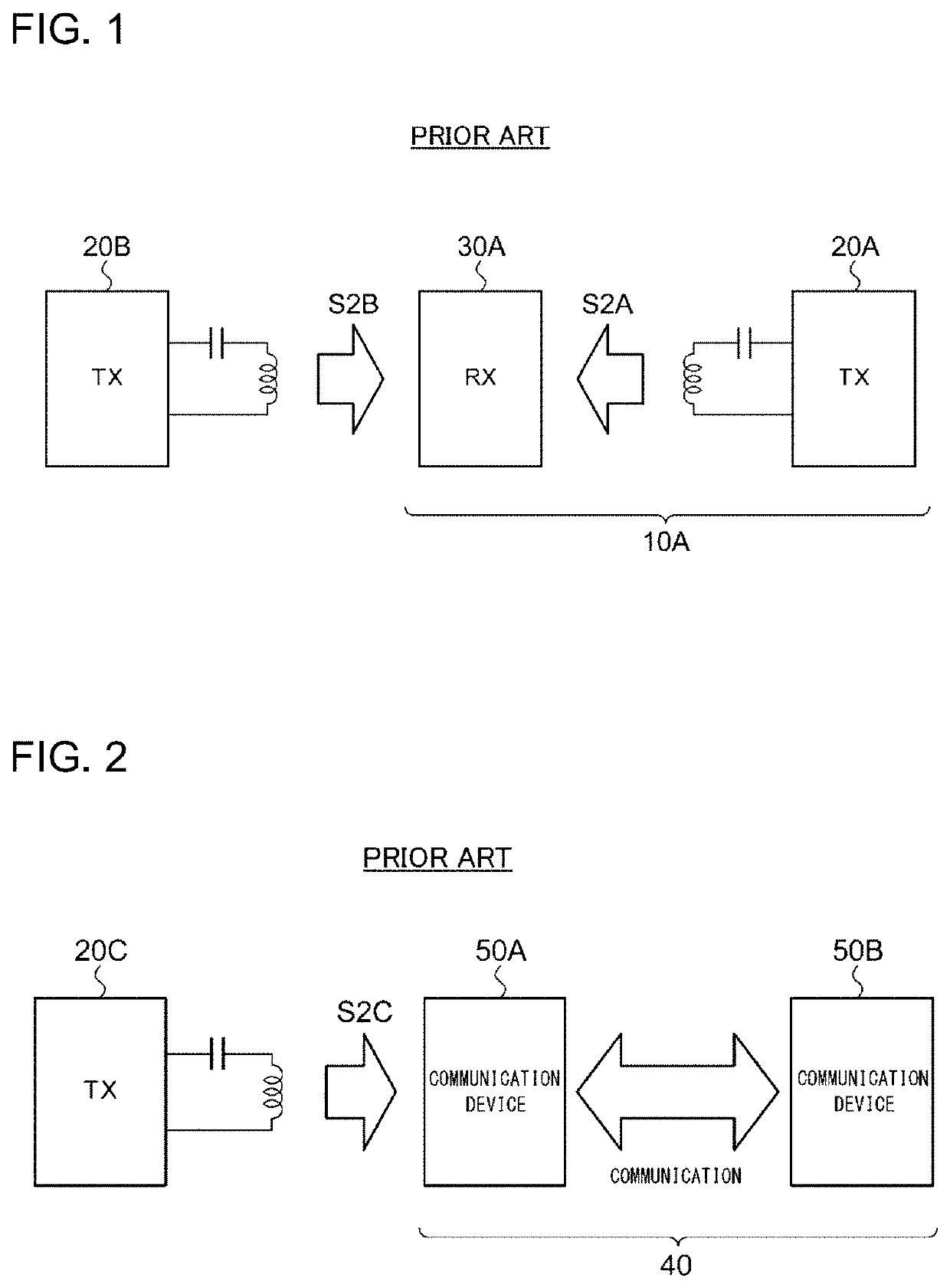

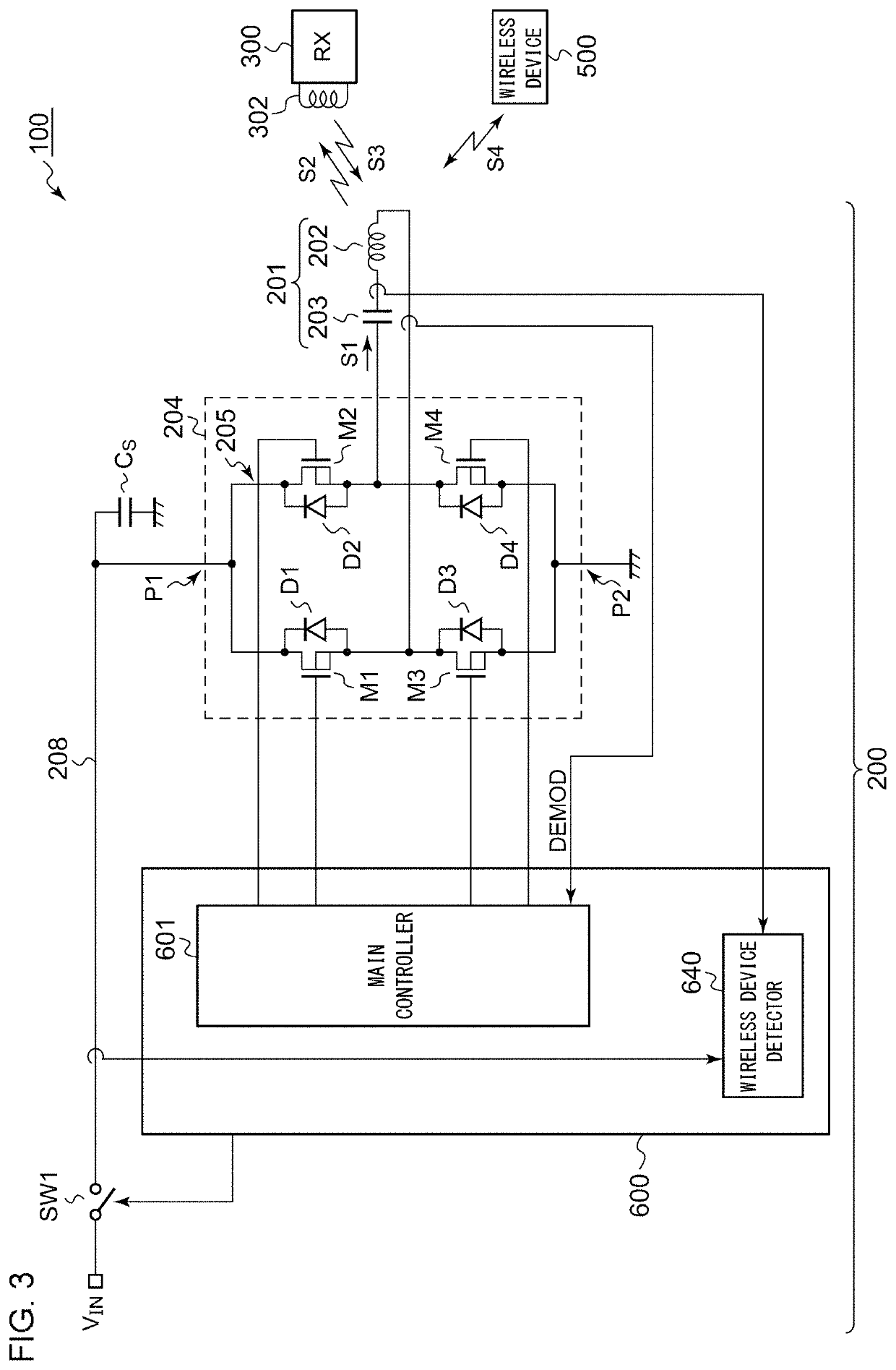

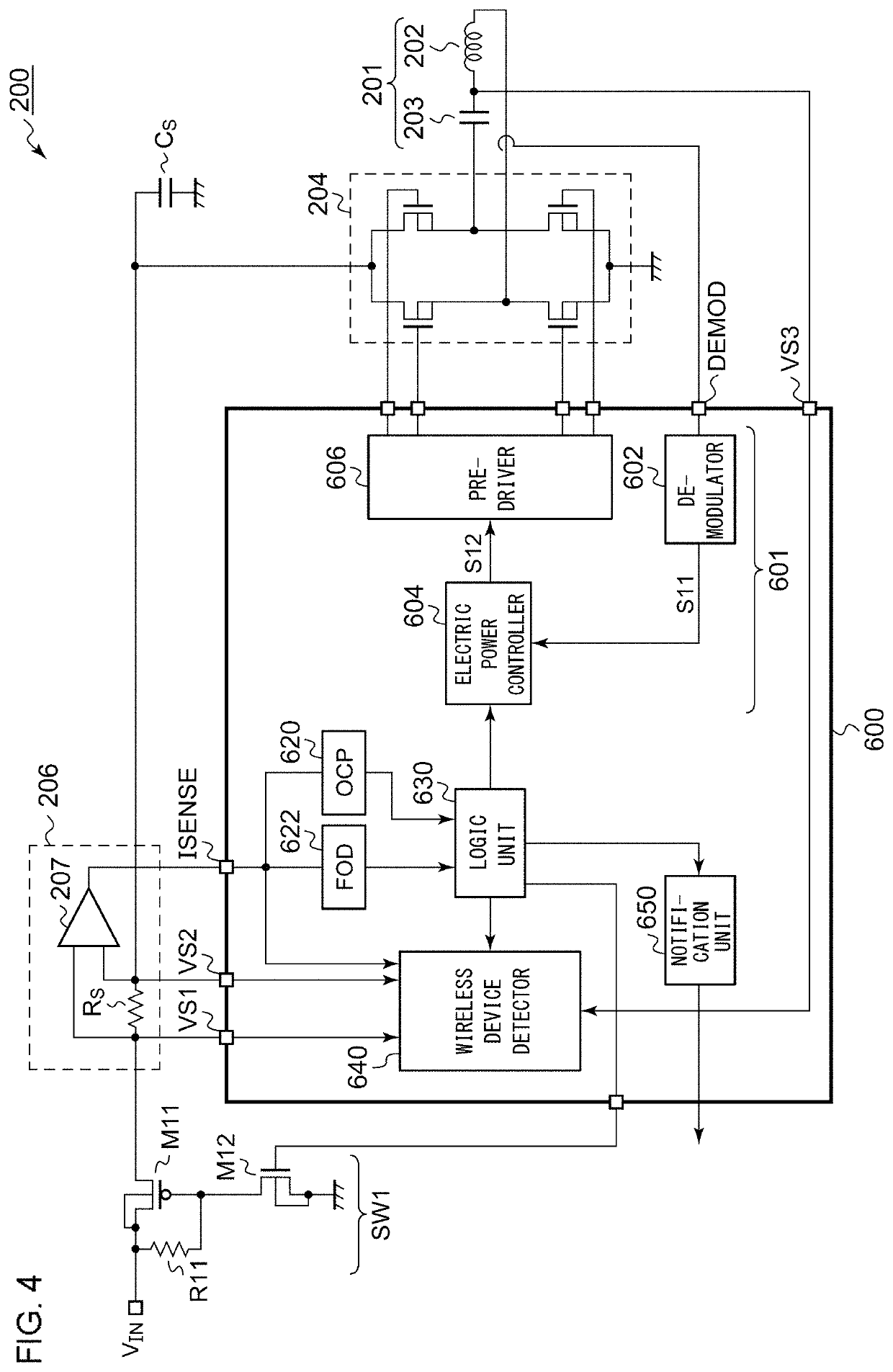

Wireless power transmitter

ActiveUS20190006889A1Reduce circuit areaUniform characteristicBatteries circuit arrangementsElectric powerElectric power transmissionEngineering

A power transmitter transmits an electric power signal S2 to a wireless power receiver. A transmission antenna includes a transmission coil and a resonance capacitor coupled in series. A driver applies a driving signal S1 to the transmission coil. A TX controller controls the driver. A wireless device detector of the TX controller detects a neighboring wireless device before electric power transmission is started.

Owner:ROHM CO LTD

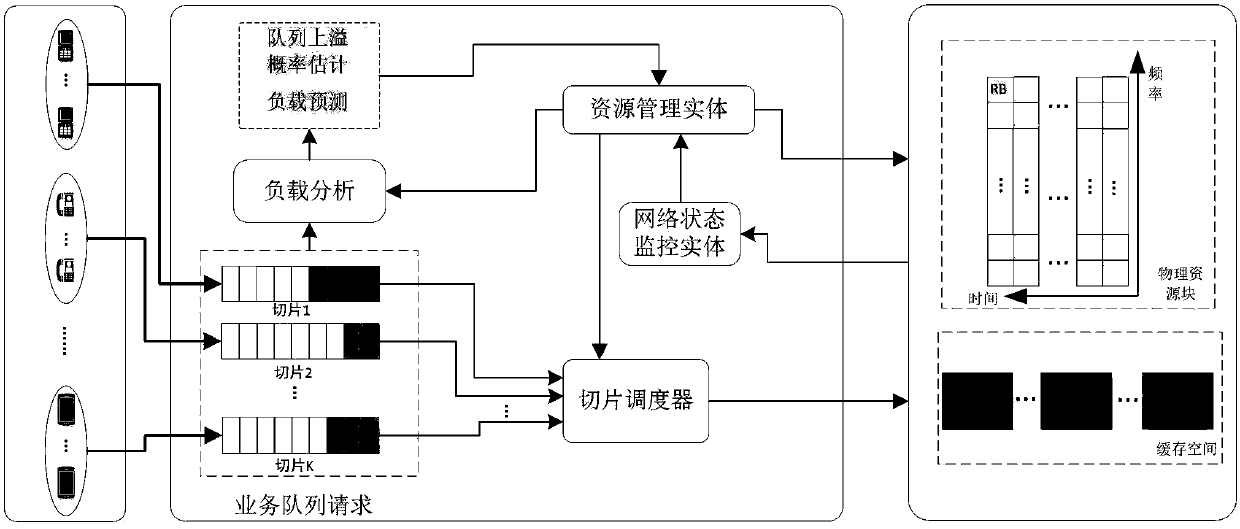

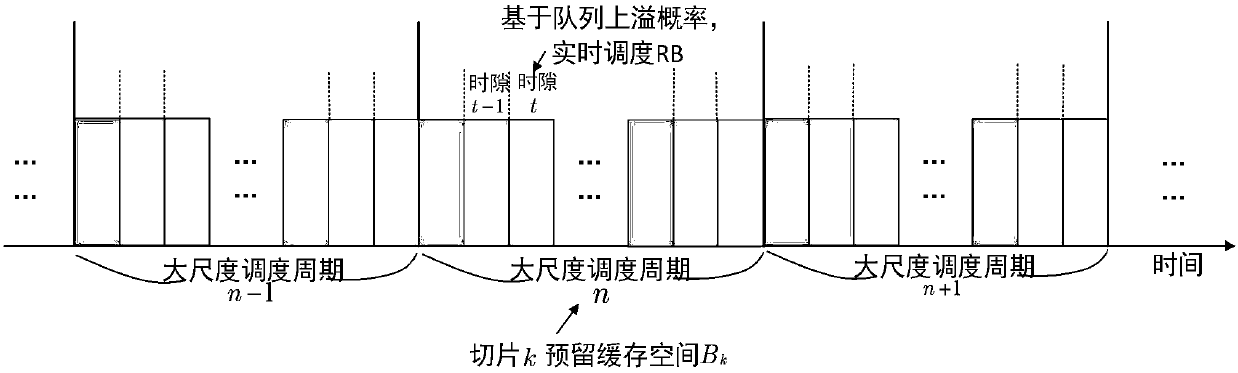

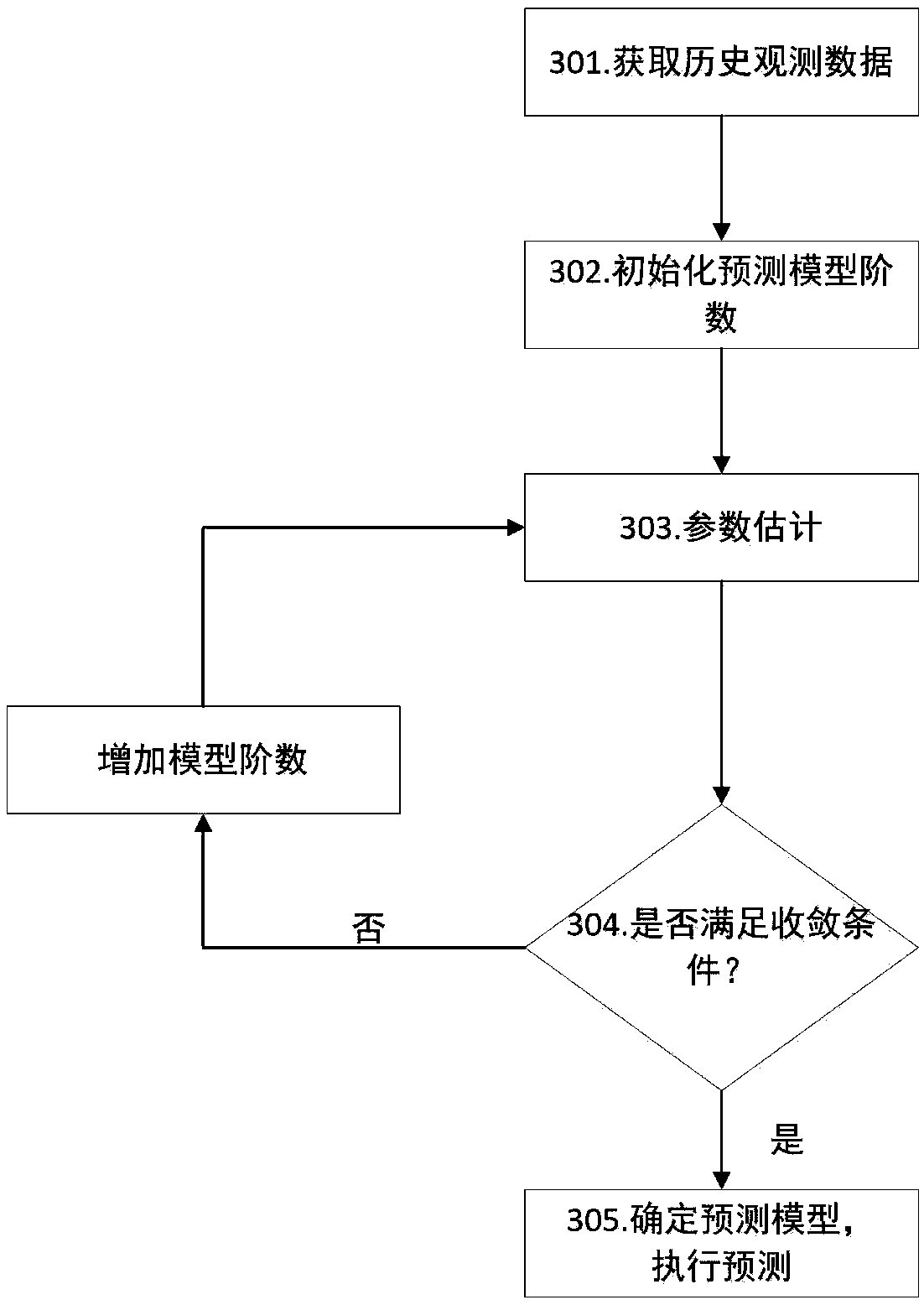

Online self-adaptive virtual resource allocation method for network slices based on service prediction

ActiveCN107743100APrevent overloadAvoid oversupplyData switching networksSelf adaptiveDynamic resource

The invention relates to an online self-adaptive virtual resource allocation algorithm based on service prediction and belongs to the field of mobile communication. The algorithm is online dynamic resource scheduling carried out by taking the minimum network slice resource mapping cost as a target on the premise of guaranteeing QoS of virtual network slices. The service of each network slice is predicted on a large time scale through a self-regression sliding average model, and the optimal buffer space size which is reserved in the next period is selected according to the predicted maximum probability load value; and the priority of each network slice is adjusted on a small time scale according to a queue overflow probability or a residual time value of each network slice, and appropriatephysical resource blocks are allocated to each network slice to ensure the service rate of each network slice on the premise of guaranteeing the queue overflow probability of each network slice. According to the online dynamic self-adaptive virtual resource allocation method provided by the invention, the QoS of each network slice can be effectively guaranteed, and meanwhile, the resource mappingcost of the network slices is minimized.

Owner:CERTUS NETWORK TECHNANJING

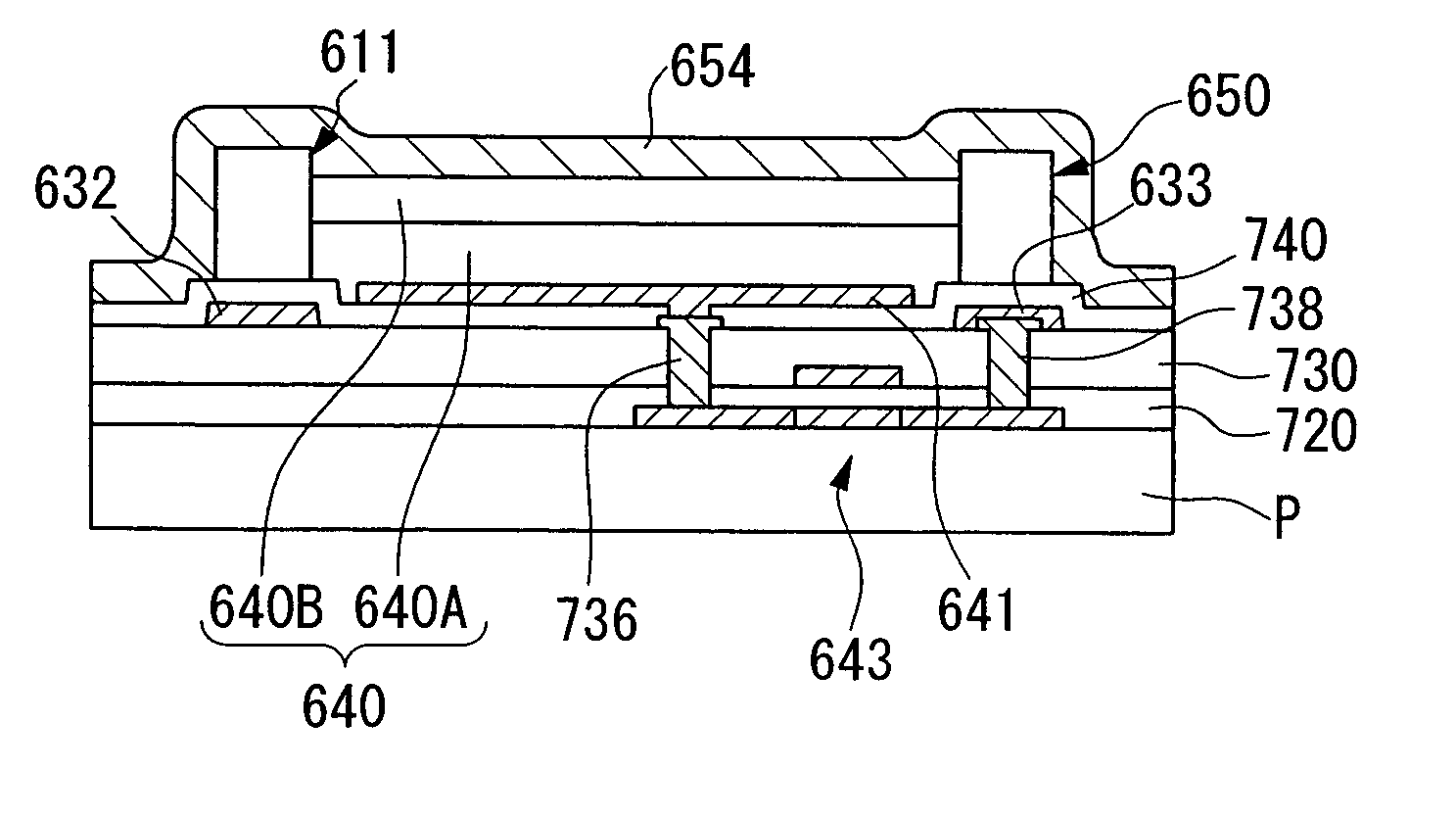

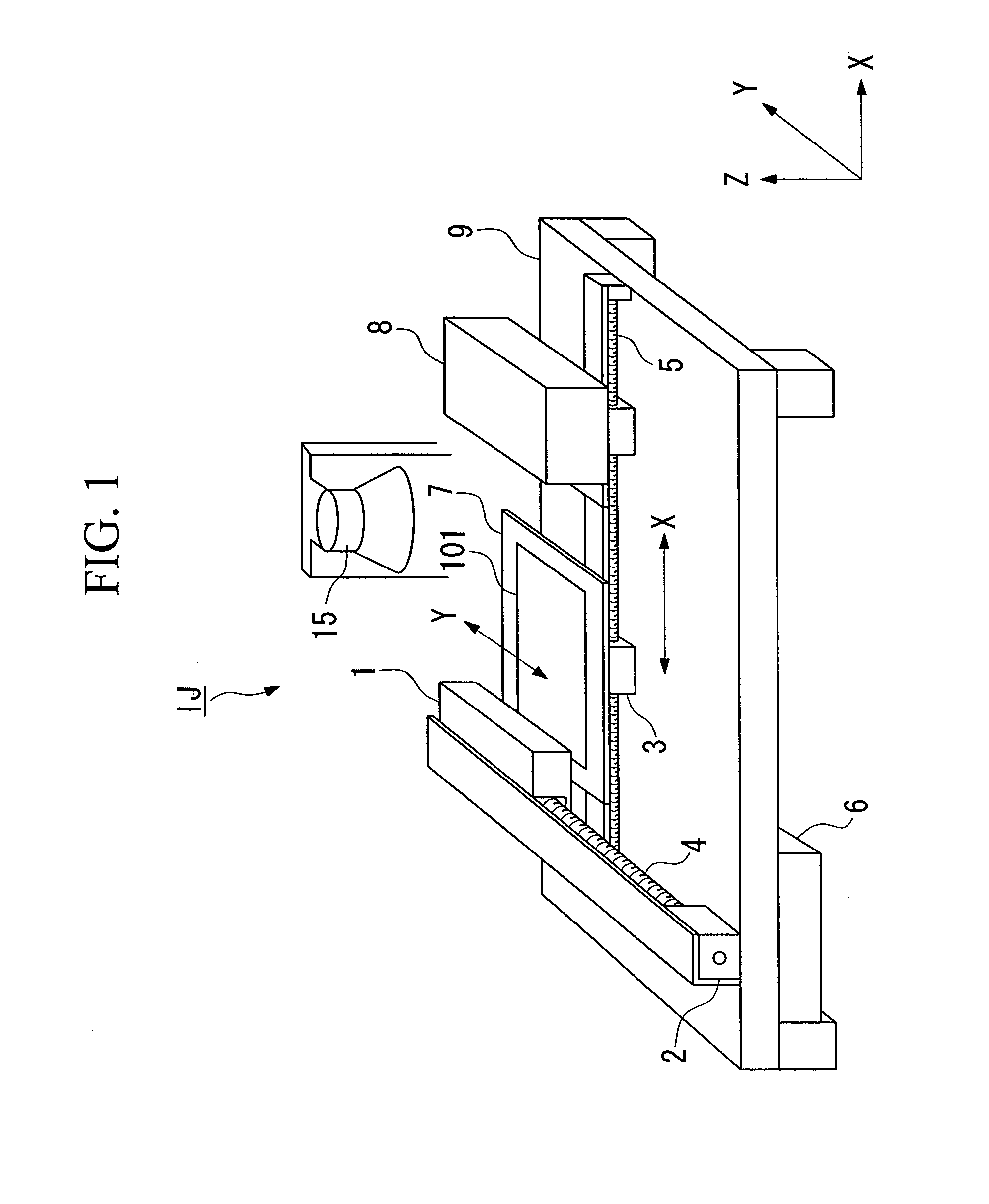

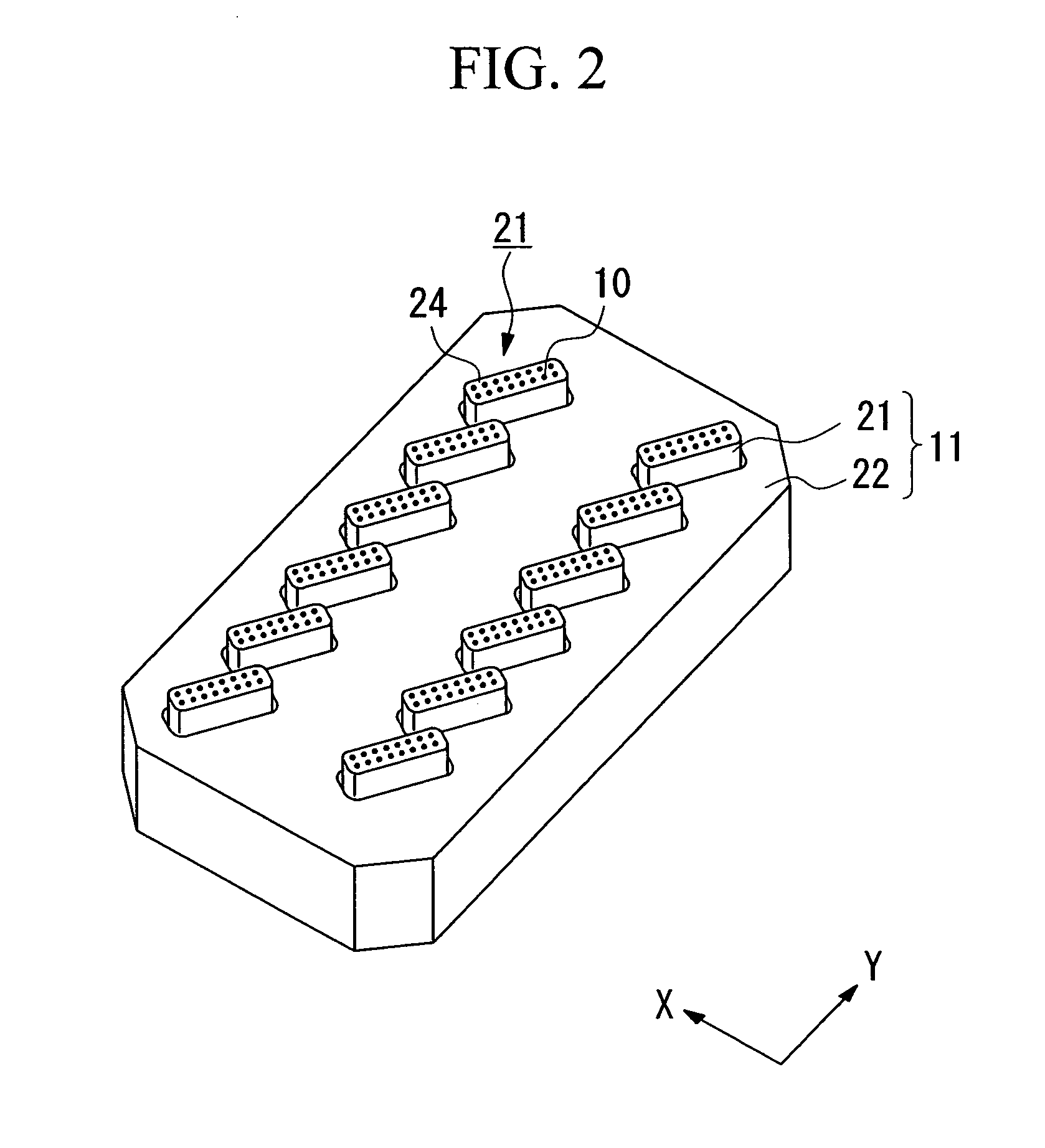

Method of manufacturing a device, device, and electronic apparatus

ActiveUS20040081768A1Simple designAvoid oversupplySingle unit pavingsOptical filtersEngineeringElectron

In this method of manufacturing a device, when discharging the liquid drops upon the substrate, a bit map made up from a plurality of pixels against which liquid drops are discharged is established upon the substrate. When establishing the pixels, when the interval of the discharge nozzles of the liquid drop discharge head 1 is taken as "a", and the size in the Y axis direction of the pixels is taken as by, the pixels are established so that the condition by=a / n is satisfied, where n is a positive integer.

