Method for controlling particles distribution by adopting electric field and gas phase polymerization fluidized bed reactor

A fluidized bed reactor and gas phase polymerization technology, which is applied in the field of particle distribution control, can solve the problem of only placing electrodes and achieve the effect of improving fluidization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

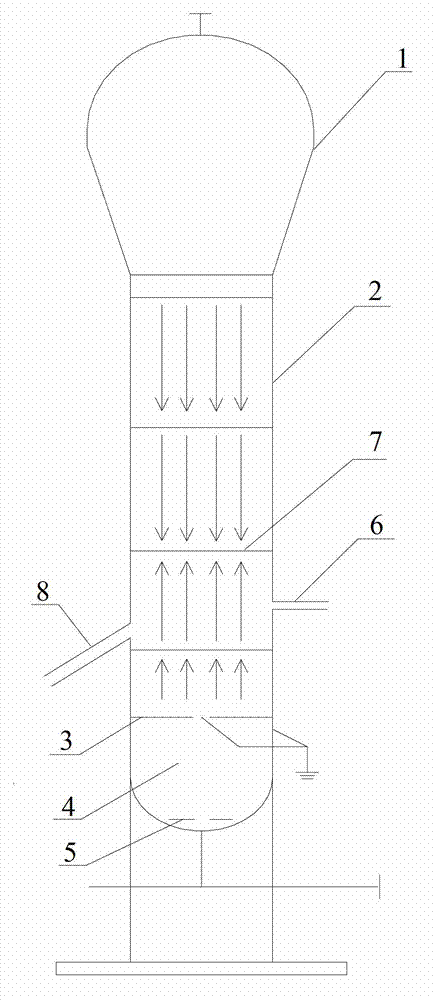

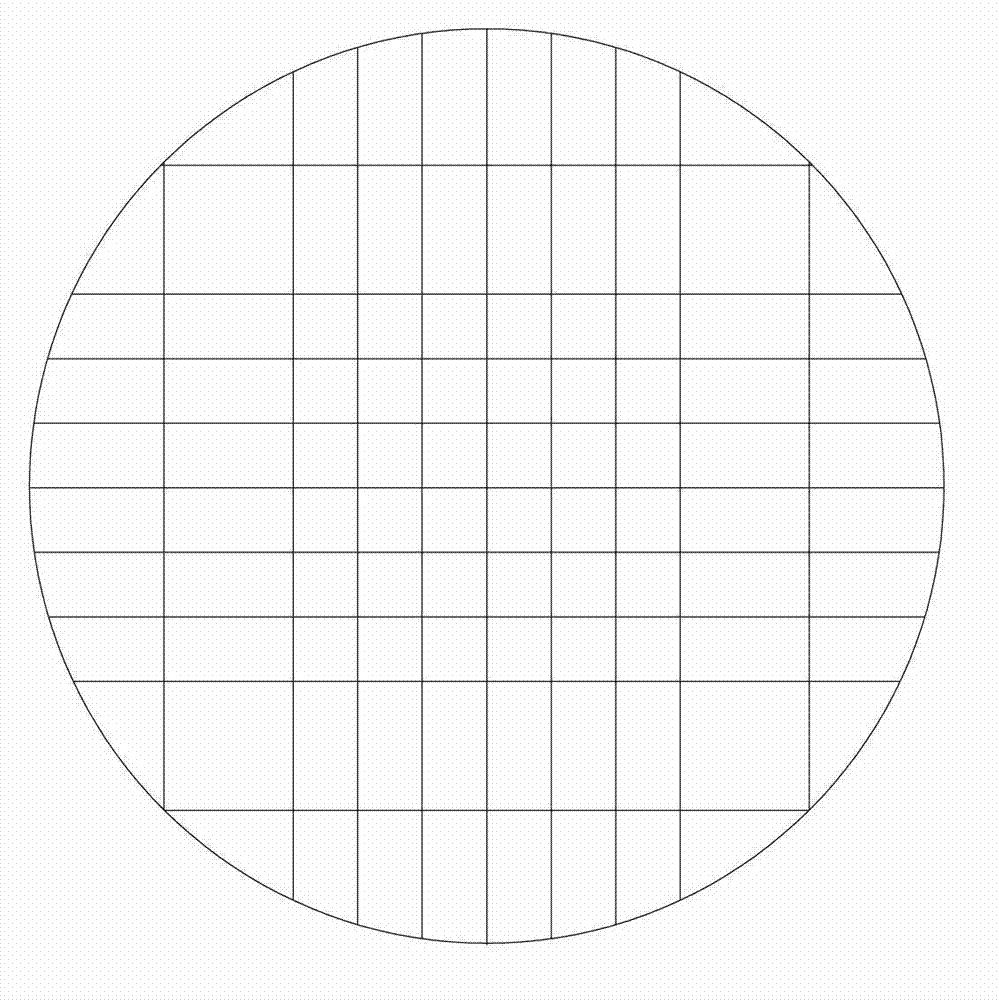

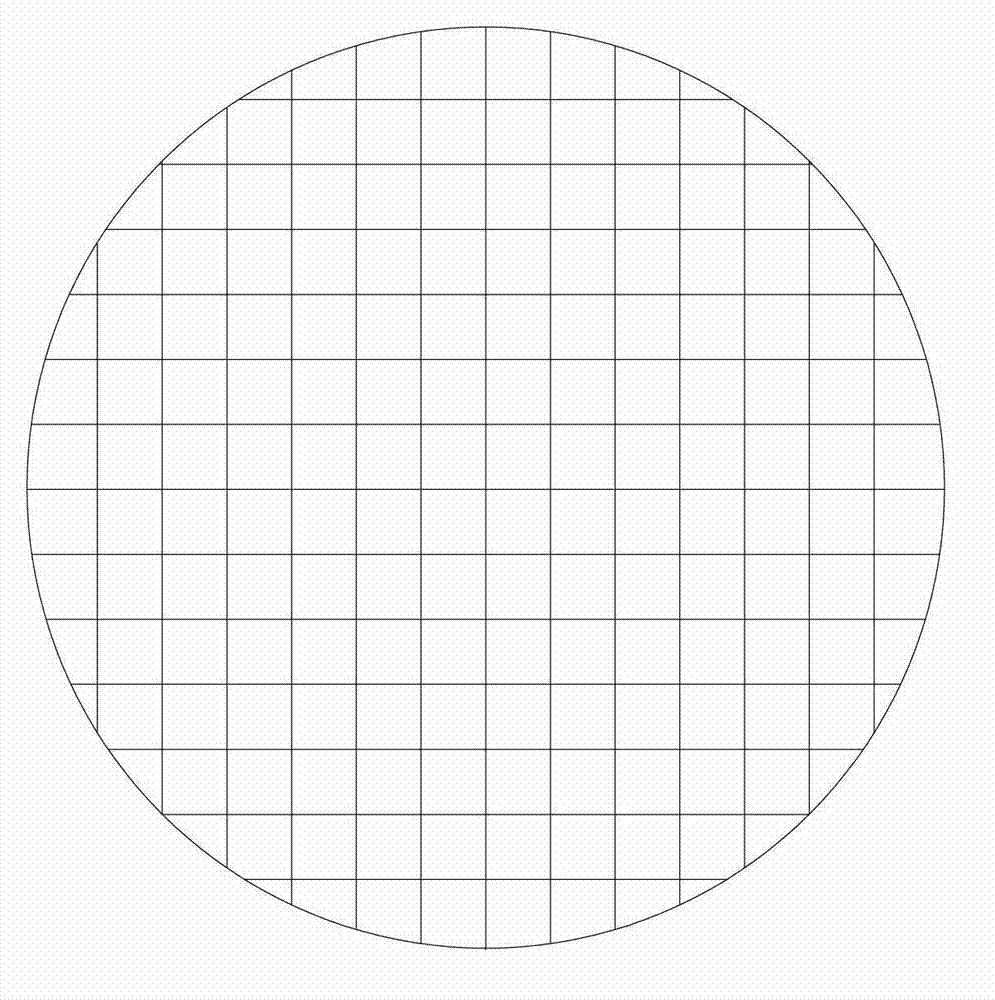

[0037] Such as figure 1 As shown, a gas-phase polymerization fluidized-bed reactor for realizing the method of controlling the particle distribution in the gas-phase polymerization reaction system by using an electric field, including a base (not shown), and a catalyst feed port 6 and a discharge port in the middle 8, the straight cylinder reaction section 2 and the expansion section 1, one end of the straight cylinder reaction section 2 is connected to the base, the other end is connected to the expansion section 1, and the side of the straight cylinder reaction section 2 close to the base is sequentially provided with a gas predistributor 5, a gas mixing Chamber 4 and gas distribution plate 3, there are four electrodes 7 perpendicular to the axis of straight reaction section 2 in straight reaction section 2. The four electrodes are from top to bottom (that is, along the straight reaction section 2 near the end of expansion section 1 to the straight reaction section 2). The d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com