Coal pulverizer equipment

A coal pulverizer and coal pulverizing technology, applied in the field of coal pulverizer devices, can solve problems such as boiler efficiency reduction and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

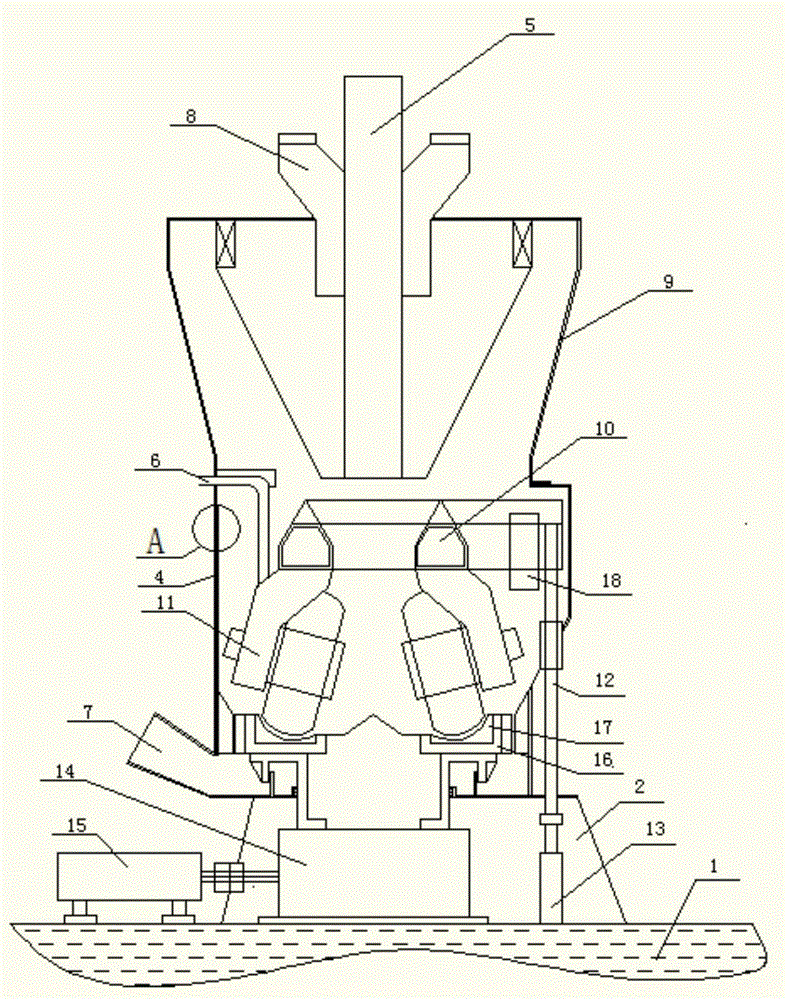

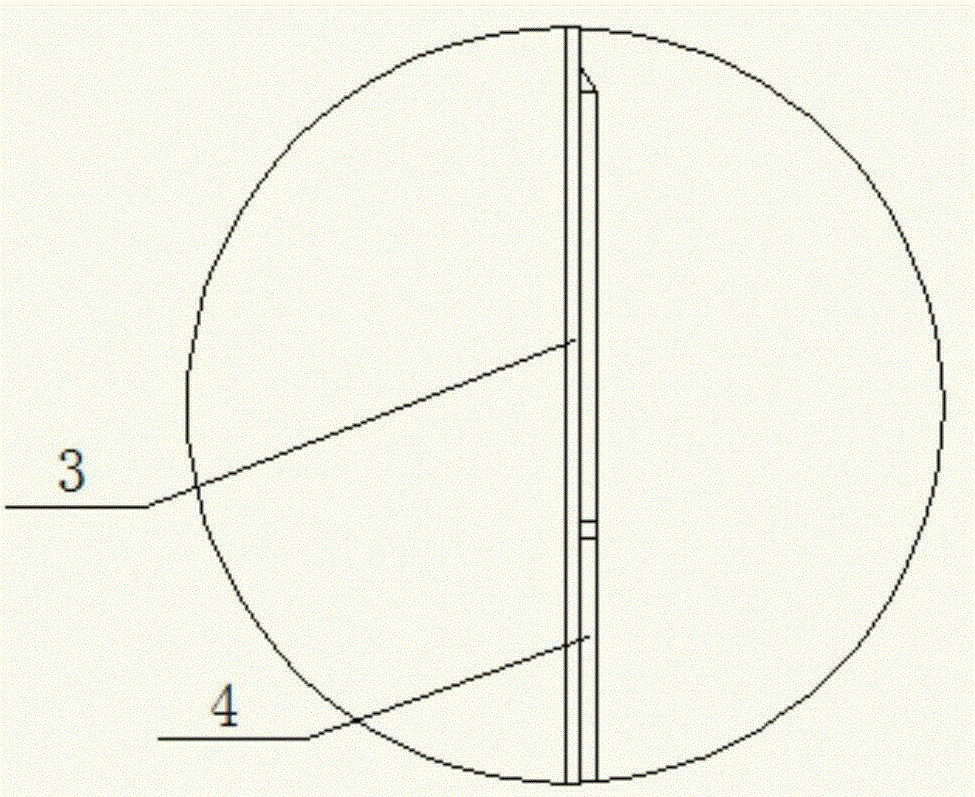

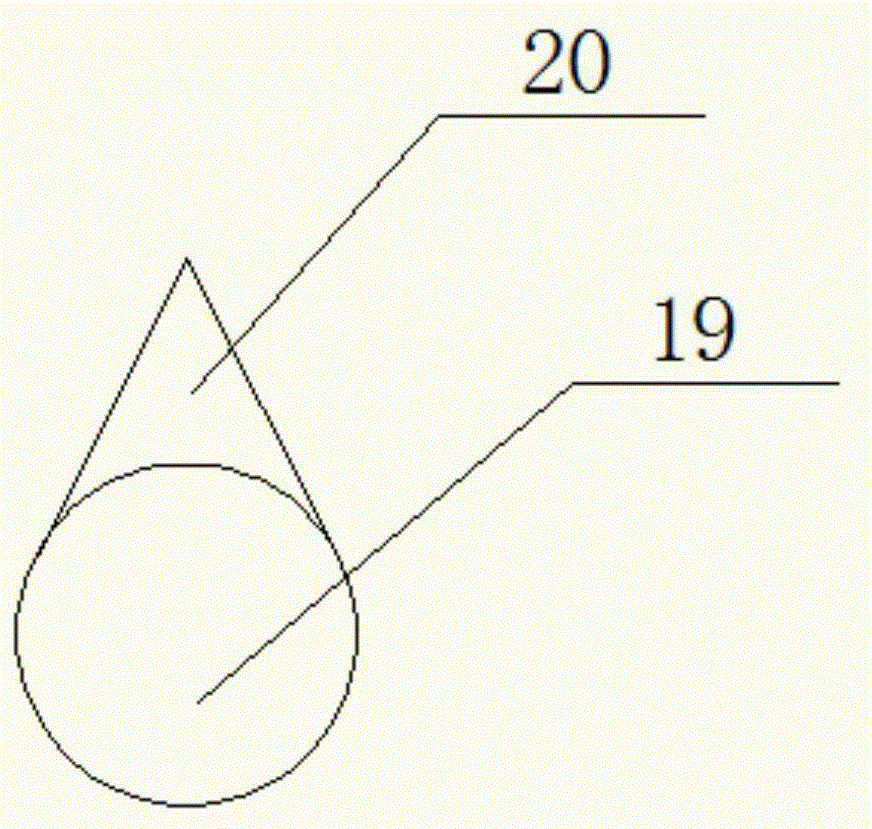

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0022] The present invention provides a coal mill device, the working principle of which is to greatly reduce the residence time of pulverized coal in the coal mill by changing the internal mechanism of the pulverizing system, improve the safety performance of the pulverizing system, and further increase the outlet heat of the coal mill once. The air temperature increases the proportion of hot air entering and reduces the proportion of cold air entering to achieve the purpose of increasing the outlet temperature of the coal mill, reducing the carbon content of boiler fly ash, reducing the carbon content of slag and improving boiler efficiency.

[0023] The present invention will be described in further detail below in conjunction with examples and specific implementation method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com