Owner:SEIKO EPSON CORP

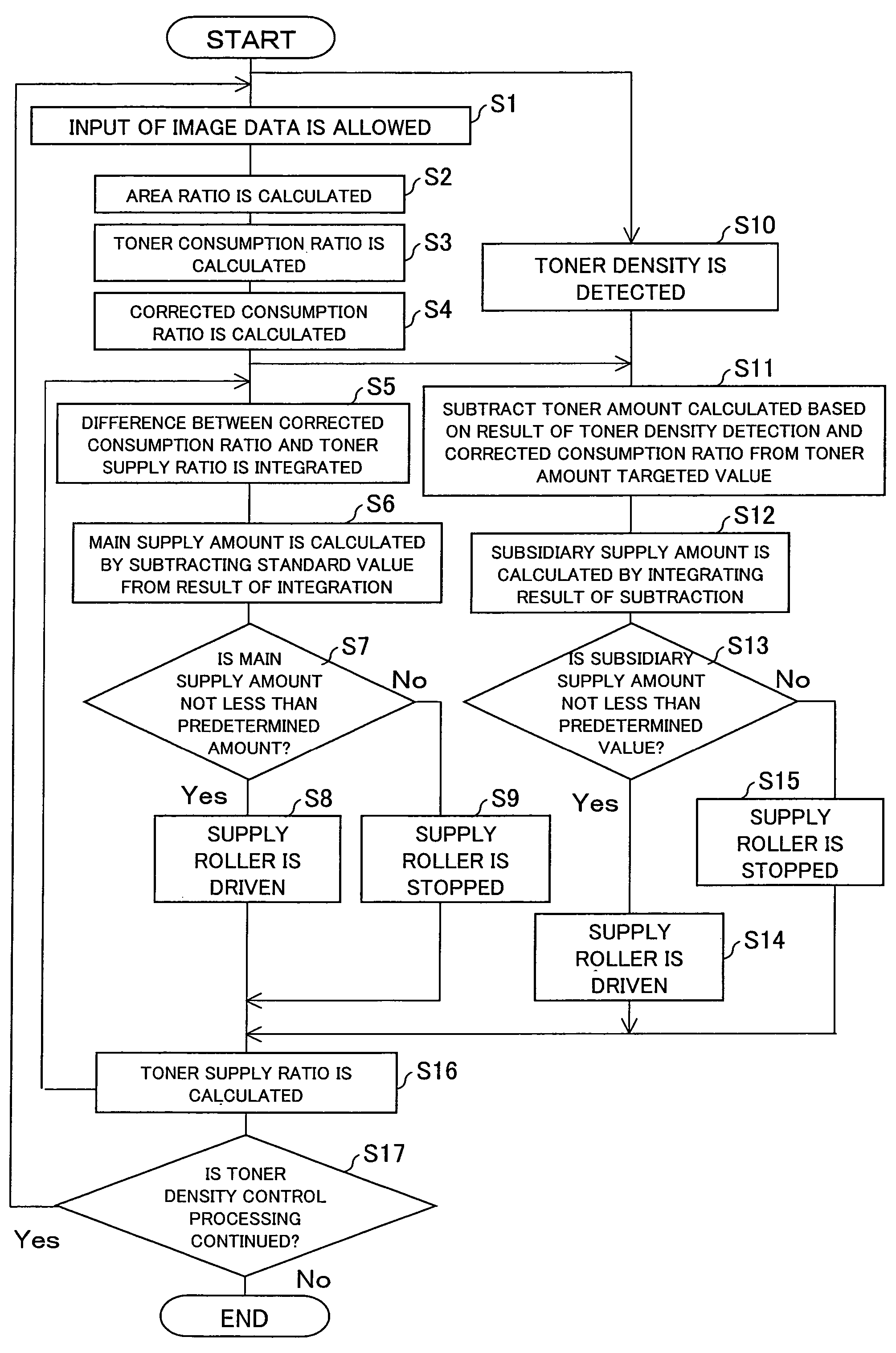

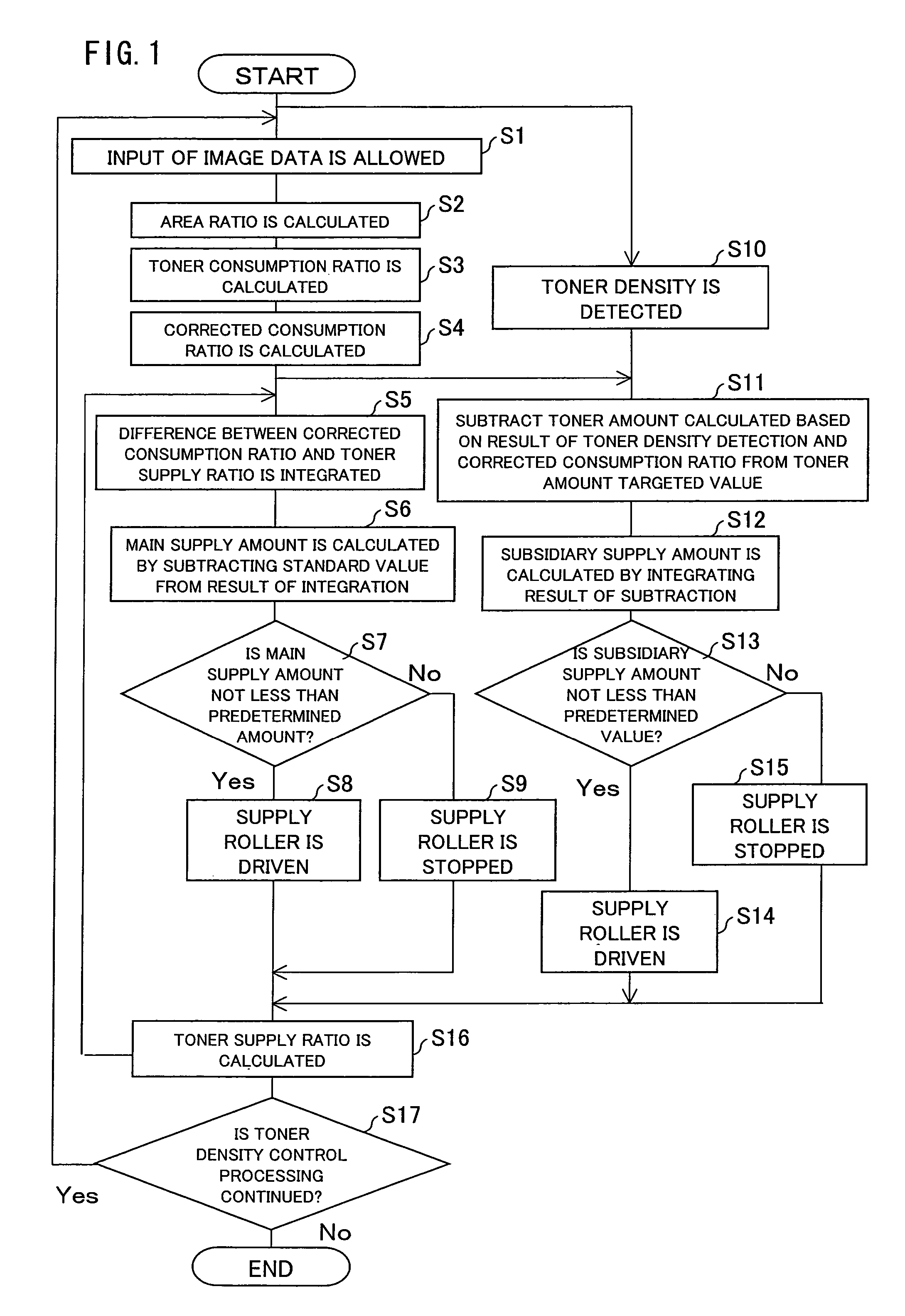

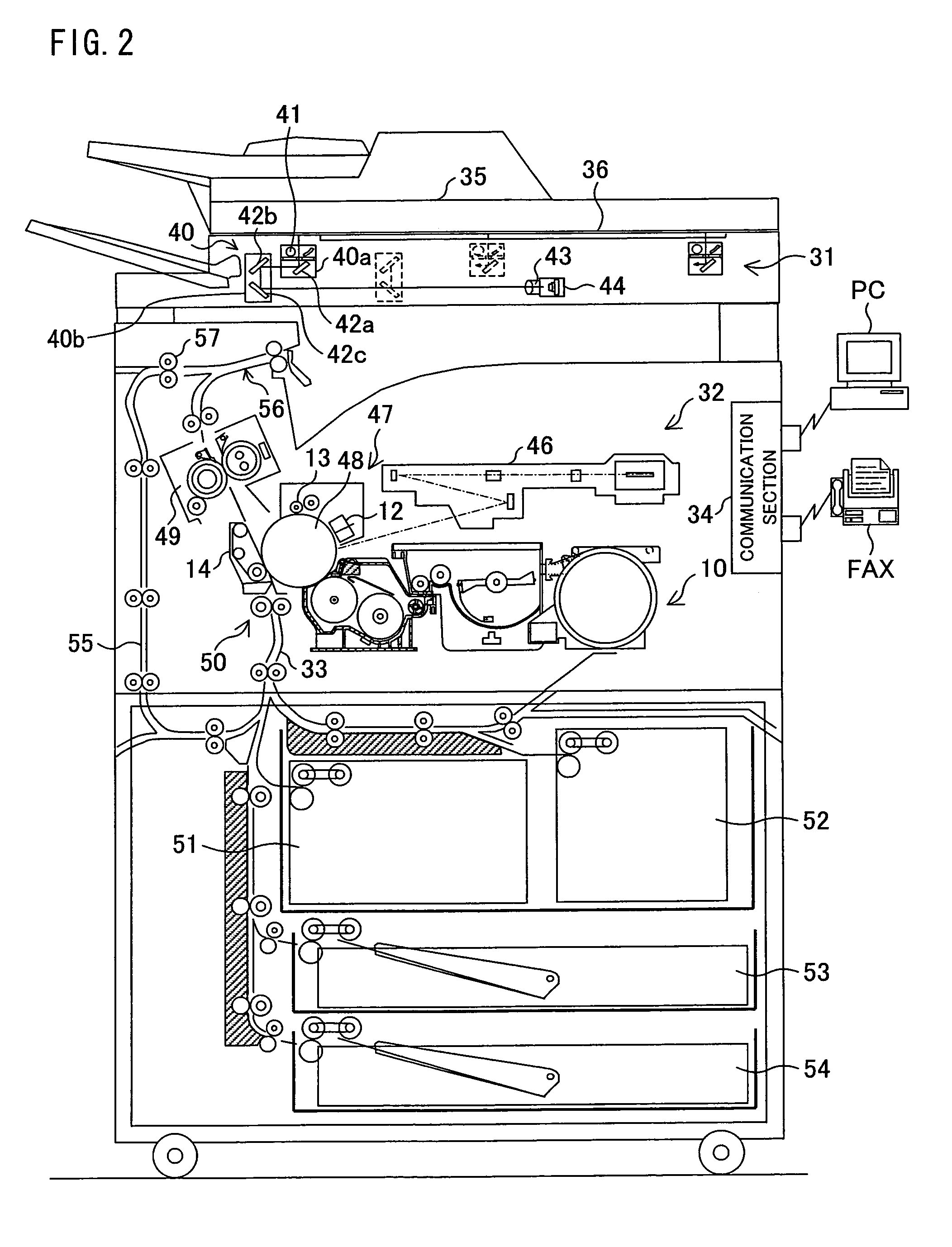

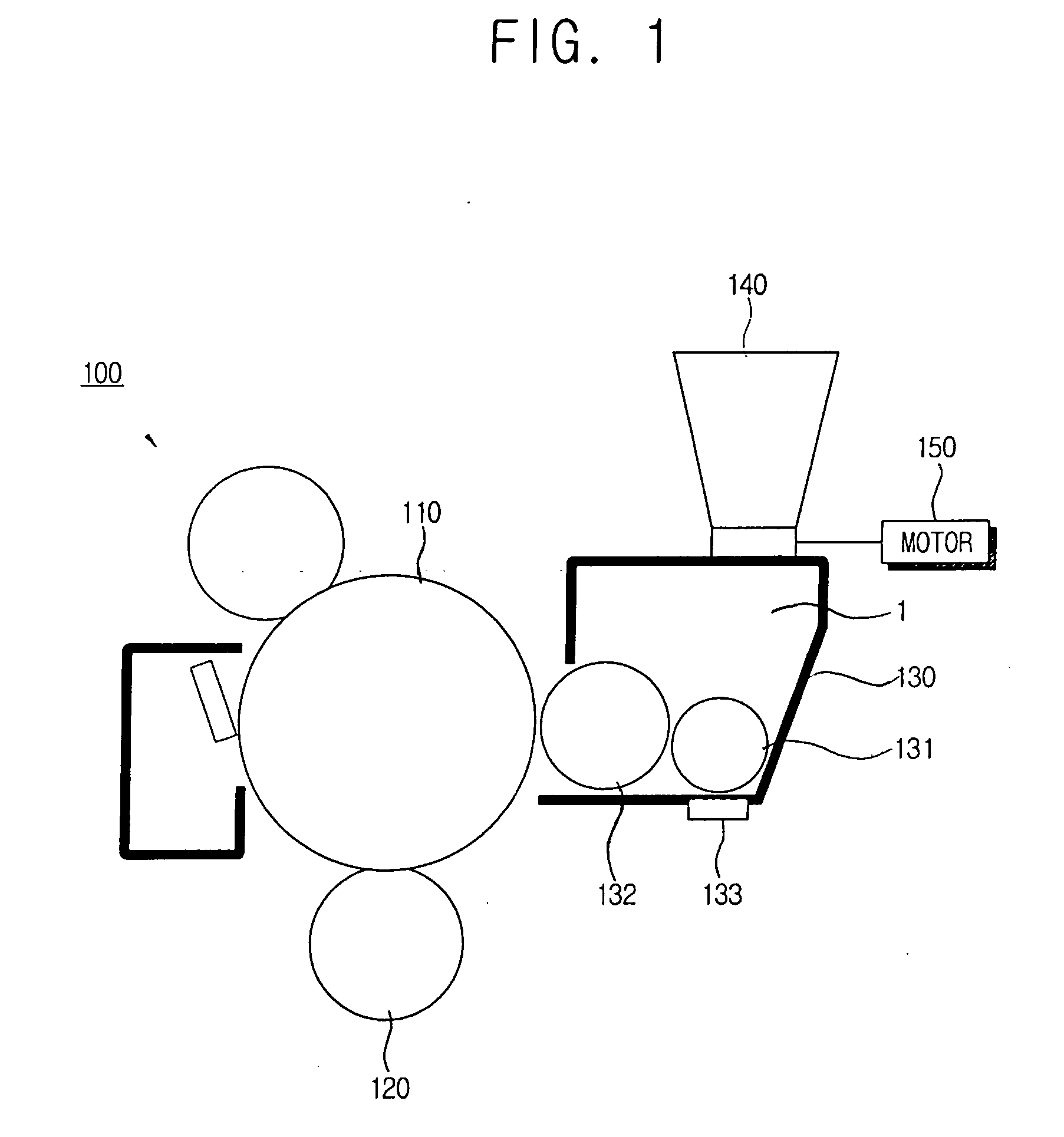

Image forming apparatus, toner density control method, toner density control program and storage medium for storing the program

InactiveUS7450867B2Avoid oversupplyPerform toner supply without time delayElectrographic process apparatusImage formationProcess engineering

Owner:SHARP KK

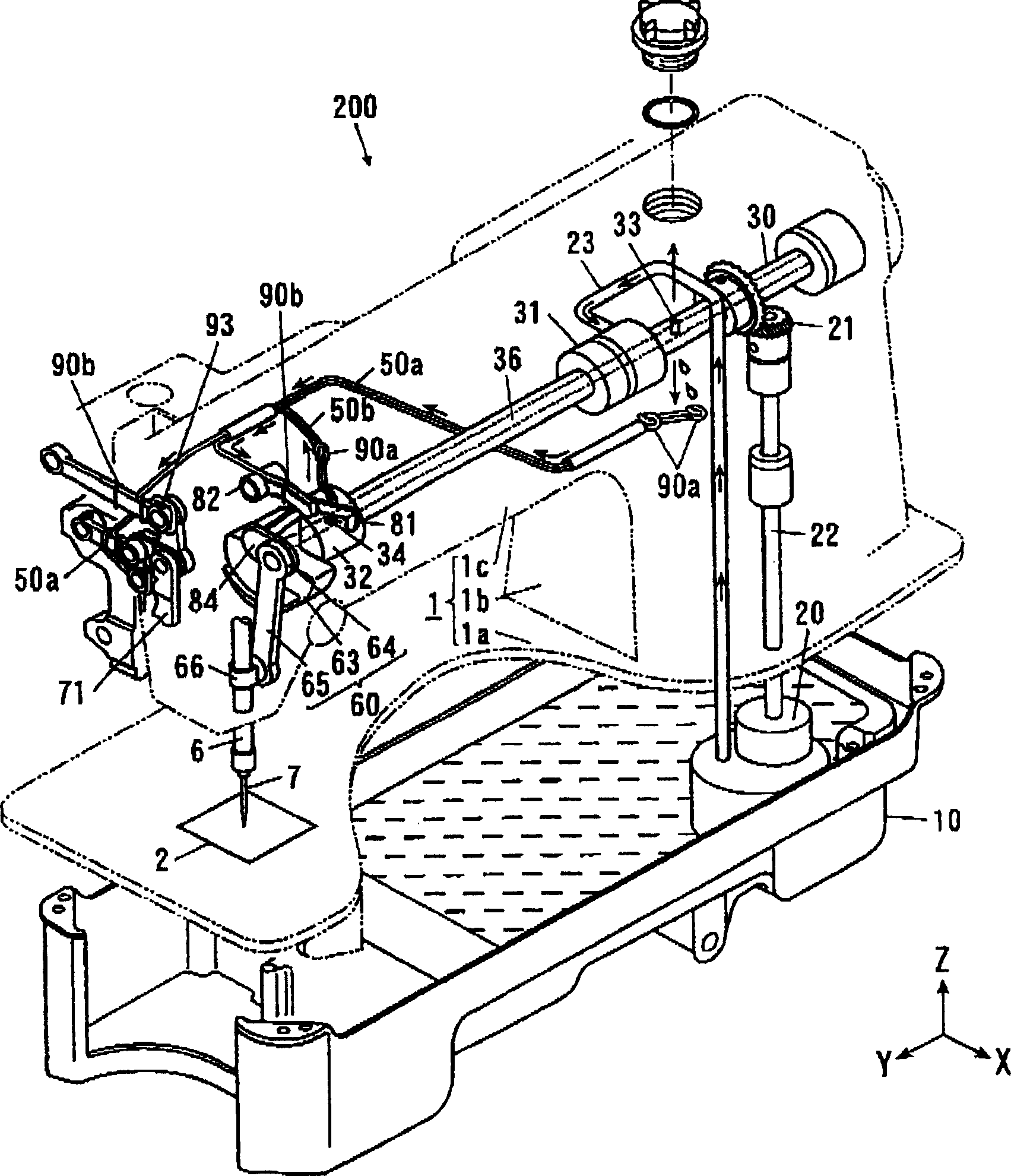

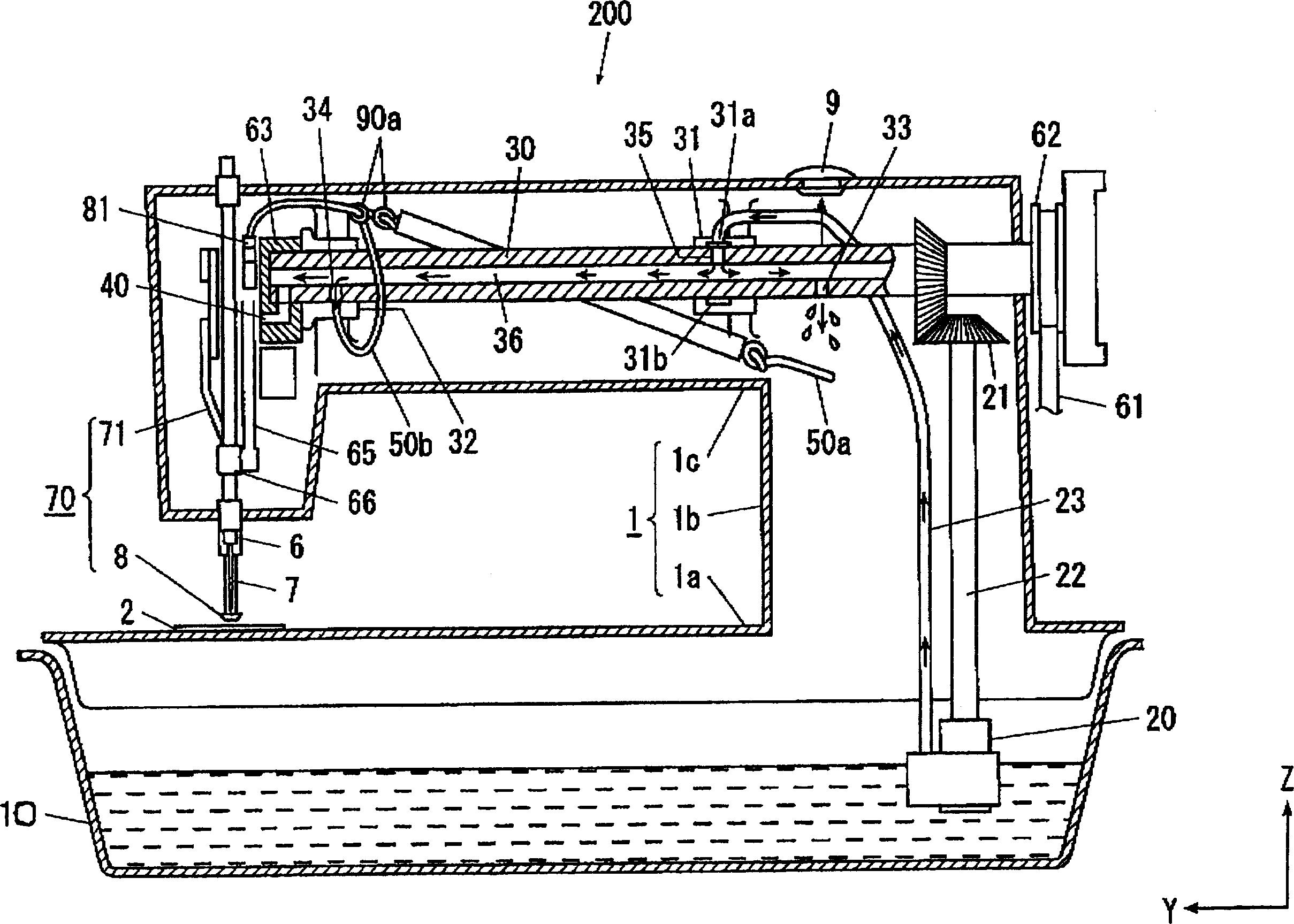

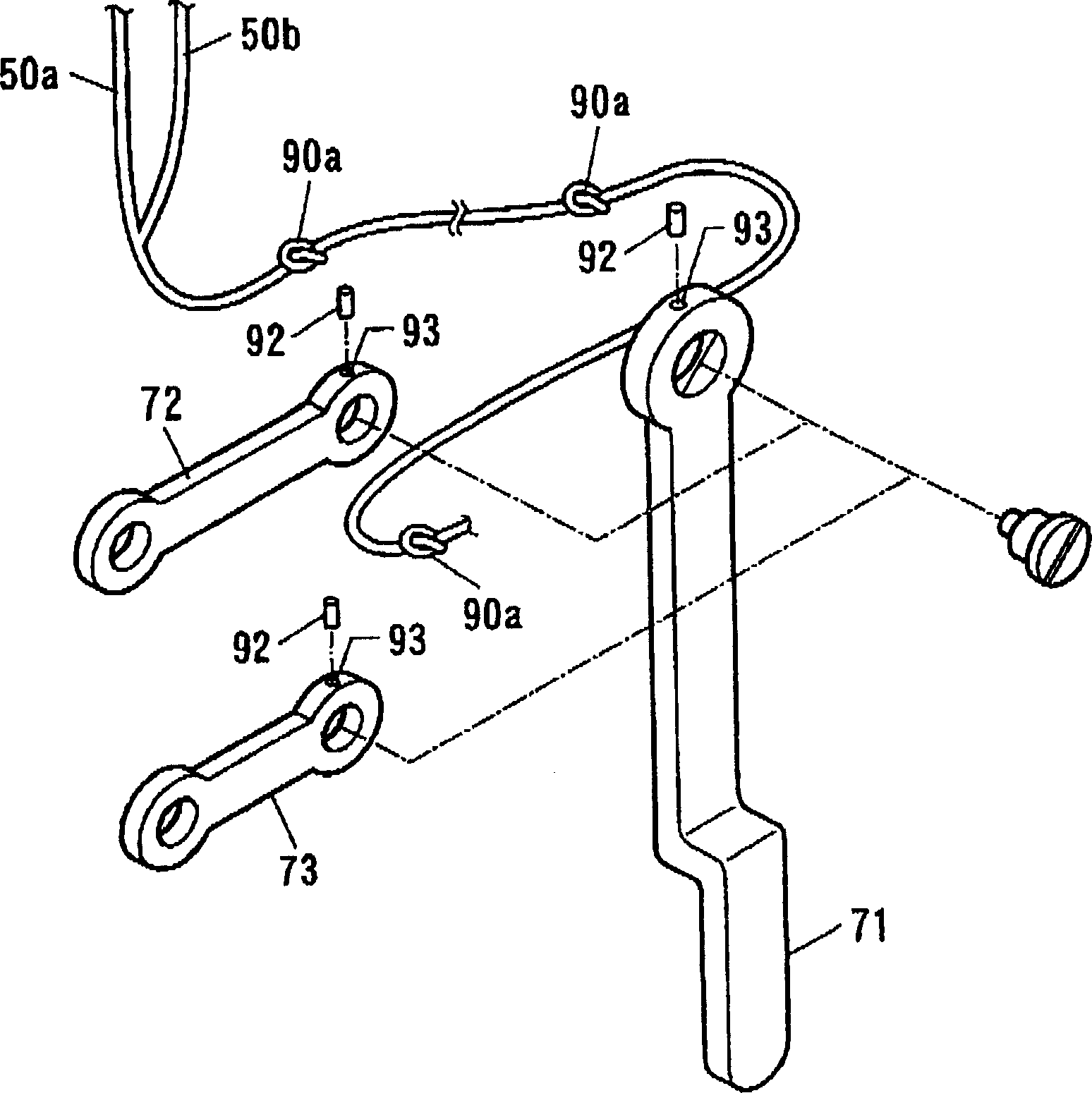

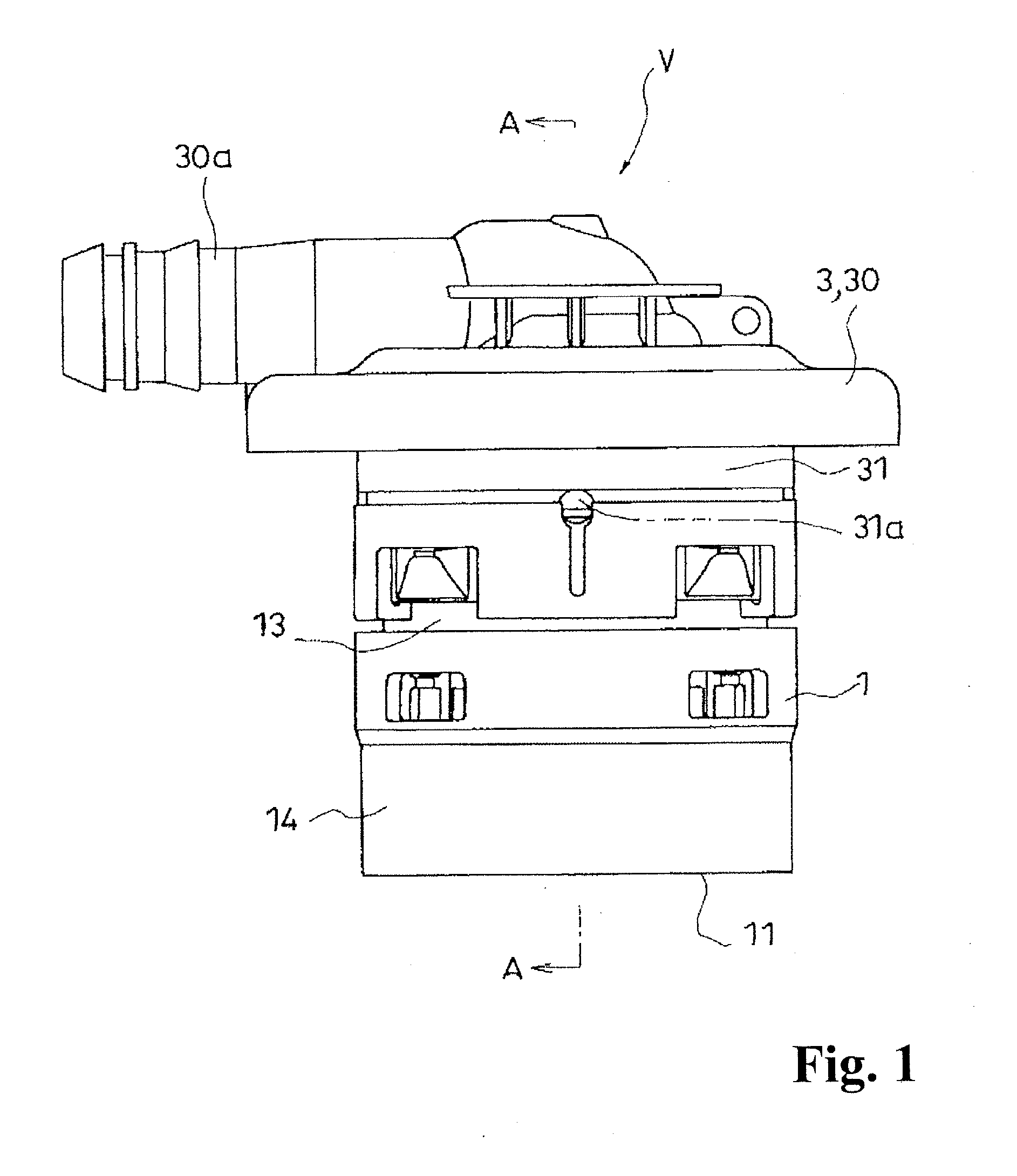

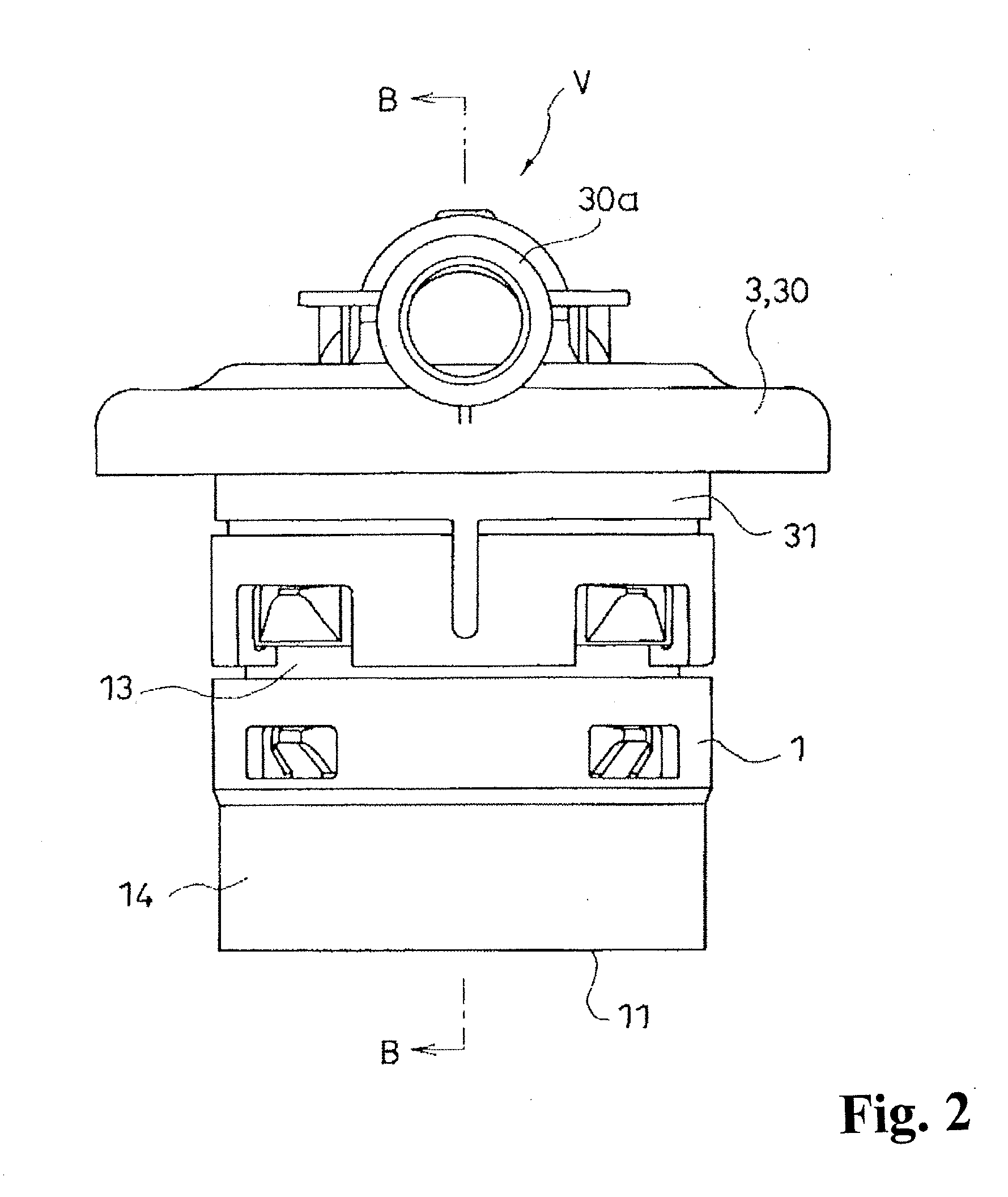

Oil feeding device of sewing machine

The present invention provides an oil supply device for a sewing machine capable of stably supplying lubricant. The oil supply device (100) of the sewing machine has: an oil pan (10) as a lubricant storage part for storing lubricant supplied to each part of the sewing machine (200); An oil supply pump (20) as a delivery device for the lubricant in the disc (10); an upper shaft (30) as a rotating shaft for supplying lubricant to its interior by the oil supply pump (20); communicated with the inside of the upper shaft and Lubricant supply channel (40) for oil supply part; lubricant is supplied from upper shaft (30) to first and second oil core members (50a, 50b) of oil supply part by capillary phenomenon. By supplying oil to one end of the first oil core member (50a) from the first discharge hole (33) formed on the upper shaft (30), excessive oil supply when the sewing machine (200) stops can be prevented.

