Aromatic hydrocarbon ammoxidation combined fluidized bed reaction device and aromatic hydrocarbon ammoxidation combined fluidized bed reaction method

A technology of fluidized bed reactor and reaction device, which is applied in the direction of hydrocarbon ammoxidation preparation, chemical instruments and methods, organic chemistry, etc., and can solve the problem of inability to maintain production due to online emergency repair of heat extractors, reduce production process economy, and insufficient raw materials Utilize and other problems to achieve the effect of improving mass transfer and fluidization quality, improving fluidization quality and heat transfer level, and increasing the time of long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

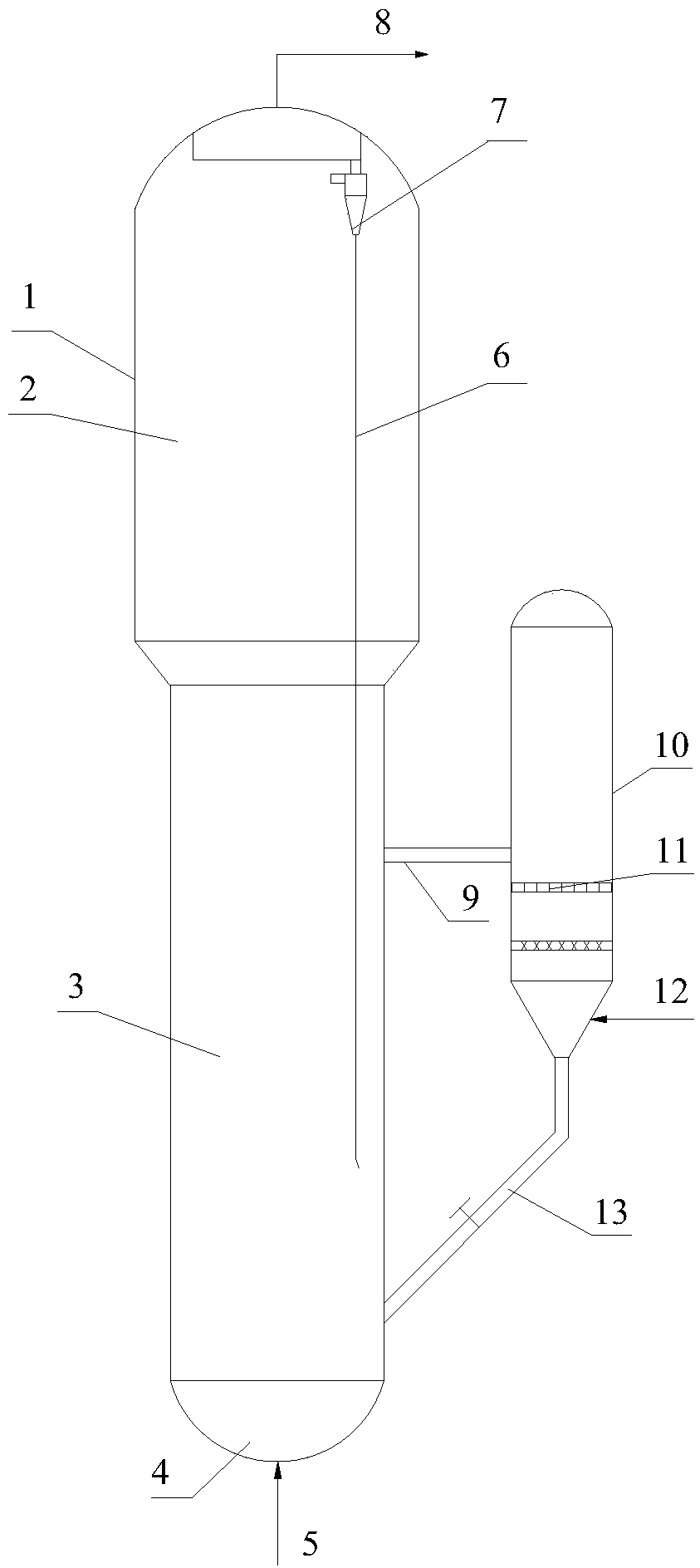

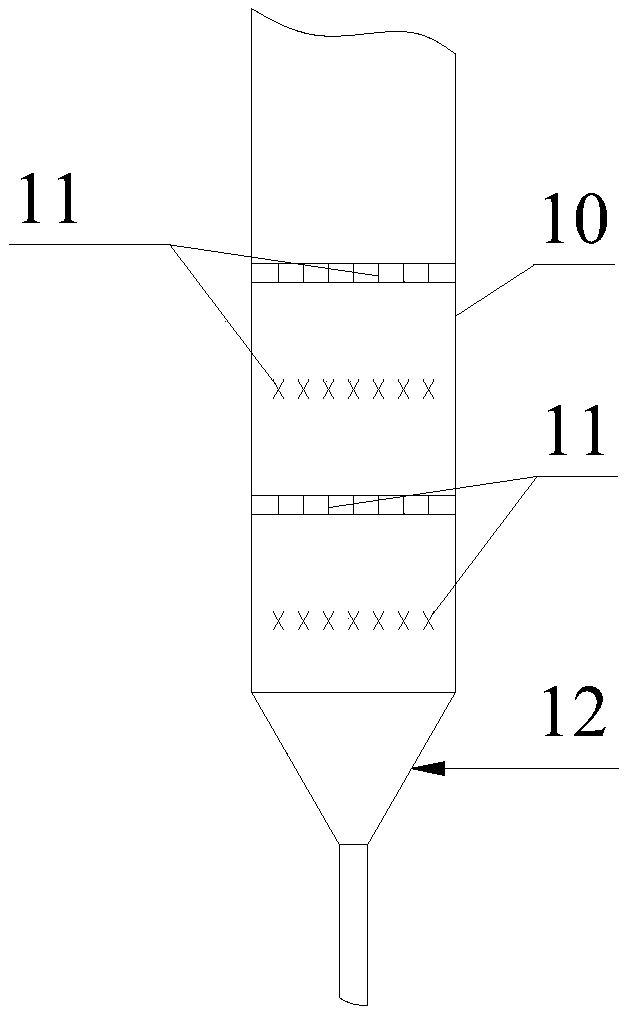

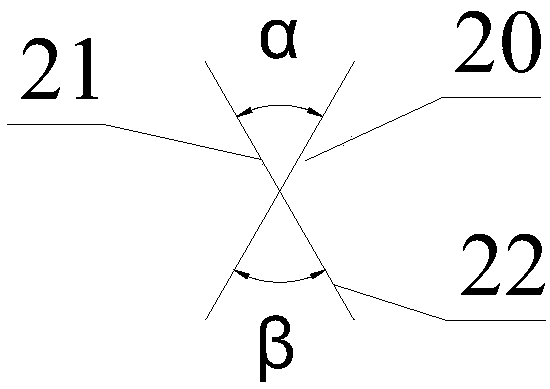

[0028] After toluene and ammonia are vaporized and air enters the dense-phase zone of the fluidized bed reactor from the gas distribution chamber, the ammoxidation reaction of aromatic hydrocarbons is carried out under the action of the catalyst; the reaction generates the corresponding benzonitrile and a small part of the catalyst leaves the reactor After the dense phase zone, it enters the dilute phase zone of the reactor. After being separated by the cyclone separator, the benzonitrile flows out of the fluidized bed reactor and is received by condensation or solvent absorption, and refined by rectification or recrystallization to obtain the product gas After being separated, the catalyst flows into the dense-phase zone of the reactor through the cyclone feed leg; after a part of the catalyst in the dense-phase zone of the reactor leaves the fluidized bed reactor, it flows into the oxygen supply heat exchanger through the circulating feed pipe under the action of the strong mi...

Embodiment 2

