Deck track positioning tool and deck track laying method

A technology for positioning tooling and laying methods, applied in cargo handling equipment, transportation and packaging, passenger handling equipment, etc., can solve the problems of high cost, low installation efficiency, large consumption of deck steel, etc., to save shipbuilding costs, save time and Cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

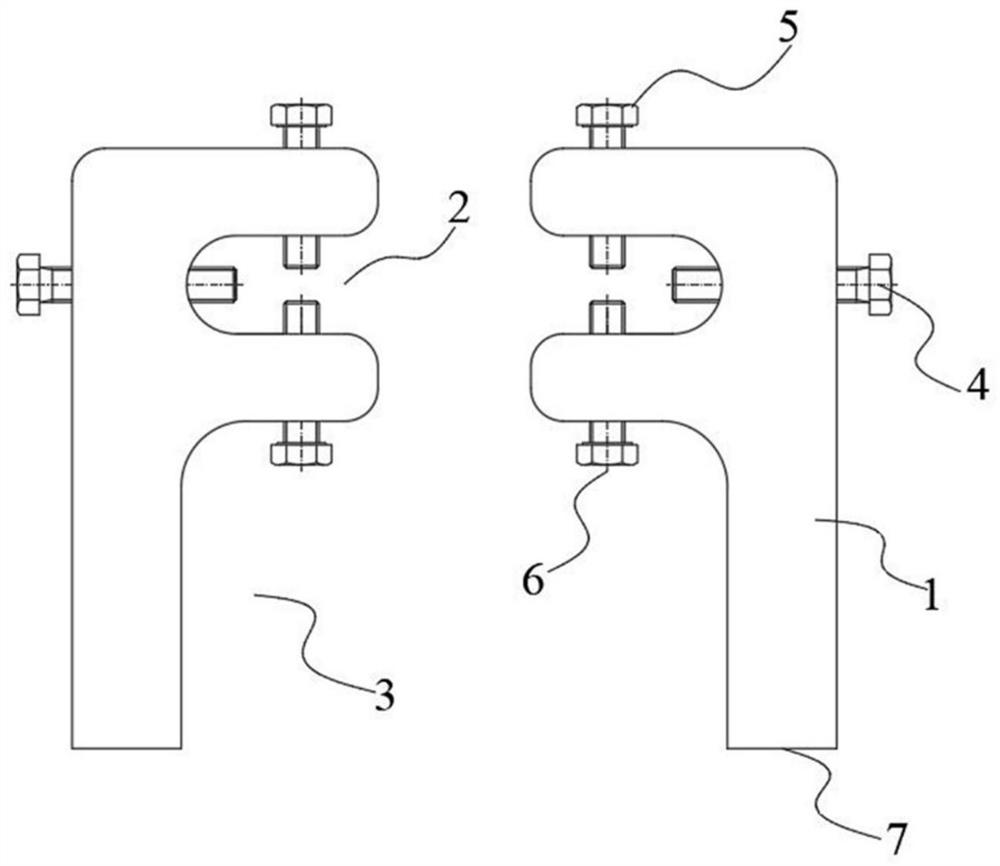

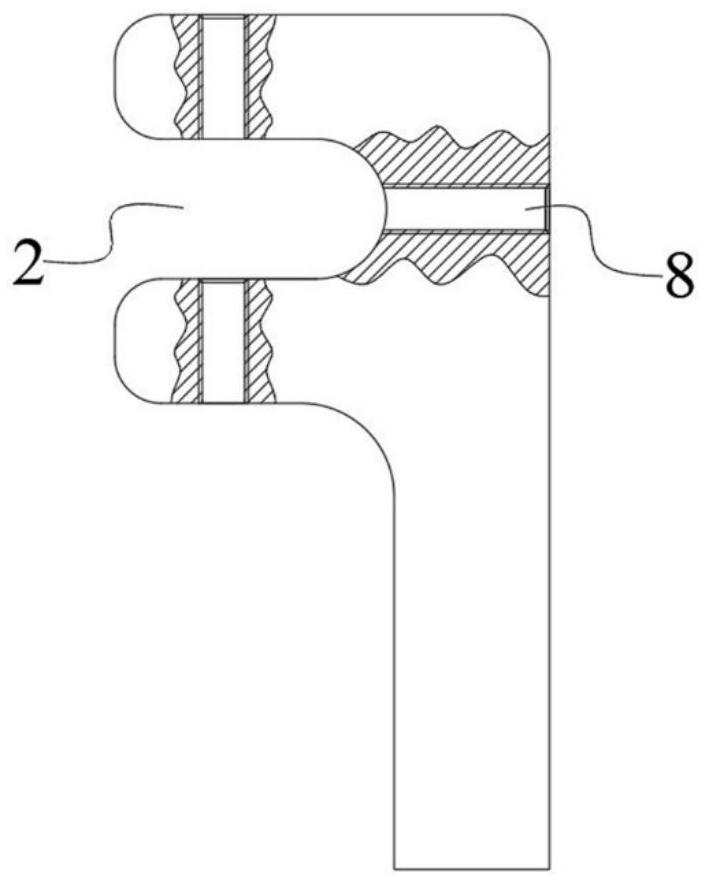

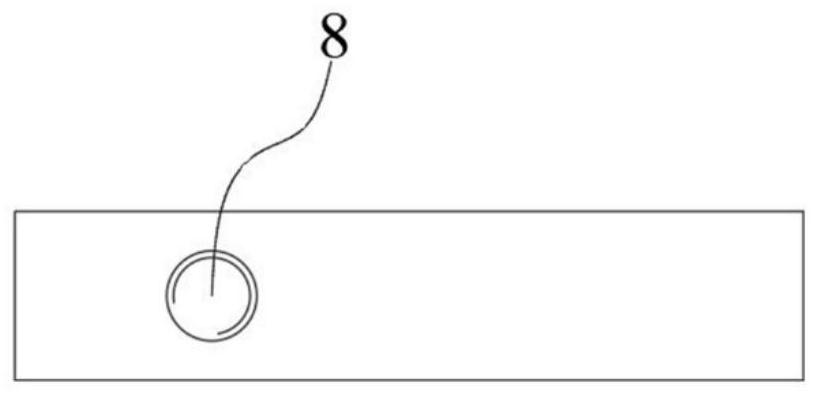

[0034] Such as Figure 1 to Figure 4 As shown, a deck rail positioning tool (hereinafter referred to as the positioning tool 9 ) is a preferred embodiment of the embodiment of the present invention. The positioning tool 9 includes a tooling body 1. The tooling body 1 is provided with a positioning groove 2 for inserting the setting part of the deck rail. The bottom of the positioning groove 2 is equipped with a first adjustment member 4. The second adjusting member 5 and the third adjusting member 6 are installed respectively, and the first adjusting member 4 is used to push the deck rail 10 to realize the displacement adjustment of the deck rail 10 in the groove depth di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com