Owner:JUKI CORP

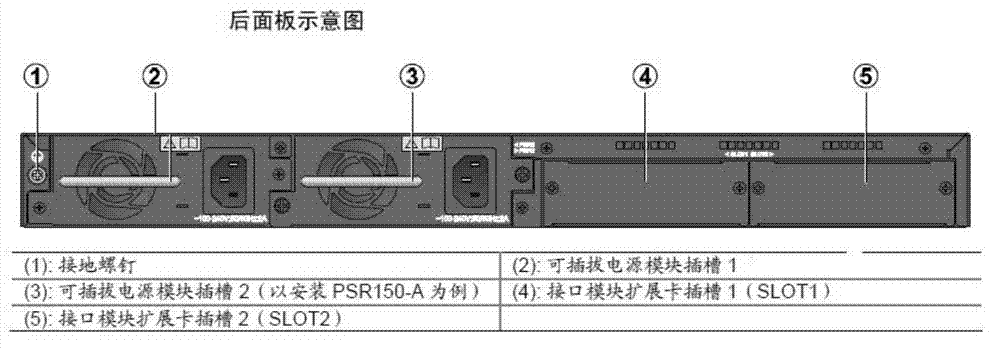

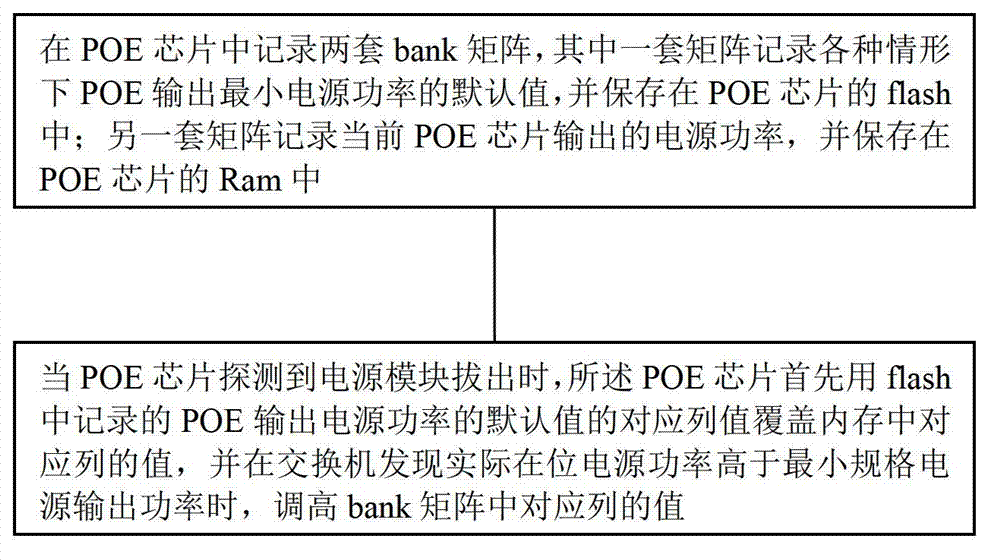

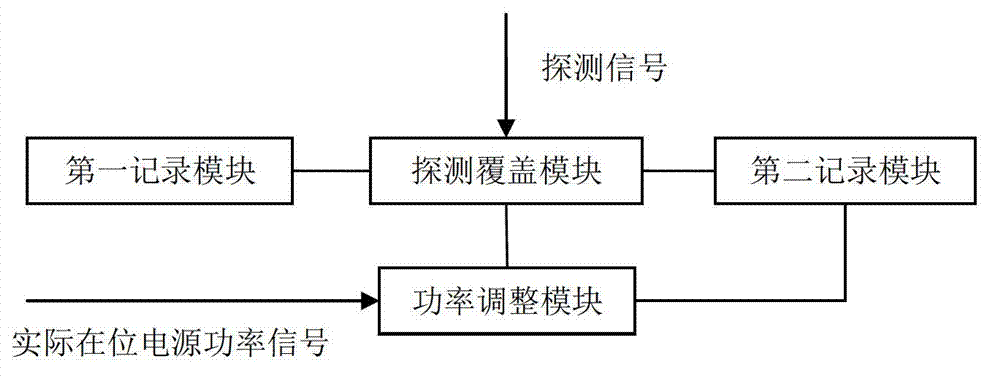

Method and device for preventing over-supply of pluggable power supply

ActiveCN102833079AMake full use of powerAvoid oversupplyData switching current supplyRandom access memoryComputer module

The invention discloses a method and a device for preventing over-supply of a pluggable power supply. According to the method, two sets of bank matrixes are recorded in a POE (Power over Ethernet) chip, wherein a default value of minimum power supply power output by the POE under various conditions is recorded in one set of matrix and is stored in a flash memory of the POE chip; power supply power output by the current POE chip is recorded in the other set of matrix and is stored in an Ram (Random access memory) of the POE chip; and when the POE chip detects that a power module is pulled out, the POE chip covers a corresponding column value in the Ram with a corresponding column value of the default value of the power supply power output by the POE recorded in the flash memory and the corresponding column value in the bank matrix is increased when a switch discovers that the actual in-situ power supply power is higher than the minimum specification power supply output power. According to the method and the device, network equipment can simultaneously support pluggable power supplies of various different powers, the power supply power is fully utilized, and meanwhile, a condition of over-supply of the power supply is prevented.

Owner:NEW H3C TECH CO LTD

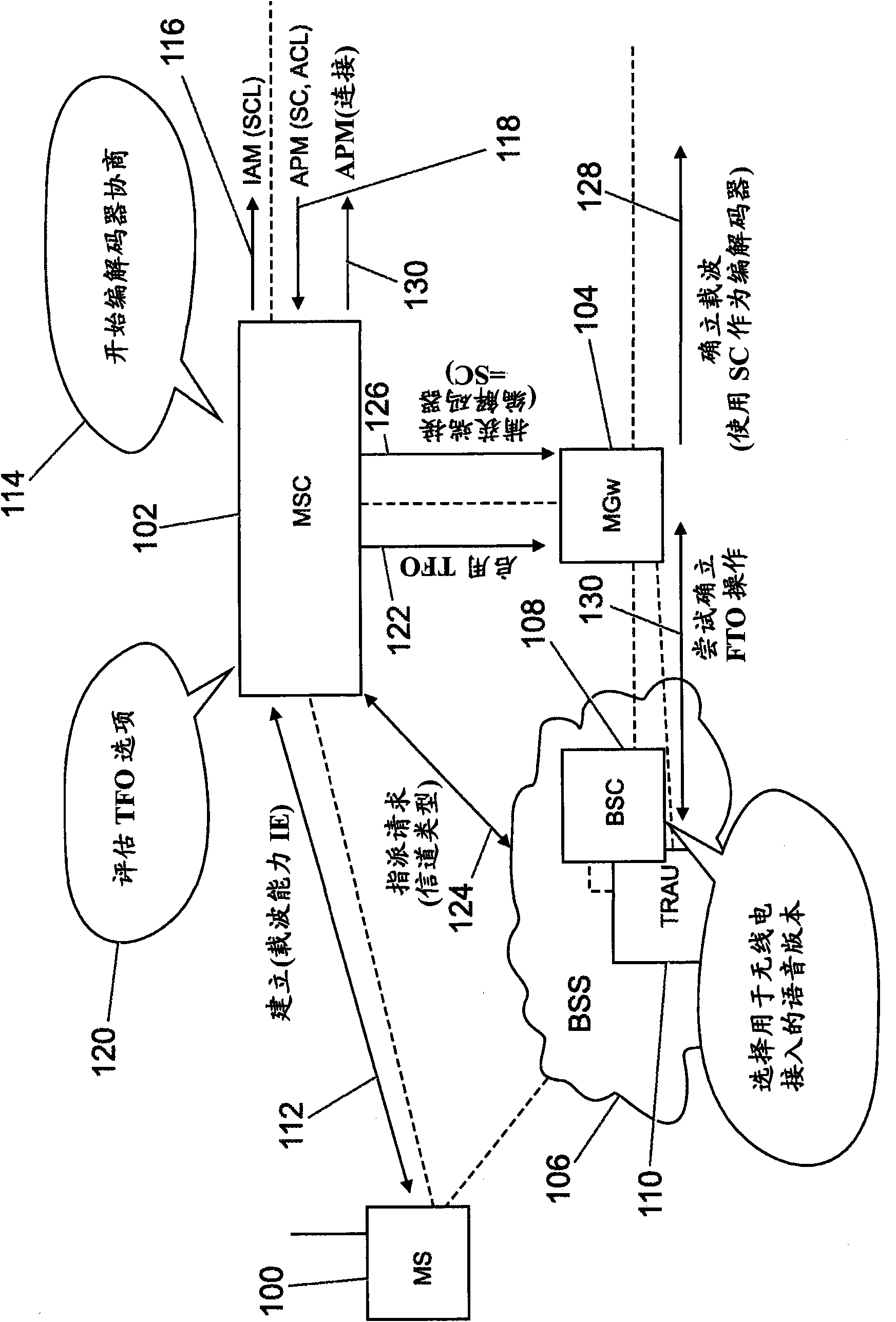

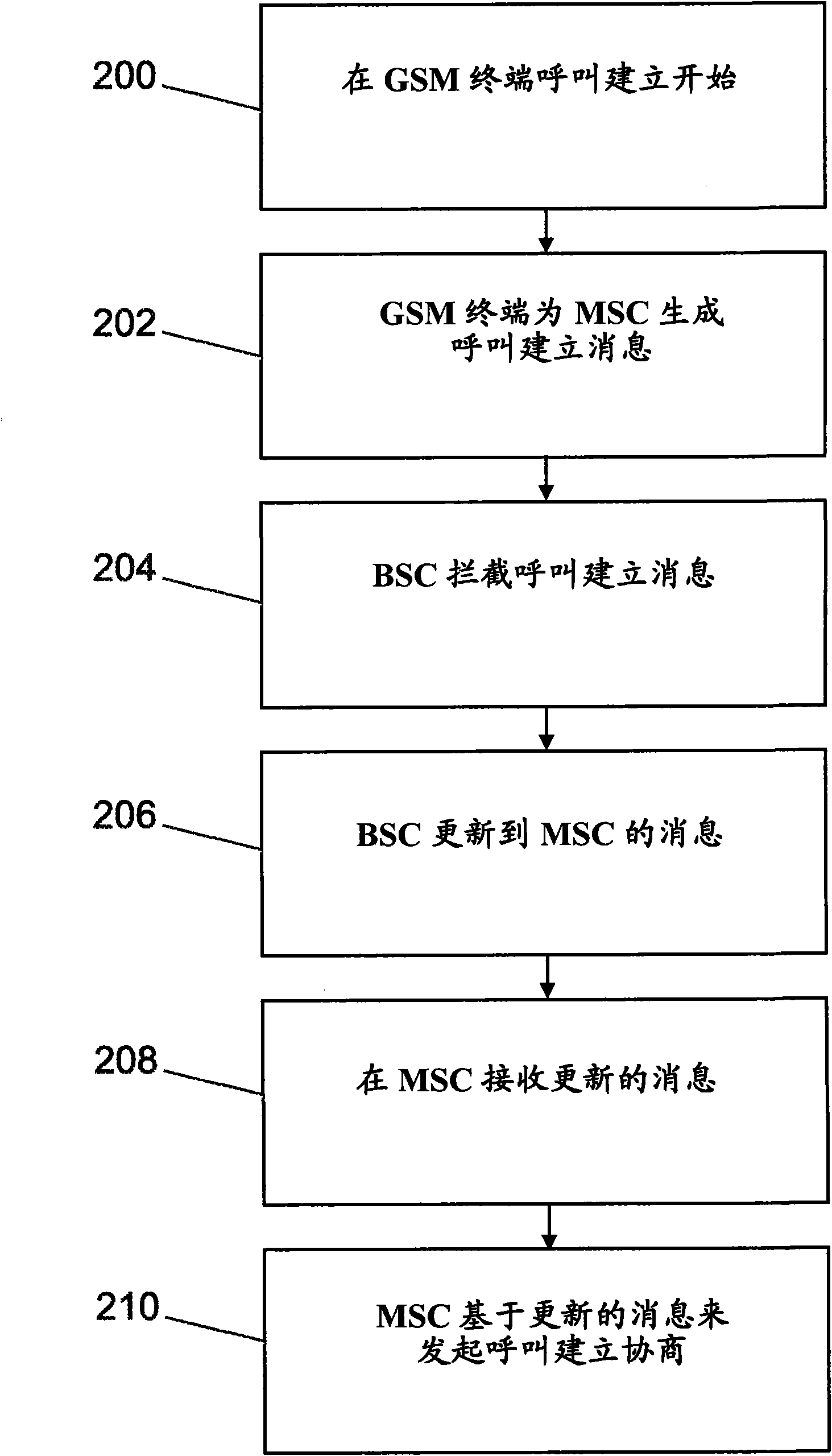

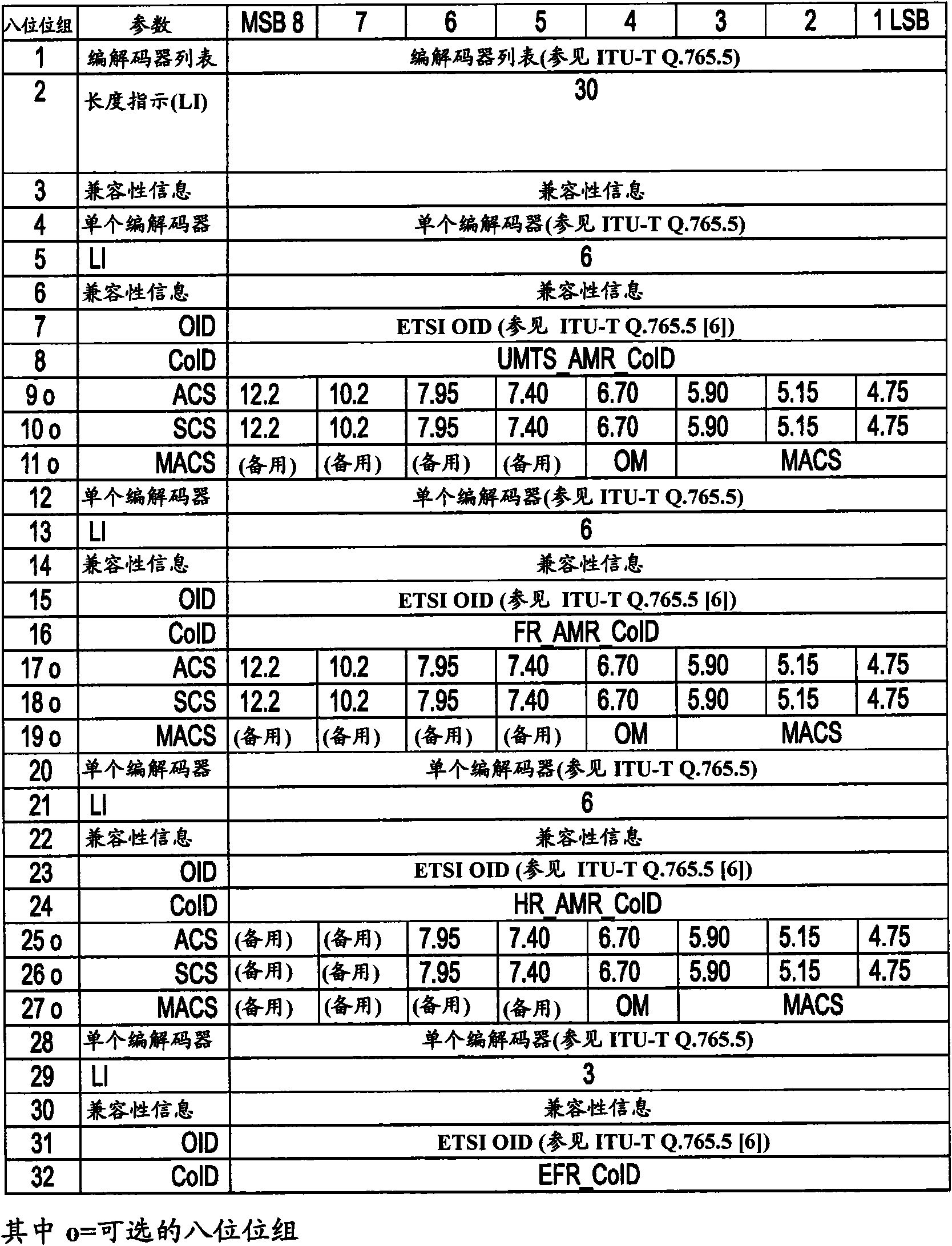

Improvements in or relating to codec negotiation and selection

InactiveCN101822093AEasy to operateAvoid oversupplyNetwork traffic/resource managementConnection managementTelecommunicationsMobile station

A method of modifying a call set up message for a call from a first terminal to a second terminal, the call set up message being sent from the first terminal (Mobile Station, MS) to a network node (e.g. MSC server, MSC-S) via an intermediate node (e.g. BSC or RNC) which handles at least some signaling or traffic associated with the call, wherein the network node is responsible for negotiating call set up requirements, the method comprising the steps of : intercepting the call set up message at the intermediate node (indicating codec list); identifying one or more codec preferences and capabilities associated with the intermediate node; modifying (e.g. by appending, removing, deleting, inserting or reordering the list) the call set up message based on information relating to said preferences or capabilities; and sending the modified call set up message to the network node.

Owner:TELEFON AB LM ERICSSON (PUBL)

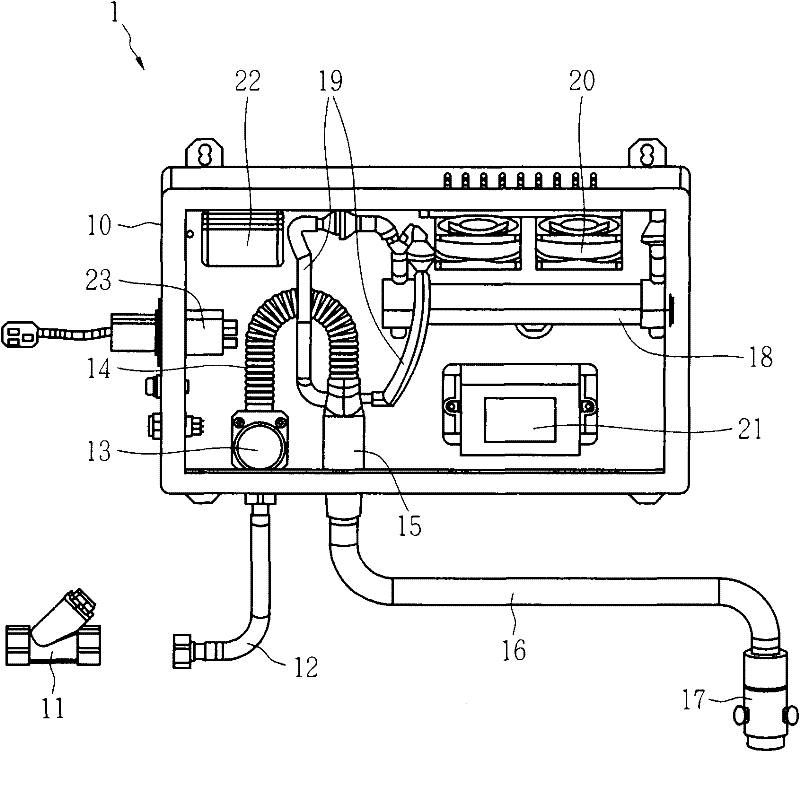

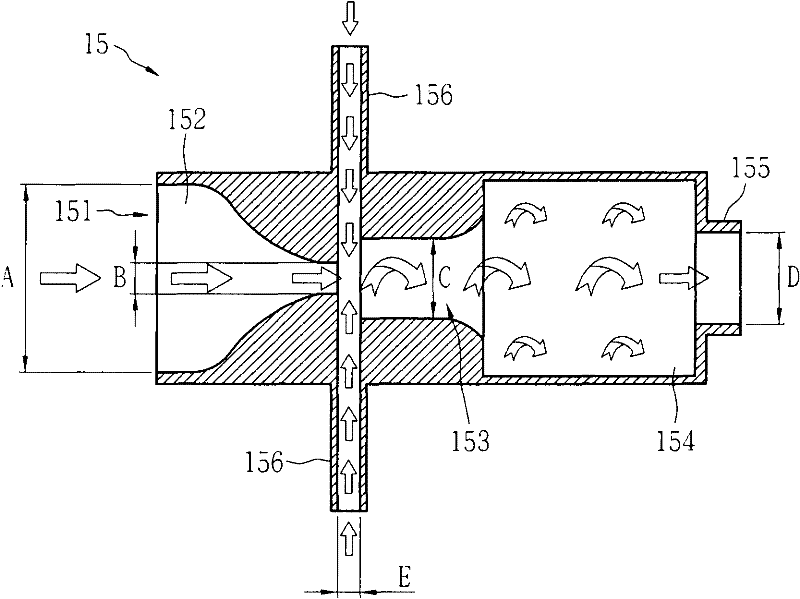

Ozone water manufacturing device

InactiveCN102125812AAvoid oversupplyAvoid pressure lossFlow mixersMixing methodsOzone generatorEnvironmental engineering

The invention relates to an ozone water manufacturing device. The ozone water manufacturing device comprises a mixer and an ozone generator. The mixer comprises a water inlet, a water outlet pipeline, a reducing pipeline, an import part and a mixing cavity. The reducing pipeline is arranged close to the water inlet, the mixing cavity is arranged close to the water outlet pipeline, the import part is arranged between the mixing cavity and the reducing pipeline, and the ozone generator is coupled with the import part. The mixer disclosed by the invention has the advantages of being capable of avoiding surplus ozone supply, avoiding pressure loss and fully mixing water and ozone.

Owner:XIAMEN TAHOE WATER SYST

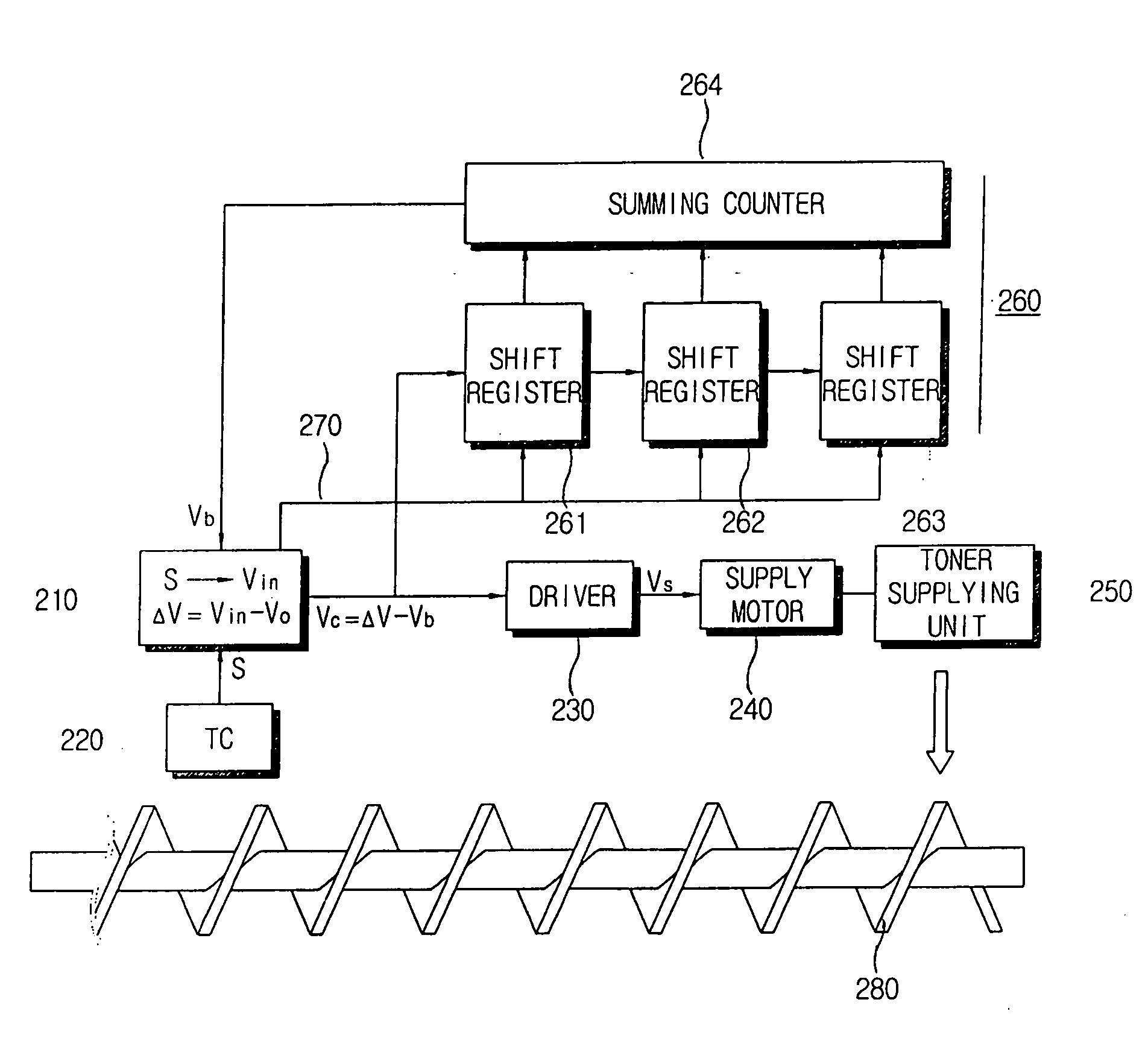

Image forming apparatus capable controlling toner supply

InactiveUS20070053704A1Avoid oversupplyElectrographic process apparatusControl signalImage formation

An image forming apparatus, including a toner supplying unit to supply toner, a toner transporting unit to transport the toner supplied from the toner supplying unit, a sensor to sense a density of the toner transported by the toner transporting unit, a compensating signal generating unit to compensate for amounts of the toner pre-supplied by the toner supplying unit, and a control unit to generate a control signal to control the toner supplying unit by receiving a sensing signal of the sensor as an input signal and a compensating signal of the compensating signal generating unit as a feedback signal.

