Patents

Literature

73results about How to "Compact steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

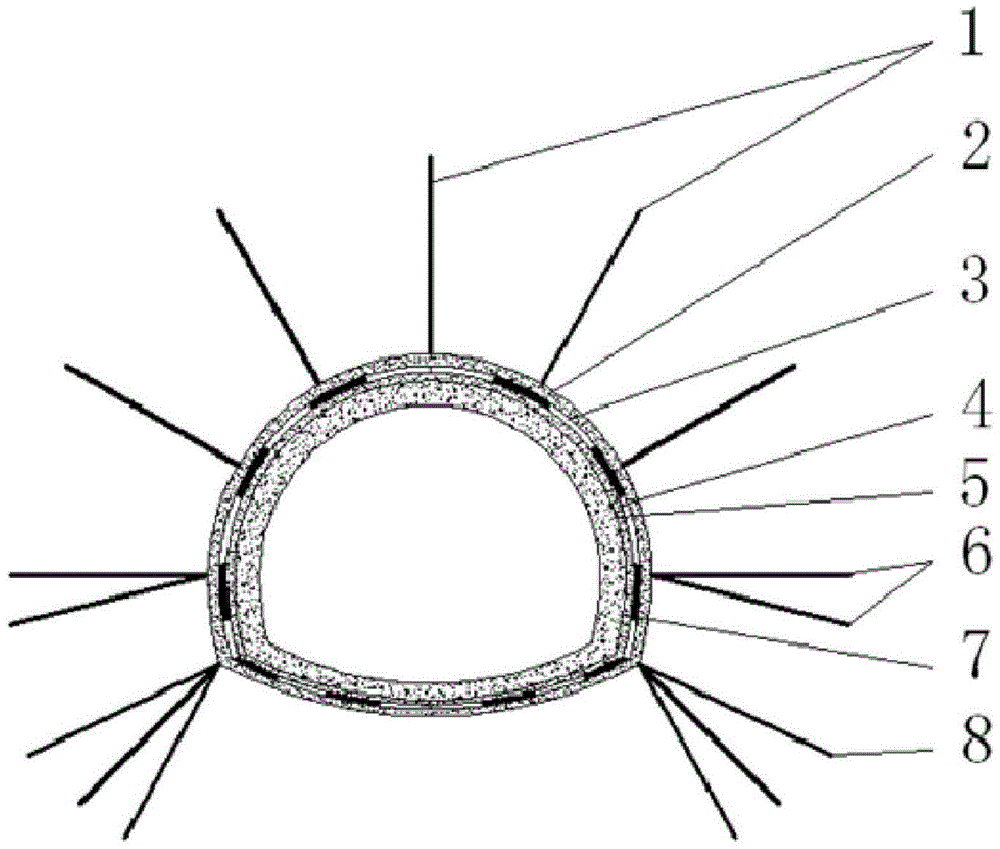

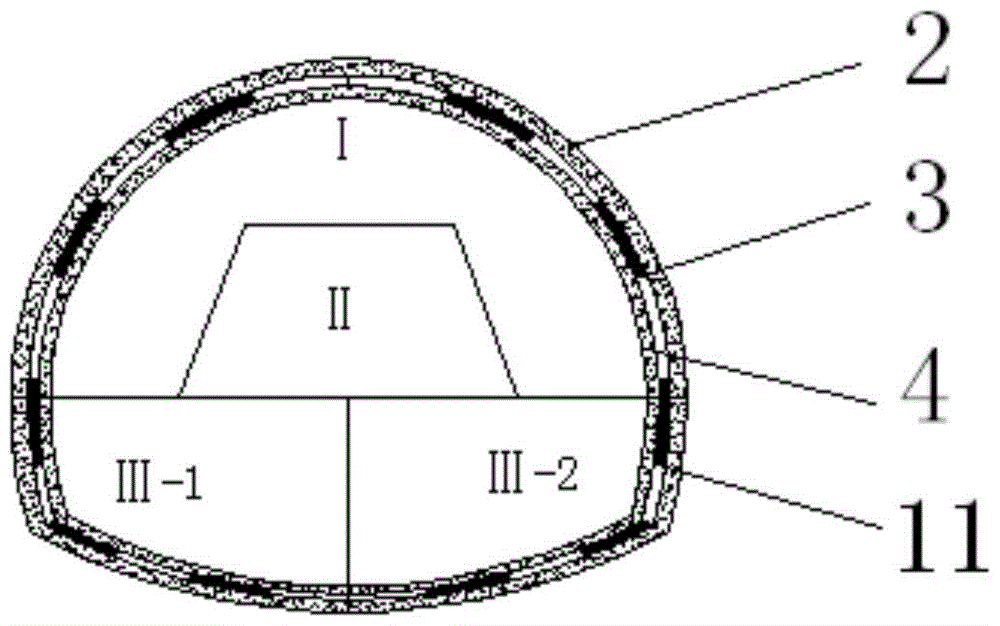

Soft rock large-deformation tunnel supporting system and construction method thereof

InactiveCN104847374AEnsure safetySmall overall deformationUnderground chambersTunnel liningSupporting systemLarge deformation

