Combustion process method for granular coal circulating fluidized bed boiler

A circulating fluidized bed and boiler combustion technology, which is applied to fluidized bed combustion equipment, combustion methods, and fuels burned in a molten state, to achieve the effects of reducing primary air pressure head, reducing bed pressure drop, and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

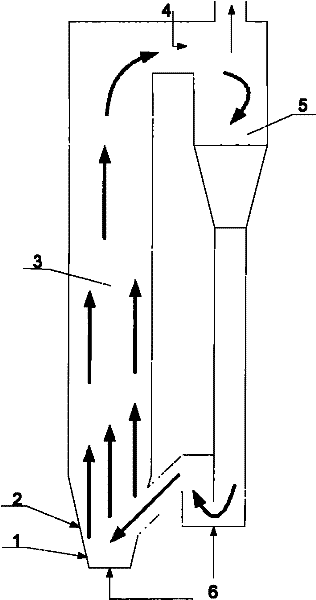

Image

Examples

Embodiment

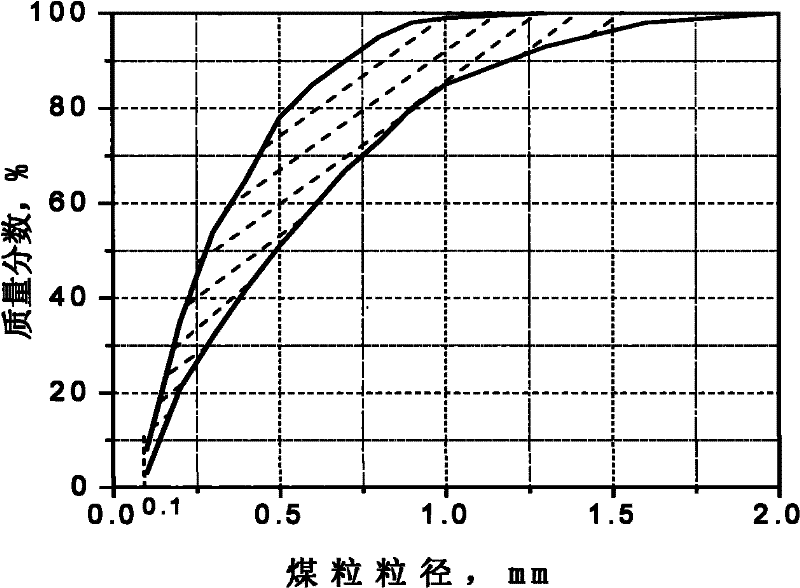

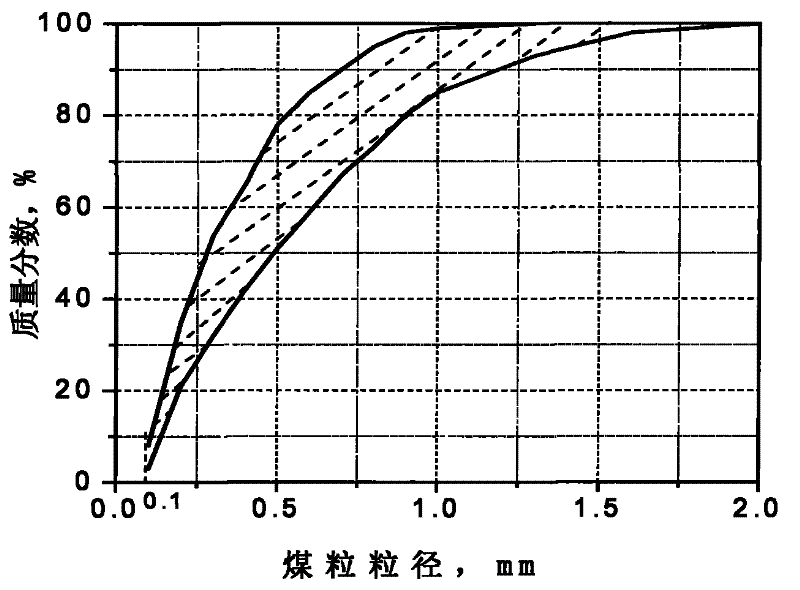

[0019] Taking a 75t / h circulating fluidized bed boiler as an example, three particle size distributions are selected according to the particle size distribution range of the granular coal provided by the present invention, as shown in the table below.

[0020]

[0021] Using the three particle size distributions of coal provided in the table above, controlling the combustion temperature in the furnace to 850-950°C, and the fluidization wind speed to 2-3.5m / s, can realize the fast bed fluid state in the upper part of the furnace and the boiler can operate normally. At this time, the bed pressure drop is between 1 and 3kPa, and the primary air pressure head is between 5 and 7kPa. Compared with the fluidized bed boiler that does not use granular coal combustion technology, the bed pressure drop and primary air pressure can be reduced by 30 % to 60%, the carbon content of fly ash is reduced by about 50%, and the power consumption of the plant is reduced by 1 to 2.5 percentage po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com