Returning device and roller drying machine with same

A tumble dryer and drum technology, applied in dryers, drying, non-progressive dryers, etc., can solve the problems of expanding the floor space, increasing the structure of drying equipment, and increasing equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

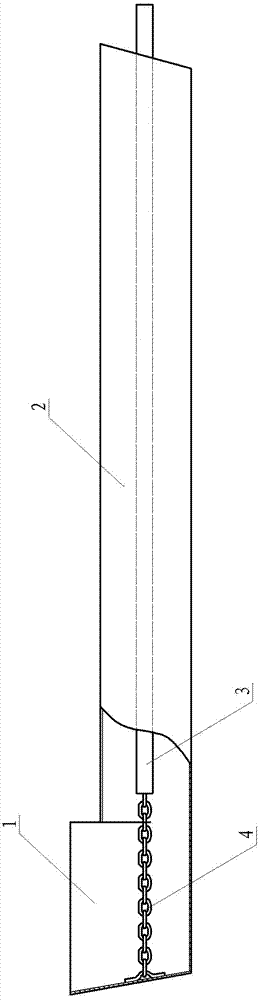

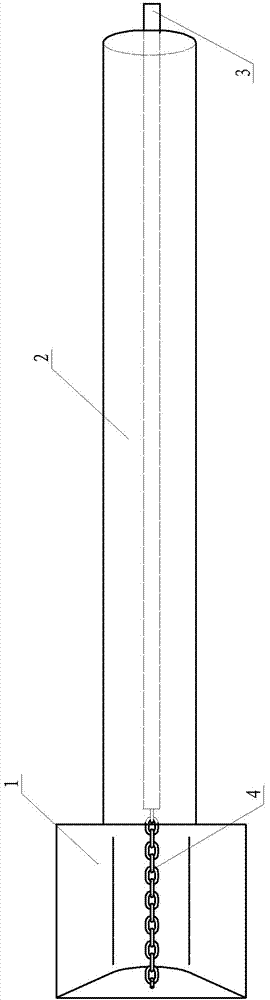

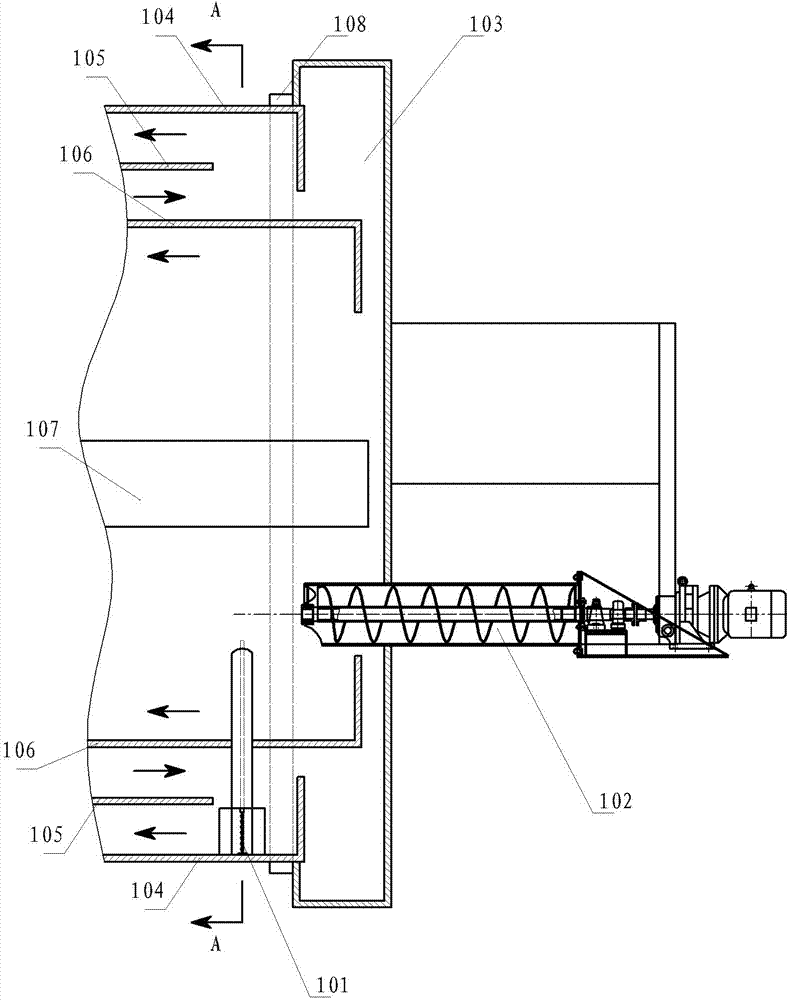

[0022] Embodiment two: see figure 1 - Figure 4 , a drum dryer with a feeding device in the figure, including a drum body, a cover at the end of the drum, and a feeding device. The drum body includes N-stage drums, and the first-stage drums are sequentially from the inside to the outside. , second-stage drum...Nth-stage drum, the feeding device passes through the cover to feed materials into the first-stage drum, and its feature is: the discharge end of the second-stage drum is the third-stage drum The feeding end is provided with several feeding devices along the circumferential direction, and the feeding device includes a hopper and a feeding pipe. The hopper is connected to one end of the feeding pipe, and a pestle rod is arranged in the feeding pipe. One end of the pestle rod is connected with a rope connector, and the other end of the rope connector extends out of the feeding pipe and is connected to the outermost end of the hopper, and the outermost end of the hopper i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com