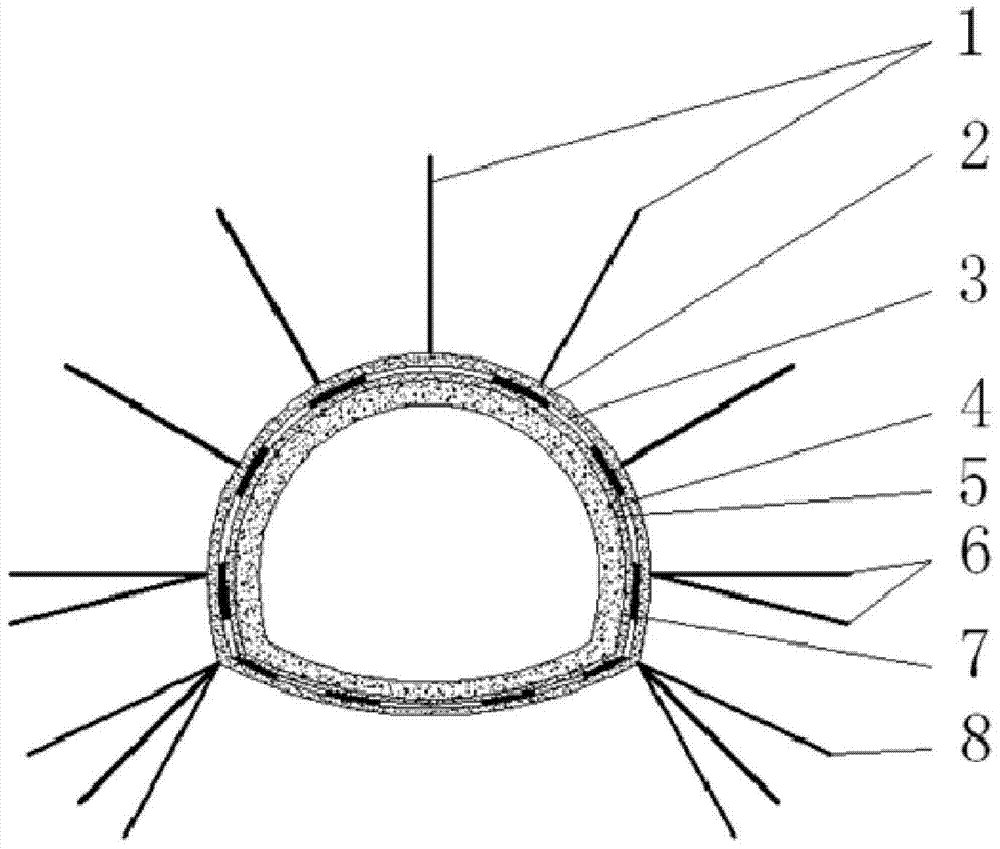

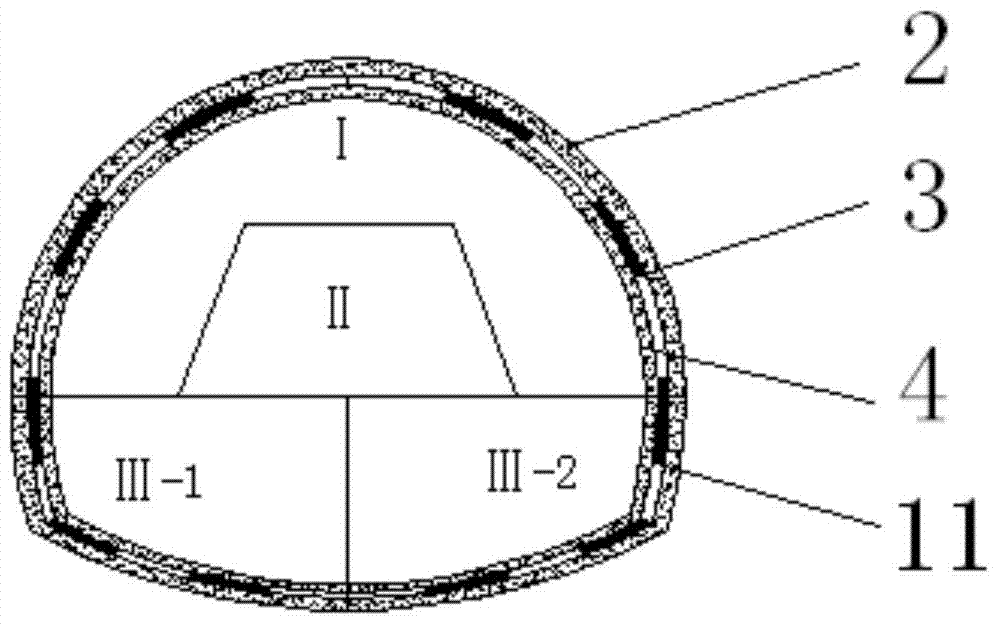

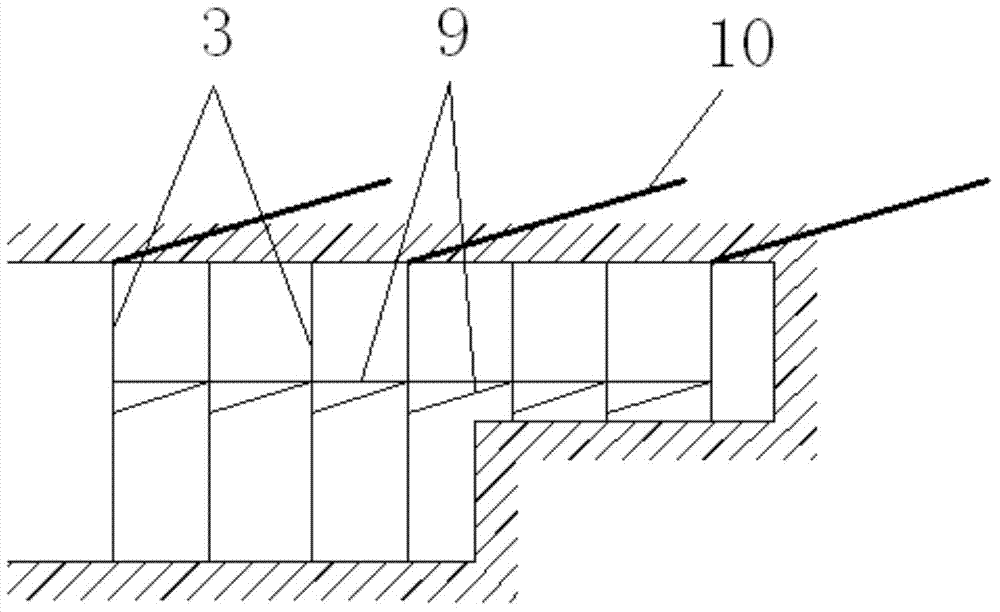

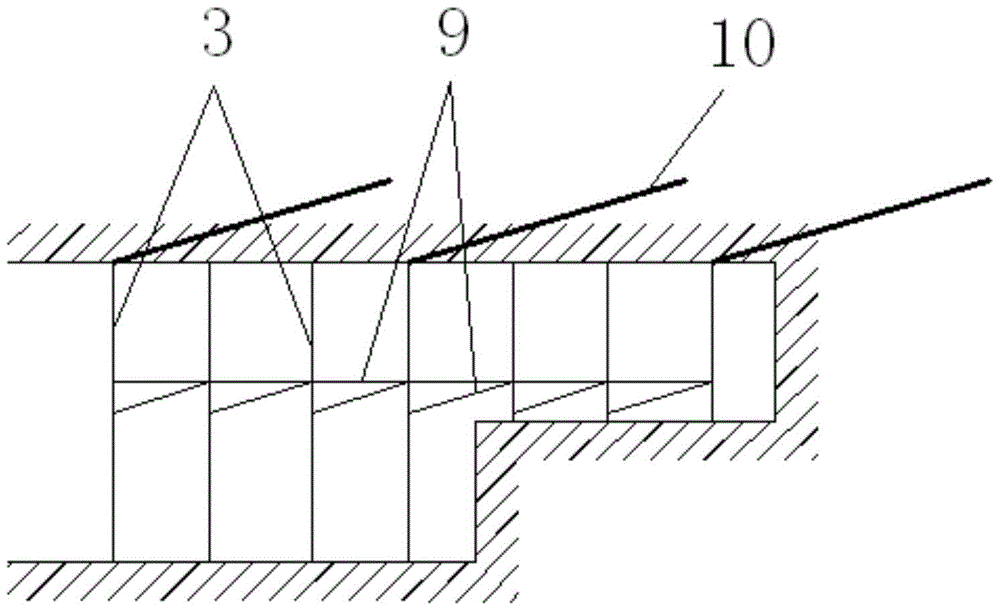

The invention discloses a soft rock large-deformation tunnel supporting system and a construction method thereof. The system comprises a forepoling, a preliminary bracing, a waterproof layer, a secondary lining and other main structures, wherein the structures are constructed in sequence according to construction procedures. Surrounding rock is reinforced through advanced small pipe grouting by means of the forepoling, the preliminary bracing comprises lengthened anchor rods, a primary spraying layer, steel arches and a re-jetting layer, feet-lock bolts are further arranged at the positions of an upper bench and arch feet to be welded to the steel arches, the adjacent steel arches are connected through longitudinal connecting ribs, and the secondary lining is constructed at last to form the supporting system. The steps are simple and linked with one another, supporting lag caused by idling of labor force is avoided, and large-deformation of tunnels is well controlled.