Owner:S PRINTING SOLUTION CO LTD

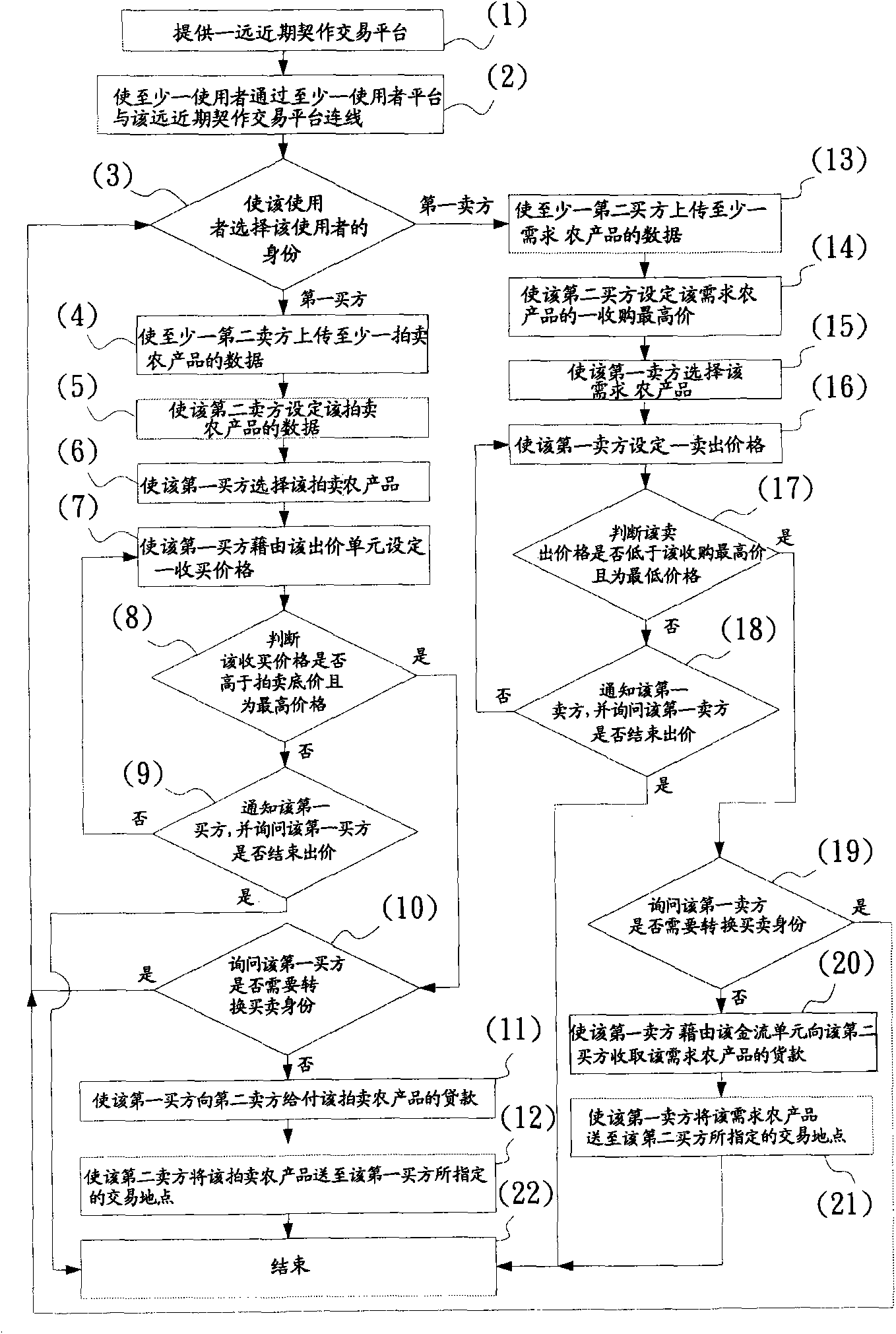

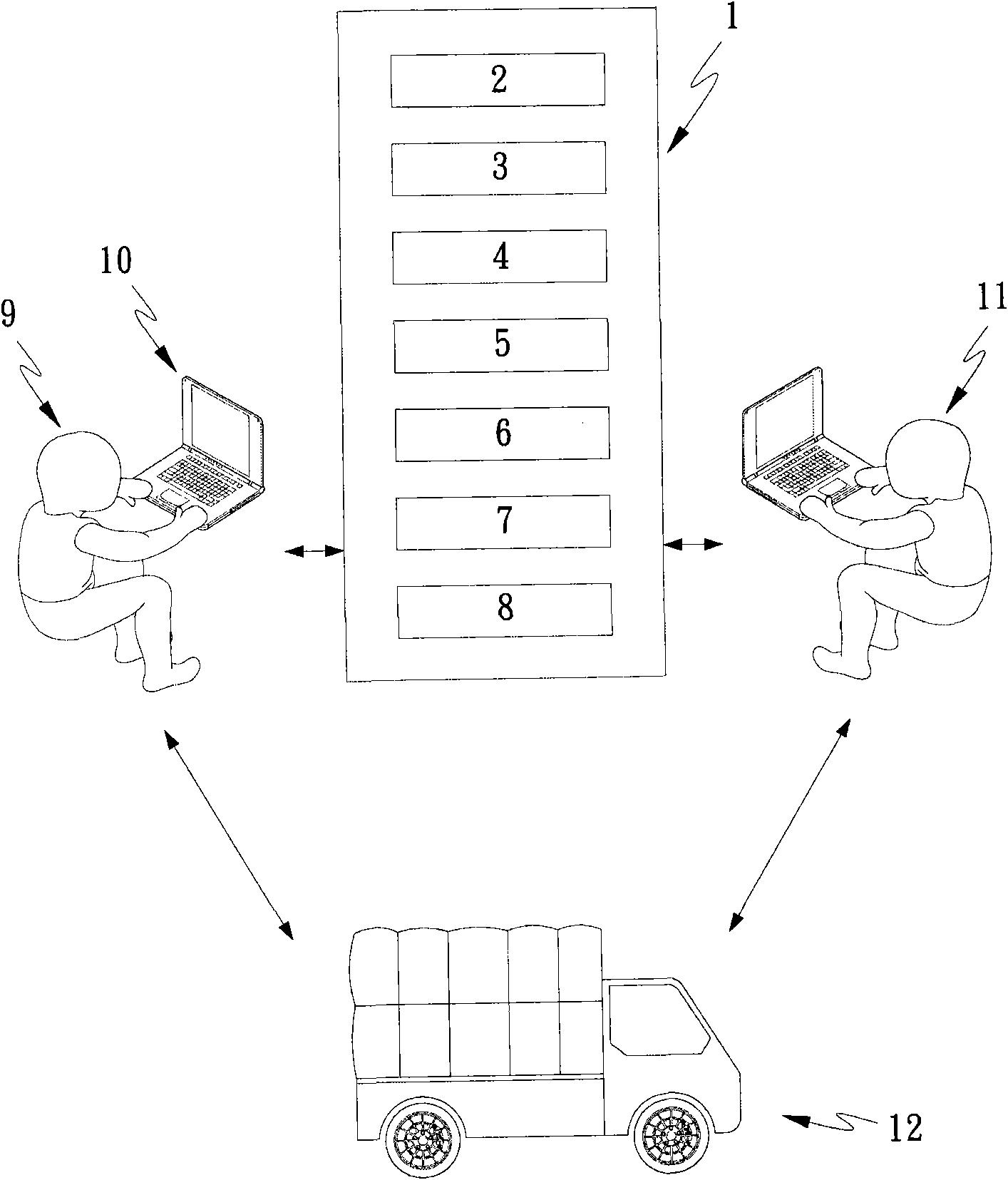

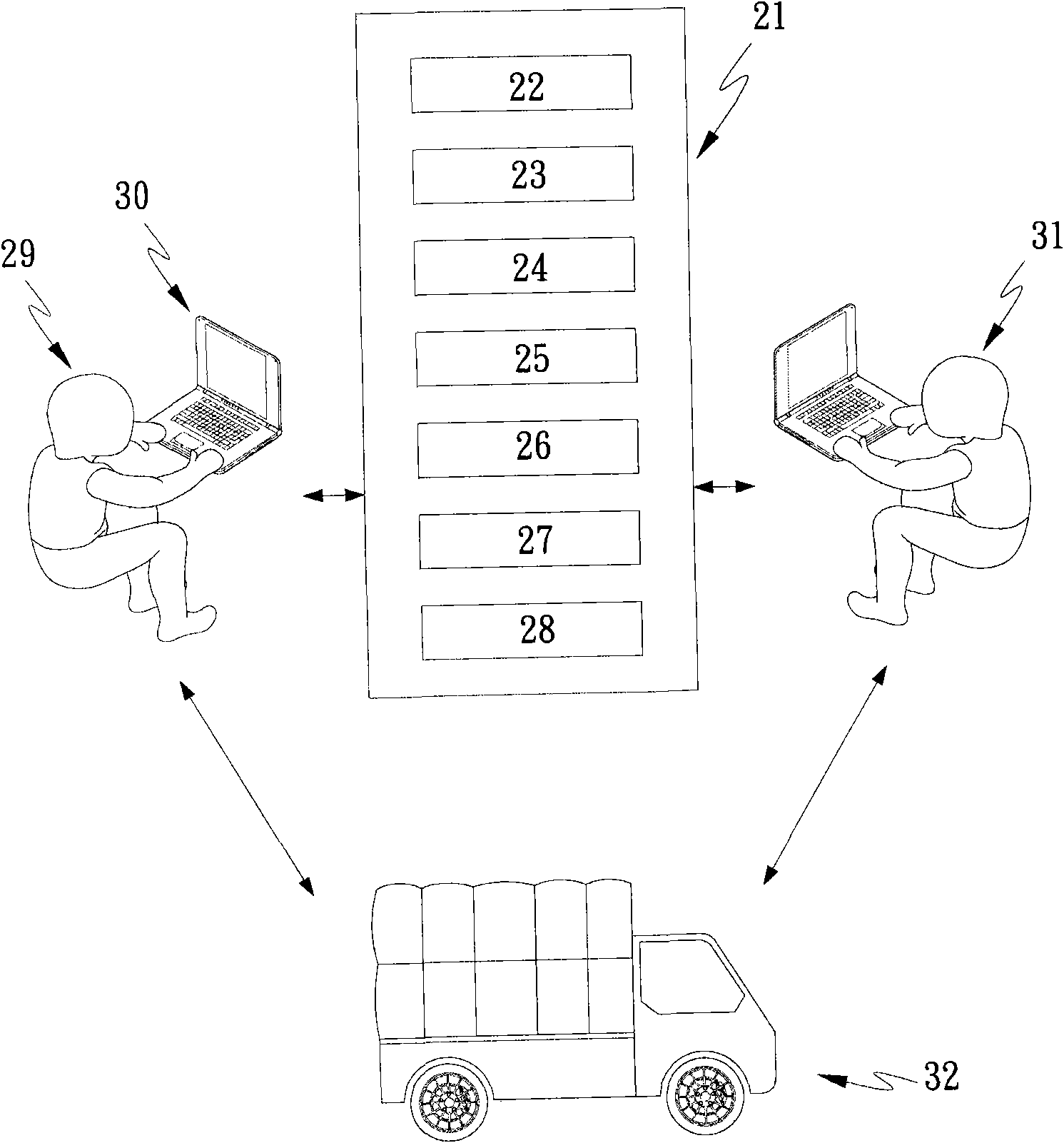

Method for transacting agricultural products by long-term and short-term combined transaction platform

The invention relates to a method for transacting agricultural products by a long-term and short-term combined transaction platform, which comprises the following steps: a long-term and short-term combined transaction platform is provided, so that at least one seller and at least one buyer are connected on line by at least one user platform and the long-term and short-term combined transaction platform; after the transaction is completed, the identifications of the seller and the buyer can be changed according to the conditions, and the agricultural products are put on shelves for the subsequent auction. Thus, the risk of the cultivators can be shared by the market; the output forecast and the regulation of supply and demand can reduce the risk of the unsalable agricultural products; the transportation distance for the agricultural products can be shortened; the transaction of the agricultural products can be advanced prior to the cultivation so as to realize the transaction in advance; the agricultural products can be transacted many times; and the economic scale can be enlarged.

Owner:陈 淑玲

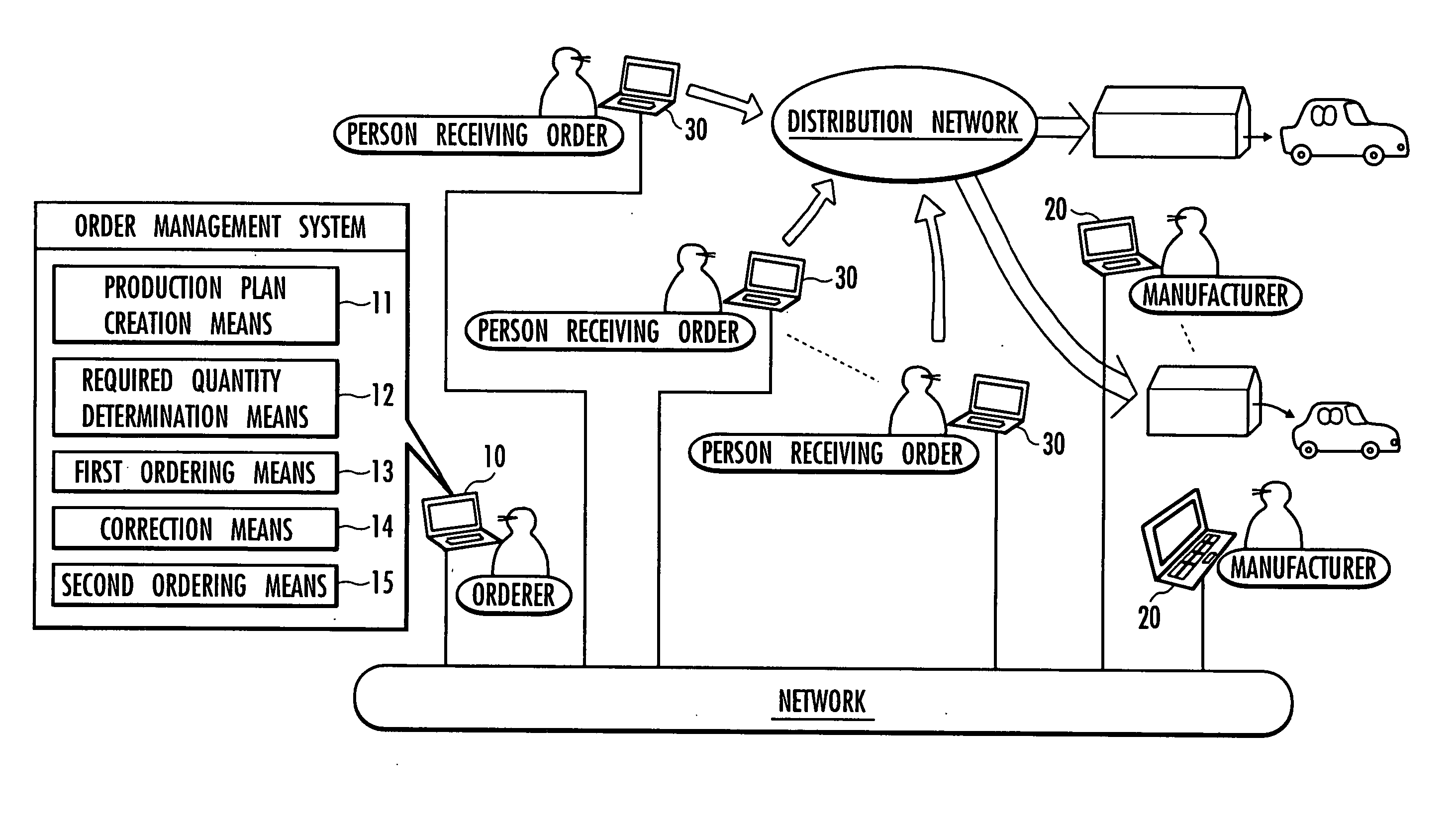

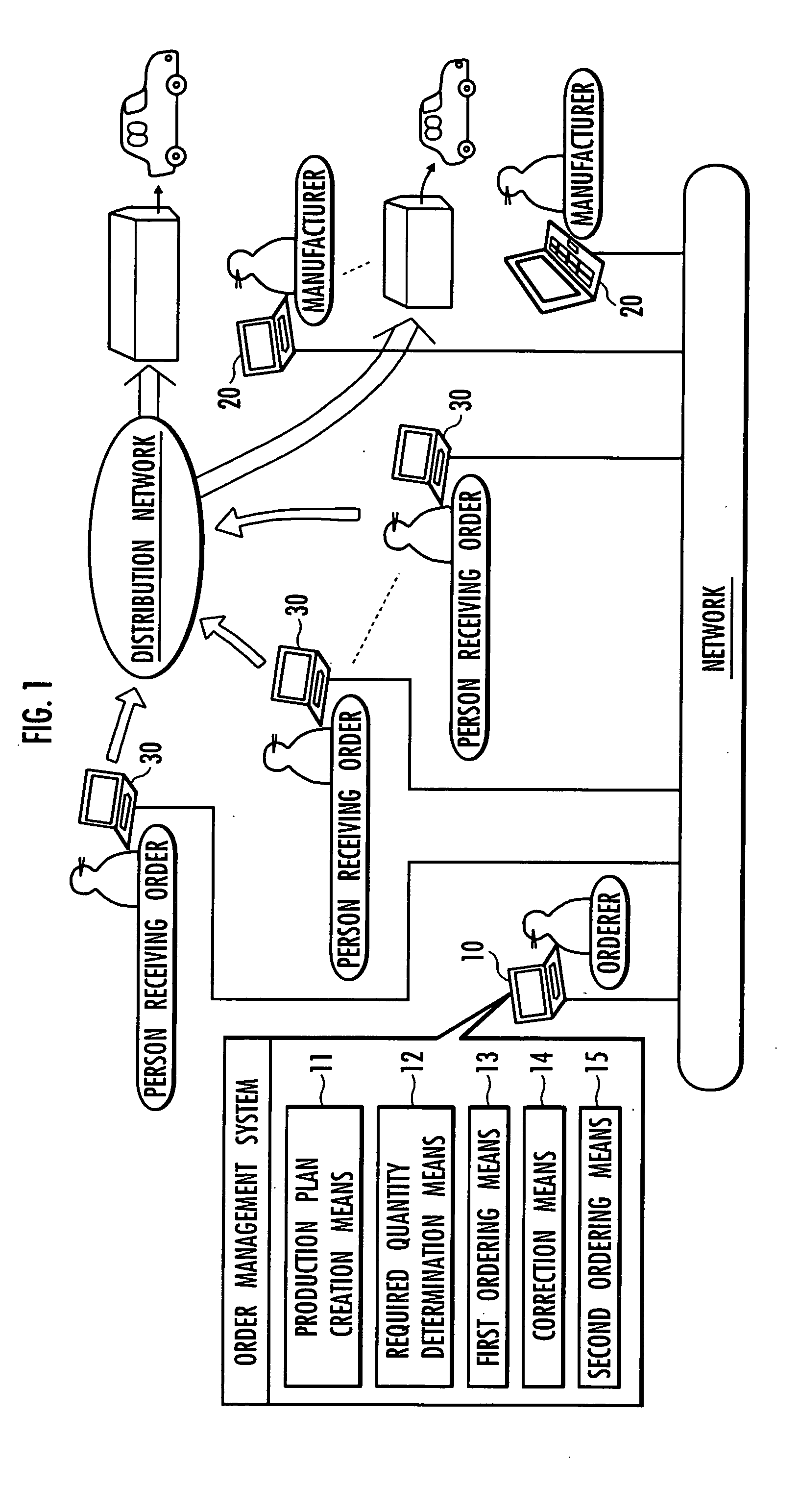

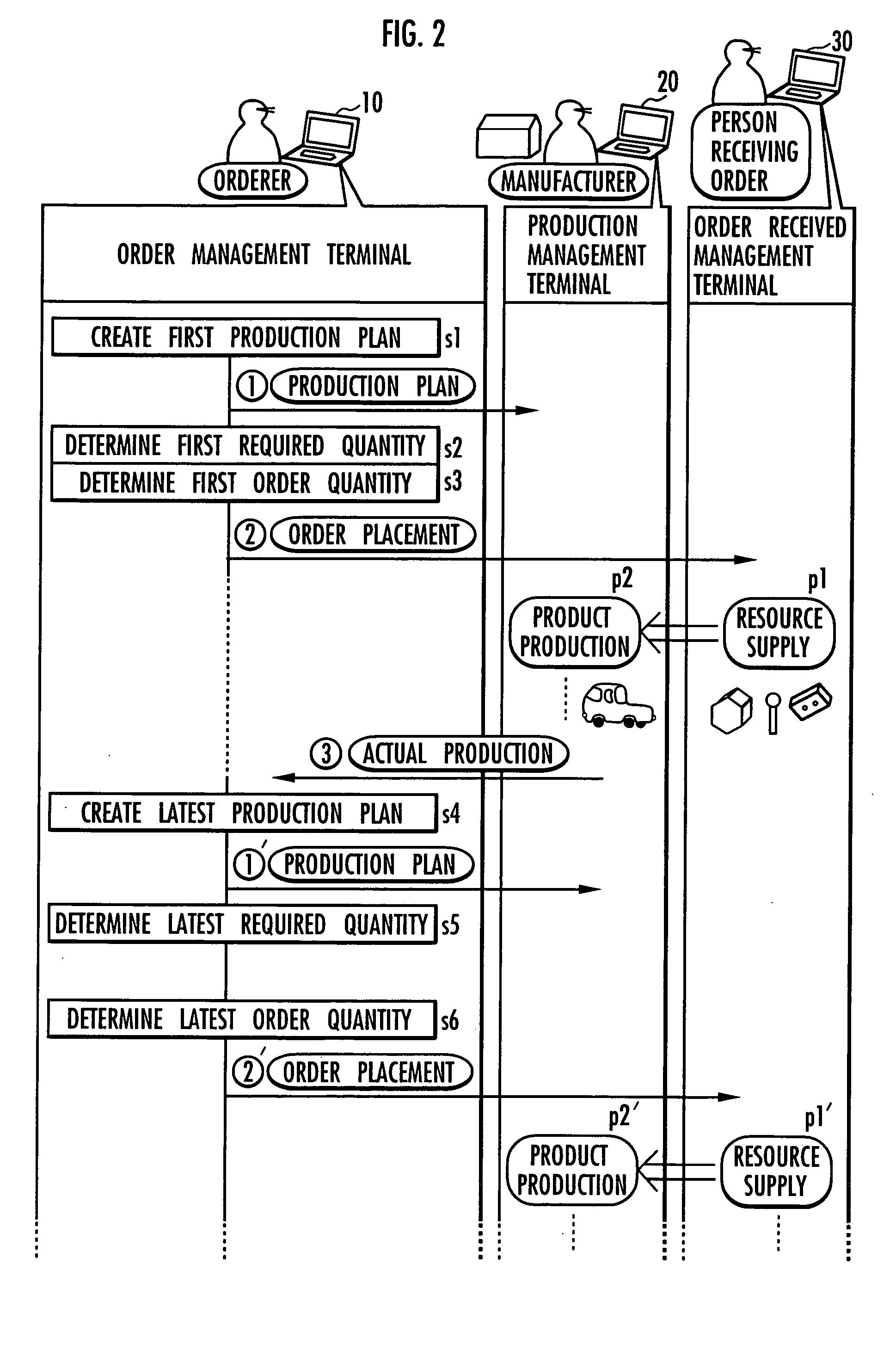

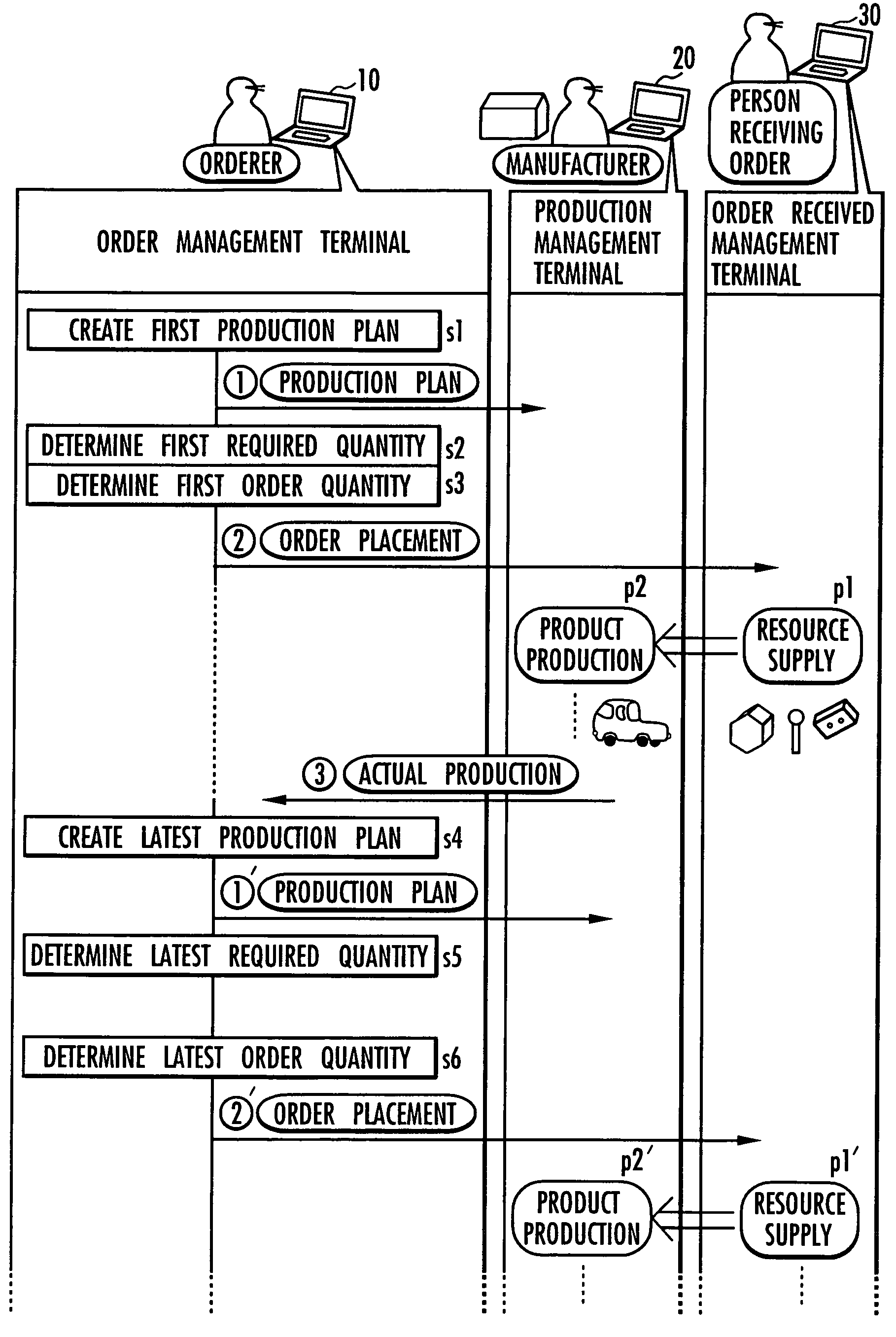

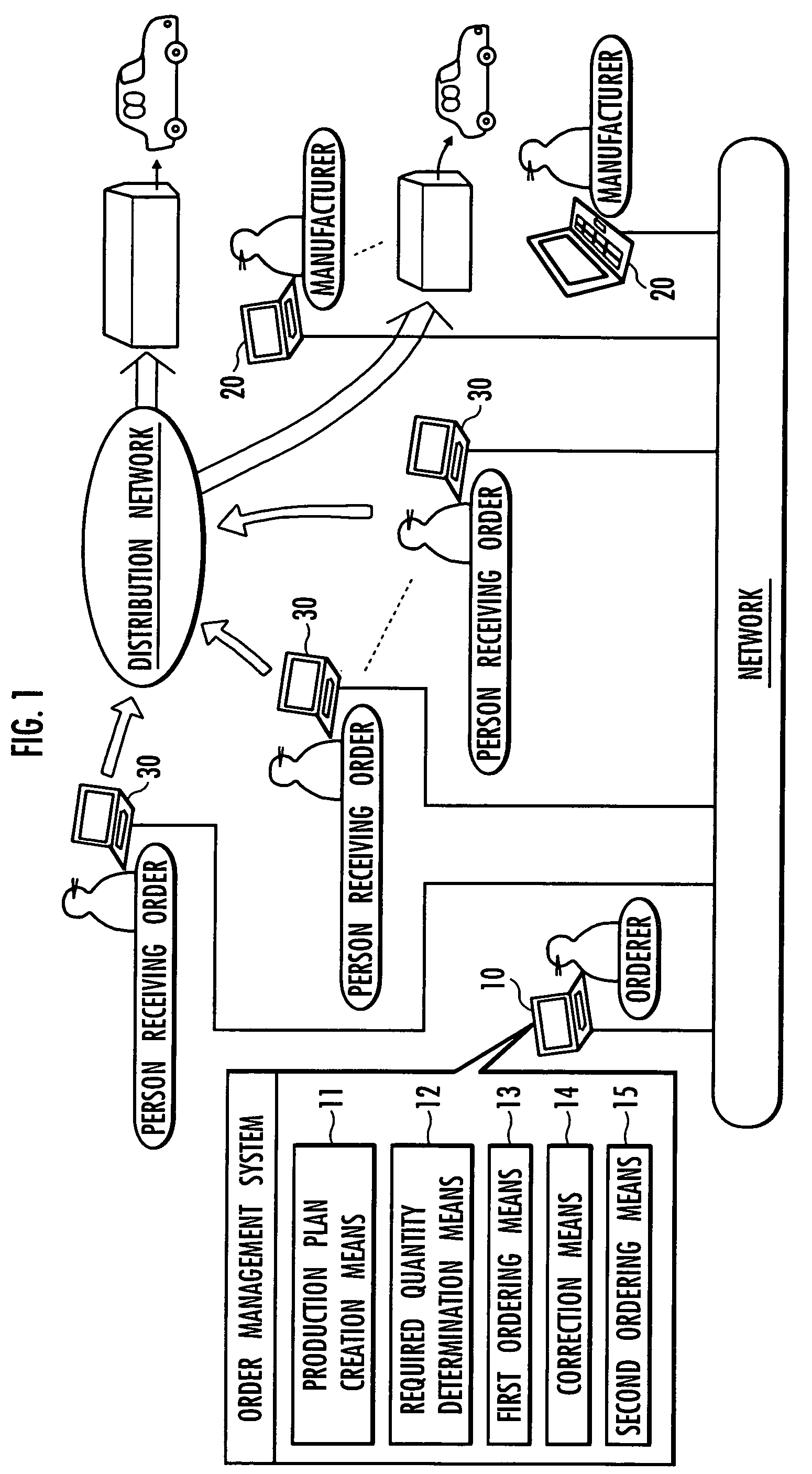

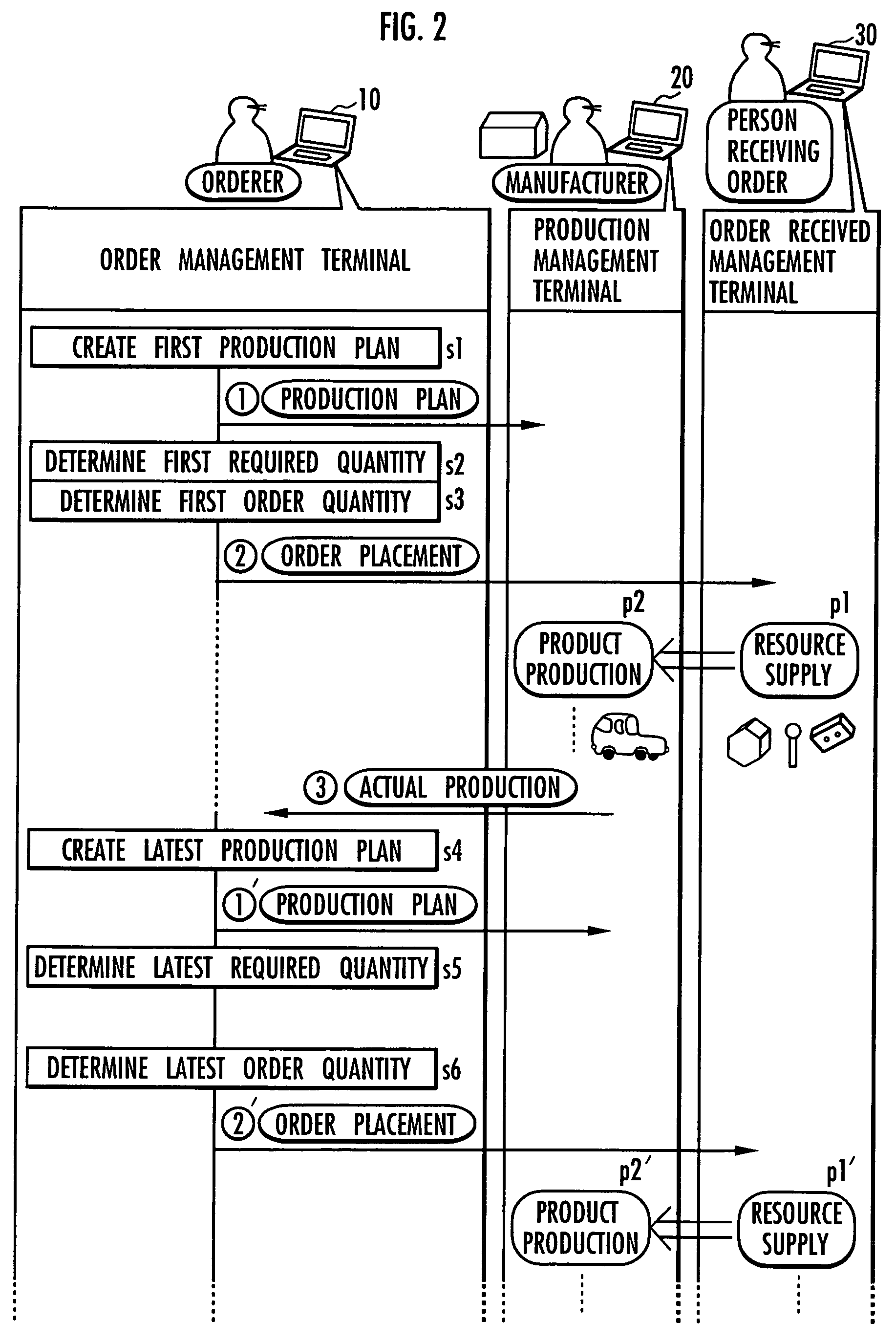

Order management system

InactiveUS20050177536A1Reduce the burden onReduce productionDigital data processing detailsBuying/selling/leasing transactionsOrder management systemOrder form

A system capable of managing orders of resources so that order quantities of resources for production of products are properly determined with consideration given to various conditions of a person receiving orders. In this system, according to the latest production plan, placed order quantities are corrected based on corrected required quantities for a plurality of periods in “the first predetermined period” and the placed order quantities are modified so as to suppress a fluctuation in the entire order quantity caused by an order quantity fluctuation in the first predetermined period for a plurality of periods in “the second predetermined period.”

