CFB boiler inlaid type hood air distributing device and improving method thereof

An air distribution device and nested technology, which is applied in the field of air distribution plate reconstruction of circulating fluidized bed boilers in thermal power plants, can solve the problem of increased power consumption of primary fans, wear of small holes in air guide pipes and air cap vents, and leakage of air chambers. slag and other problems, to achieve the effect of improving the uniformity of air distribution, avoiding the risk of coking, and improving the quality of fluidization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

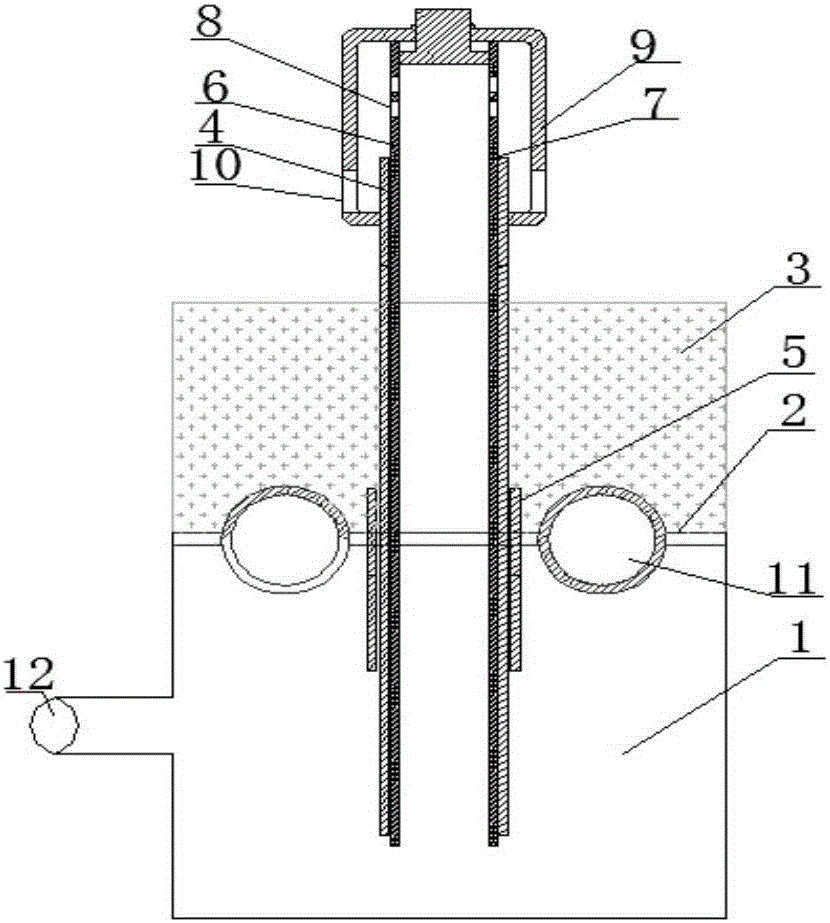

[0016] like figure 1 As shown, a CFB boiler nested hood air distribution device includes an air chamber 1 with an air duct 12; wherein: it also includes a flower plate 2, a castable for the air distribution plate 3, an A air pipe 4, and a reinforced sleeve 5. B air duct 6, welding point 7, "I" type air cap 9, furnace water wall pipe 11; the flower plate 2 is located on the upper part of the air chamber, and the furnace water wall pipe 11 is uniformly arranged on the flower plate 2, the air distribution plate pouring material 3 is laid on the flower plate 2, and there is a gap in the center of the flower plate 2, and the B air duct 6 is nested inside the A air duct 4, and all pass through The flower plate 2 with a gap extends into the air chamber 1, the upper end of the A air duct 4 is fixed to the B air duct 6 through the welding point 7, and the reinforcing sleeve 5 is fixedly arranged between the A air duct 4 and the flower. At the intersection of the plates 2, a small air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com