Owner:CHANGAN UNIV

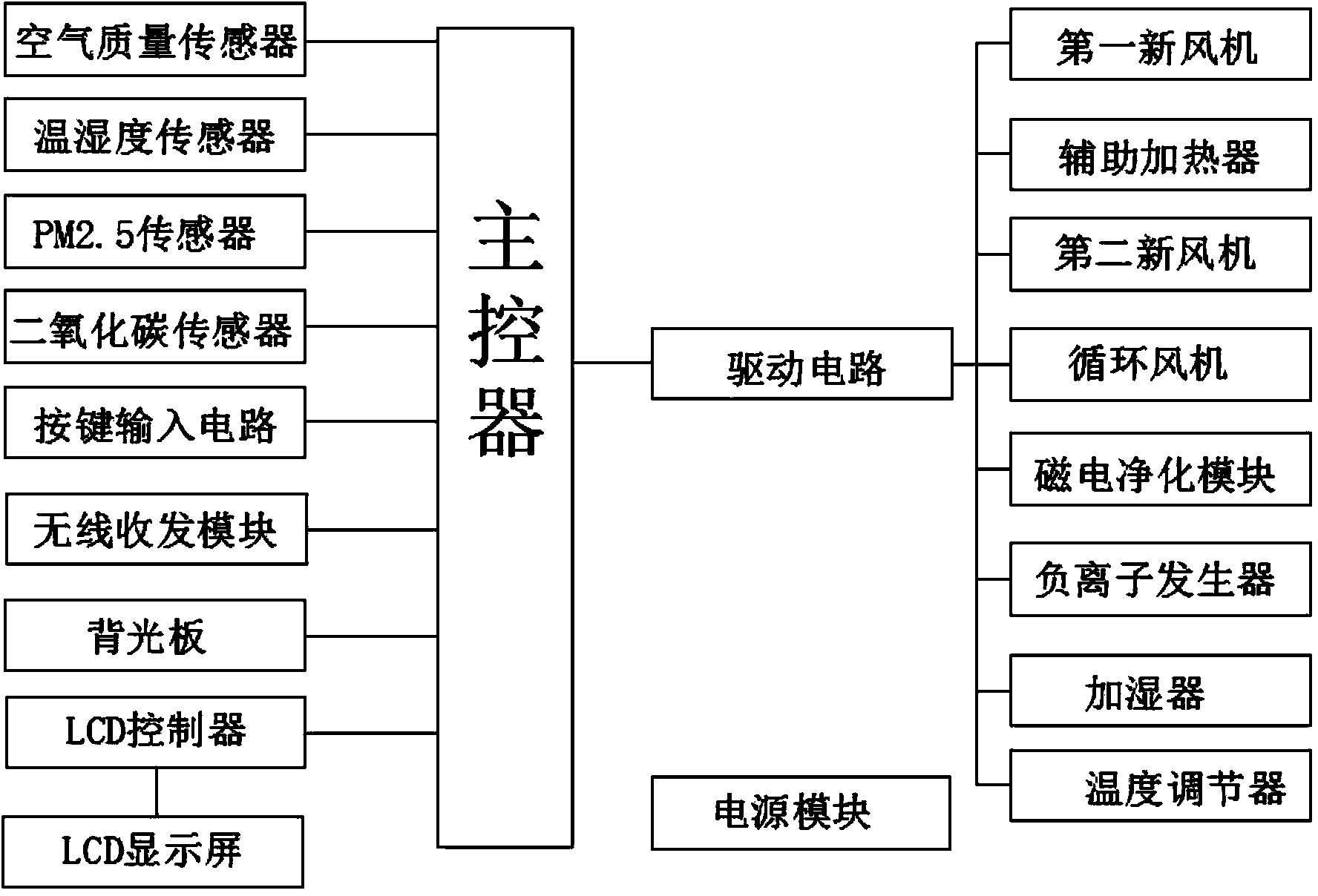

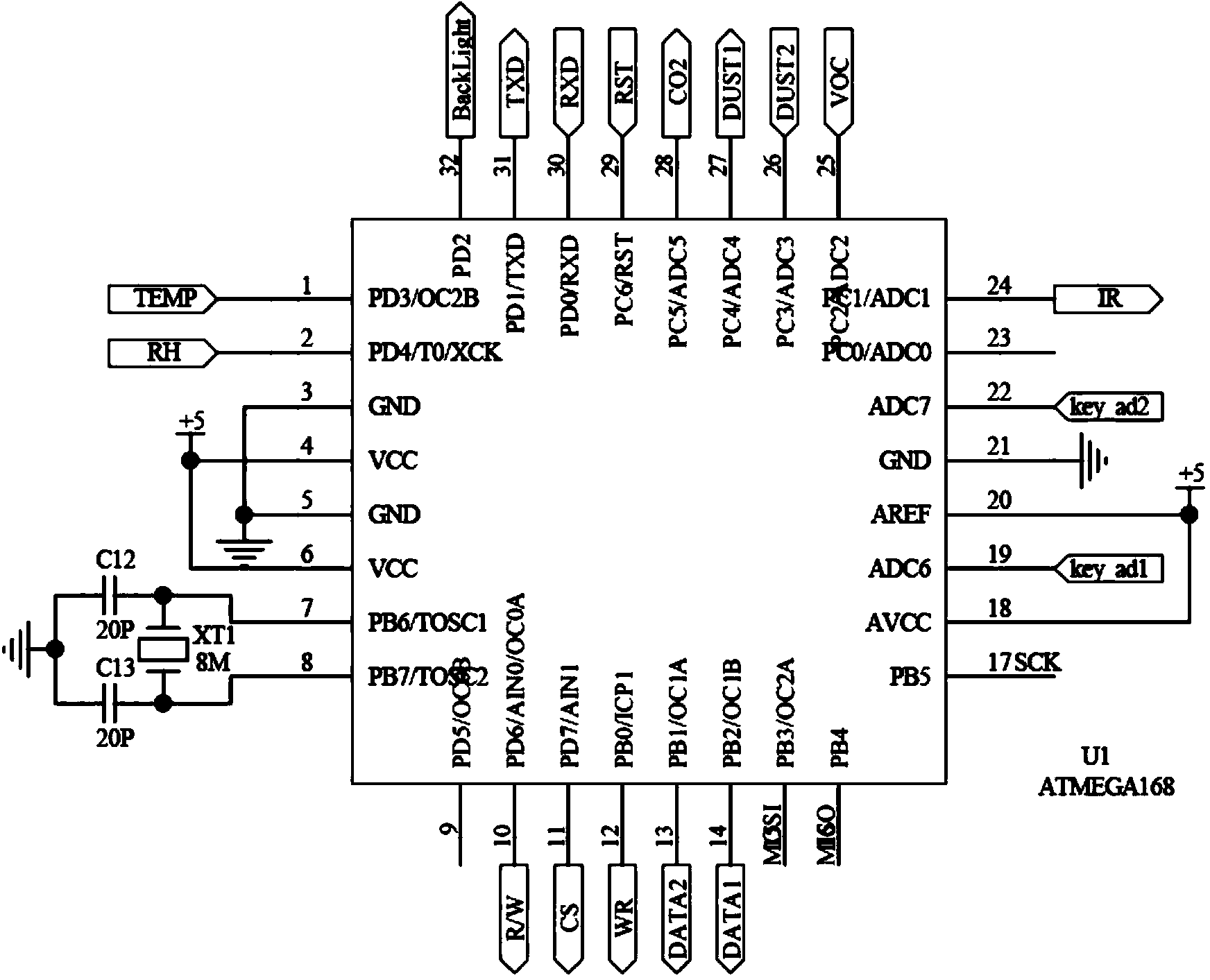

Indoor air quality intelligent control system

InactiveCN103776134AGuarantee air qualityRealize processingSpace heating and ventilation safety systemsLighting and heating apparatusIndoor air qualityAir filter

