Center air ring concentrated type turbulent burner

A swirling burner and concentrated technology, which is applied in the direction of burners, burners for burning powder fuel, and combustion methods, can solve the problems of unfavorable pulverized coal preheating and volatilization analysis, increased carbon content of fly ash, and pulverized coal Delayed ignition and other issues, to achieve the effect of timely ignition and stable combustion, reduce the carbon content of fly ash, and reduce the carbon content of large slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

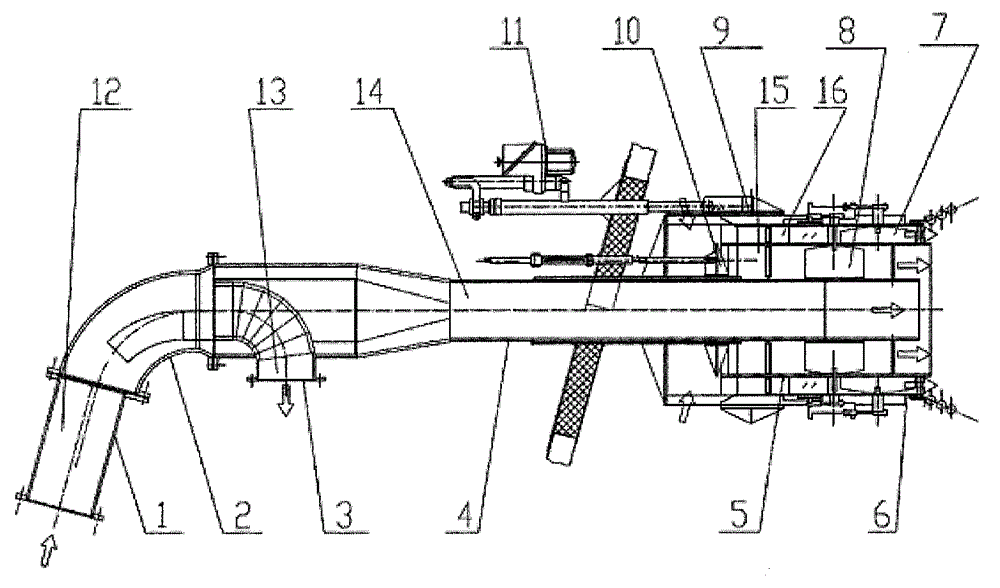

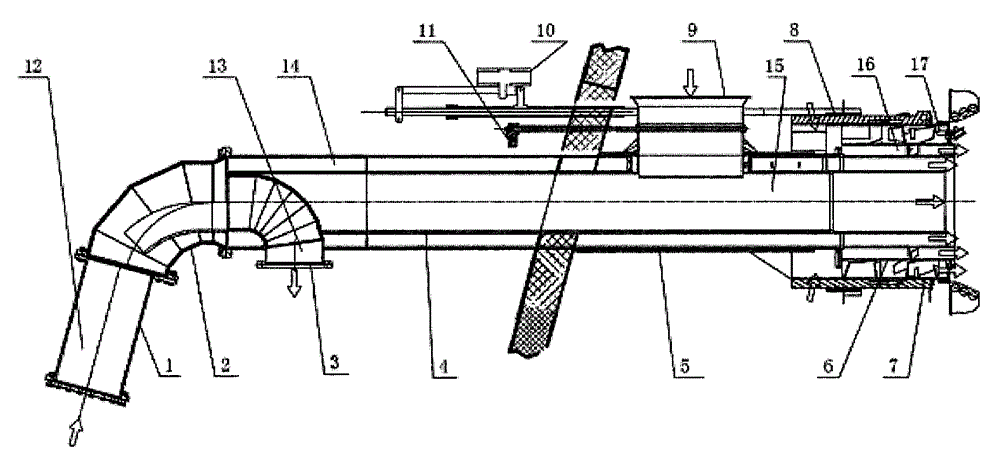

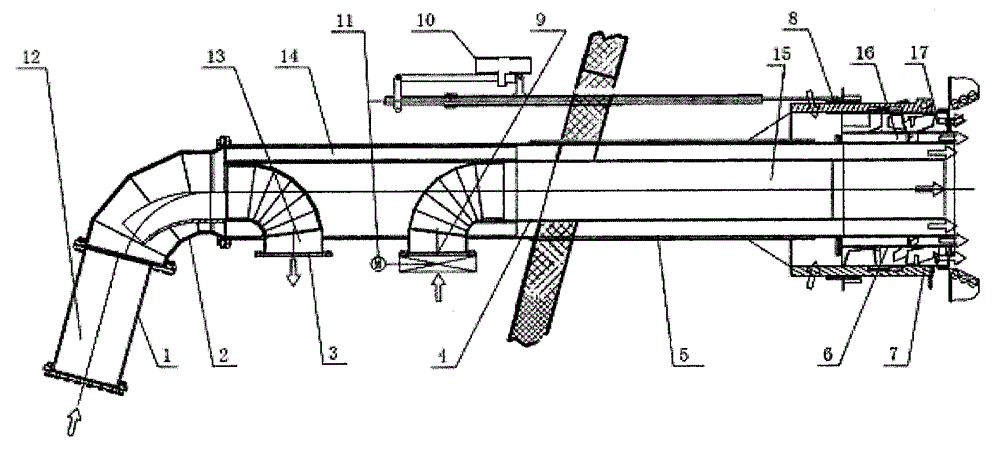

[0021] The novel "central wind ring concentration type swirl burner" provided by the present invention will be further described in detail below in conjunction with specific examples, but the present invention is not limited thereto.

[0022] The central air ring concentrated swirl burner includes primary air pulverized coal pipeline, inner secondary air duct, outer secondary air duct, exhaust pipe, deflector duct, elbow, pulverized coal nozzle, and central air pulverized air in the pulverized primary air duct. Pipeline, the primary air pulverized coal pipeline and the central air pipeline form an annular passage, and the pulverized coal is heated by the high-temperature central air and internal secondary air in the annular passage.

[0023] Preferably, the pulverized coal nozzle is an annular nozzle, and after the pulverized coal is ejected from the annular nozzle, it is surrounded by the central air and the internal and external secondary air.

[0024] Preferably, the introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com