Owner:HONDA MOTOR CO LTD

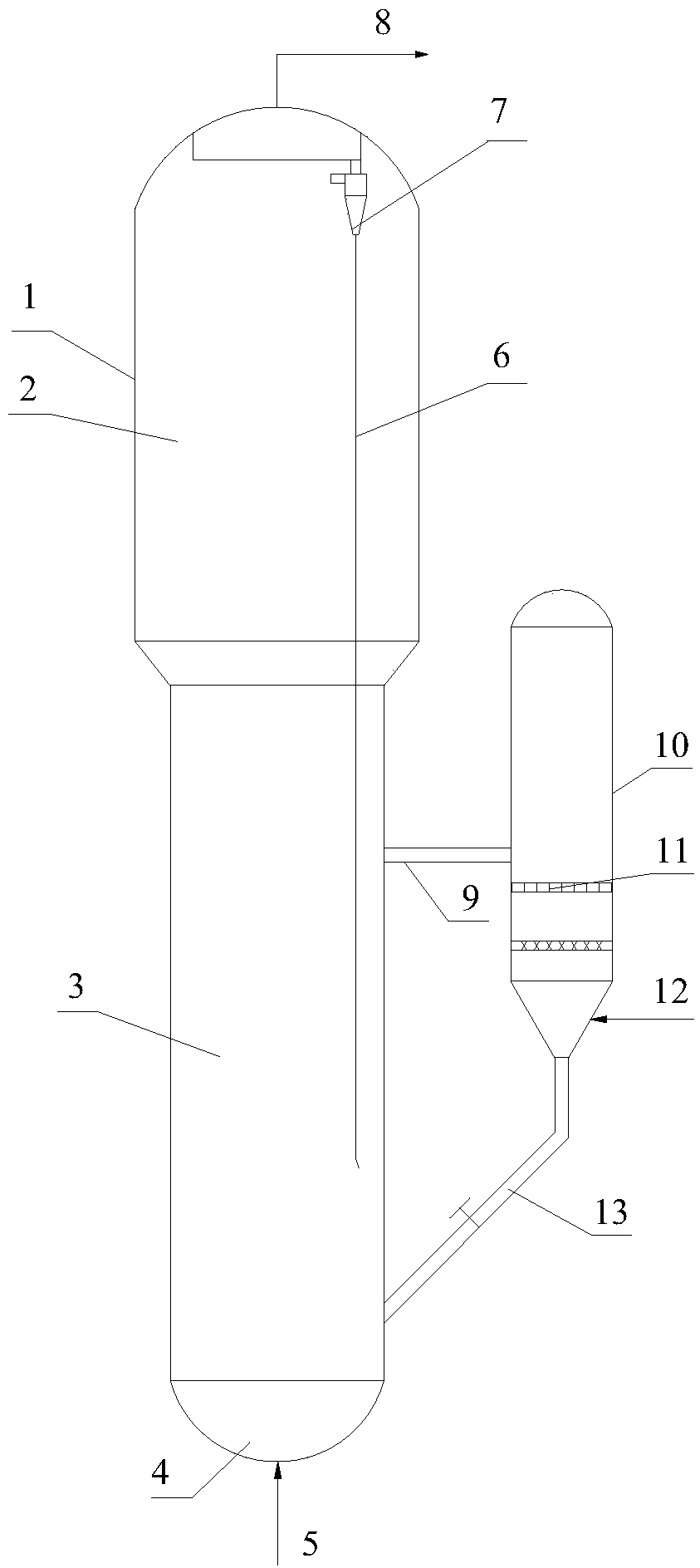

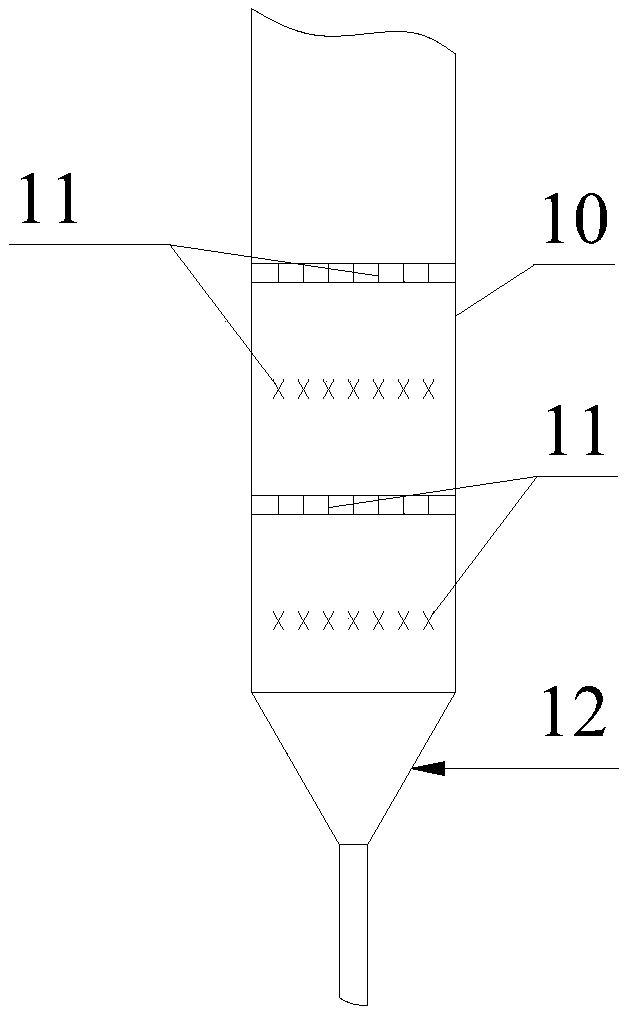

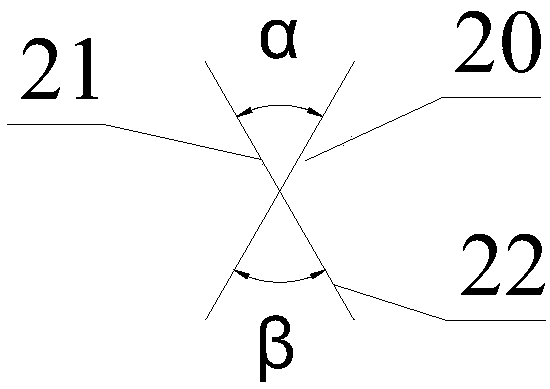

Aromatic hydrocarbon ammoxidation combined fluidized bed reaction device and aromatic hydrocarbon ammoxidation combined fluidized bed reaction method

ActiveCN111111562AHigh yieldAvoid oversupplyPreparation by hydrocarbon ammoxidationChemical recyclingPtru catalystFluidized bed

The invention relates to an aromatic hydrocarbon ammoxidation combined fluidized bed reaction device and an aromatic hydrocarbon ammoxidation combined fluidized bed reaction method. In the prior art,the heat regulation range in the reactor of the existing device is small, the heat collector cannot be repaired on line to keep production after being abraded, the ammonia ratio is large, the air ratio is large and the raw material utilization rate is low. A purpose of the invention is mainly to solve the problems in the prior art. The invention discloses an aromatic hydrocarbon ammoxidation combined fluidized bed reaction device and a reaction method thereof. According to the technical scheme, aromatic hydrocarbon / ammonia is vaporized and then enters a reactor together with air from a gas distribution chamber, an aromatic hydrocarbon ammoxidation reaction is carried out under the action of a catalyst, heat released in the reaction process is brought into an oxygen supply heat exchanger through the catalyst, efficient heat exchange is carried out under the action of a strong mixing member while catalyst lattice oxygen supplementing treatment is carried out, and then the low-temperaturehigh-lattice-oxygen catalyst circularly returns into the reactor to continuously participate in the aromatic hydrocarbon ammoxidation reaction. By adopting the technical scheme, the technical problems are well solved. The device and the method can be used in production of aromatic nitrile by aromatic ammonia oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

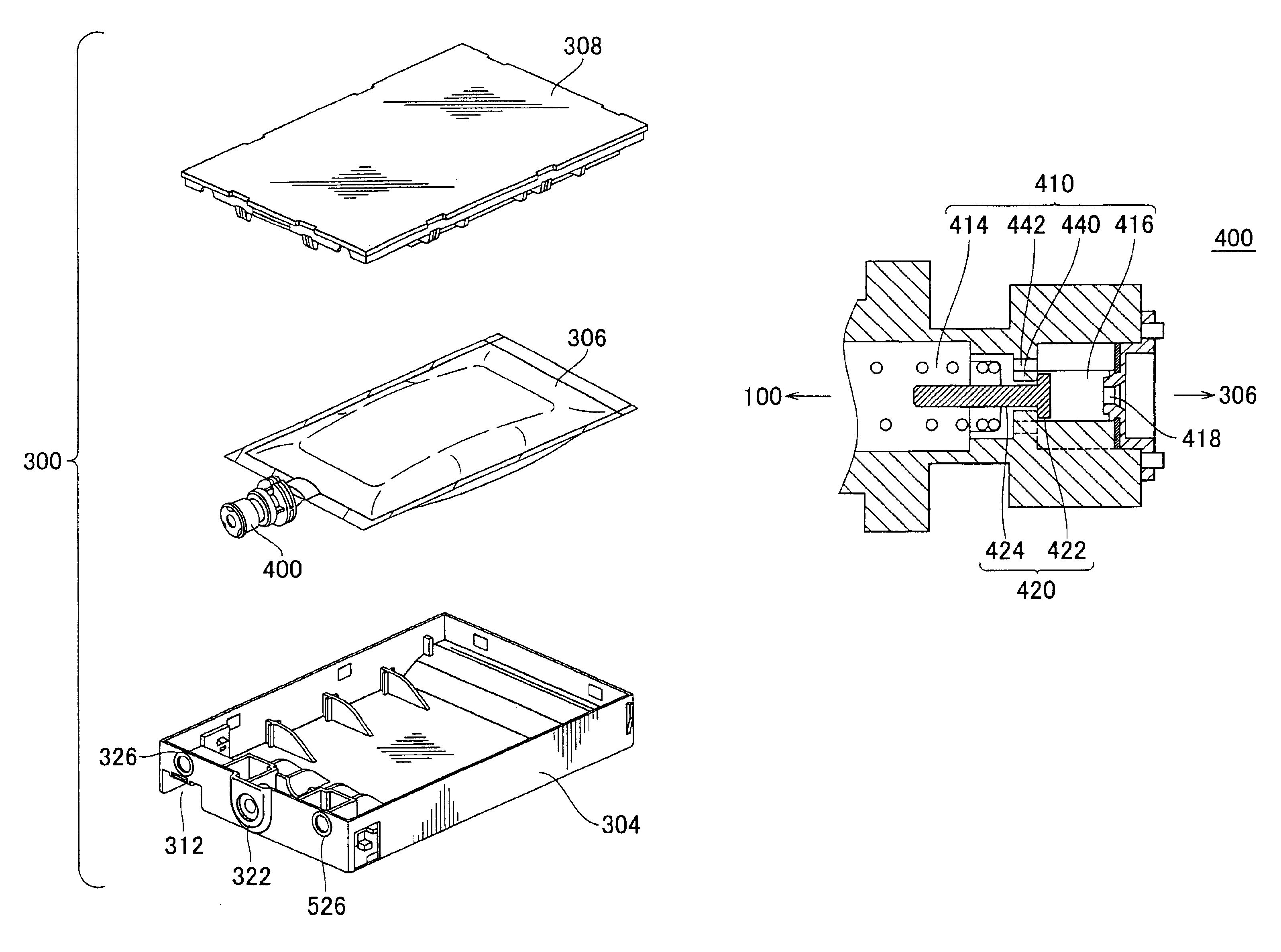

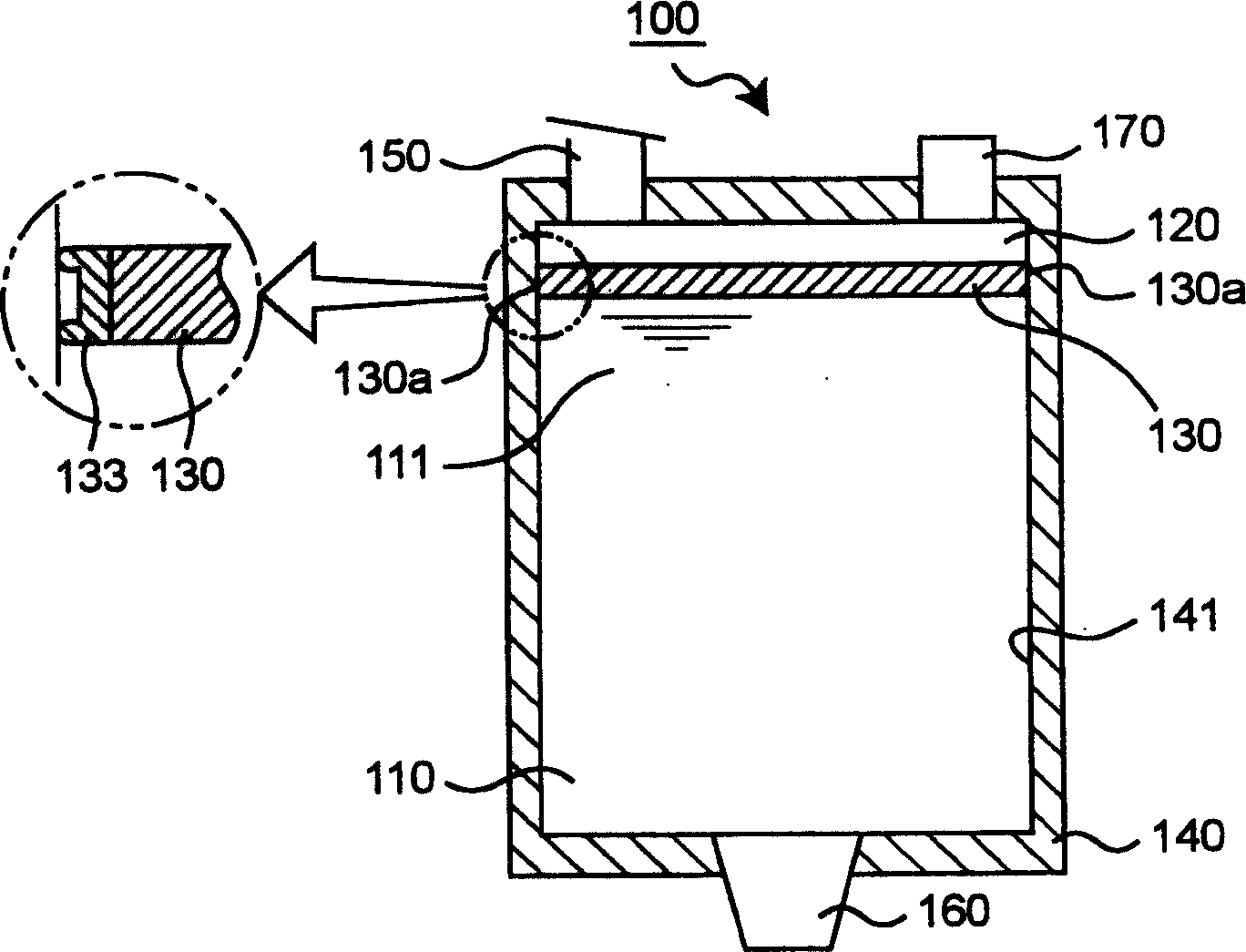

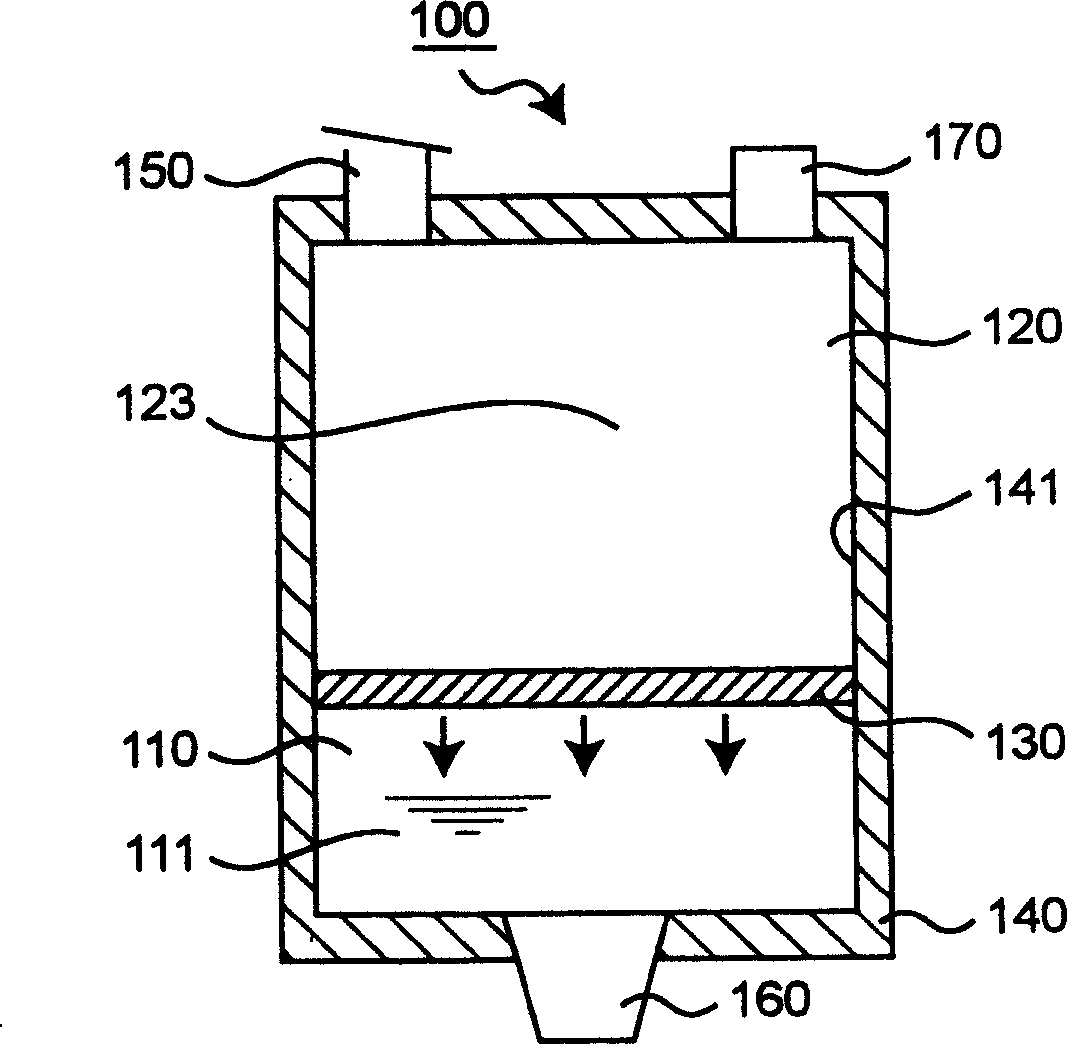

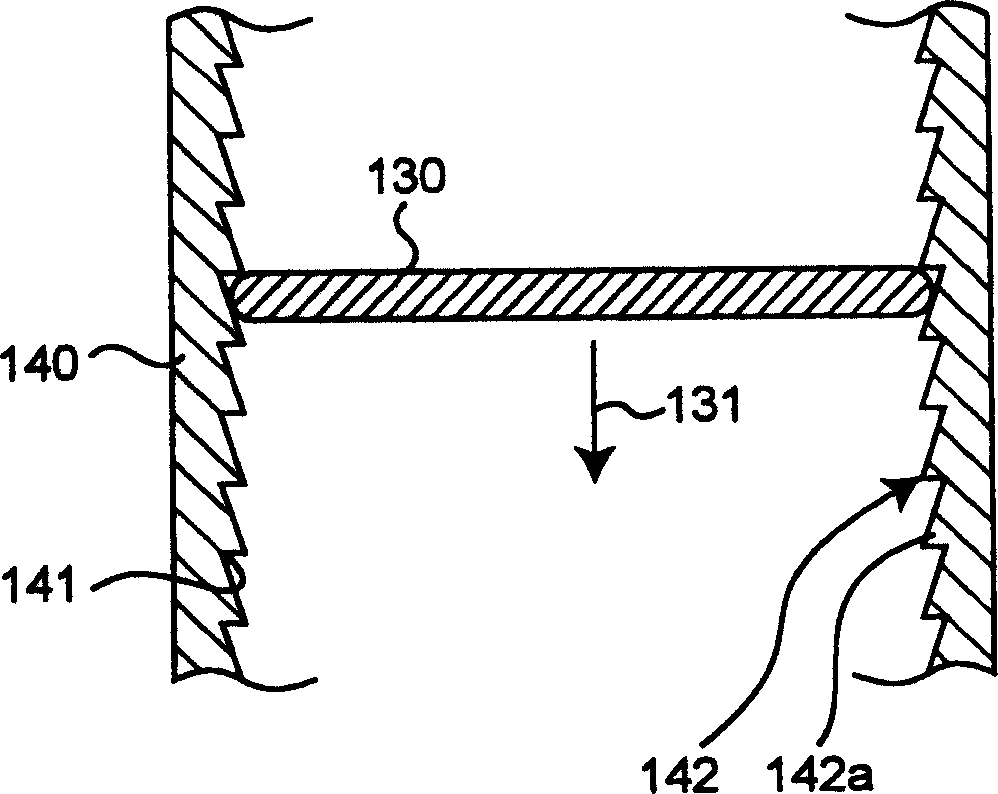

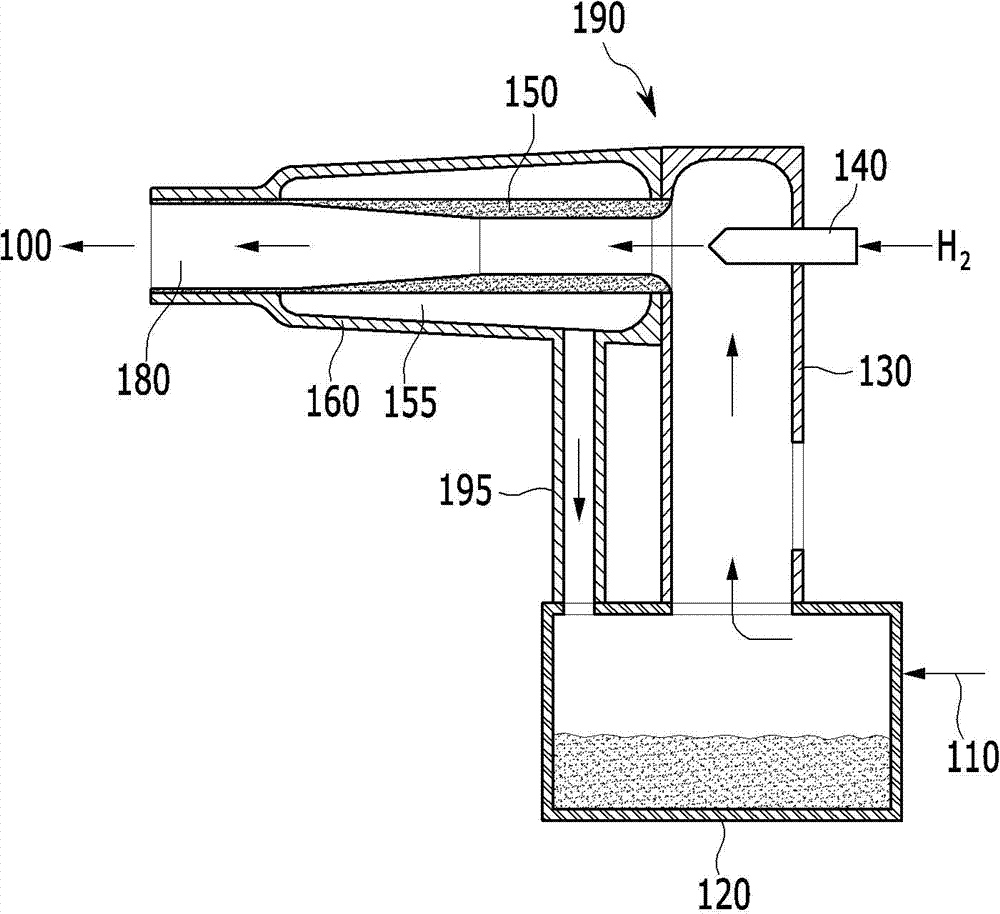

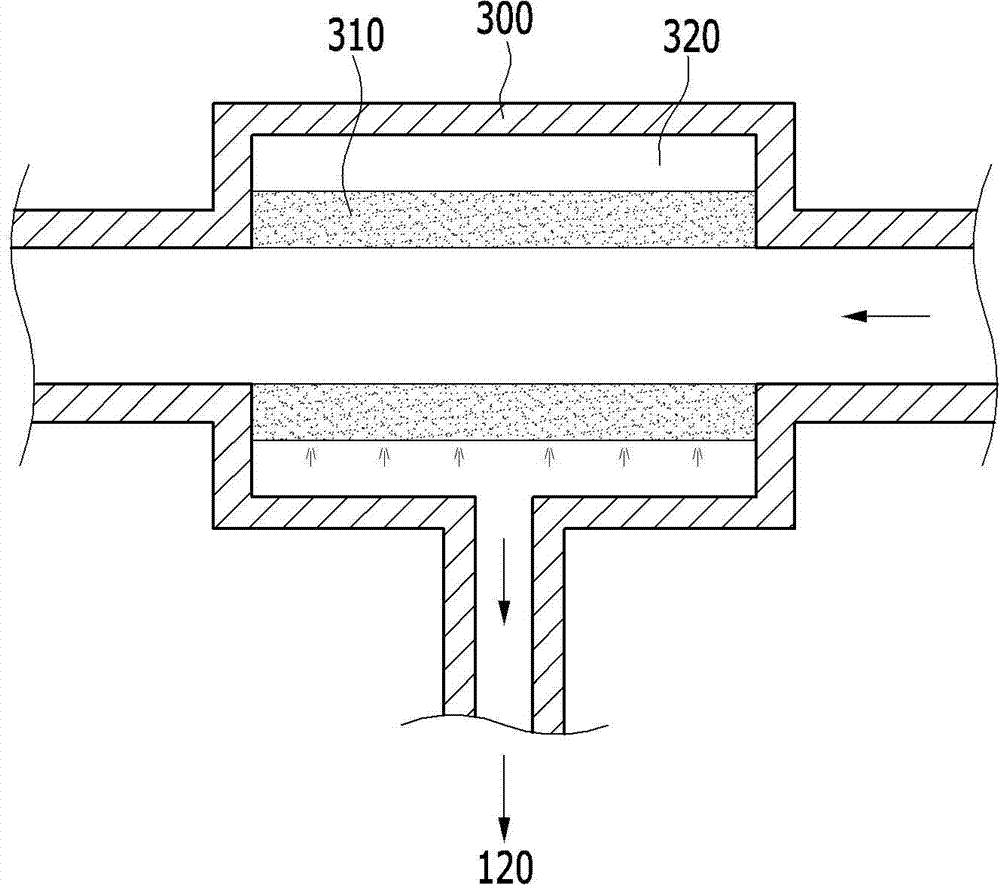

Fuel tank for fuel-cell and fuel cell system

InactiveCN1574436AStable supplySimple compositionReactant parameters controlLarge containersFuel cellsFuel tank

Provided is a fuel tank for a fuel cell and fuel cell system capable of supplying fuel in any direction of installment and processing exhausted substance. The fuel tank is constructed so as to press the fuel (111) to be supplied to the fuel cell main body (200) by pressing a separation plate (130) moving through the inside of a casing (140) by the exhausted substance (123) exhausted from the fuel cell main body. By the above, the fuel can be stably supplied to the fuel cell main body whether the fuel tank for the fuel cell (100) and the fuel cell system (30) are installed in any direction. In addition, since the exhausted substance is utilized for pressing the separation plate, the exhausted substance can be processed.

