Special support tooling for installing translational hatch cover of bulk carrier and installation method thereof

An installation method and hatch cover technology, applied in the directions of transportation and packaging, ship parts, ships, etc., to ensure the quality of installation, easy operation, and shorten the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

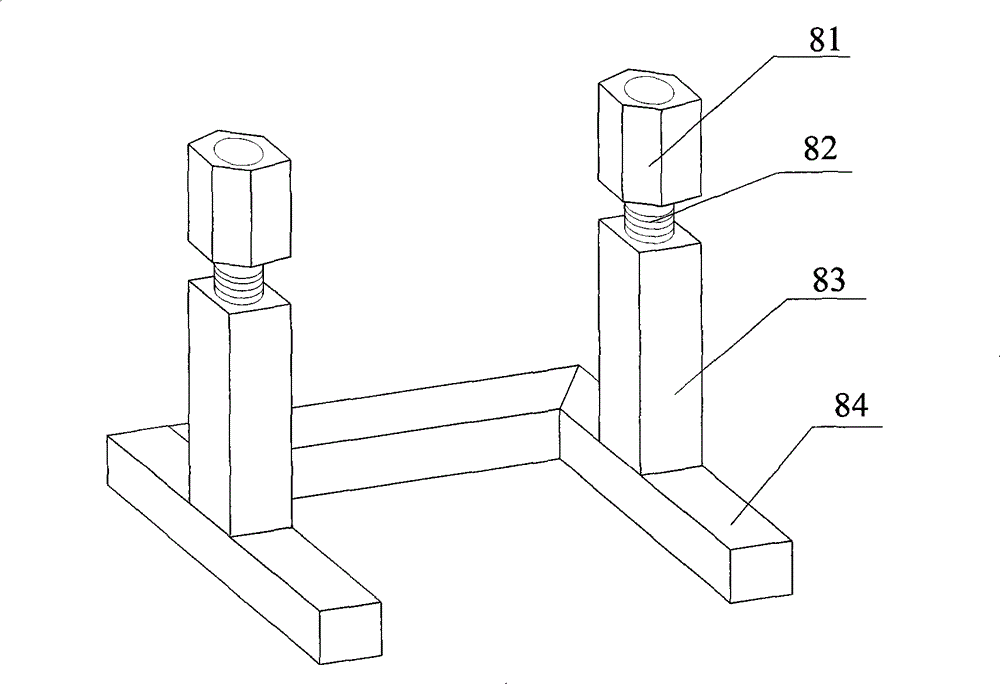

[0034] Such as figure 2 As shown, the special support tooling 8 for bulk carrier translation hatch cover installation of the present invention includes a base 84 and a support frame 83, and the top of the support frame is provided with an adjustment block 81; the base 84 is welded sequentially by three cuboid iron rods. into, forming a "door" word box. The support frame 83 is vertically welded on both sides of the base 84 by two cuboid iron rods, the top of the support frame 83 is provided with a threaded column 82, and the adjusting block 81 is a hexagonal bolt screwed on the column 82, so that The overall height of the special support tooling equipment 8 can be adjusted up and down.