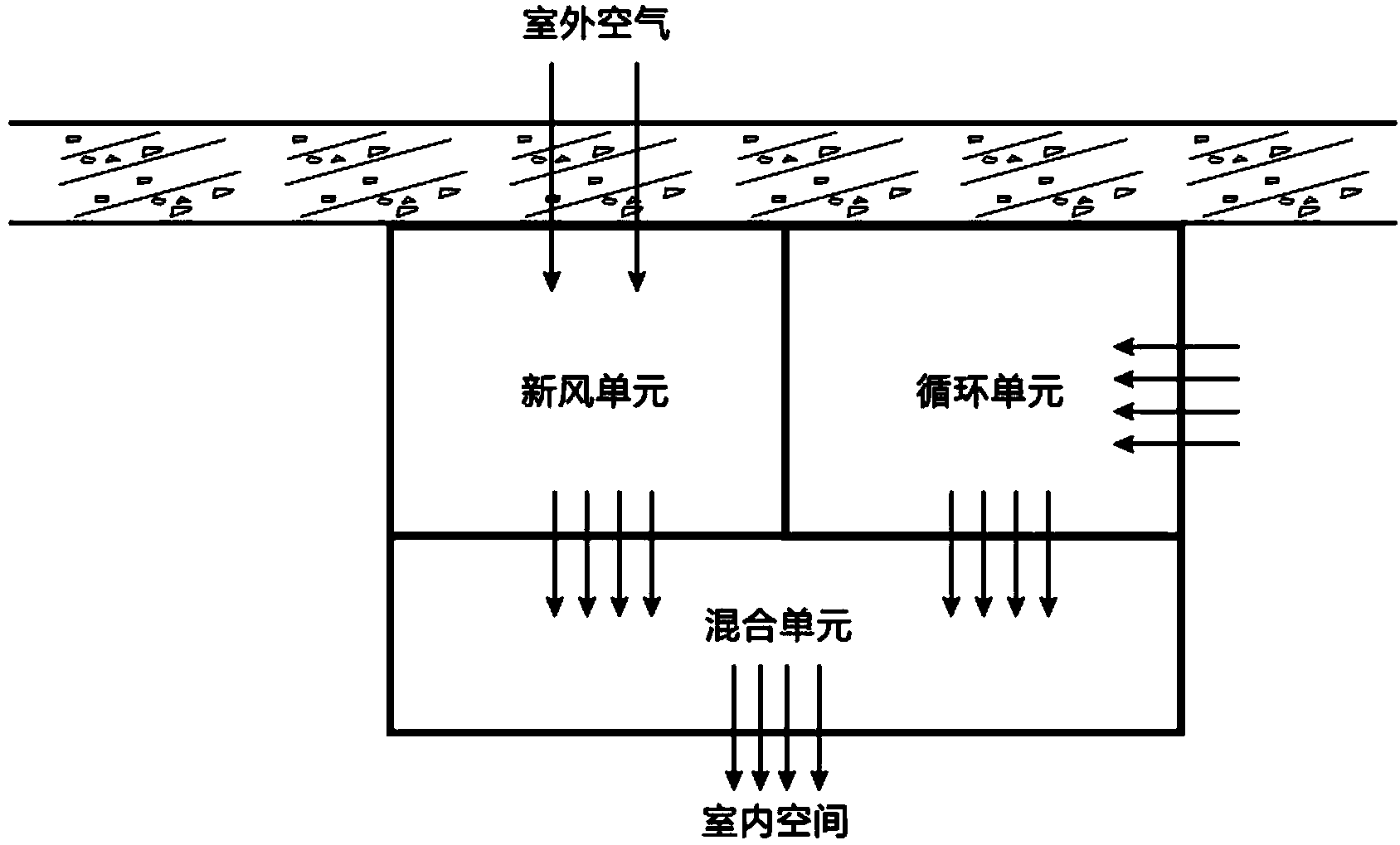

The invention discloses an indoor air quality intelligent control system, which comprises a fresh air unit, a circulation unit and a mixing unit, wherein the fresh air unit is provided with a first fresh air fan, an auxiliary heater, a fresh air filter and a second fresh air fan, the circulation unit is provided with a circulation air filter and a circulation fan, the mixing unit is used for realizing the mixing of outdoor fresh air and indoor circulation air, electromagnetic purification modules are respectively arranged in the fresh air filter and the circulation air filter, all modules are respectively connected onto a driving circuit, the driving circuit is connected with a main controller, and an air quality sensor, a temperature and humidity sensor, a PM2.5 sensor, a carbon dioxide sensor, a press key input circuit and an LCD (liquid crystal display) display circuit are respectively connected onto the main controller. The indoor air quality intelligent control system has the effects that the regulation and control of the outdoor fresh air and the indoor circulation air are integrated, the structure of the system is simple and novel, the arrangement is compact, the installation is convenient, the treatment on the indoor air can be realized, the air quality can be ensured according to requirements, the harm to human bodies caused by outdoor pollution can be reduced, and the energy consumption is reduced.

