Reactor of fluidized bed

A fluidized bed reactor and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as inability to meet chemical process conditions, reasonable reactor design and processing difficulties, etc., to improve the quality of fluidization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

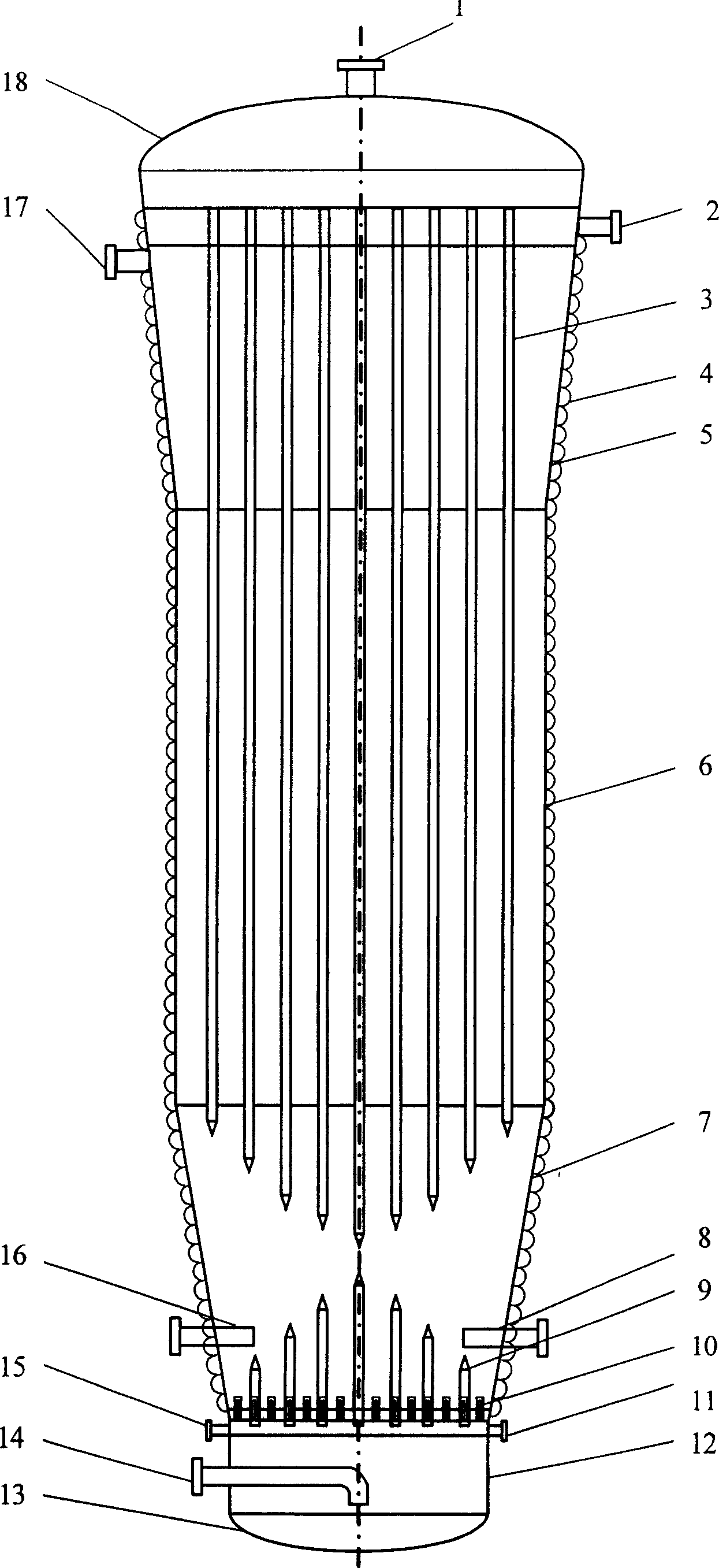

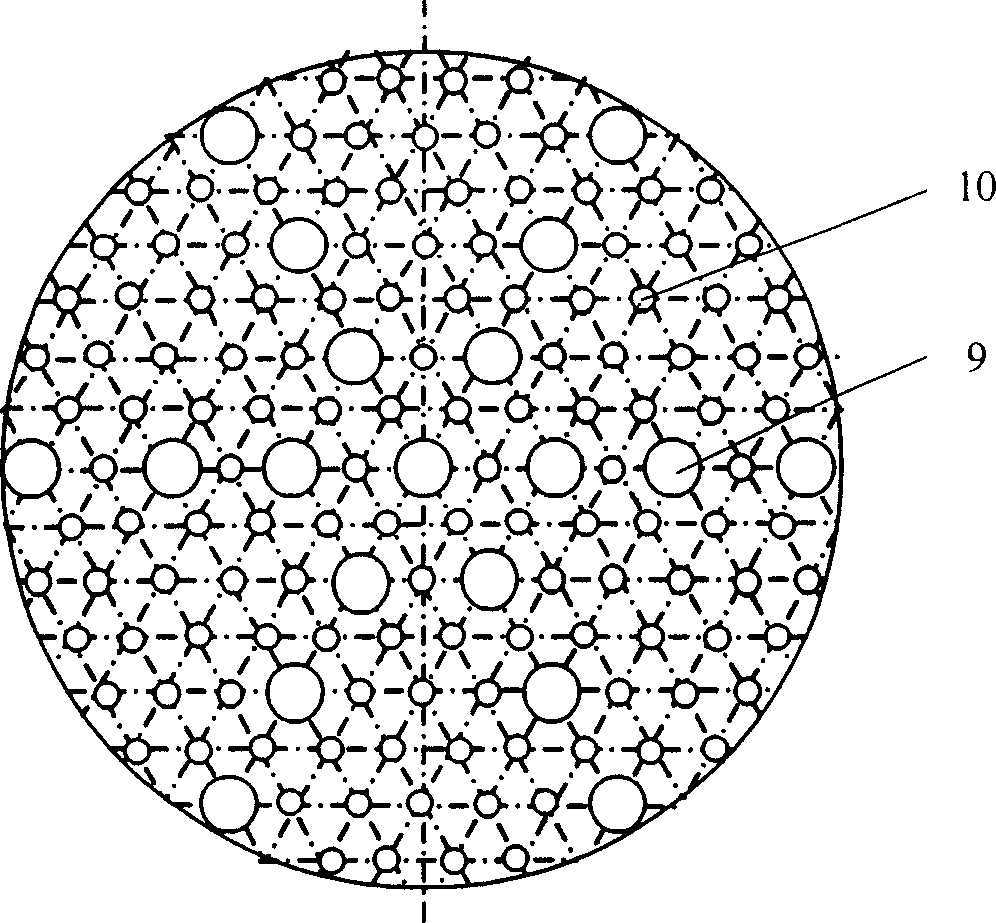

[0037] Example: Figure 4 It is a comparison chart of the superficial gas velocity of the fluidized bed reactor of the present invention and the traditional semi-cone straight cylindrical bed reactor. Figure 4 The abscissa of is the fluidized bed reactor height H, Figure 4 The ordinate is the superficial gas velocity V. Compared with the commonly used semi-conical straight fluidized bed reactor (diameter 1.6 meters), the variable conical bed body of the present invention cooperates with the finger-shaped heat exchange tube bundle, and the formed cross-sectional area is smaller at the bottom of the reactor, and the empty tower gas The higher velocity V is conducive to the fluidization of large particles; the cross-sectional area at the top of the reactor is relatively larger, and the superficial gas velocity is significantly reduced, which is conducive to the fall of small particles or catalyst powder and reduces the load on separation and filtration devices. The reaction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com