Cyclone burner and air burnout arrangement structure for boiler

A swirl burner, the technology of arrangement structure, which is applied in the direction of burning with multiple fuels, burning with block fuel and liquid fuel, burning with block fuel and gaseous fuel, etc. Corrosion, low boiler combustion efficiency, etc., to reduce high-temperature corrosion and slagging, improve operating efficiency, and increase residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

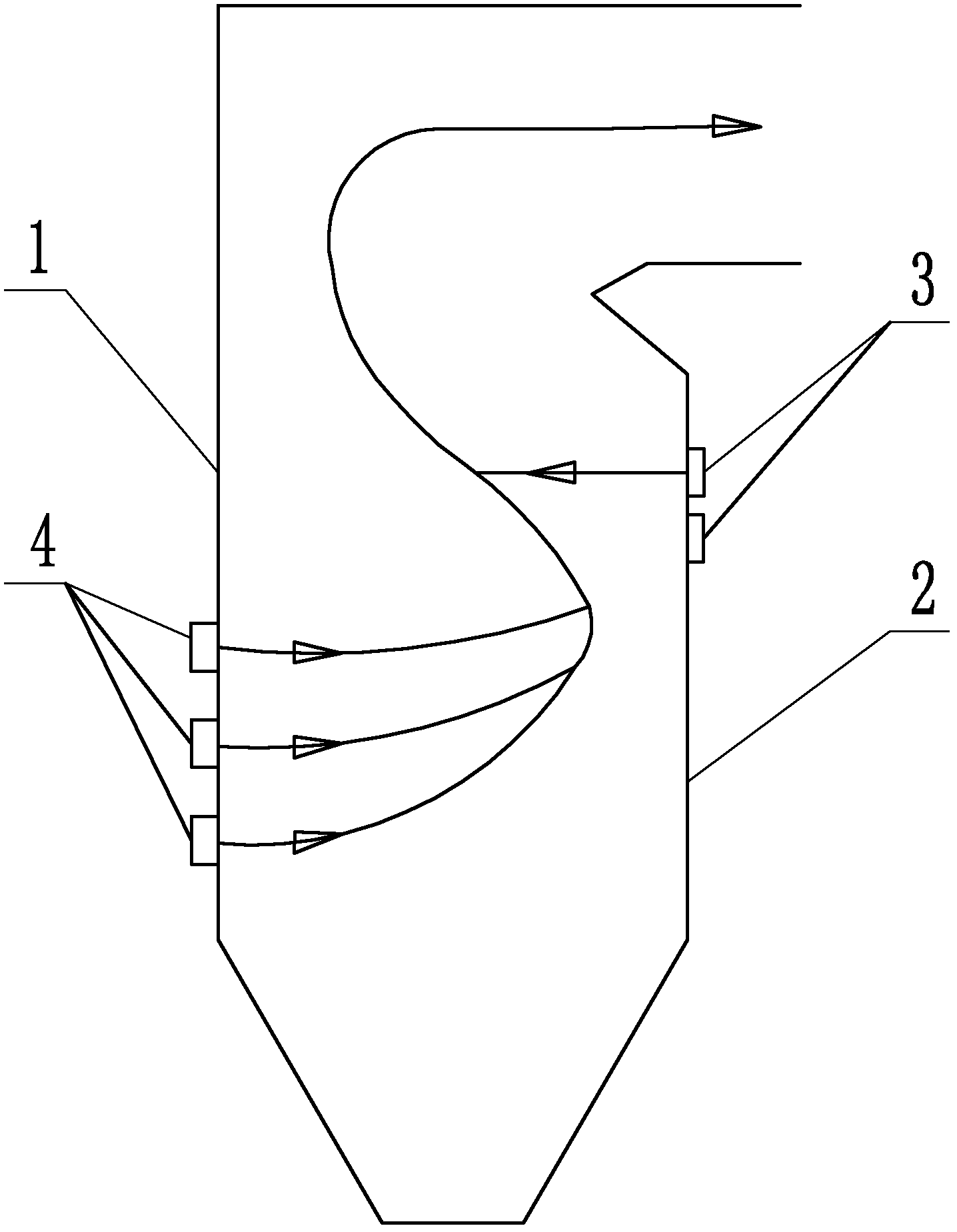

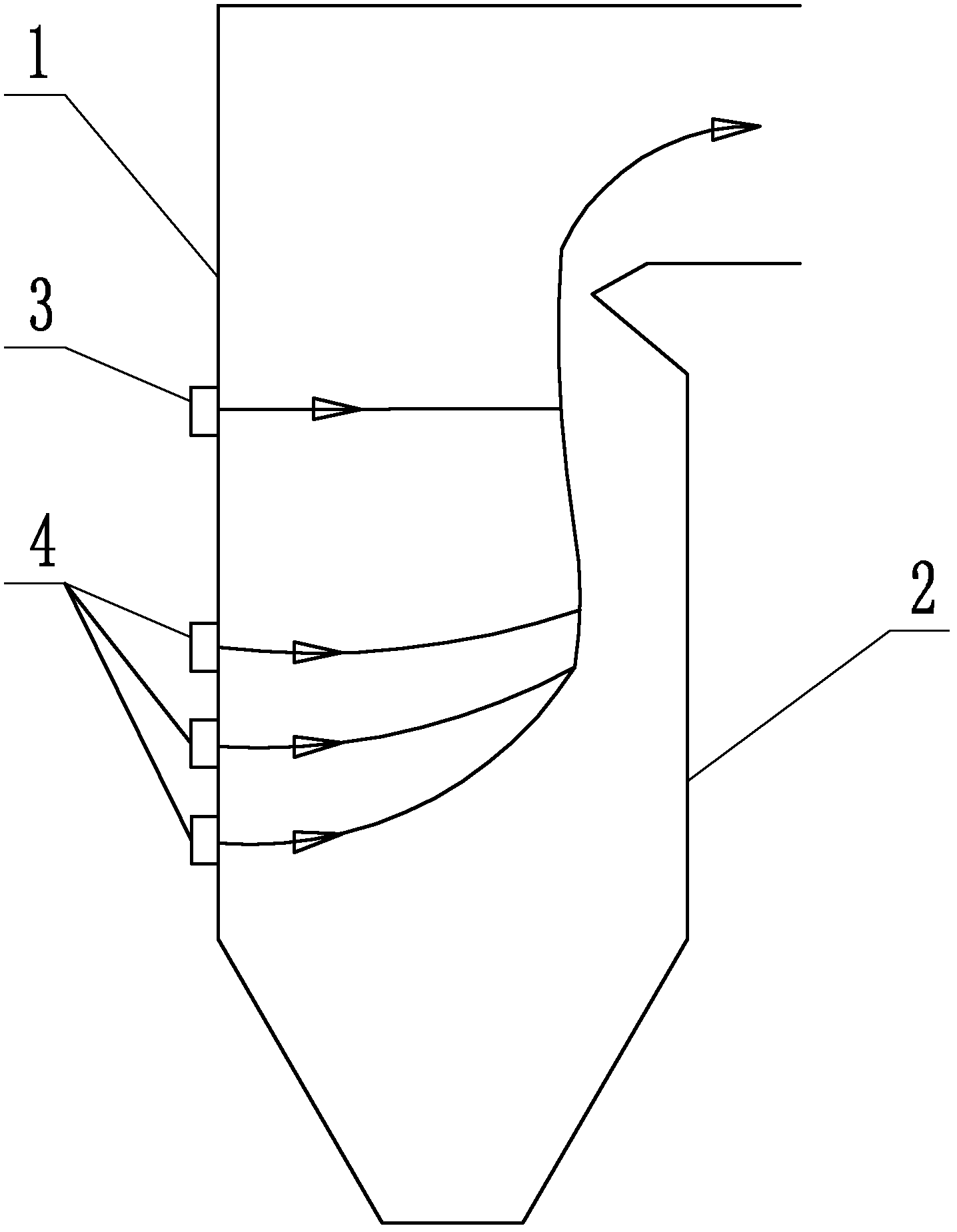

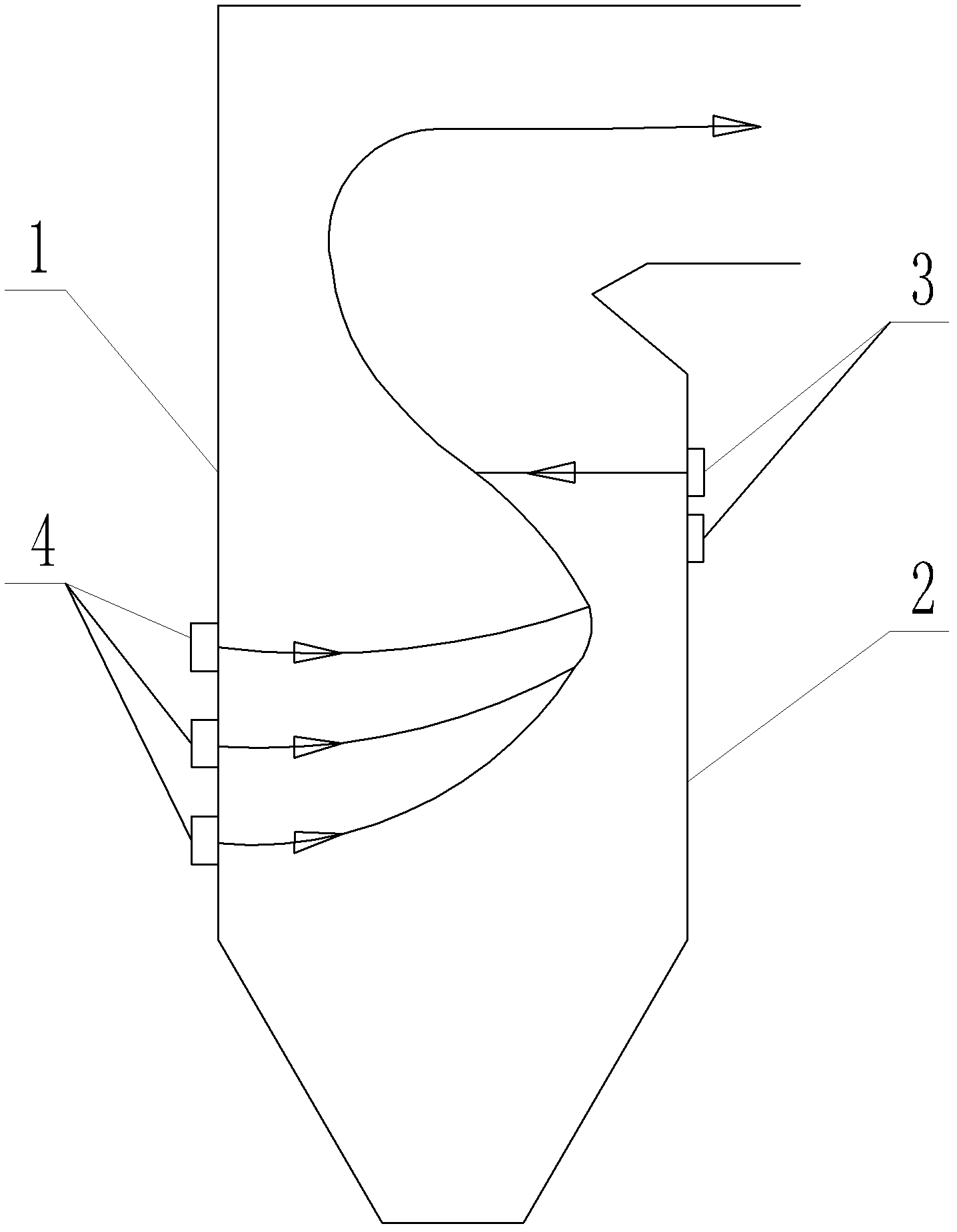

[0011] Specific implementation mode one: combine figure 1 Explain that the arrangement structure of the boiler's swirl burner and overfired air in this embodiment includes at least one layer of overfired air nozzle 3 and three layers of swirl burners 4, and the swirl burner 4 is arranged on the front wall 1 of the boiler. The overfire air nozzle 3 is arranged on the rear wall 2 of the boiler and is located above the side of the swirl burner 4 .

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 Note that the number of the overburning air nozzle 3 in this embodiment is one. Such a design can prevent high-temperature corrosion of flue gas, increase flue gas travel, increase the residence time of combustibles in the furnace, effectively reduce the carbon content of boiler fly ash, and improve boiler operating efficiency. Other compositions and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 Note that the number of overburning air nozzles 3 in this embodiment is two. With this design, the overfired air enters the furnace in two stages, and the air volume of each layer of overburned air can be adjusted during operation to facilitate the adjustment of the combustion of combustibles in the furnace. Other compositions and connections are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com