Owner:章宏兵

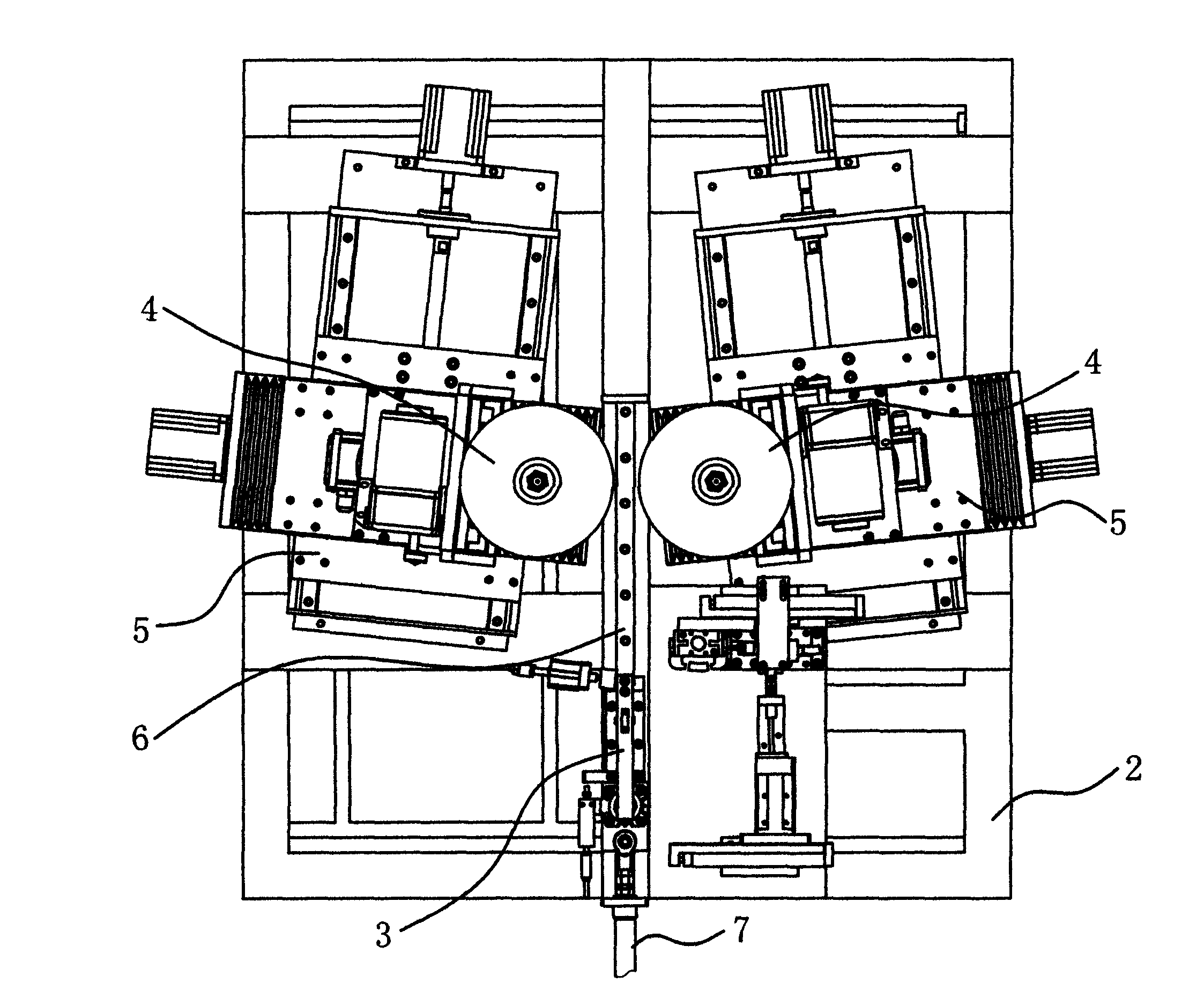

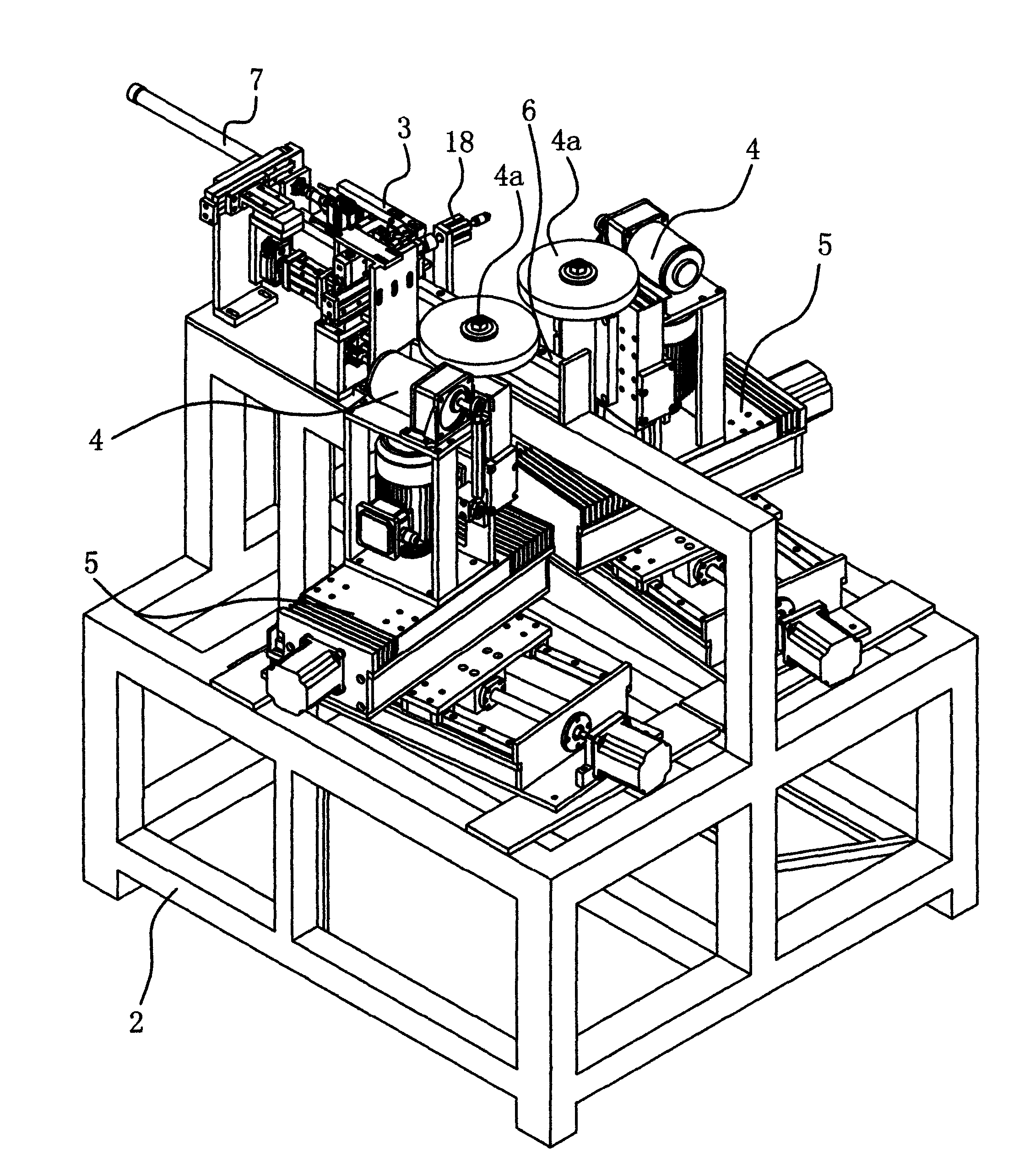

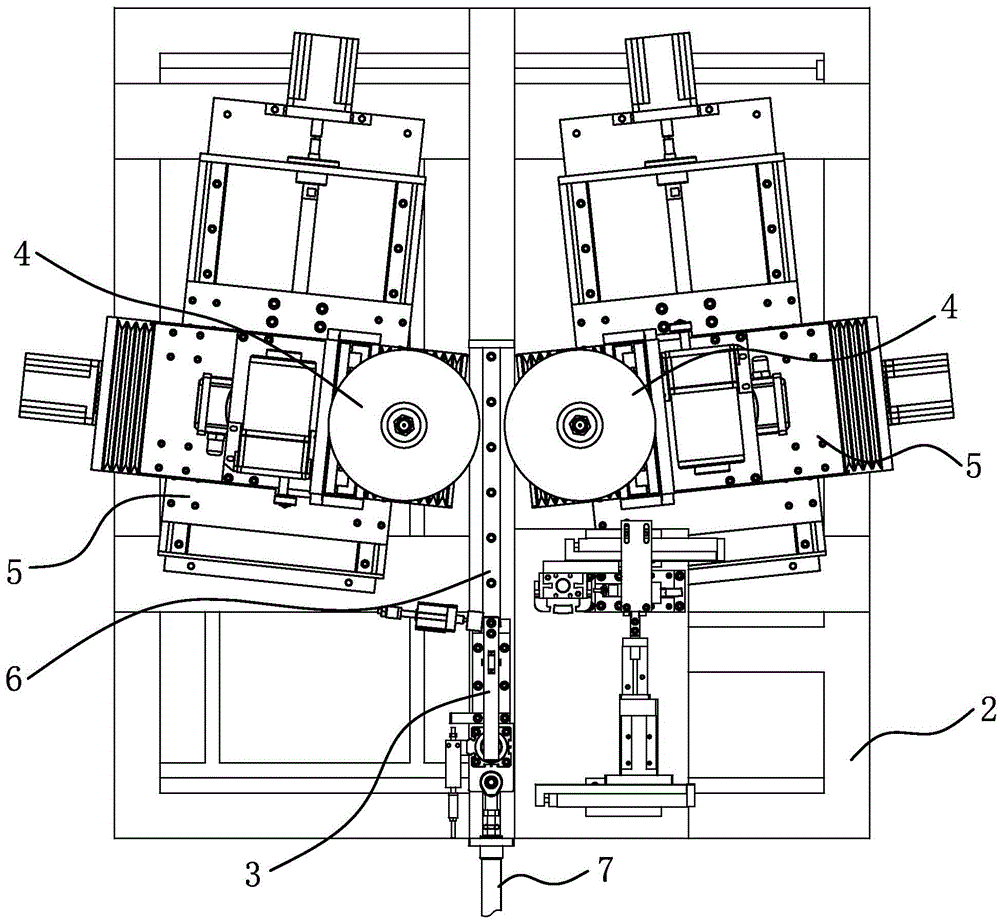

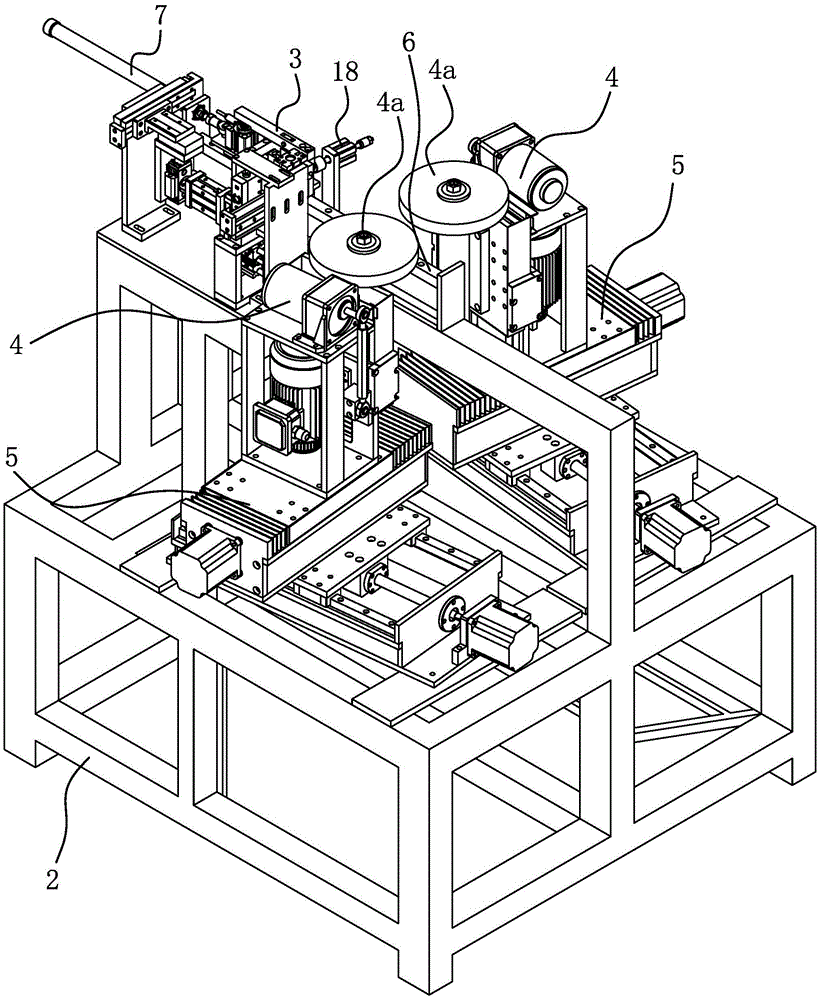

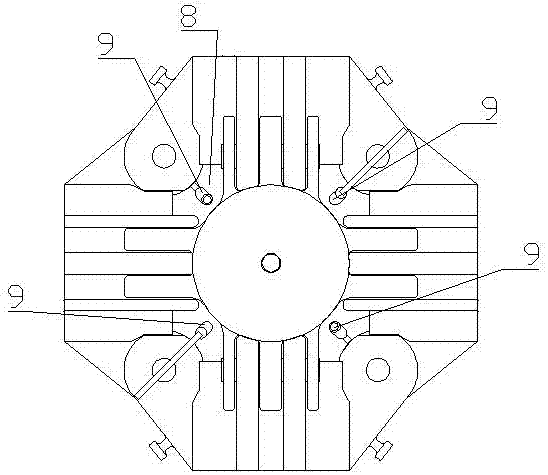

Diamond tool bit slope grinding device

ActiveCN103317407AIncrease productivityGuaranteed grinding accuracyEdge grinding machinesGrinding drivesTool bitGeneral purpose

