A combined denitrification device and method for a layer-fired boiler

A denitrification and boiler technology, applied in the field of pollutant emission control of coal-fired bed-fired boilers, can solve the problems of high natural gas prices, increased operating costs, poor denitrification effects, etc., and achieve the effects of energy saving, thermal efficiency improvement and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

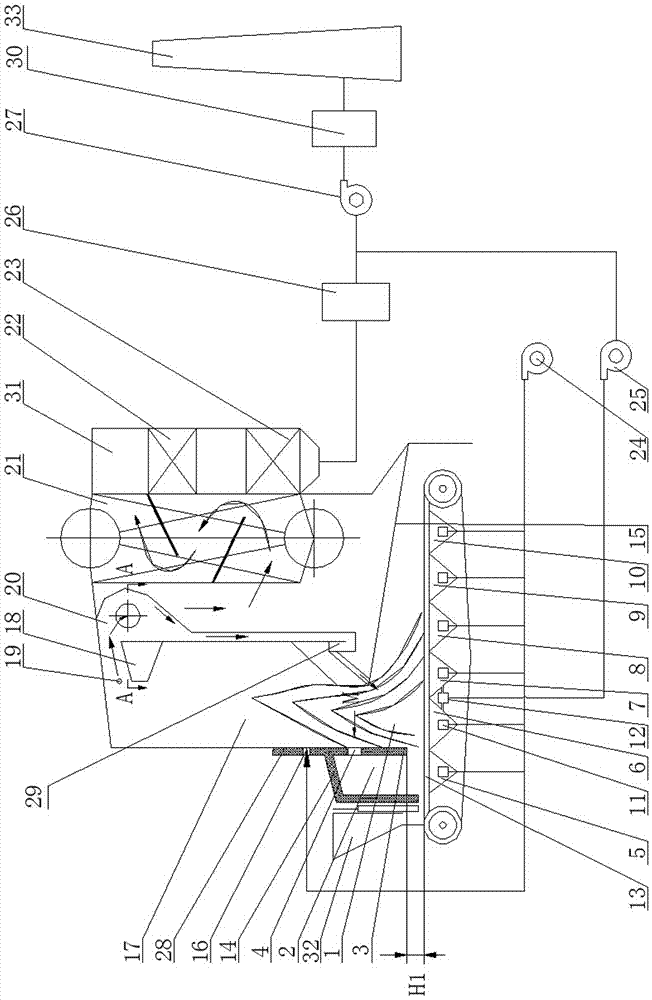

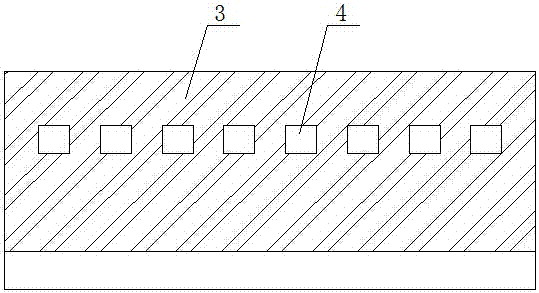

[0025] Specific implementation mode one: as Figure 1~Figure 4 As shown, a combined denitrification device for a layer-fired boiler includes a gasification chamber 2, a furnace partition wall 3, a flue gas channel 12, a fire grate 13, a furnace front arch 14, a furnace 17, a nozzle 19, and a horizontal cyclone with an acceleration section Separator 20, convection pipe 21, economizer 22, air preheater 23, blower 24, recirculation fan 25, dust collector 26, induced draft fan 27, return valve 29 and six air chambers; the six The air chambers are the gasification air chamber 5, the first air chamber 6, the second air chamber 7, the third air chamber 8, the fourth air chamber 9 and the fifth air chamber 10;

[0026]The lower front part of the furnace 17 is provided with a gasification chamber 2. The gasification chamber 2 is surrounded by a furnace front arch 14, a furnace partition wall 3 and two side walls of the furnace chamber. The furnace partition wall 3 is provided with a pl...

specific Embodiment approach 2

[0028] Specific implementation mode two: as figure 1 and Figure 4 As shown, in the combined denitrification device for the floor-fired boiler described in Embodiment 1, the grate 13 is a chain grate or a reciprocating grate, and the distance H1 between the lower surface of the furnace partition wall 3 and the upper surface of the chain grate is =450~550mm (preferably 500mm), the distance between the vertical extension surface of the rear side of the furnace partition wall 3 and the intersection line of the upper surface of the reciprocating fire grate to the lower surface of the furnace partition wall 3 H2=450~550mm ( 500mm is preferred). Such setting, on the one hand, can prevent the downward diffusion of gas, and on the other hand, the heat generated by the gasification chamber 2 is isolated from the outside, which is used for better coal gasification. In addition, it is also convenient for maintenance.

specific Embodiment approach 3

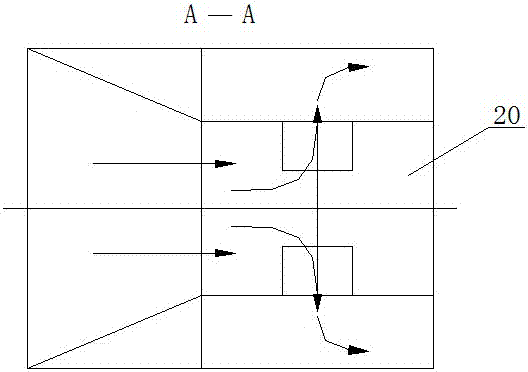

[0029] Specific implementation mode three: as figure 1 and Figure 4 As shown, in the combined denitrification device of the floor-fired boiler described in Embodiment 1, the outlet of the furnace 17 is located below the horizontal cyclone separator 20 with an acceleration section, and a flame angle 18 is provided. The effect is: on the one hand, the furnace 17 has a good flame filling degree, and strengthens the radiation heat transfer; on the other hand, it forms the acceleration section of the horizontal cyclone separator 2, ensuring that the separation efficiency of the horizontal cyclone separator 2 is greater than 95%, and at the same time, the urea and Good mixing of the flue gas is very beneficial.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com