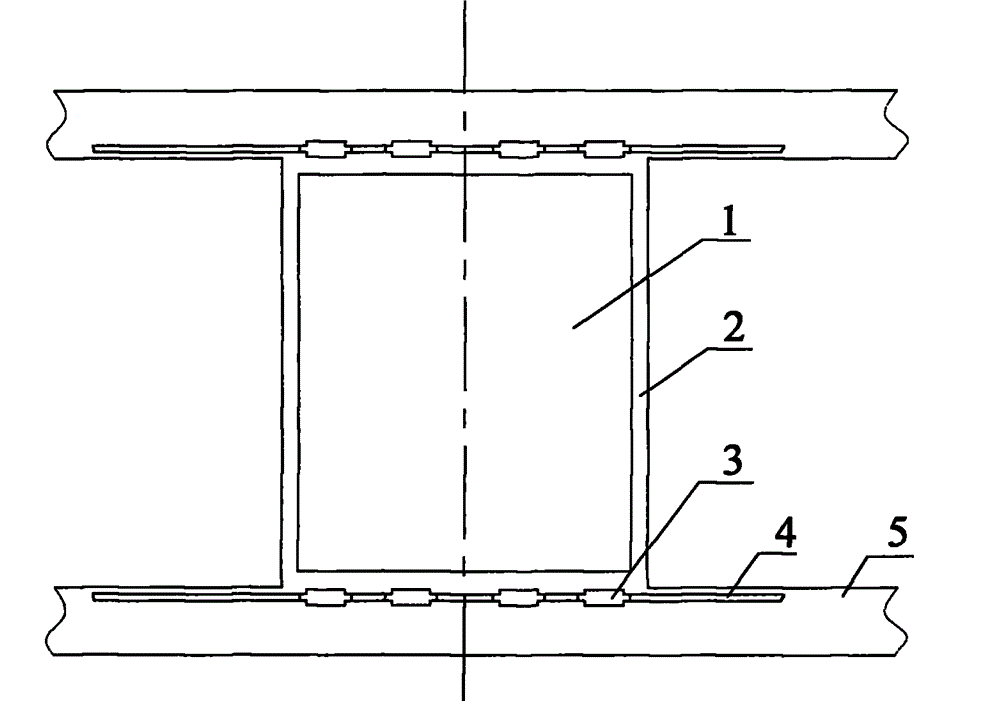

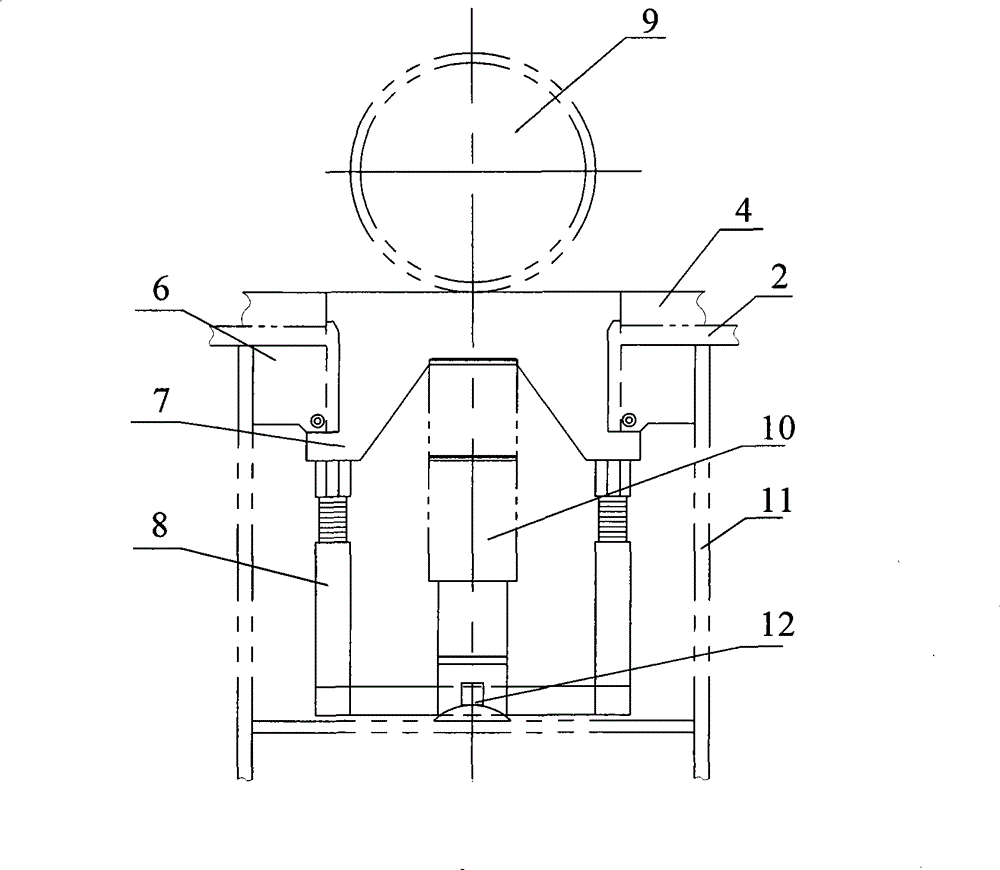

[0035] Such as image 3 As shown, the installation method of the bulk carrier translational hatch cover using the above-mentioned special supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com