The invention provides a diamond tool bit slope grinding device, belongs to the technical field of operations and solves the problem of low production efficiency due to the fact that presently, diamond tool bit slopes are grinded through the general-purpose machine tool. The diamond tool bit slope grinding device comprises a machine frame and a clamp arranged on the machine frame and used for clamping a diamond tool bit. The clamp is provided with a group of grinding mechanisms with grinding wheels relative to the outer sides of two slopes of the clamped diamond tool bit, and feeding mechanisms capable of feeding the grinding wheels along the corresponding target slopes in parallel are arranged between the grinding mechanisms and the machine frame. The diamond tool bit slope grinding device automatically feeds and grinds the slopes of the diamond tool bit and the two slopes are processed simultaneously, and therefore the diamond tool bit slope grinding device has the advantage of high production efficiency. The grinding wheels of the diamond tool bit slope grinding device can be automatically supplemented after being decreased gradually through grinding, and therefore the diamond tool bit slope grinding device has the advantages of being high in production efficiency and ensuring grinding accuracy.

Owner:HEBEI XINGLONG ELEVATORING EQUIP CO LTD

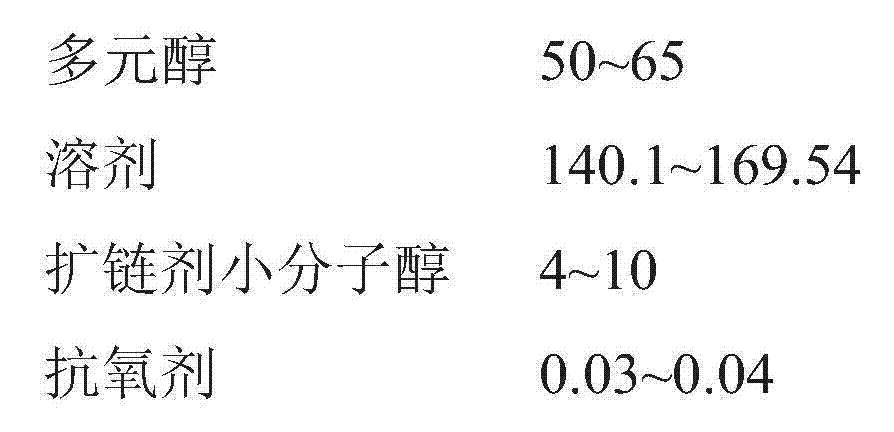

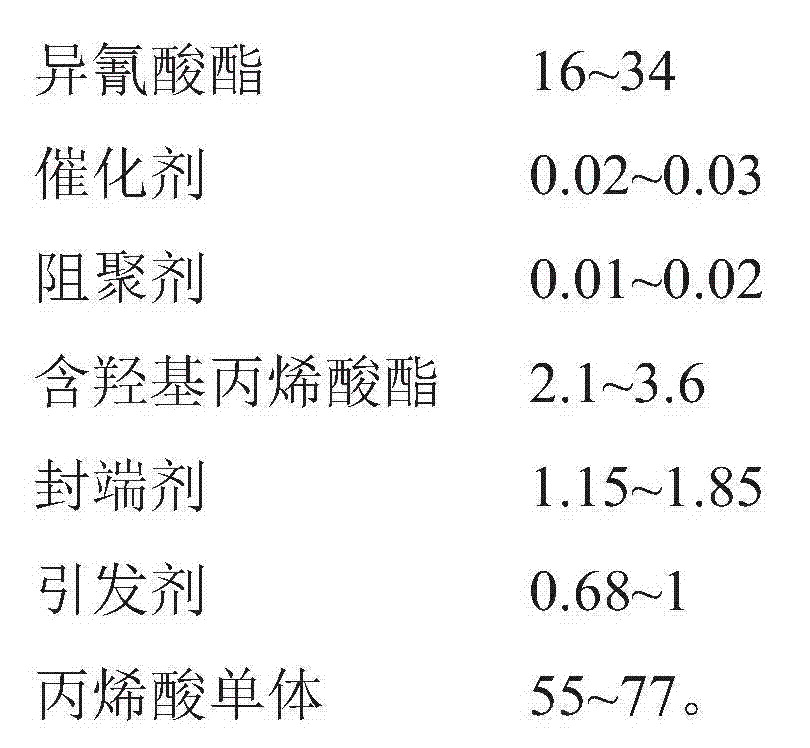

Acrylate modified polyurethane resin for leather finish and preparation method thereof

ActiveCN103772618AOvercome the disadvantage of low solid contentReduce the disadvantages of low solid contentCoatingsAlcoholAntioxidant

The invention discloses acrylate modified polyurethane resin for leather finish. The acrylate modified polyurethane resin for leather finish is characterized by being prepared from the following components in parts by weight: 50-65 parts of polyalcohol, 140.1-169.54 parts of solvent, 4-10 parts of chain extender micromolecular alcohol, 0.03-0.04 part of antioxidant, 16-34 parts of isocyanate, 0.02-0.03 parts of catalyst, 0.01-0.02 part of polymerization inhibitor, 2.1-3.6 parts of hydroxyl acrylate, 1.15-1.85 parts of end-capping reagent, 0.68-1 part of initiator and 55-77 parts of acrylic monomer. The invention further discloses a preparation method of the acrylate modified polyurethane resin for leather finish. By adopting polyurethane resin as a base material and acrylate as a main modifying material, the product provided by the invention has the advantages of two resins, and the cost is reduced by over 30% compared with that of pure polyurethane. The acrylate modified polyurethane resin for leather finish disclosed by the invention has excellent composite material performance and higher cost performance, so that the solid content is improved by over 50%.

