Deflection nozzle

A sprinkler and core technology, which is used in injection devices, injection devices, building maintenance, etc., can solve the problems of inability to break concrete and strike concrete, and achieve the effects of high focusing, constant pressure, and high striking force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

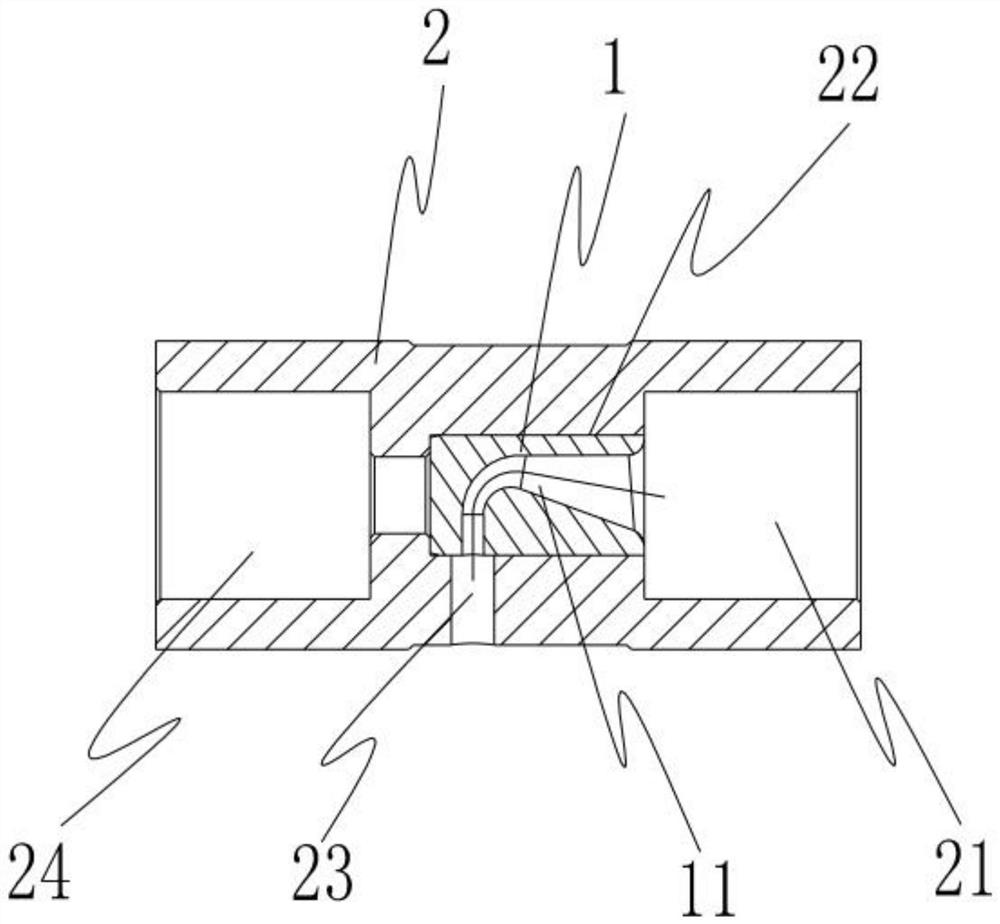

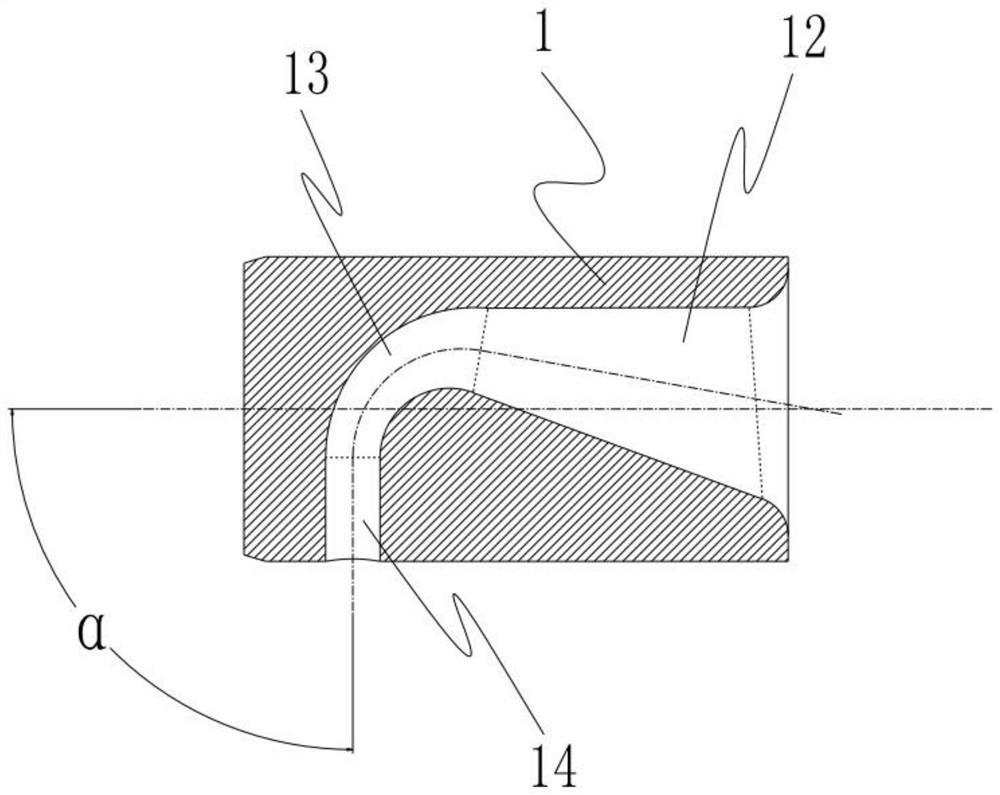

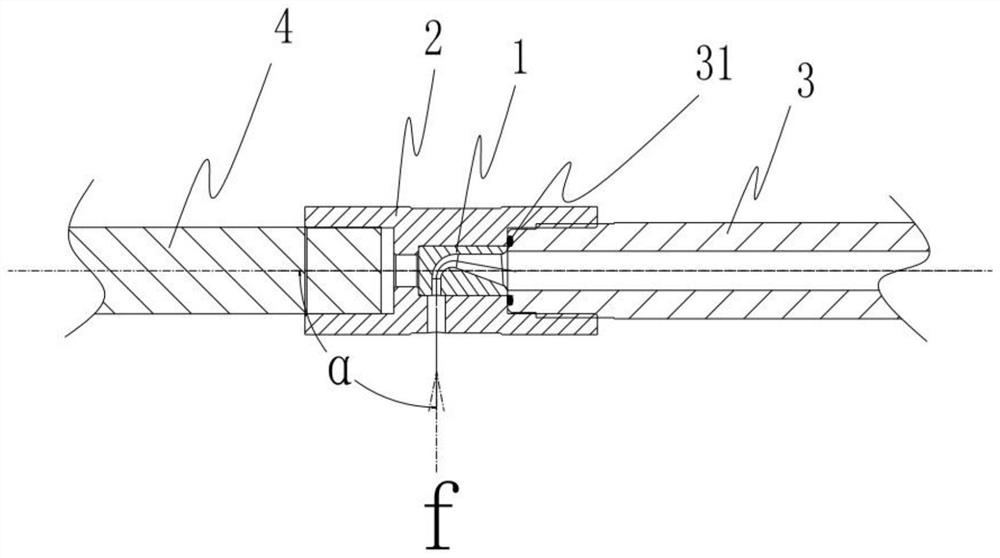

[0028] As an embodiment of the present invention, the nozzle housing 2 is straight cylindrical, one end of the nozzle housing 2 is provided with a high-pressure pipe connection groove 21, and the bottom of the high-pressure pipe connection groove 21 is provided with a nozzle for installing the riser. 1, the nozzle housing 2 has a nozzle 23 that communicates with the riser installation chamber 22 and the outside of the nozzle housing 2; after the riser 1 is installed, the conical shrinkage The outlet channel section 12 communicates with the high-pressure pipe connection groove 21 , and the straight tube channel section 14 communicates with the nozzle 23 . The structure of the sprinkler housing 2 is set in a straight cylinder, which is similar to a conventional linear sprinkler. Therefore, the width of the sprinkler housing 2 is small, and it can be inserted into the cracks between the concrete for demolition; in order to prevent water leakage, install high-pressure Behind the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com