Owner:PANASONIC CORP

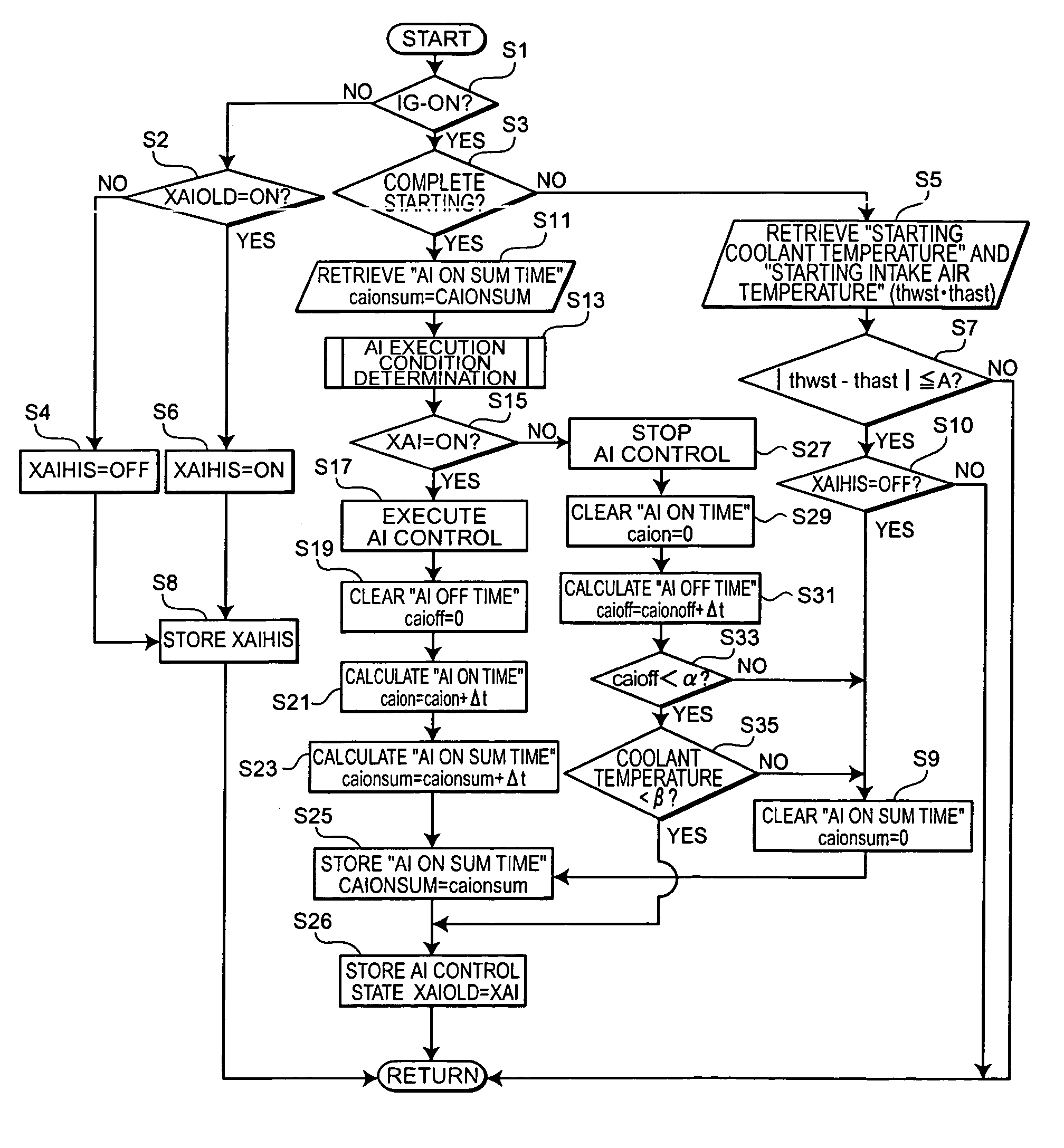

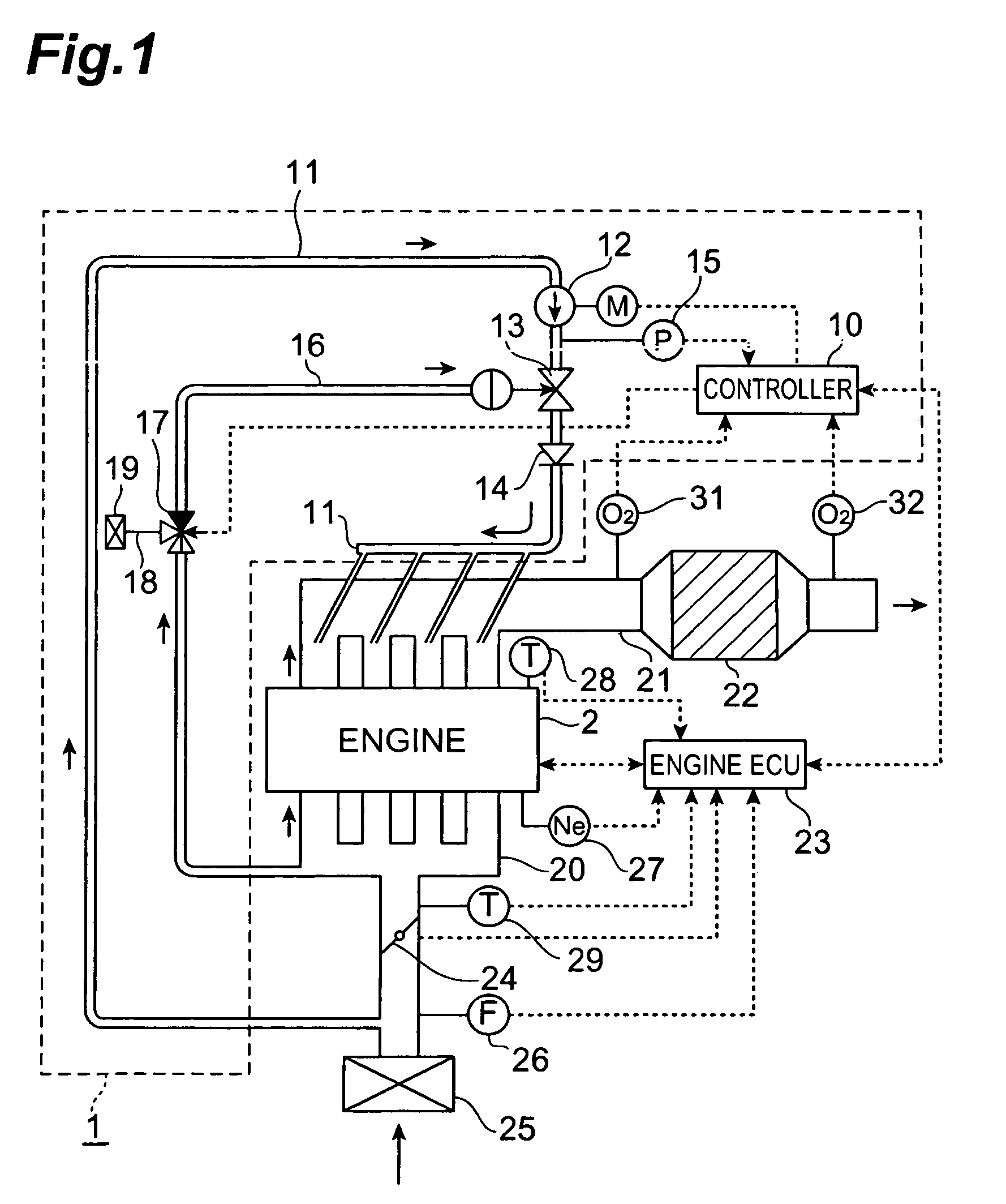

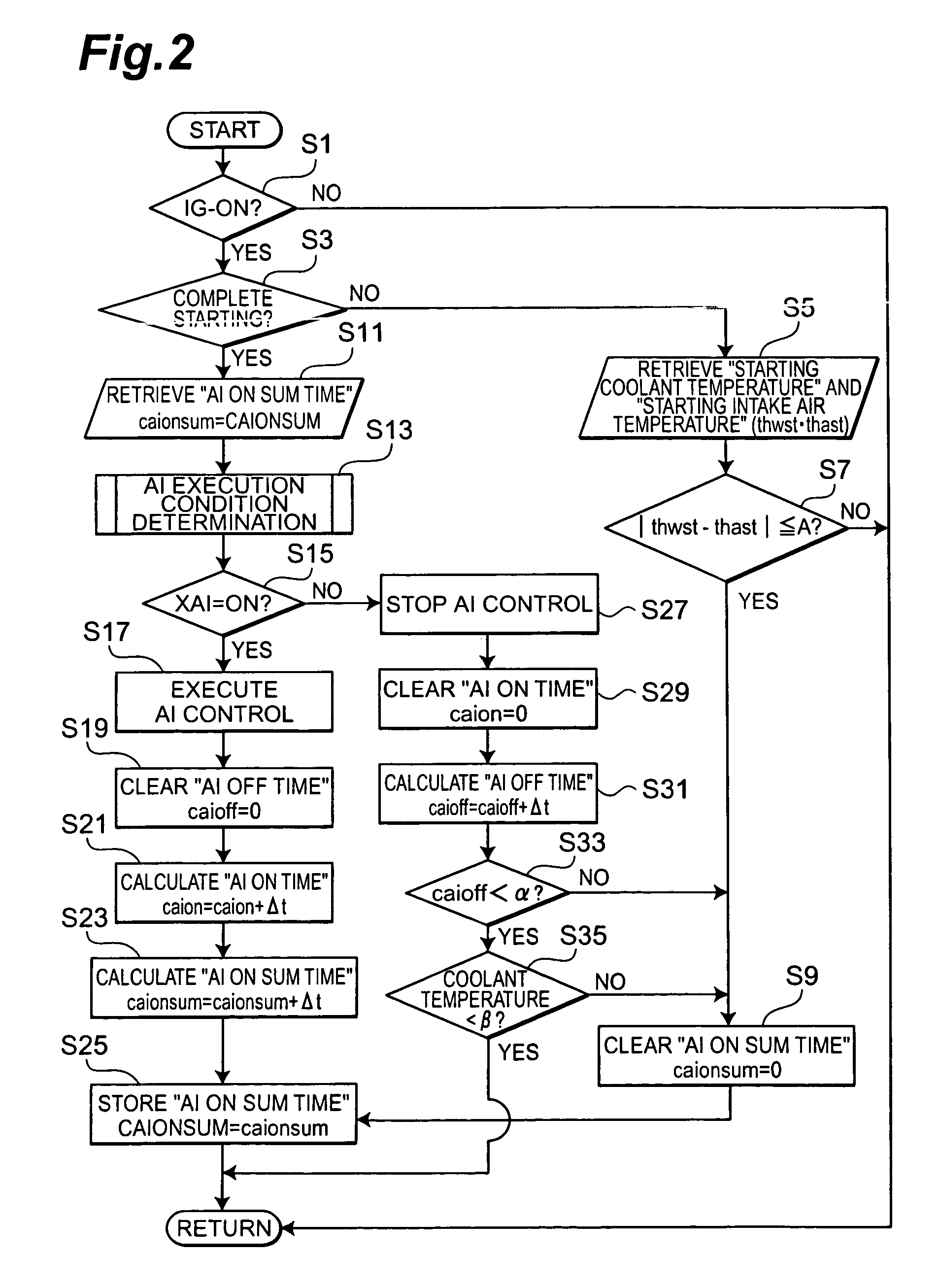

Secondary air supplying apparatus

ActiveUS7107762B2Suppressing overheatingShorten the overall cycleElectrical controlCoolant flow controlInternal combustion engineBiological activation

A secondary air supplying apparatus of the present invention comprises a secondary air supplying device for supplying secondary air to upstream of an emission purifying device in an exhaust system of an internal combustion engine, a coolant temperature sensor for detecting a temperature of a coolant for the engine, an intake air temperature sensor for detecting a temperature of intake air, a supply controller for actuating the secondary air supplying device in accordance with a predetermined secondary air supply condition, and a summing unit for summing an actuation period of the secondary air supplying device and storing a sum. The supply controller stops the secondary air supply by the secondary air supplying device when the sum stored by the summing unit reaches a predetermined upper limit. The summing unit resets the stored sum, if a difference between the coolant temperature and the intake air temperature at a point before the actuation of the secondary air supplying device is not more than a predetermined value. This configuration enables the apparatus to suppress oversupply of secondary air and overheating of a catalyst so as to implement appropriate activation of the catalyst.

Owner:TOYOTA JIDOSHA KK

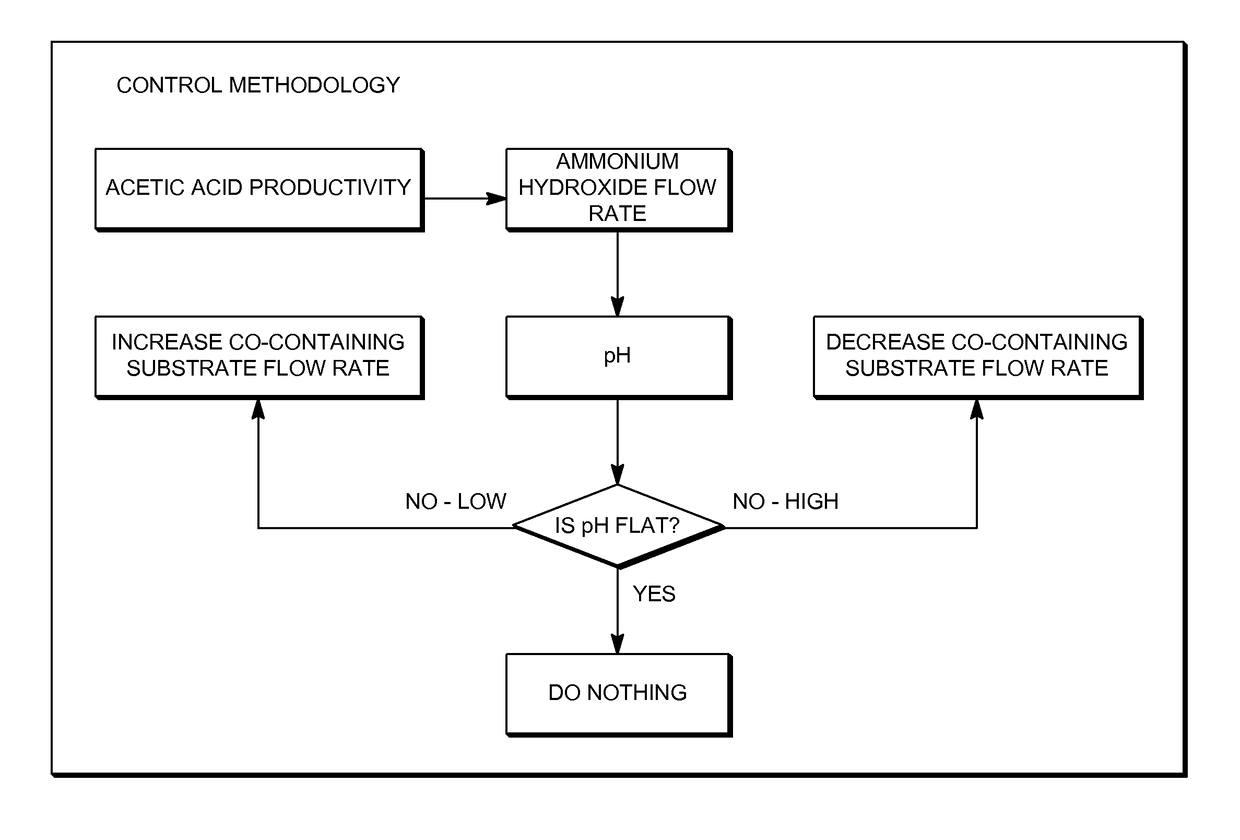

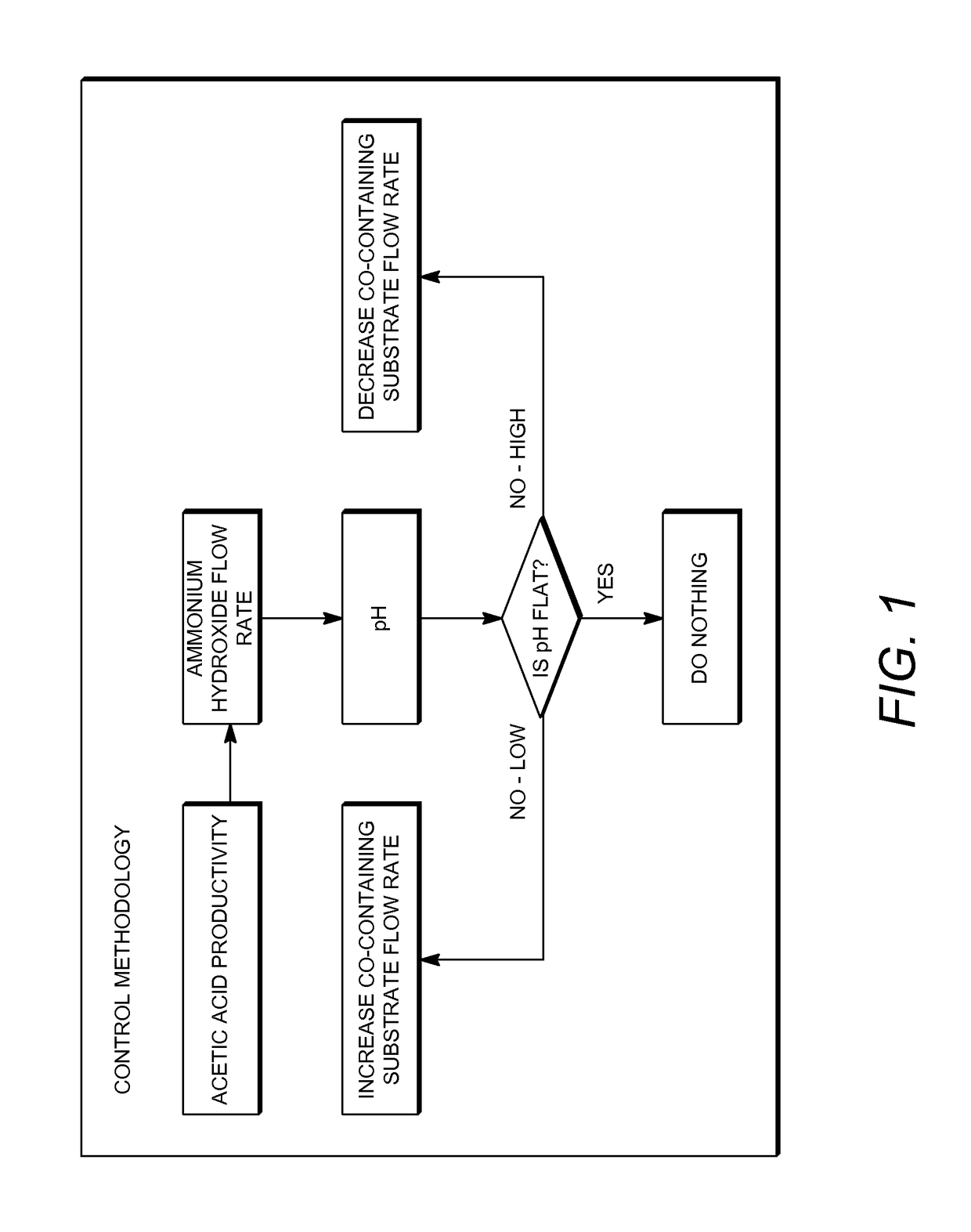

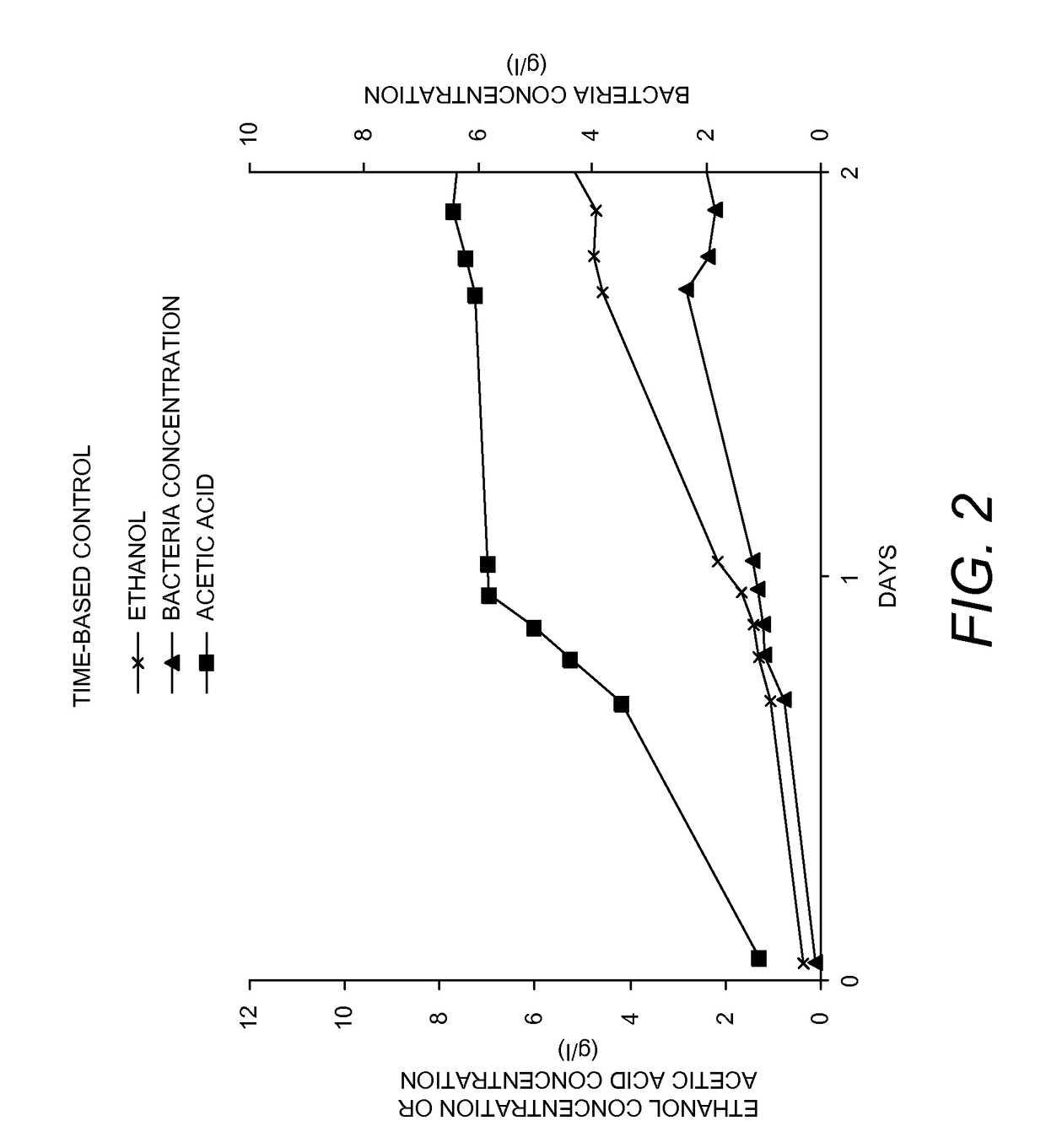

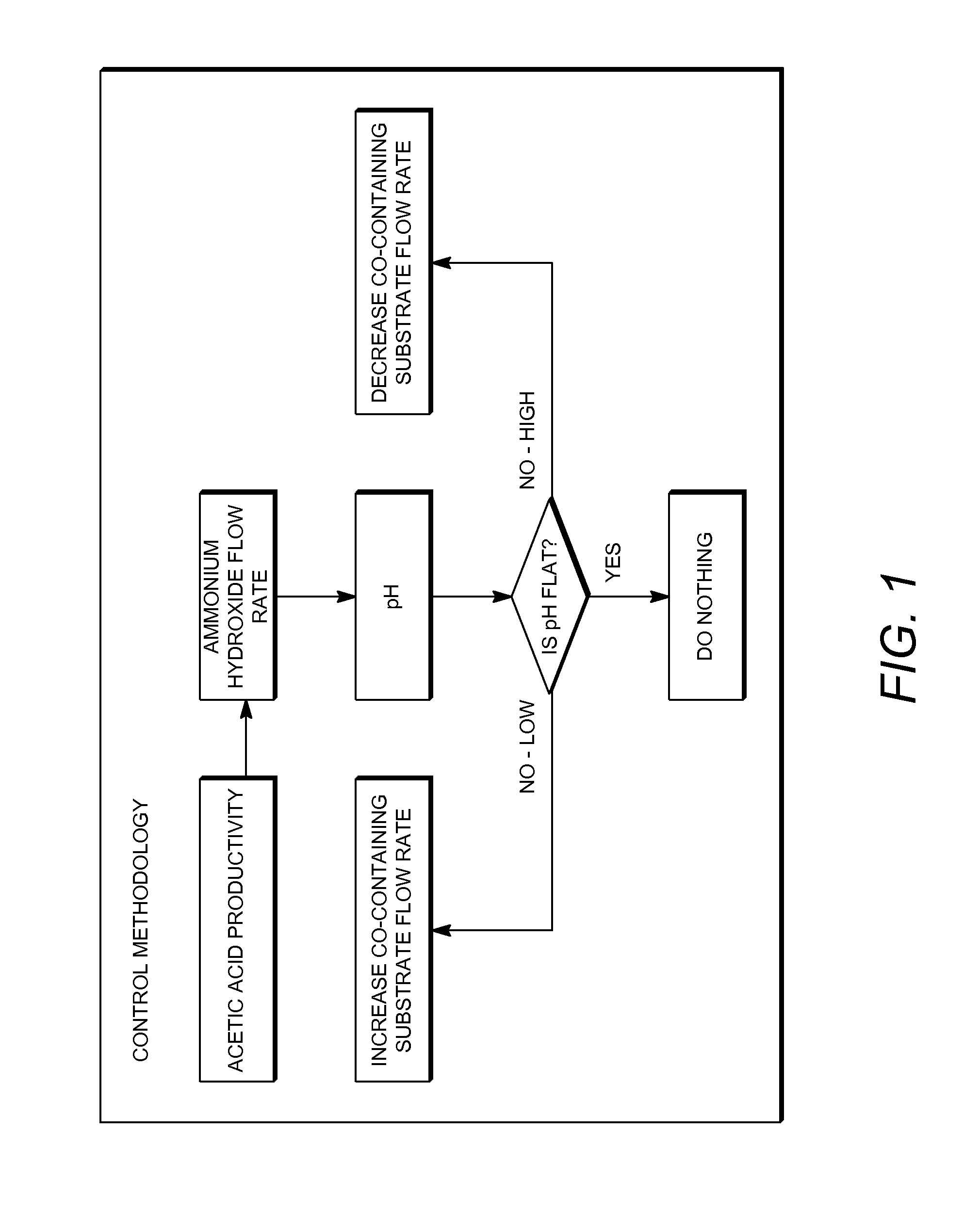

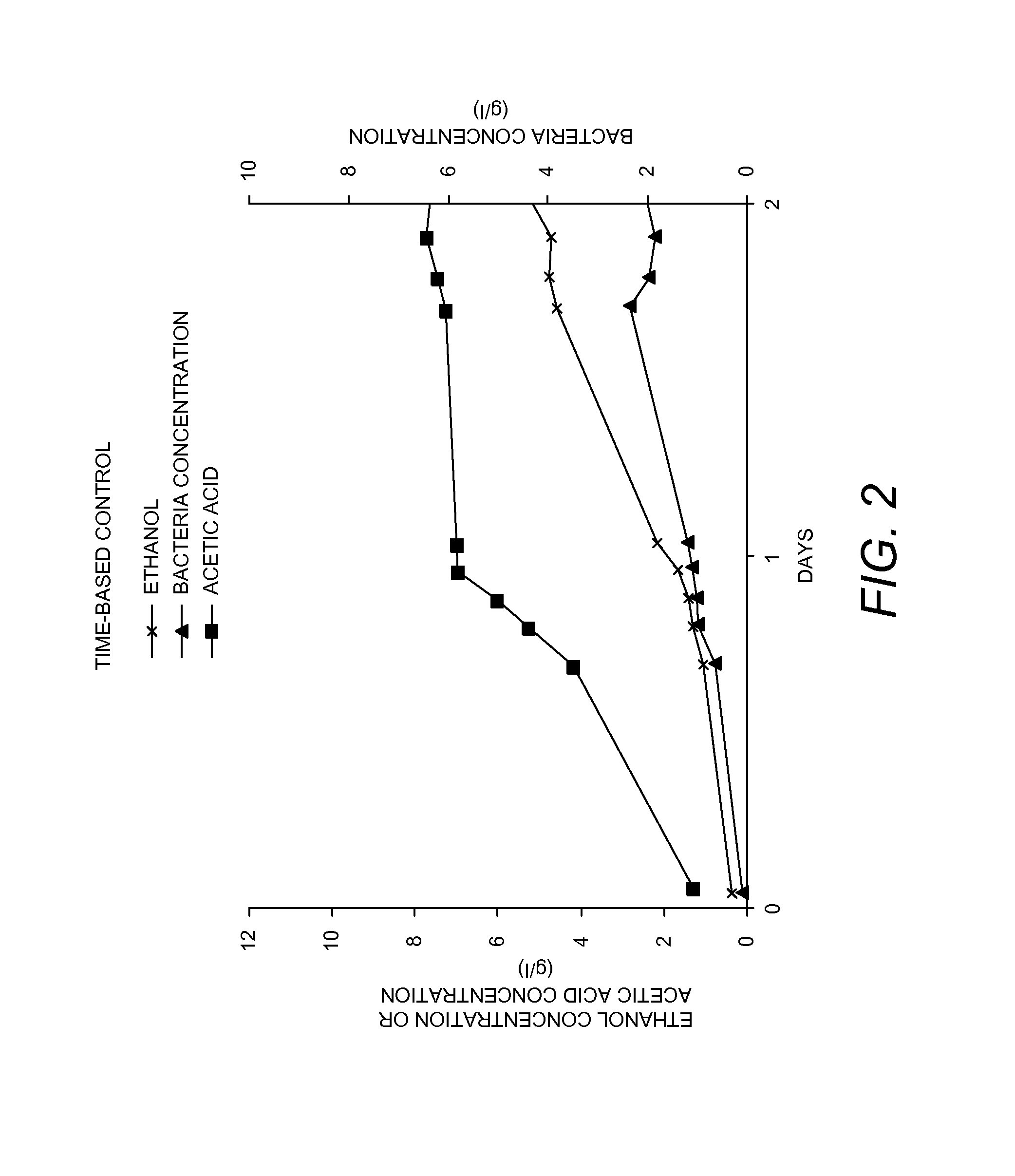

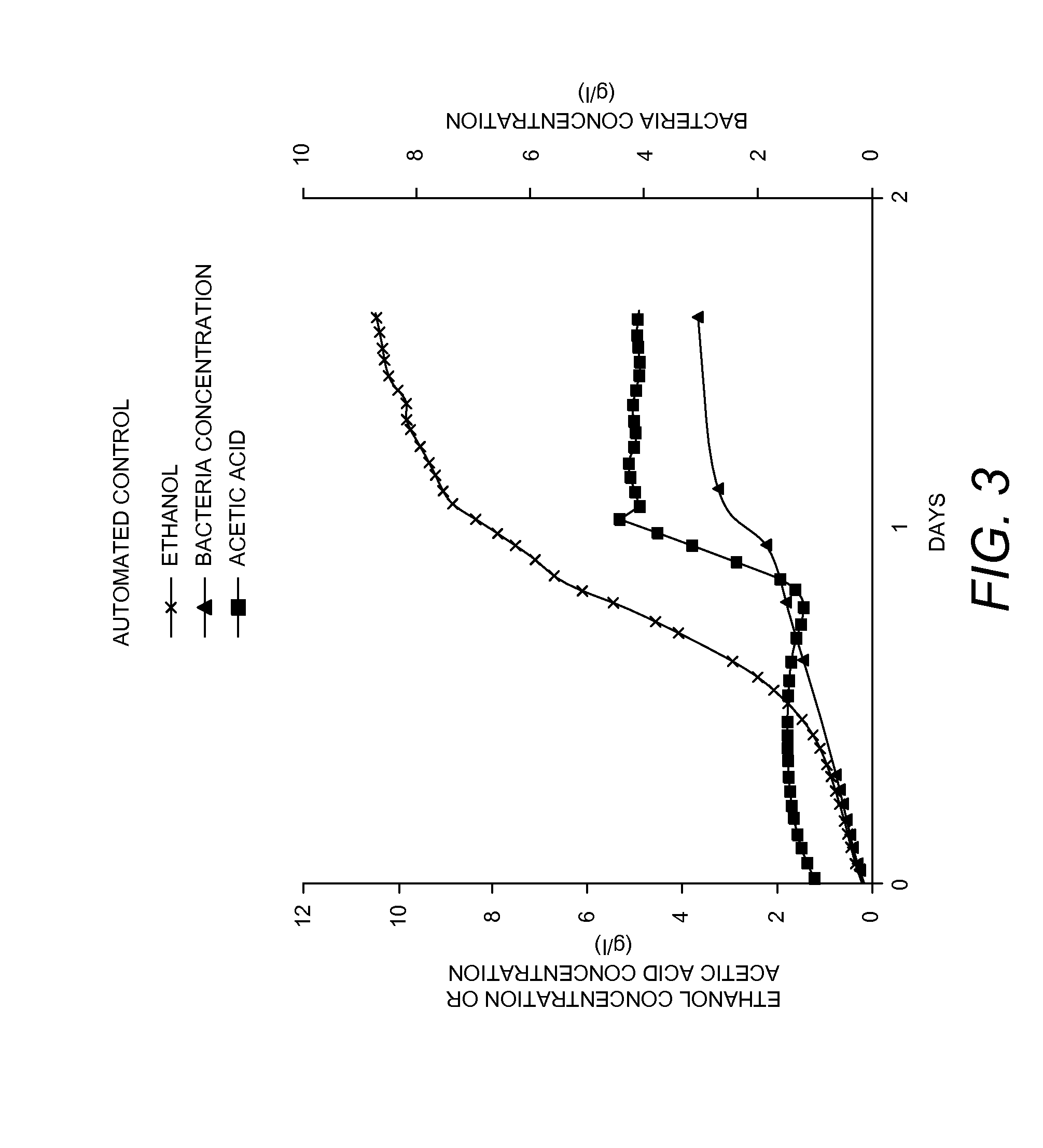

Control of bioreactor processes

ActiveUS9617566B2Reduce the valueImprove concentrationBiofuelsLiquid production bioreactorsBatch operationProcess engineering

Processes, as well as associated systems and computer program (software) products, are disclosed for the biological conversion of CO into desired end products such as ethanol. The control methodologies used for these processes can advantageously result in a reduced time required for a batch operation or other initial operating period, prior to achieving a continuous operation, which may be demarcated either by the addition of fresh culture medium at a defined flow rate or by another process initiation target. The control methodologies may alternatively, or in combination, improve a process performance parameter, such as productivity of the desired end product or bacterial growth rate, during this batch operation or other initial operating period.

Owner:LANZATECH NZ INC

Valve device for fuel tank

ActiveUS20120279581A1Avoid oversupplyPrevention of excessive supplyNon-fuel substance addition to fuelFuel injection apparatusFuel tankEngineering

A valve device for a fuel tank includes a float element accommodated vertically movably in a case. The float element has a seal member at an upper portion thereof. The fuel flowing into the case through the inflow portion rises the float element to seat the seal member on the vent valve port. A ventilation portion connecting between inside of the tank and inside of the case is formed at an upper face portion of the case positioned above a waterline of the float element when seated. The upper face portion of the float element positioned in close proximity to the upper face portion reduces the amount of ventilation through the ventilation portion when seated. The valve device for a fuel tank further includes a regulation portion at the upper face portion of the case in which the interval is constant between the upper face portion of the case and the upper face portion of the float element when seated.