Owner:DONGGUAN HONGDA POLYUREFHANE RESIN

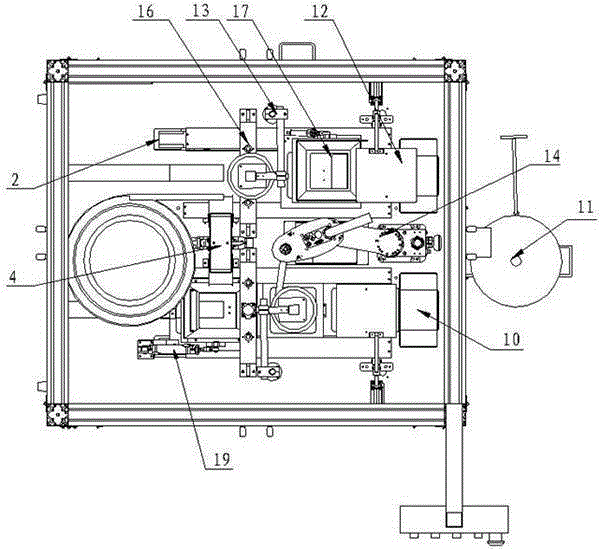

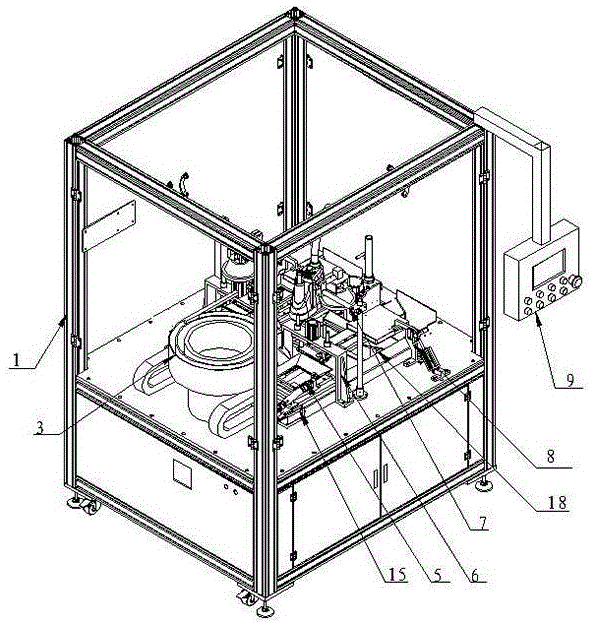

Robot sorting system for soft capsules and method thereof

The invention discloses a robot sorting system for soft capsules and a method thereof. The robot sorting system for the soft capsules comprises a workbench, wherein a vibratory feeding mechanism, a weighing and distributing mechanism, a first movable conveying mechanism, a first visual recognition mechanism, a second movable conveying mechanism, a second visual recognition mechanism and a sorting robot, wherein the weighing and distributing mechanism is arranged at an outlet end of the vibratory feeding mechanism; the first movable conveying mechanism and the second movable conveying mechanism are arranged on two sides of the weighing and distributing mechanism in parallel; the first visual recognition mechanism and the first movable conveying mechanism are arranged on the same side and are located at the upper end of the first movable conveying mechanism; the second visual recognition mechanism and the second movable conveying mechanism are arranged on the same side and are located at the upper end of the second movable conveying mechanism; the sorting robot is located between the first movable conveying mechanism and the second movable conveying mechanism. The system also comprises a controller. The robot sorting system for the soft capsules is high in sorting accuracy, high in accuracy rate and high in automation degree; the manpower consumption and the cost are reduced.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

