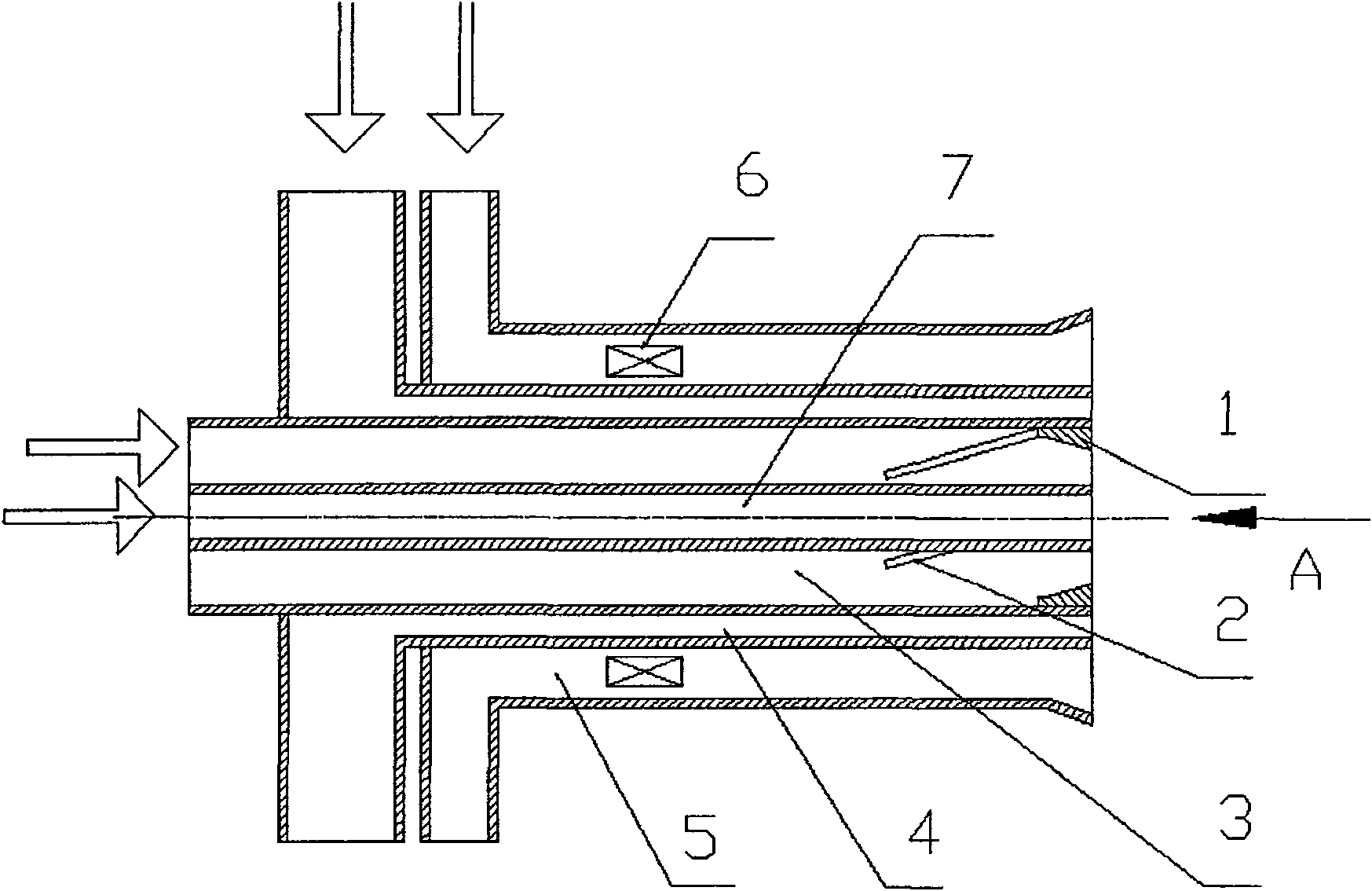

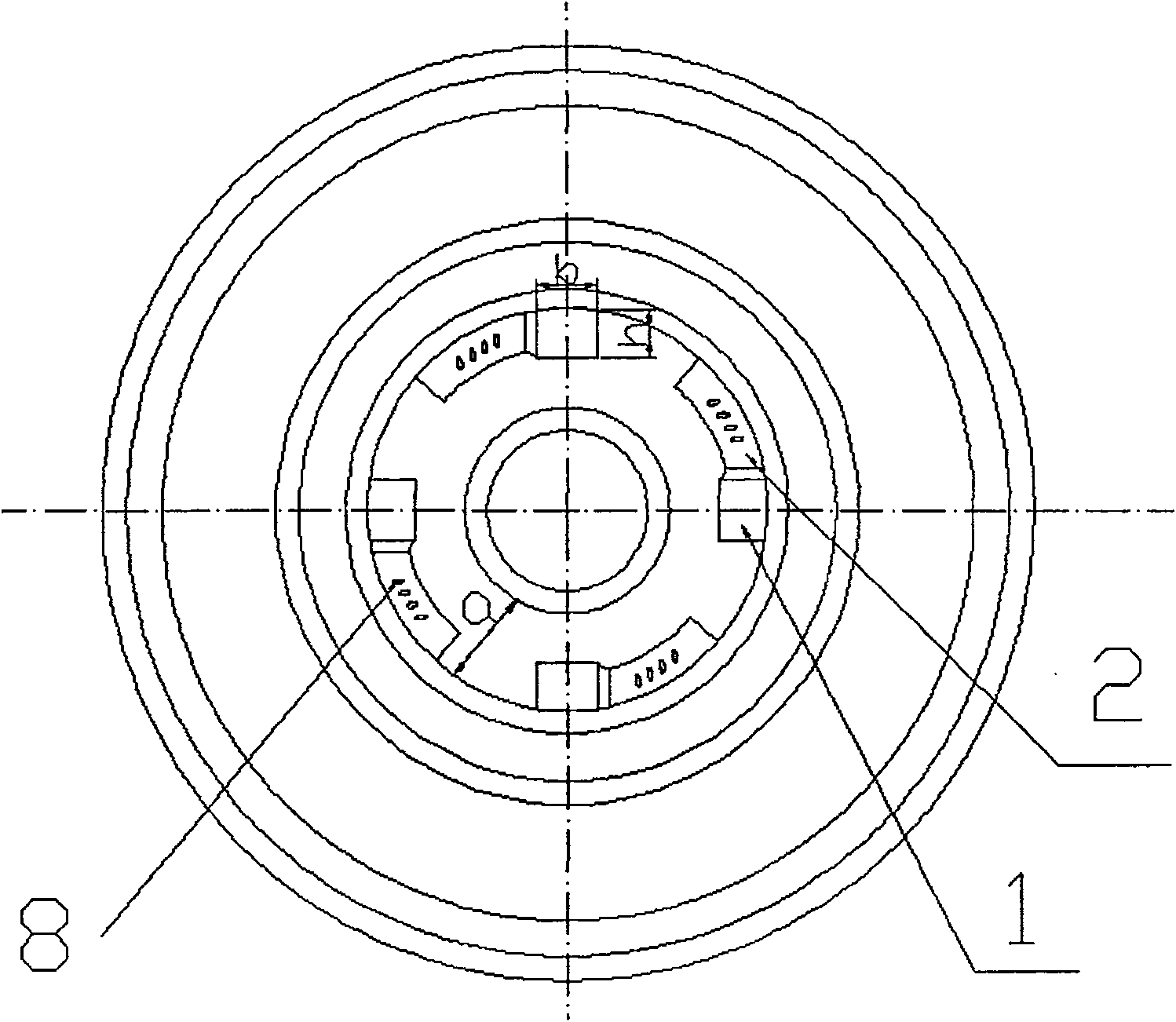

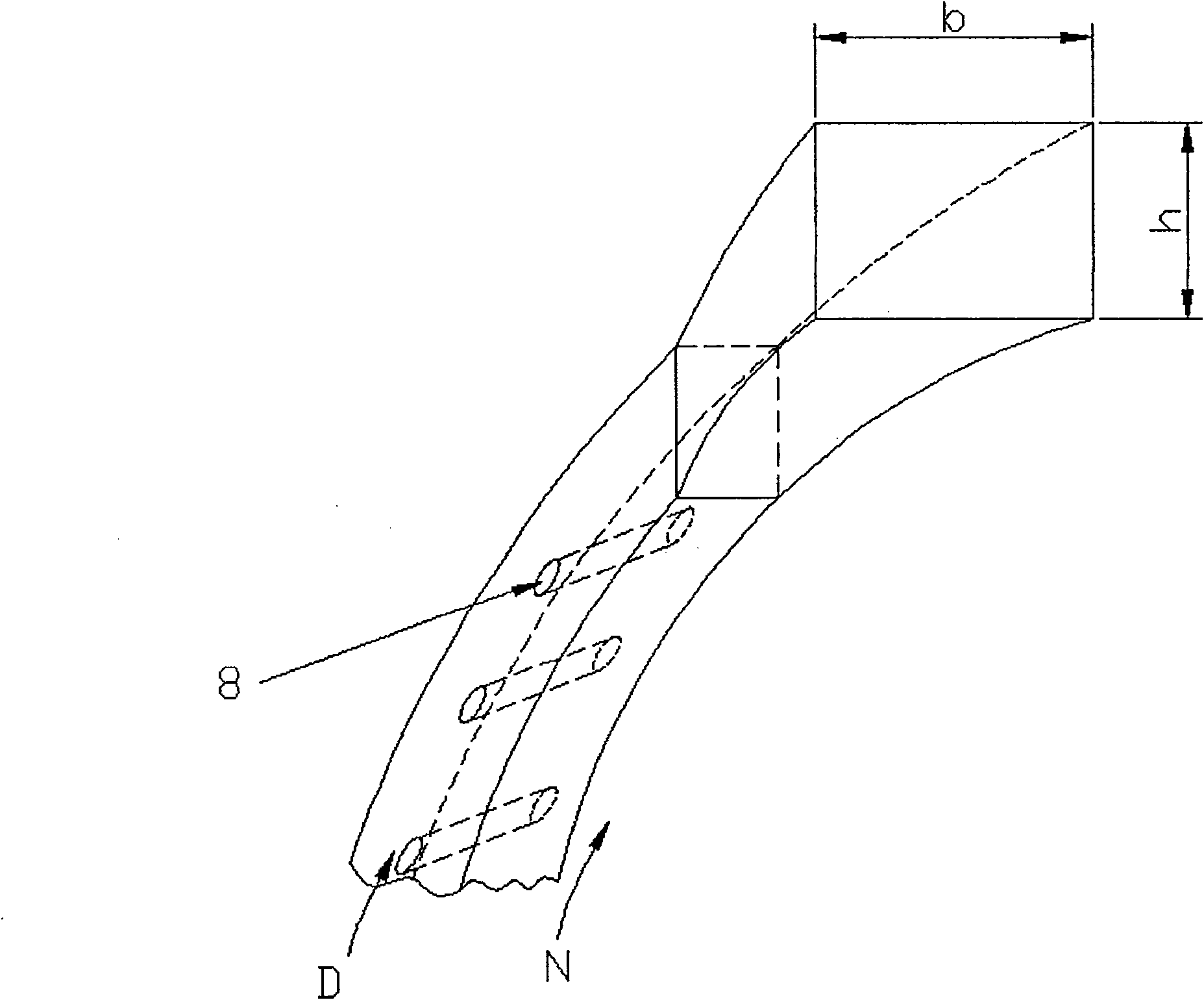

Vortex combustor of coal fines circumferential direction concentration sectional stopping whorl

A swirl burner and trapped vortex technology, which is applied to burners, burners, combustion methods and other directions for burning powder fuel, and can solve the problem of not using the concentration-lean separation technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0029] 1. For lean coal,

[0030] The invention is applied to a certain Eπ-670-13.8-545KT steam boiler. The rated generating capacity of the unit is 215MW. Boiler is T-shaped layout, double furnace structure.

[0031] The quality of coal used is as follows:

[0032] Mt.

ad

Vdaf

St, d

Qnet, ar(kJ / kg)

6.53

32.77

15.87

2.83

20438.31

[0033] Effect after applying the present invention:

[0034] ① After the application of the present invention, the stable combustion capability of the boiler with low load and no oil input is reduced from 75% before the change to 50%

[0035] ②The cooling flow of reheater spray water is reduced from 15t / h before the modification to 0t / h after the modification, which greatly improves the economical efficiency of the unit.

[0036] 2. For inferior bituminous coal

[0037] The invention is applied to a certain 670-13.8-545KT type steam boiler. The rated generating capacity of the unit i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com