Owner:NIFCO INC

Order management system

InactiveUS7574384B2Reduce productionSecure resourceBuying/selling/leasing transactionsOrder management systemOrder form

A system capable of managing orders of resources so that order quantities of resources for production of products are properly determined with consideration given to various conditions of a person receiving orders. In this system, according to the latest production plan, placed order quantities are corrected based on corrected required quantities for a plurality of periods in “the first predetermined period” and the placed order quantities are modified so as to suppress a fluctuation in the entire order quantity caused by an order quantity fluctuation in the first predetermined period for a plurality of periods in “the second predetermined period.”

Owner:HONDA MOTOR CO LTD

Wireless power transmitter

ActiveUS10897163B2Avoid oversupplyAvoid interferenceBatteries circuit arrangementsElectric powerTransmitter coilElectric power transmission

A power transmitter transmits an electric power signal S2 to a wireless power receiver. A transmission antenna includes a transmission coil and a resonance capacitor coupled in series. A driver applies a driving signal S1 to the transmission coil. A TX controller controls the driver. A wireless device detector of the TX controller detects a neighboring wireless device before electric power transmission is started.

Owner:ROHM CO LTD

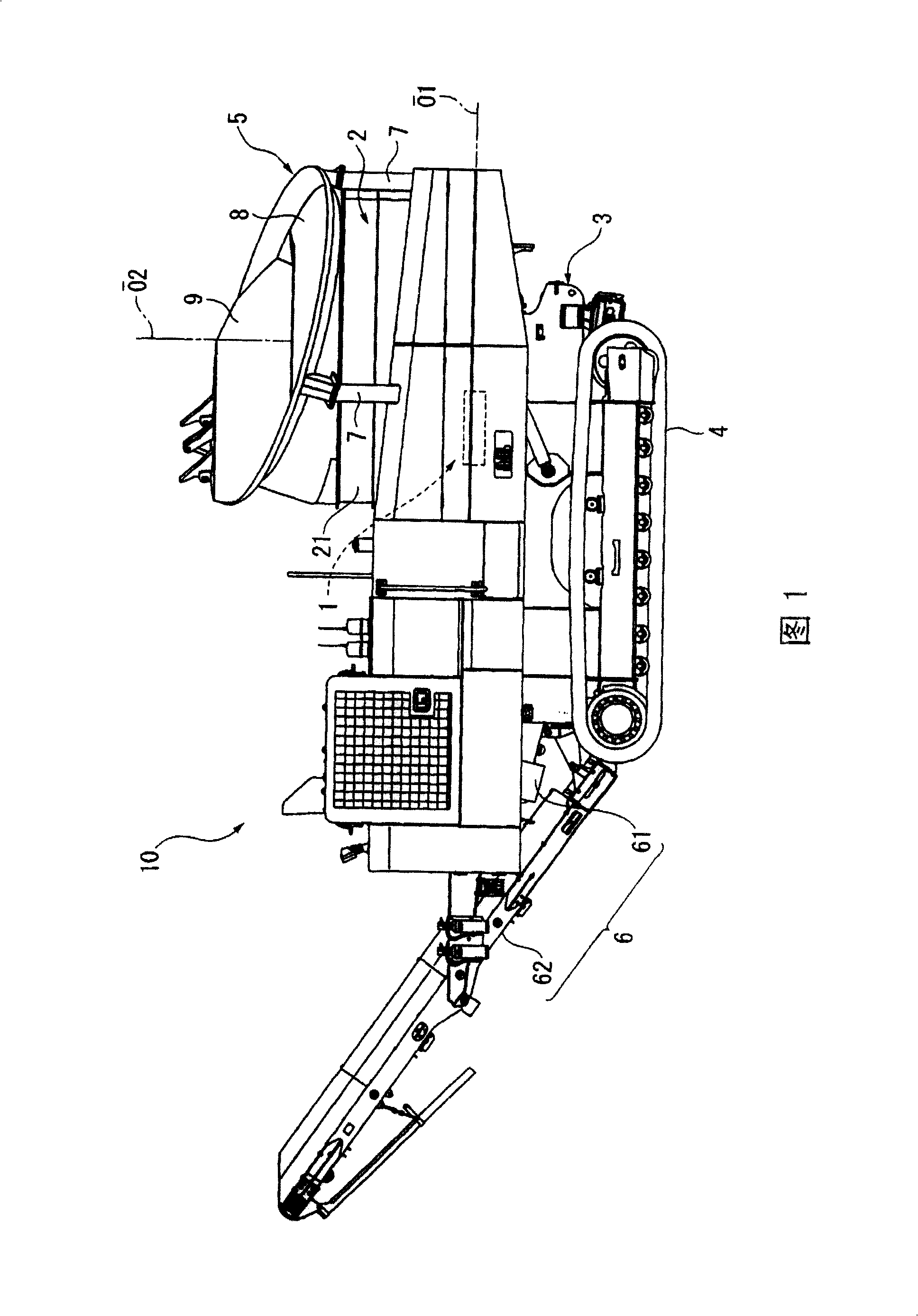

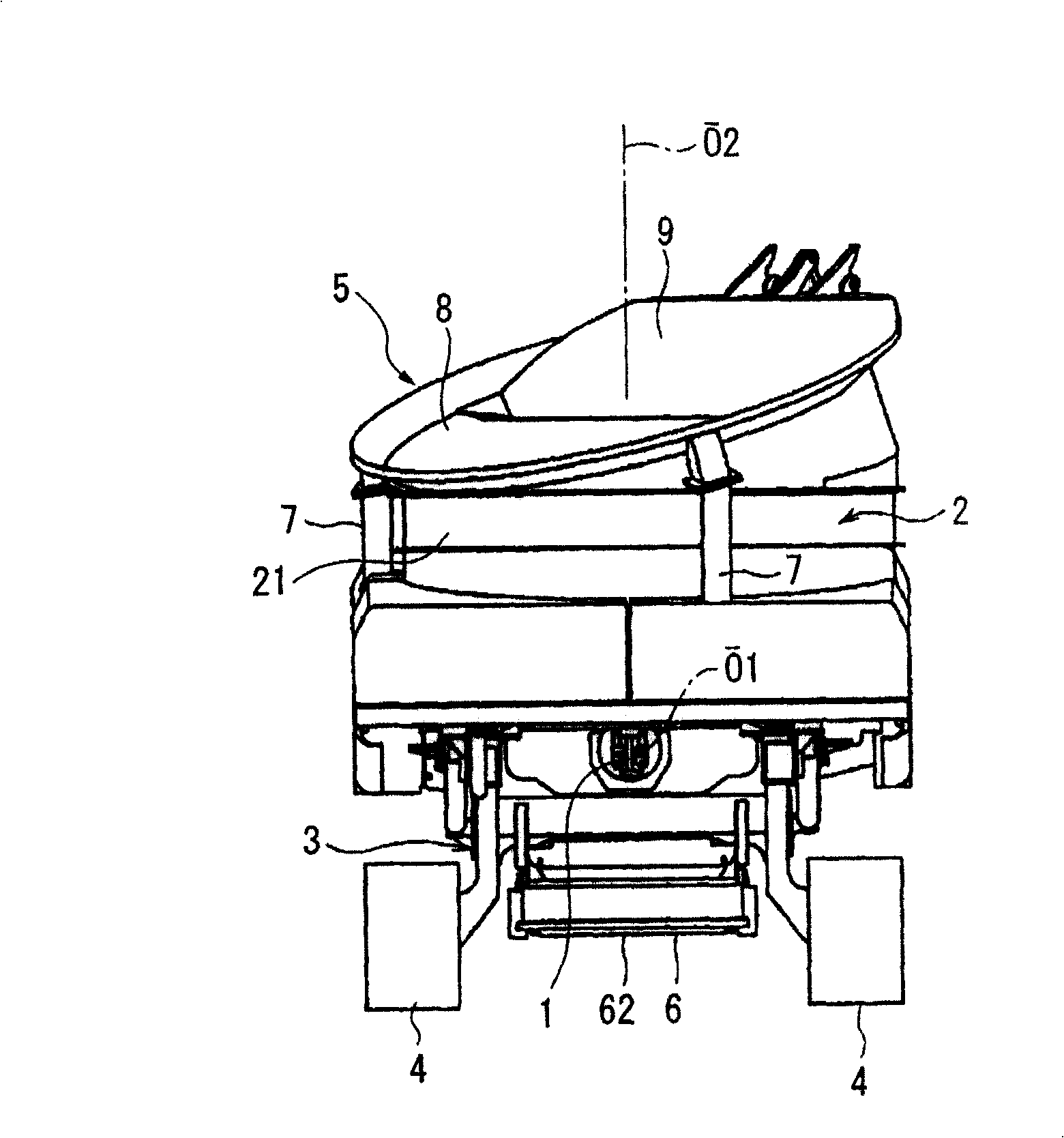

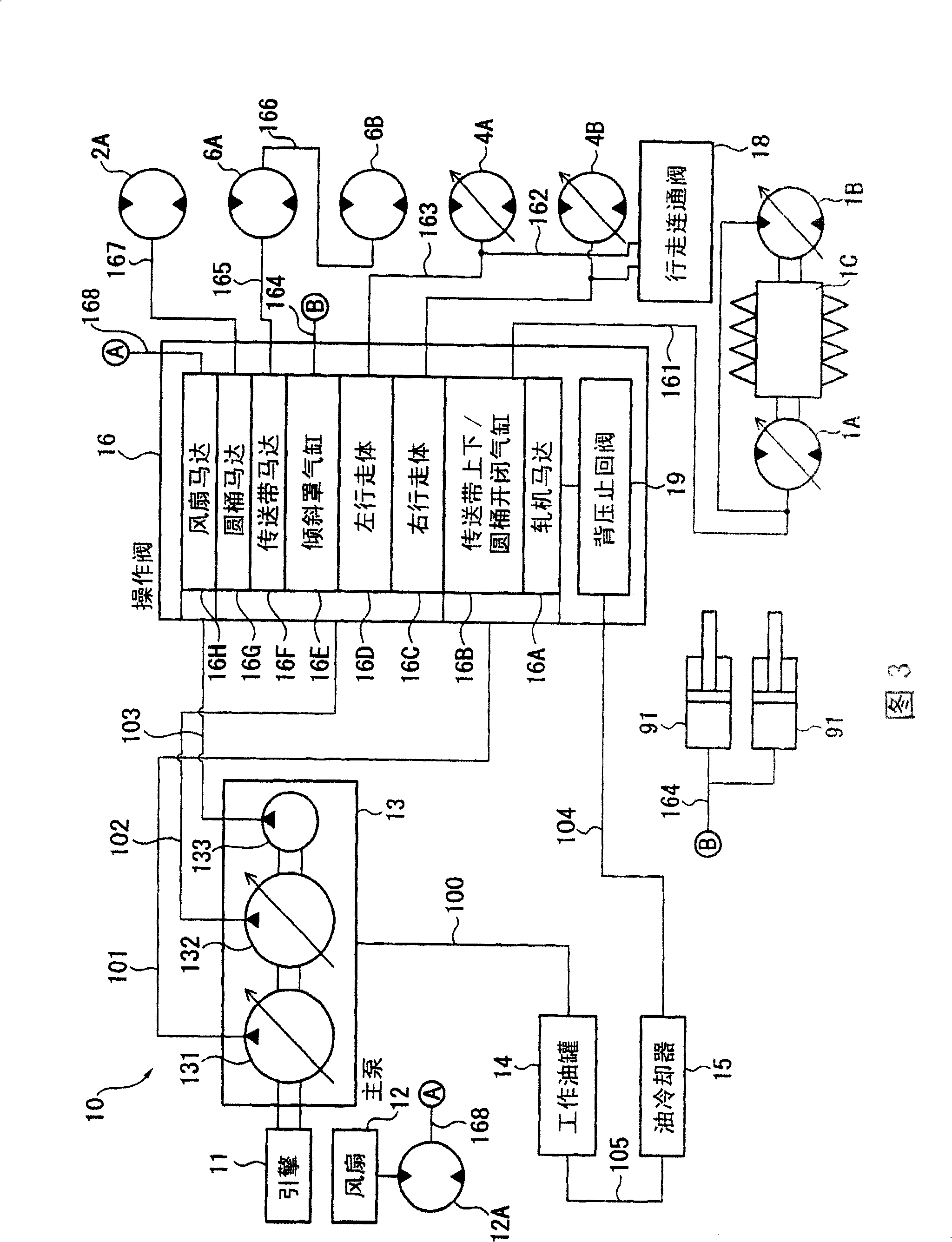

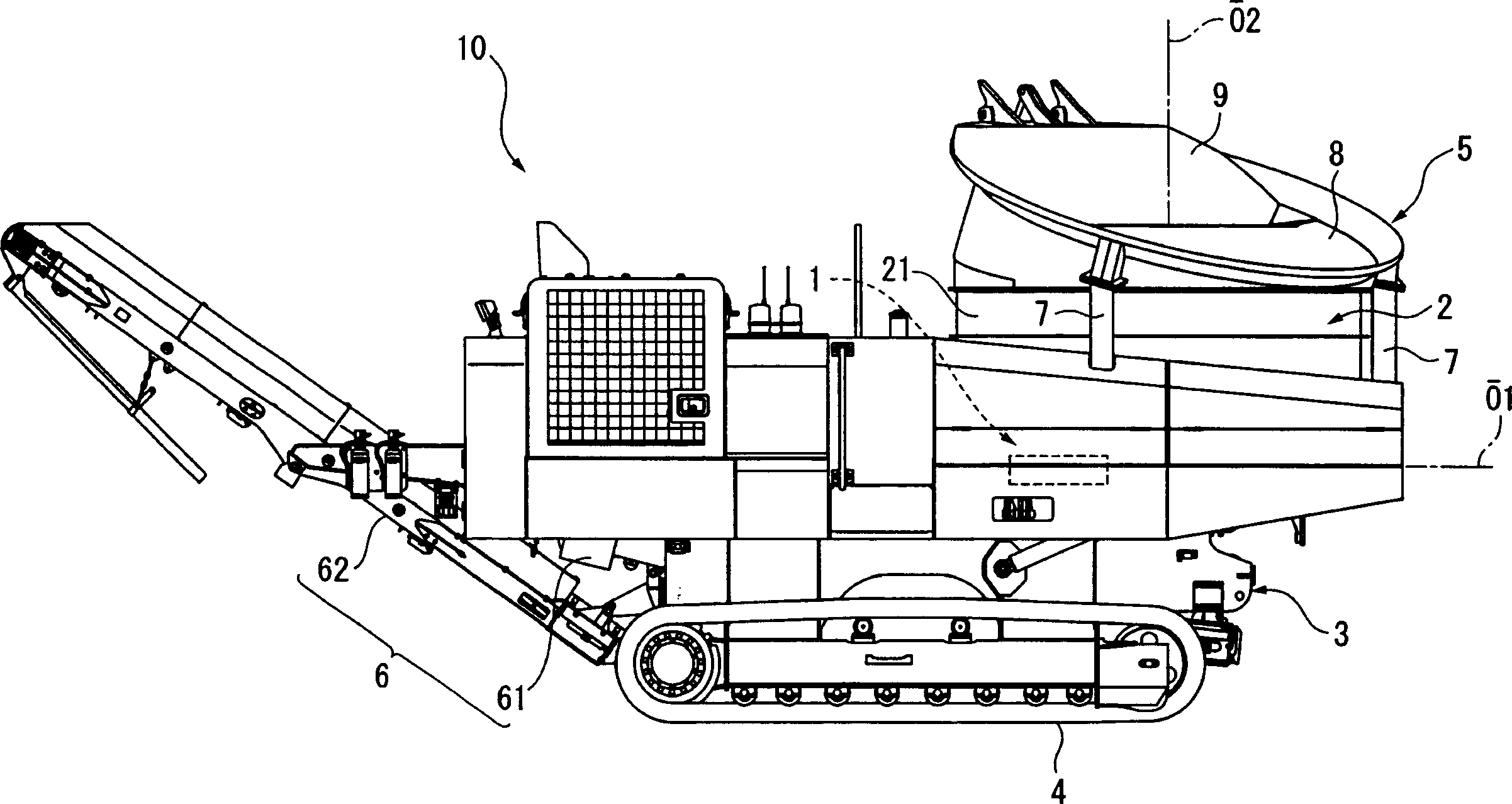

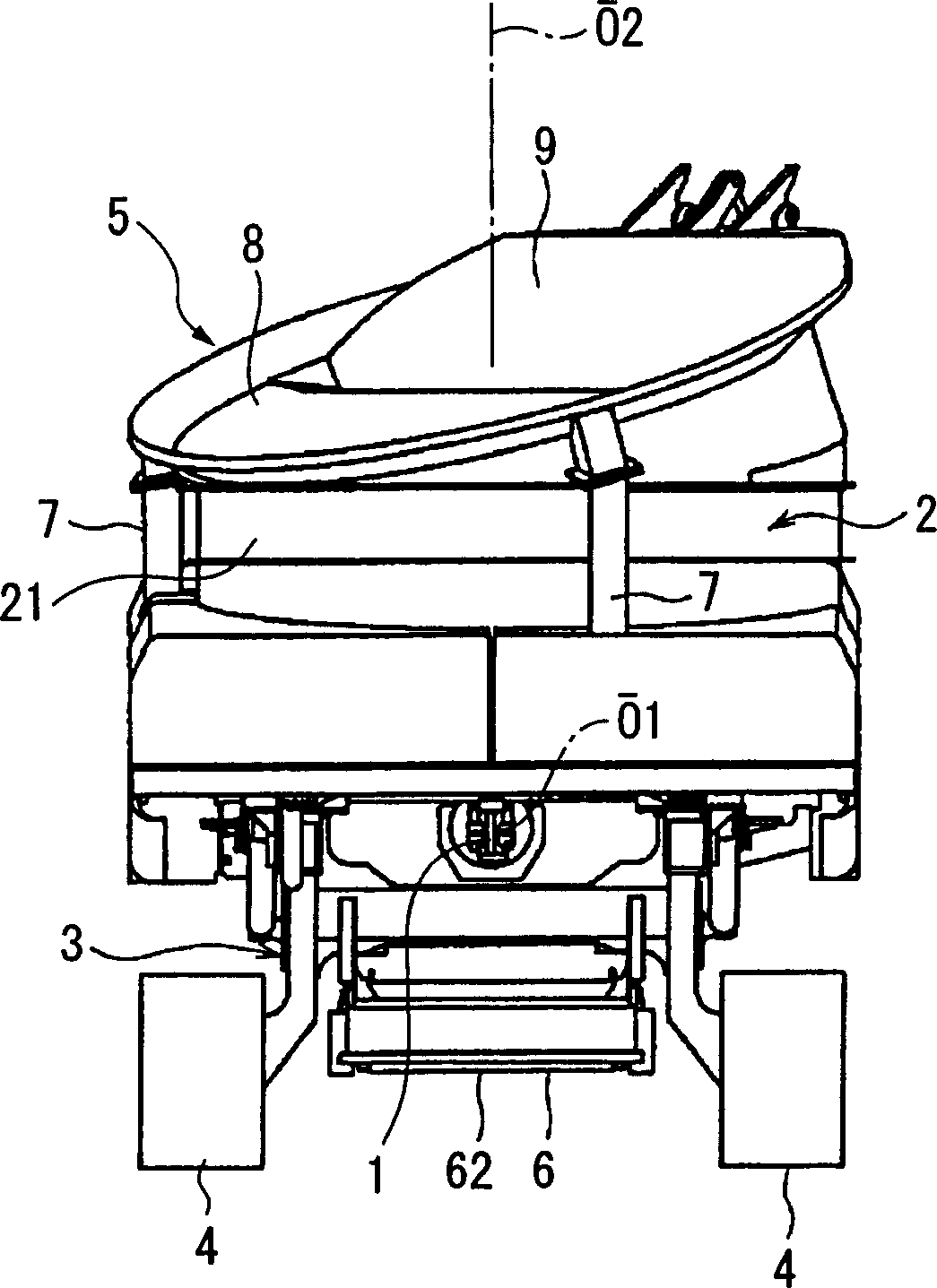

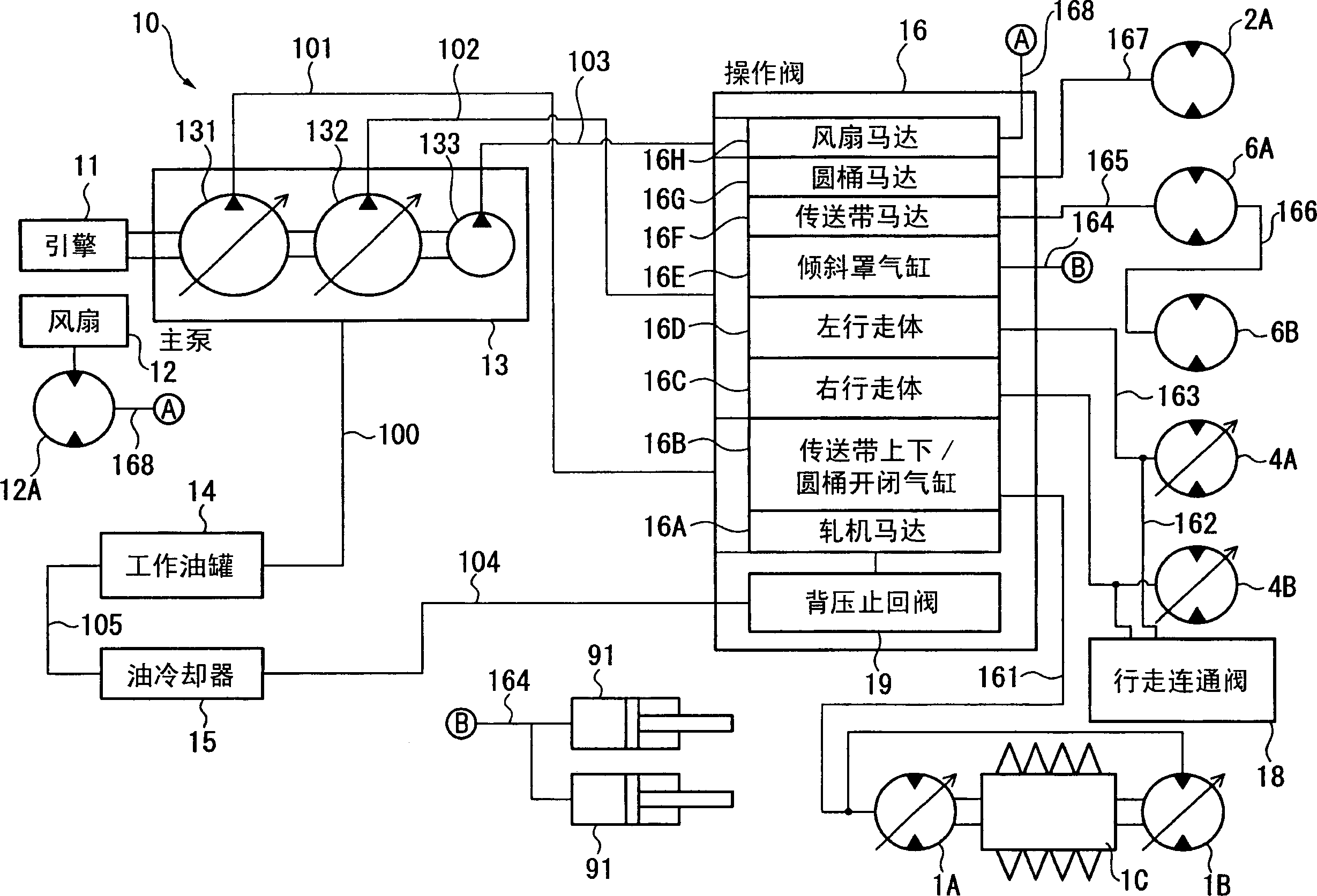

Crushing apparatus

The invention provides a rotary crushing device. The rotary crushing device equipped with a hydraulic motor for driving the crusher is equipped with: a load detection mechanism for detecting the load state of the hydraulic motor, a load determination mechanism for determining the load state of the hydraulic motor, Then stop the supply of the crushed object by the supply device, and start the supply quantity control mechanism of the supply device to the crushed object when it is judged to be low load, and immediately change the The capacity of the capacity motor is changed to the motor capacity control mechanism on the large capacity side. Since the capacity of the hydraulic motor is switched to the large capacity side when the supply device stops, the wood in the crusher can be crushed at a high torque, the load can be reduced, and the original state can be restored in a short time.

Owner:KOMATSU LTD

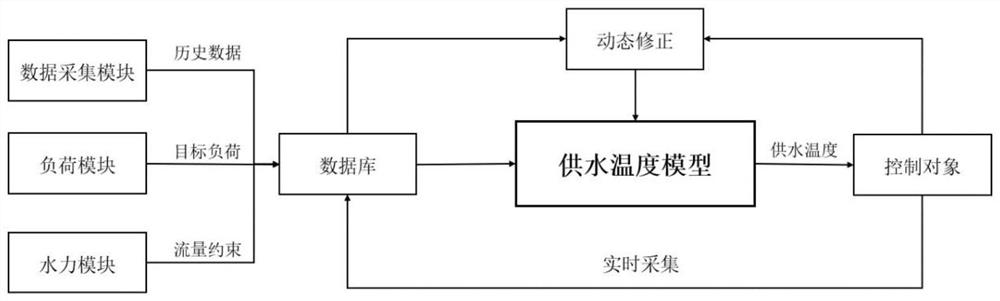

Water supply temperature regulation and control method based on target energy consumption management and control

ActiveCN114484556ARealize clean and efficient heatingSelf-learningDigital data information retrievalLighting and heating apparatusControl engineeringProcess engineering

The invention relates to a water supply temperature regulation and control method based on target energy consumption management and control, which is used for calibrating model parameters according to historical data of a heat supply network in combination with a specific scene, and carrying out periodic calibration and dynamic correction in an operation process. According to the water supply temperature regulation and control method based on target energy consumption management and control, the water supply temperature is determined based on the target load and the flow constraint of an actual system, the self-learning, self-adaption and self-optimization-approaching capabilities are achieved, and target energy consumption accurate management and control of on-demand heat supply under the dual-carbon target background can be achieved.

Owner:TIANJIN UNIV +1

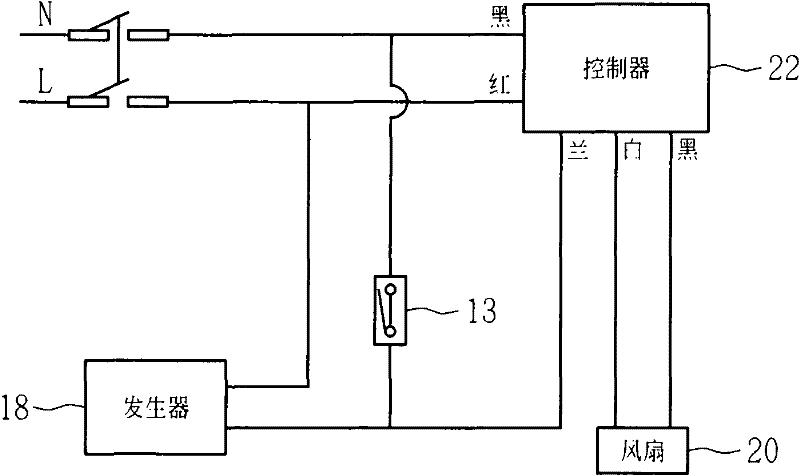

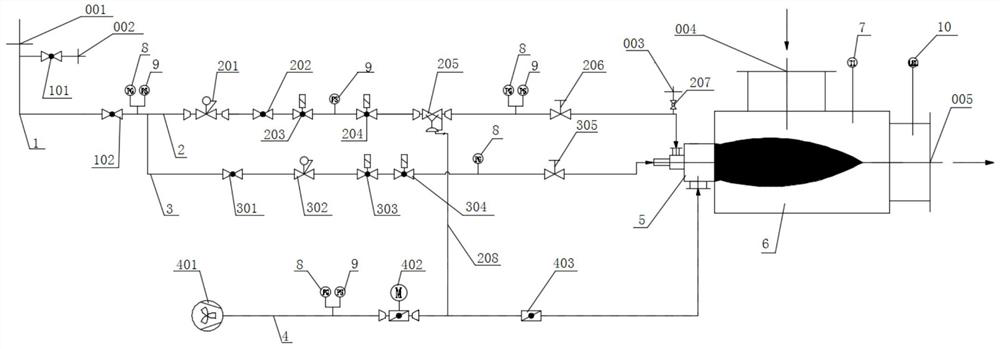

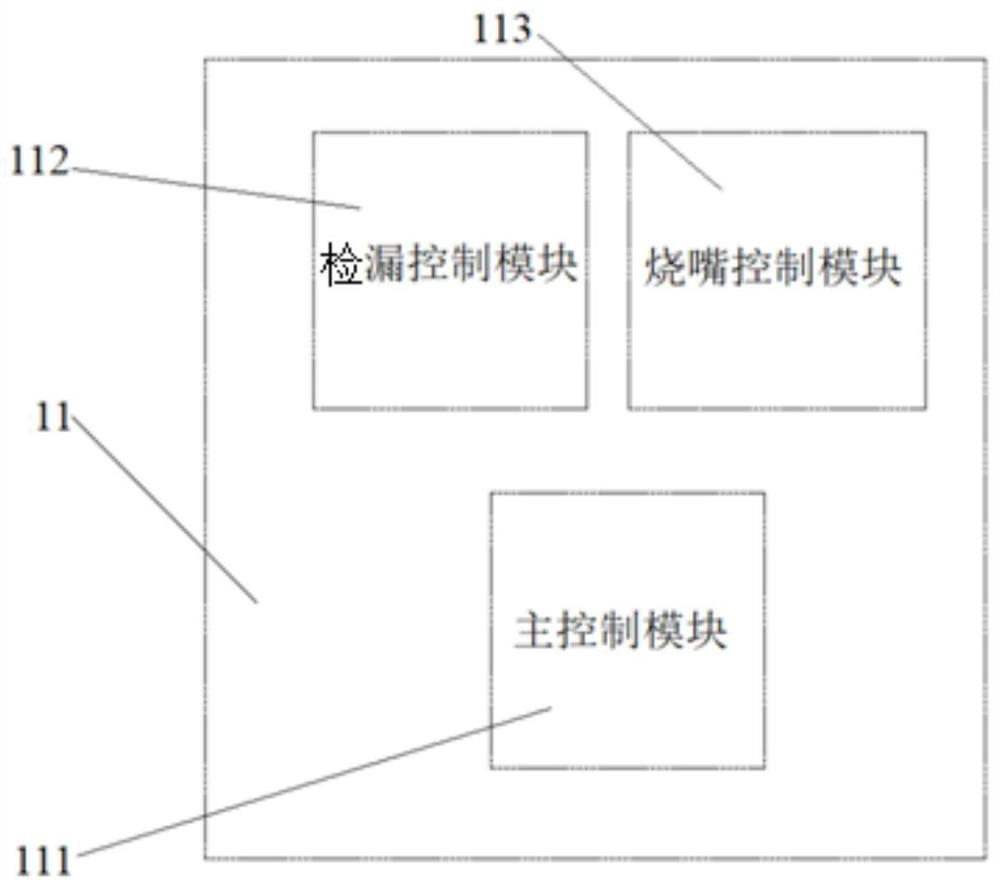

Full-automatic high-safety low-nitrogen hot air heating combustion system and operation method thereof

ActiveCN112611110AImprove stability and securityIncrease the leak detection process before ignitionAir heatersInlet pressureAir heating

The invention discloses a full-automatic high-safety low-nitrogen hot air heating combustion system and an operation method thereof. In the system, when the combustible gas component on the outlet side of a hot blast heater exceeds a safety set value, the total gas inlet pressure is lower than a set safety pressure value, the pressure of a combustion-supporting air pipeline is lower than the set safety pressure value, and the pressure in front of a main gas manual adjusting valve is higher than the set safety pressure value, an alarm is given to a controller so that the system cannot be started or automatically stops running; a first main gas cut-off valve and a second main gas cut-off valve are controlled by the controller, and whether the cut-off valves leak or not can be automatically detected by combining a pressure switch between the first main gas cut-off valve and the second main gas cut-off valve; an air-fuel proportional valve is connected into the combustion-supporting air pipeline through a pressure taking pipeline, and the air-fuel ratio is automatically adjusted in a linkage mode in real time through the pressure of the combustion-supporting air pipeline; a first ignition gas cut-off valve and a second ignition gas cut-off valve are controlled by the controller; and the controller can conduct PID control over an electric adjusting valve according to the difference value between the temperature uploaded by a thermocouple and the target temperature. The full-automatic high-safety low-nitrogen hot air heating combustion system is high in safety and stability and ultralow in NOx emission.