[0032] After toluene and ammonia are vaporized and air enters the dense-phase zone of the fluidized bed reactor from the gas distribution chamber, the ammoxidation reaction of aromatic hydrocarbons is carried out under the action of the catalyst; the reaction generates the corresponding benzonitrile and a small part of the catalyst leaves the reactor After the dense phase zone, it enters the dilute phase zone of the reactor. After being separated by the cyclone separator, the benzonitrile flows out of the fluidized bed reactor and is received by condensation or solvent absorption, and refined by rectification or recrystallization to obtain the product gas After being separated, the catalyst flows into the dense-phase zone of the reactor through the cyclone feed leg; after a part of the catalyst in the dense-phase zone of the reactor leaves the fluidized bed reactor, it flows into the oxygen supply heat exchanger through the circulating feed pipe under the action of the strong mi...

Embodiment 3

[0036] After toluene and ammonia are vaporized and air enters the dense-phase zone of the fluidized bed reactor from the gas distribution chamber, the ammoxidation reaction of aromatic hydrocarbons is carried out under the action of the catalyst; the reaction generates the corresponding benzonitrile and a small part of the catalyst leaves the reactor After the dense phase zone, it enters the dilute phase zone of the reactor. After being separated by the cyclone separator, the benzonitrile flows out of the fluidized bed reactor and is received by condensation or solvent absorption, and refined by rectification or recrystallization to obtain the product gas After being separated, the catalyst flows into the dense-phase zone of the reactor through the cyclone feed leg; after a part of the catalyst in the dense-phase zone of the reactor leaves the fluidized bed reactor, it flows into the oxygen supply heat exchanger through the circulating feed pipe under the action of the strong mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com