Owner:WISDRI WUHAN WIS IND FURNACE

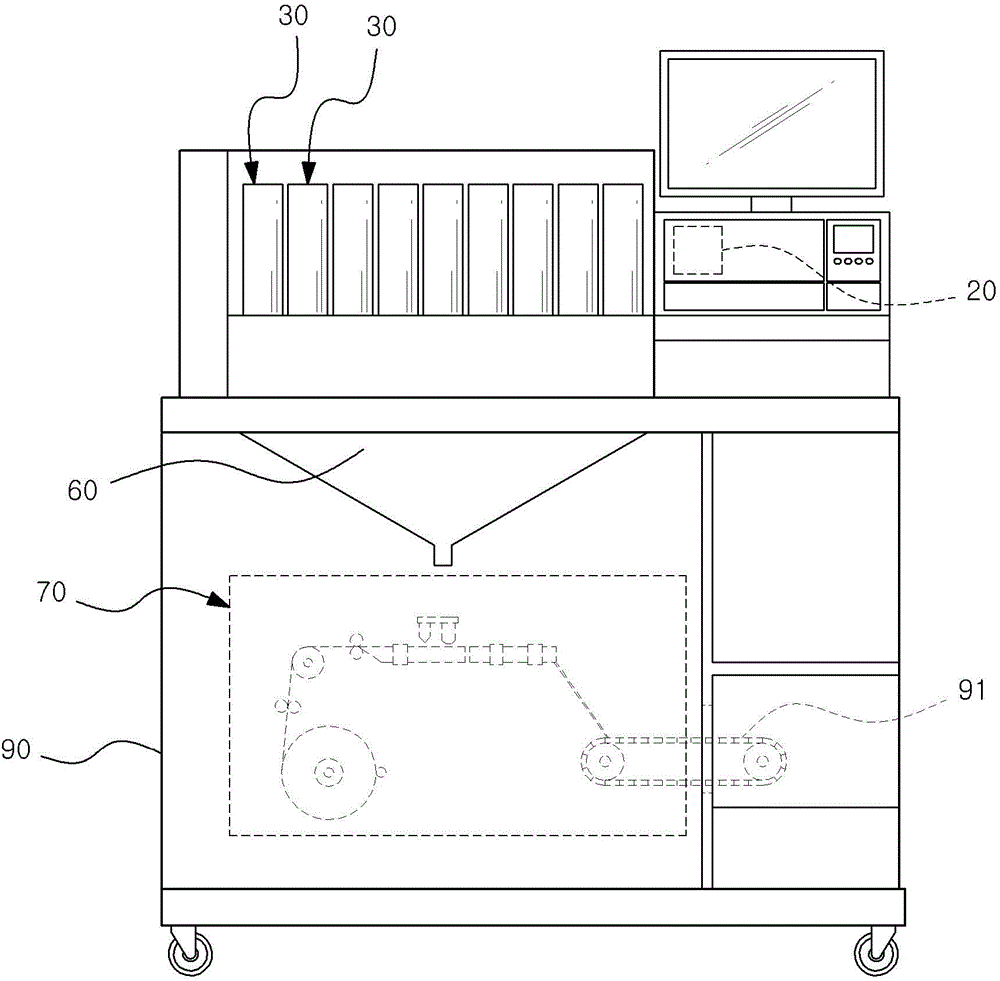

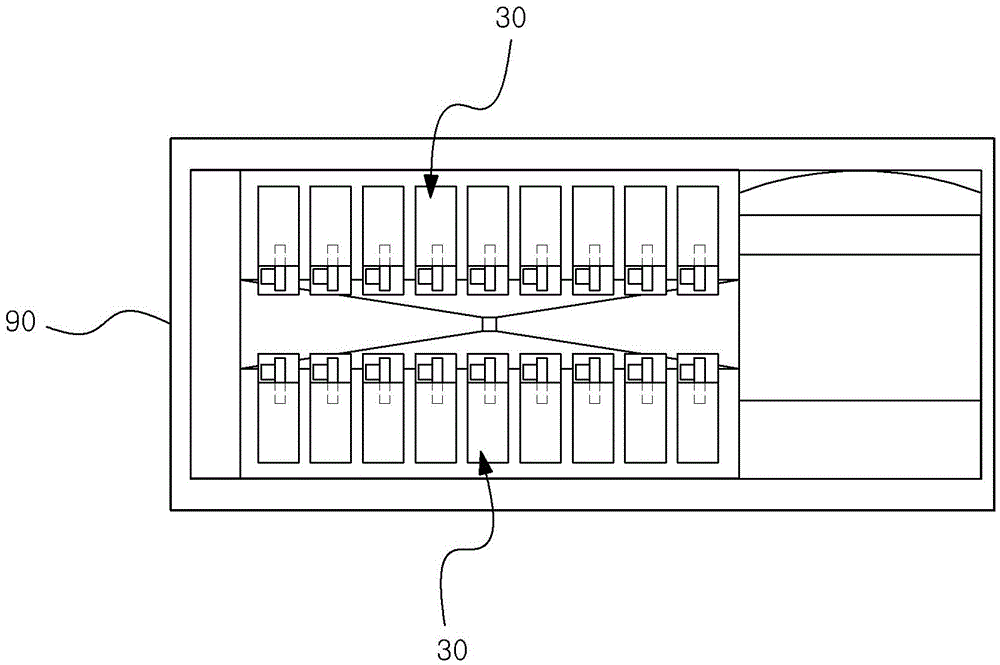

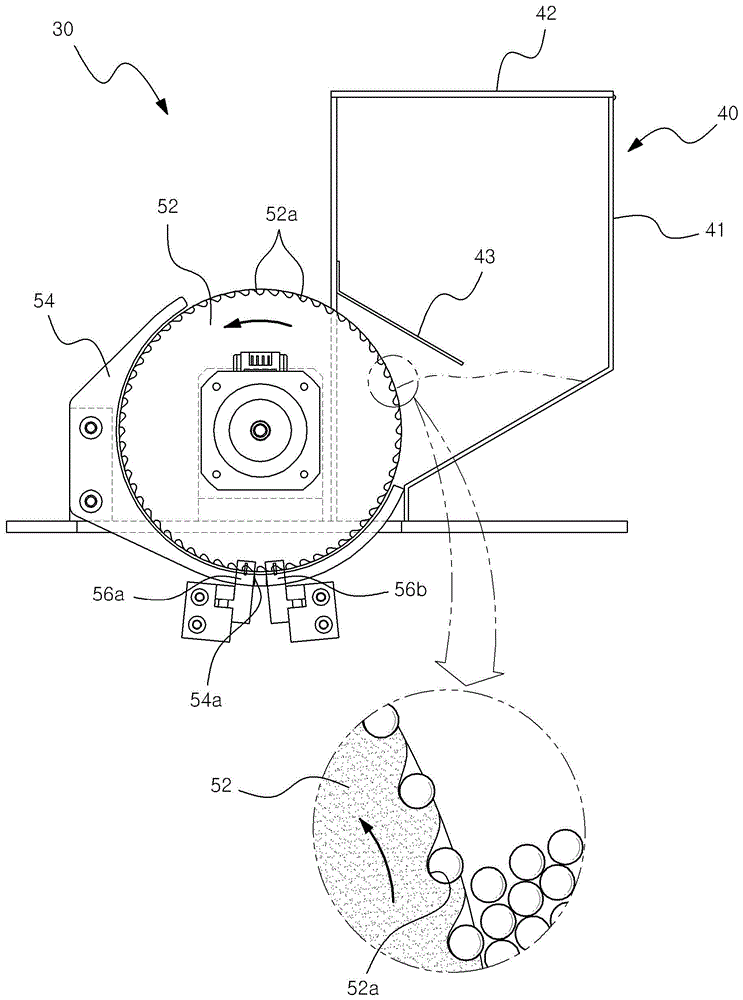

Device and system for preparing individually customized nutritional supplement

ActiveCN104968314AAvoid oversupplyStable supplyDrug and medicationsNutrition controlPrescription dataComputer science

Disclosed is an individualized nutrient preparation apparatus to prepare an individualized nutrient according to user characteristics. The individualized nutrient preparation apparatus includes a data processing unit configured to generate individual nutrient prescription data, a plurality of supply units configured to independently supply different nutrient granules according to the individual nutrient prescription data, each of which supplying a predetermined number set of the nutrient granules, and a packing unit configured to pack a mix of the nutrient granules.

Owner:ARIBIO CO LTD +1

Fuel cell system having ejector

ActiveCN104716356AAvoid oversupplyReduce the problem of output degradationReactant parameters controlFuel cell detailsFuel cellsEngineering

A fuel cell system having an ejector includes a stack for generating electricity by using air and fuel gas being supplied thereto. A fuel gas circulating line re-circulates the fuel gas from an outlet of the stack to an inlet of the stack. An ejector is mounted to the fuel gas circulating line for supplying fresh fuel gas and circulating the fuel gas. The ejector includes a vacuum suction pipe having one side connected to the fuel gas re-circulating line and a fuel gas spray nozzle mounted to the vacuum suction pipe for spraying the fuel gas to form a vacuum. An inner housing through which the fuel gas sprayed from the fuel gas spray nozzle passes. An outer housing is arranged on an outside of the inner housing to construct a condensed water space with the inner housing. The inner housing drains water from an inside of the inner housing to the condensed water space.

Owner:HYUNDAI MOTOR CO LTD

Control of bioreactor processes

ActiveUS20160010116A1Low ph valueIncrease concentrationBiofuelsLiquid production bioreactorsChemistryContinuous operation

Processes, as well as associated systems and computer program (software) products, are disclosed for the biological conversion of CO into desired end products such as ethanol. The control methodologies used for these processes can advantageously result in a reduced time required for a batch operation or other initial operating period, prior to achieving a continuous operation, which may be demarcated either by the addition of fresh culture medium at a defined flow rate or by another process initiation target. The control methodologies may alternatively, or in combination, improve a process performance parameter, such as productivity of the desired end product or bacterial growth rate, during this batch operation or other initial operating period.

Owner:LANZATECH NZ INC

Crushing apparatus

A rotary crushing apparatus having a hydraulic motor for driving a crusher, comprising a load detection means detecting the loading state of the hydraulic motor, a load determination means determining the loading state of the hydraulic motor, a supply amount control means which, when the hydraulic motor is determined to be overloaded by the load determination means, stops the supply of crushed materials by a supply device and, when determined to be less loaded, starts to supply the crushed materials by the supply device, and a motor capacity control means which, when the motor is determined to be overloaded by the load determination means, changes the capacity of the variable displacement motor to a large capacity side. Since the capacity of the hydraulic motor is switched to the large capacity side when the supply device is stopped, the motor can crush wood in the crusher with a high torque and can be returned, under a low load, to the original state in a short time.

Owner:KOMATSU LTD

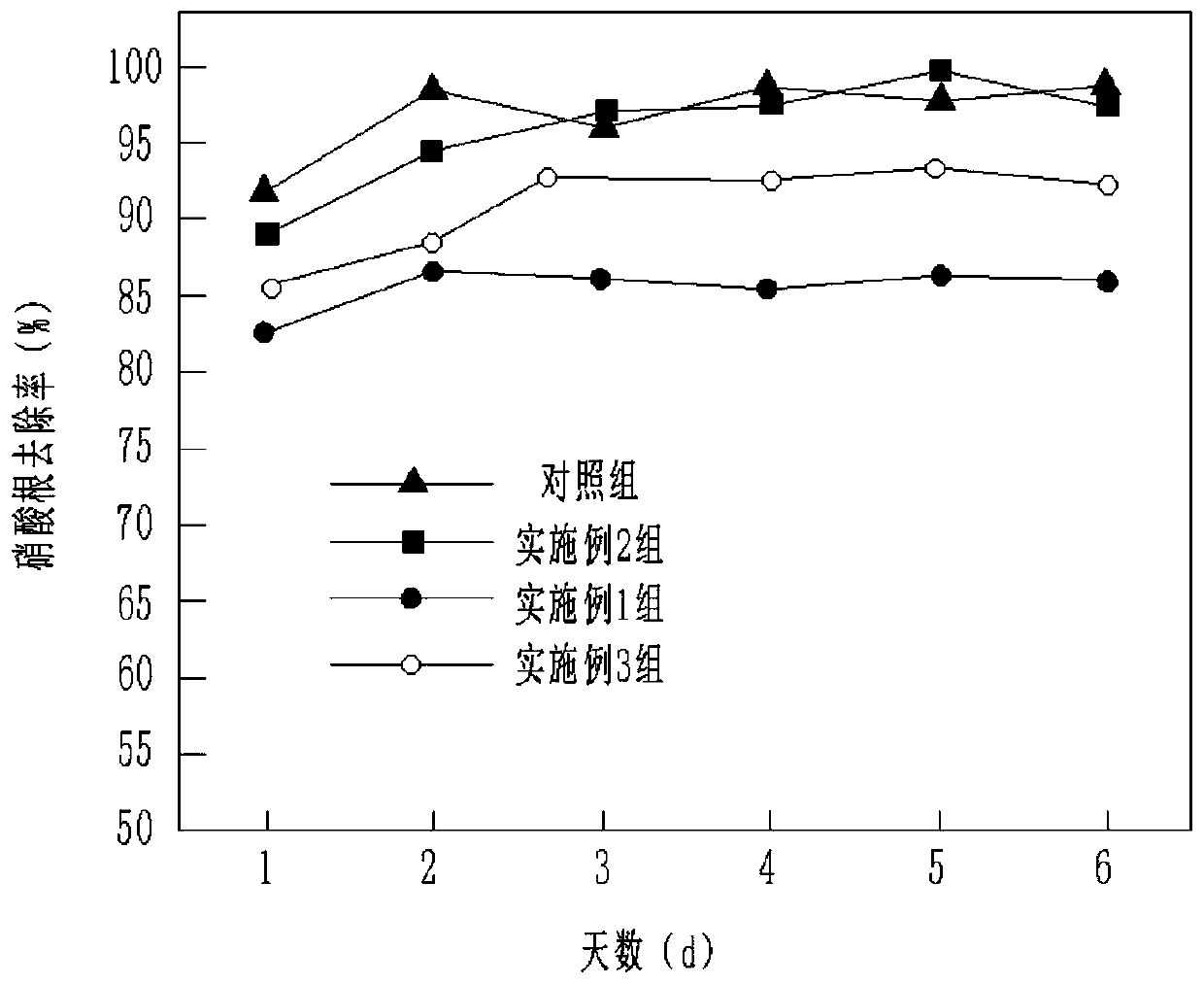

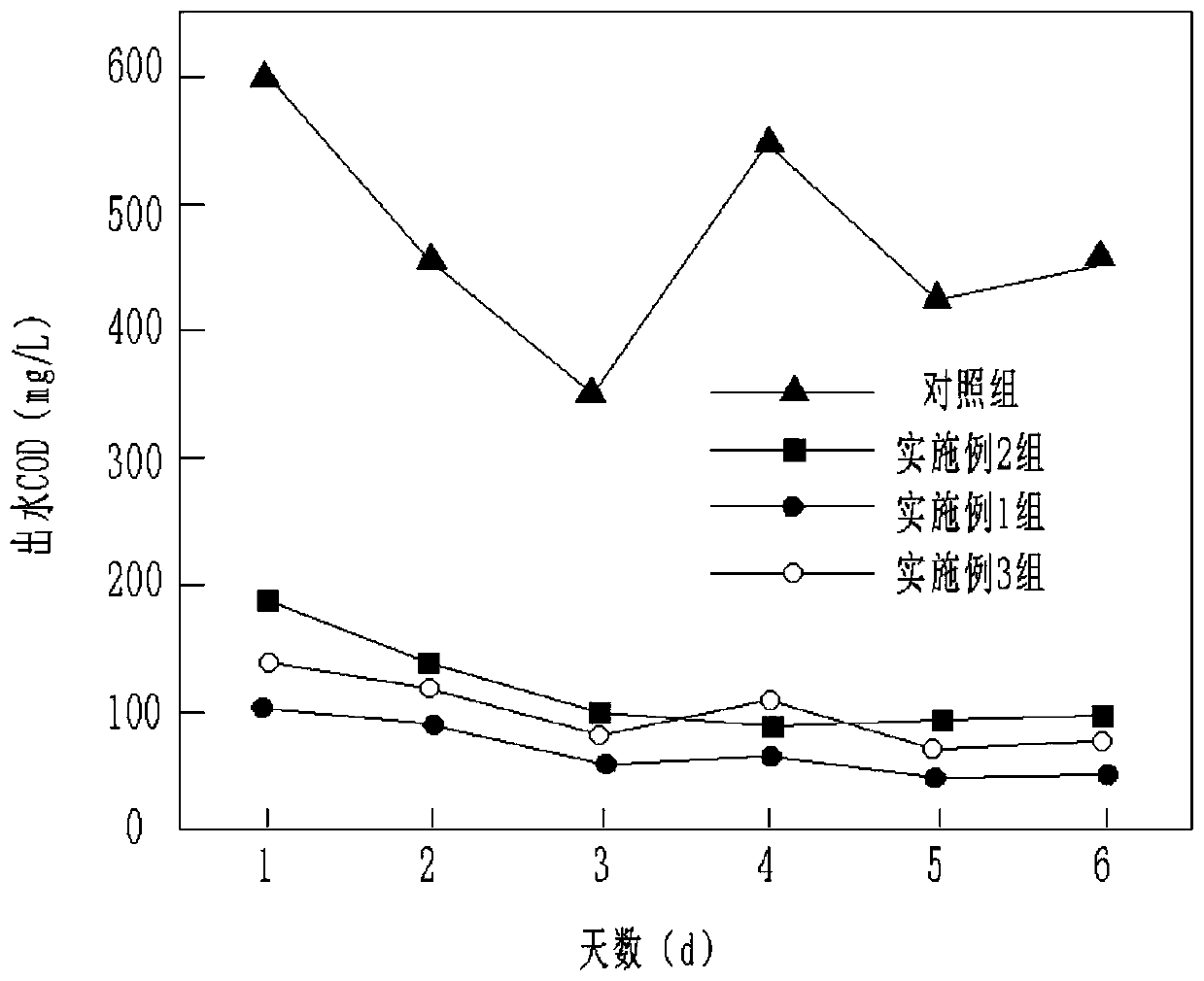

A kind of biodegradable slow-release carbon source filler and preparation method thereof

ActiveCN107935202BSolve the problem of single nutritionLarge specific surface areaWater treatment parameter controlWater treatment compoundsCelluloseCarbon nanotube

Owner:湖南长宏新能源材料有限责任公司

Novel thermal inlet load dynamic prediction and regulation and control method

ActiveCN114565167AMeet thermal needsGuaranteed uptimeForecastingResourcesModelSimProcess engineering

The invention relates to a novel thermal inlet load dynamic prediction and control method, mechanism and data hybrid driving is adopted, target energy consumption accurate control is taken as a core, a steady-state heat transfer equation and a machine language are fused for modeling, and the method is simple and feasible, has self-learning, self-adaption and self-optimization-approaching capacities, is suitable for time-division, time-division and temperature-division accurate heat supply, and has a wide application prospect. The condition of user side oversupply can be effectively avoided; and in combination with adjustment of the heat source side of the energy center, efficient operation of the whole system is facilitated, on-demand heat supply is achieved when the time scale and the space scale are small enough as much as possible, and energy conservation and emission reduction are remarkably achieved while the heat requirement of a user is met.

Owner:TIANJIN UNIV +1

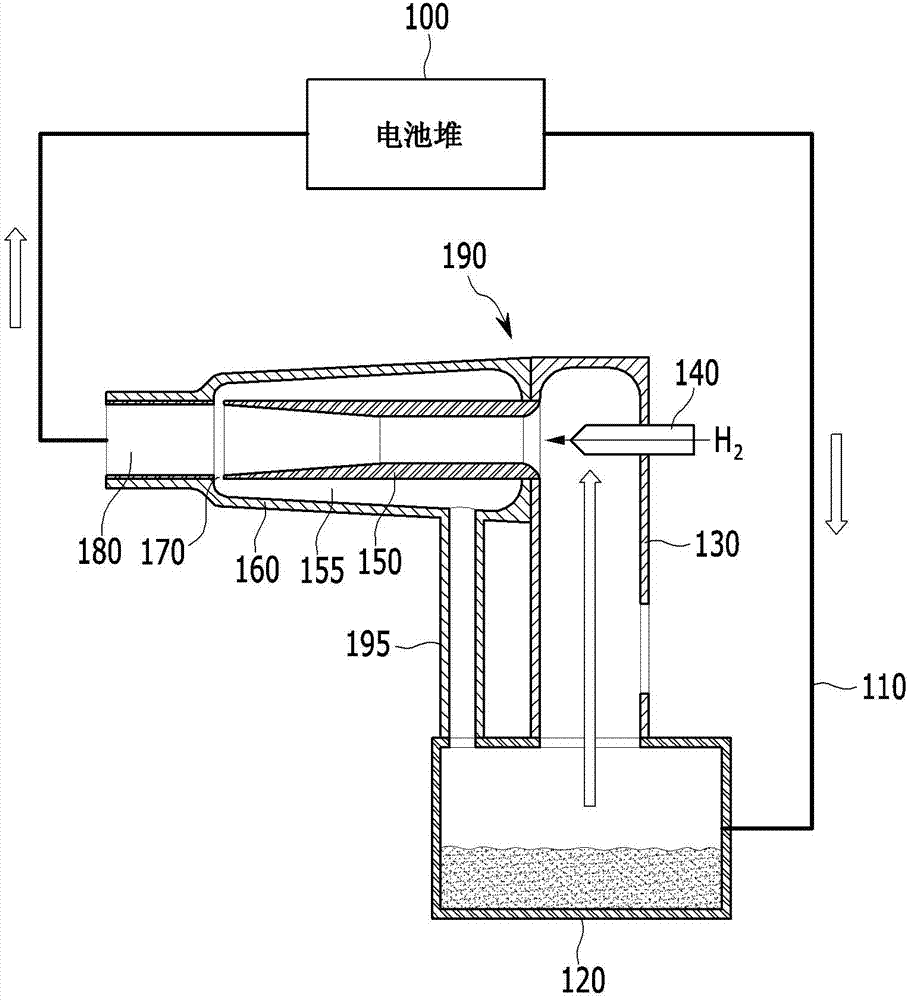

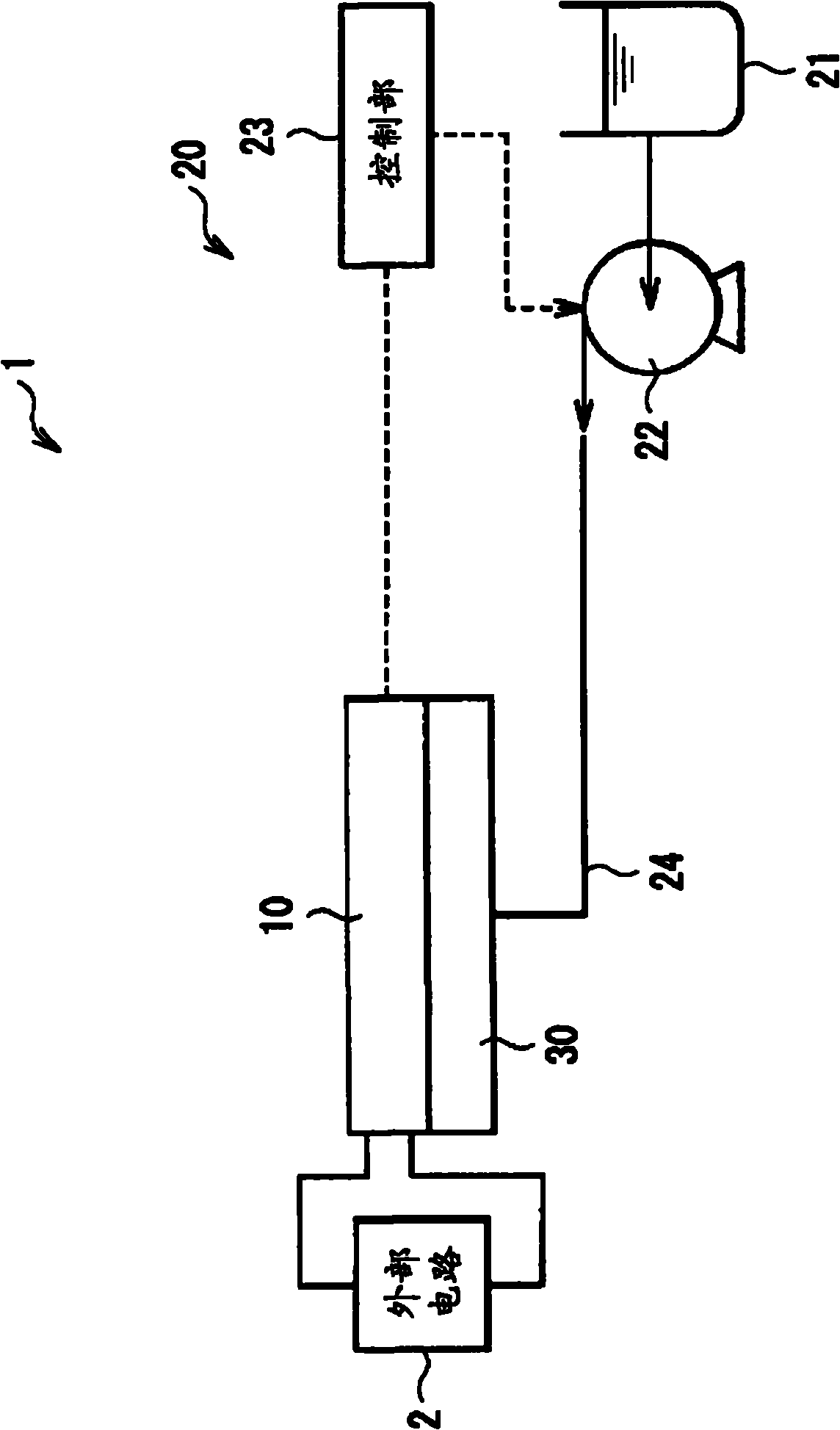

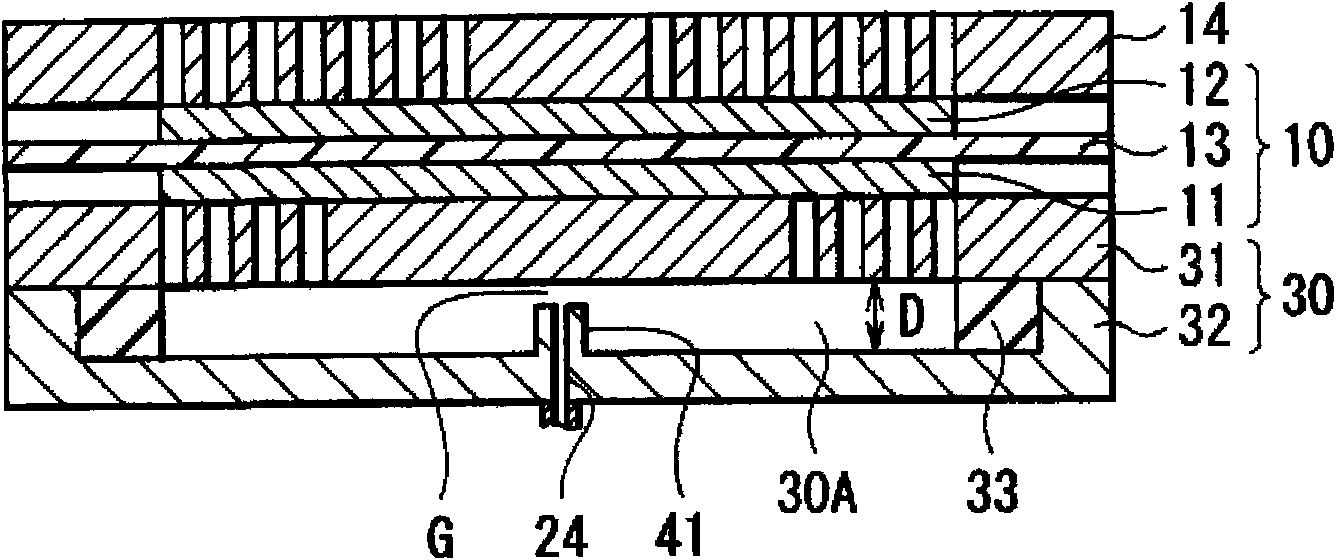

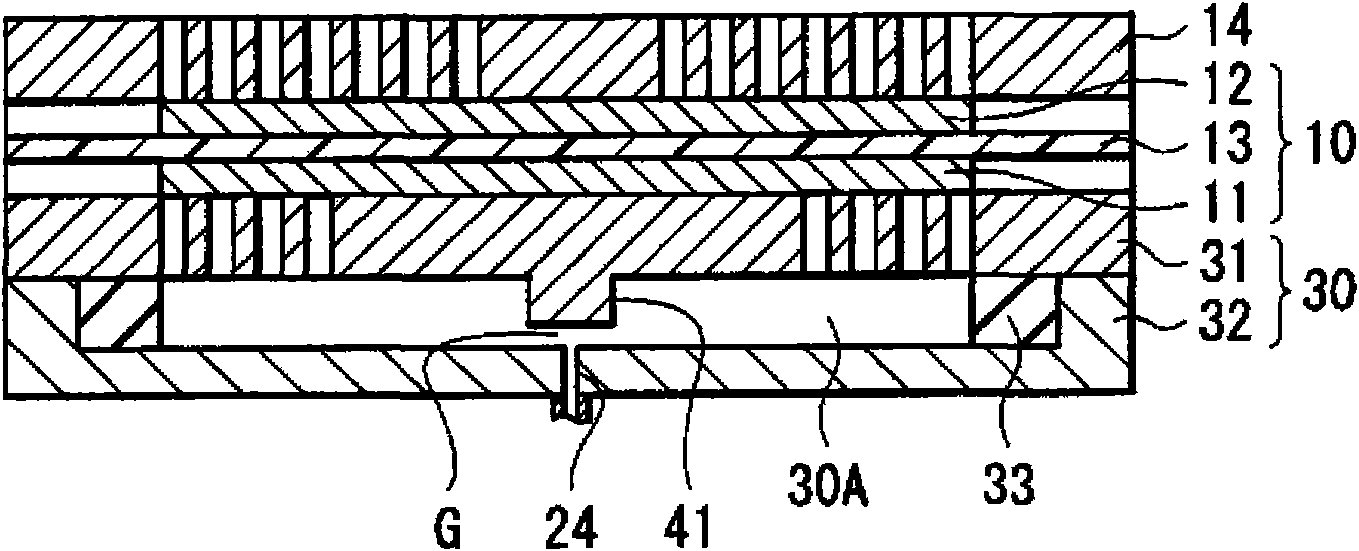

Fuel cell system, and electronic device

InactiveCN101803096AAvoid oversupplyAvoid undersupplyFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsCarburetor

Provided are a fuel cell system which can avoid an excess or insufficient feed of a gasified fuel thereby to generate an electric power stably in a high output, and an electronic device using the system. In a carburetor chamber (30A), a protrusion (41) is formed as a heat transfer portion for transferring the heat generated in a generator unit (10), to a liquid fuel fed to the carburetor chamber (30A). Between the leading end of the protrusion (41) and the inner wall face of an inner member (31), there is formed a gap (G), in which the liquid fuel fed from the leading end of a fuel feed passage (24) is gasified by transferring the heat efficiently to it. The protrusion (41) may also contact the inner wall face of the inner member (31) near the leading end portion of the fuel feed passage (24), thereby to transfer the heat of the generator unit (10) to the inner member (31) through the protrusion (41) so that the liquid fuel may be gasified by transferring the heat to it through the inner member (31). Thus, the area to be heated can be restricted according to the position of the protrusion (41), and the quantity of the heat to be transferred to the liquid fuel can also be controlled according to the size of the protrusion (41).

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com