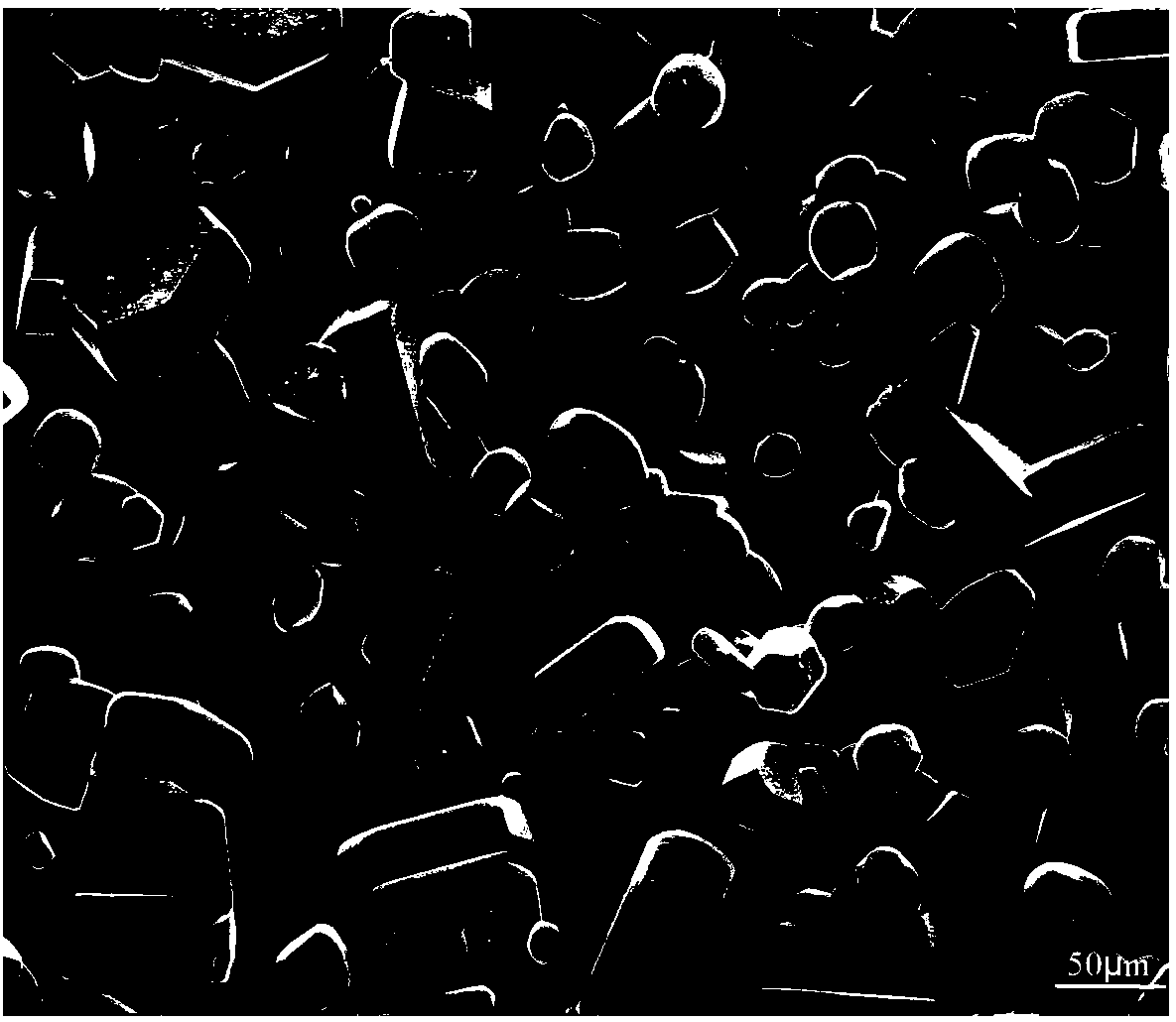

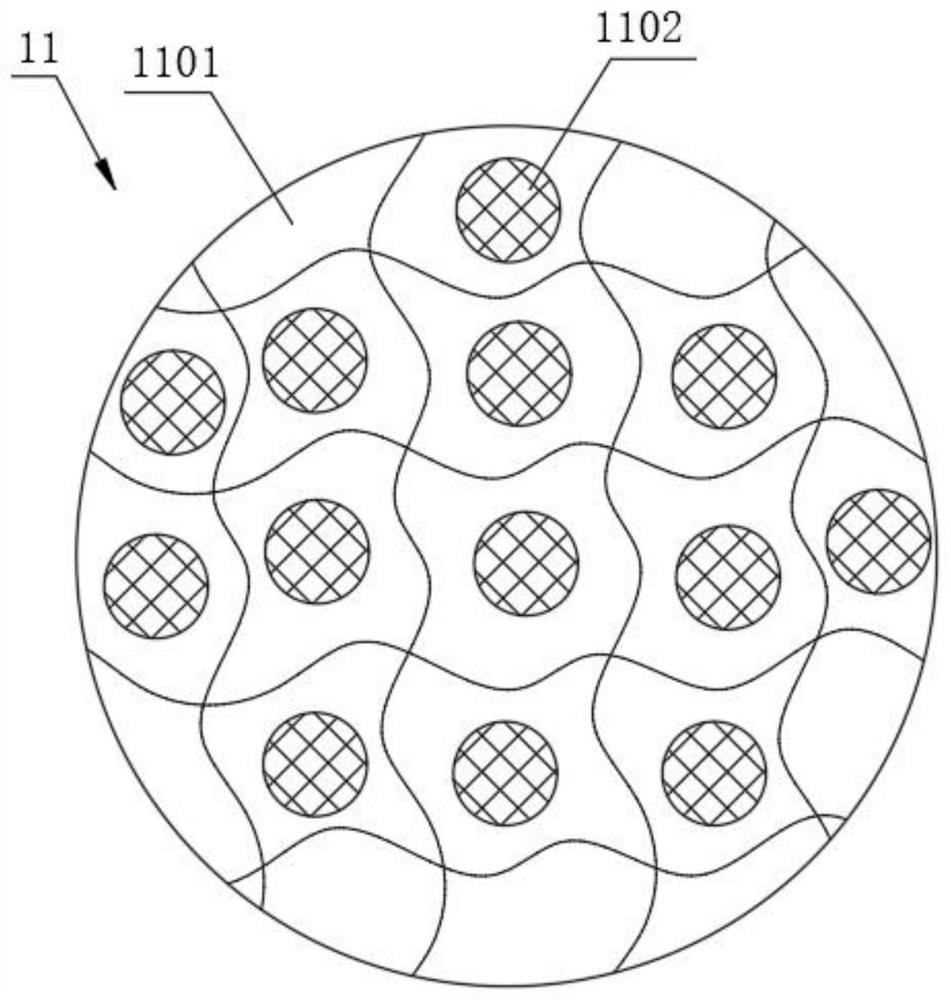

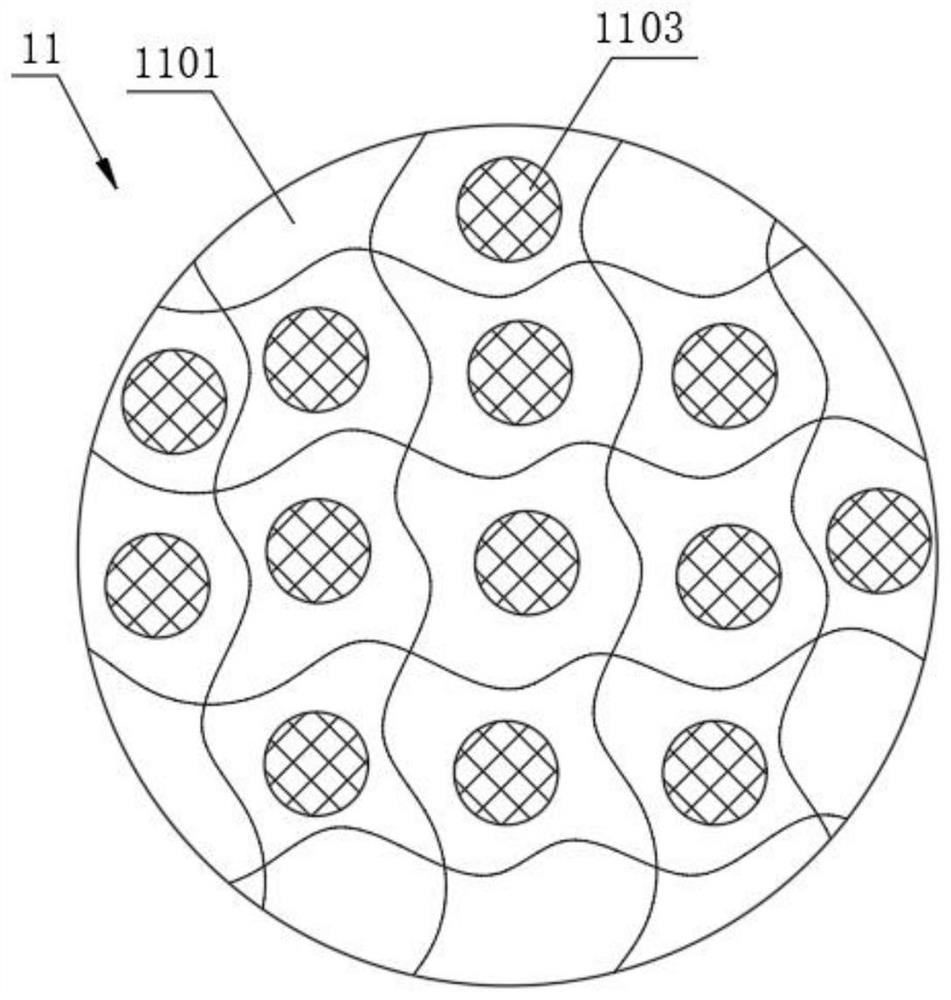

Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic and preparation method thereof

The invention discloses a preparation method of Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic. The preparation method comprises the following steps: taking silicon carbidepowder A, silicon carbide powder B, Al<4>SiC<4> and Al powder as main materials, adding a metal oxide accounting for 5-15 wt% of the main materials as a sintering aid, on the basis of the mass of themain material, dissolving 7.5wt% of cellulose, 3-5 wt% of a surfactant, 1.5-3.5 wt% of vegetable oil and 1-4 wt% of glycerol in equal mass of water to obtain a binding agent, mixing the main materials, the sintering aid and the binding agent uniformly, so as to obtain a mixture; pouring the mixture into a vacuum extruder for forming, performing drying, so as to obtain a honeycomb ceramic green body; heating the honeycomb ceramic green body to 2000-2200 DEG C under an argon atmosphere condition, preserving heat for 1-3 hours; and performing natural cooling, so as to obtain the Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic. According to the Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic prepared by the method, raw material utilization rate is high, the production efficiency is high, the structure of the product is wall-flow type, the purification capacity on the waste gas is improved, the microstructure is good, the micropore distribution is uniform, and the mechanical strength is high.

Owner:NANJING KERUI SPECIAL CERAMICS

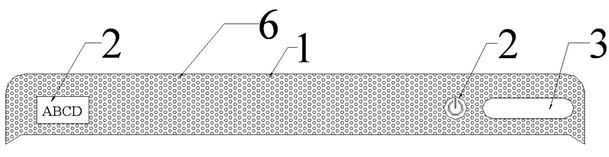

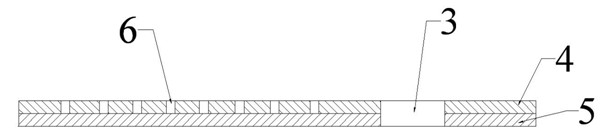

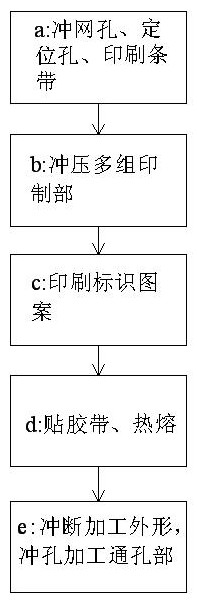

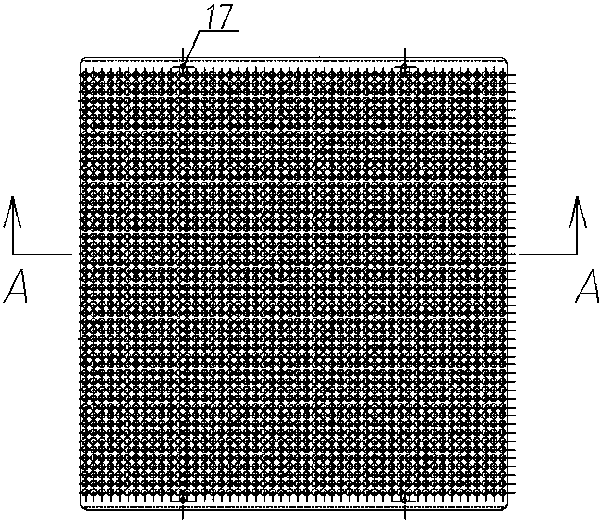

Loudspeaker mesh enclosure capable of being directly printed and production method thereof

ActiveCN102340711AOvercome the flaws that are not beautiful enoughCompact stepsTransducer detailsPolyesterPunching

The invention discloses a loudspeaker mesh enclosure capable of being directly printed and a production method thereof. The loudspeaker mesh enclosure capable of being directly printed comprises a mesh enclosure body with meshes and is characterized by also comprising printing parts which are integrally formed with the mesh enclosure body, are located in the same plane of the meshes, are provided with printing planes and are printed with identifications; and the loudspeaker mesh enclosure capable of being directly printed has the beneficial effects that the printing parts capable of being directly printed are integrally formed with the mesh enclosure body, so that the defect that a combined loudspeaker mesh enclosure is not attractive enough caused by the reason that a traditional mesh enclosure body part and a label part are independently processed and formed is overcome. The production method disclosed by the invention comprises the following steps of: processing a thin plate made of polyester through a punching machine many times; carrying out rubberizing, hot melting, thrusting and forming; and finally forming the loudspeaker mesh enclosure capable of being directly printed disclosed by the invention. The method disclosed by the invention has the beneficial effects that: the steps are relatively simple and compact, the yield of products can be improved, and the production efficiency is higher.

Owner:KUNSHAN GUANGDA TONGCHUANG NEW MATERIAL

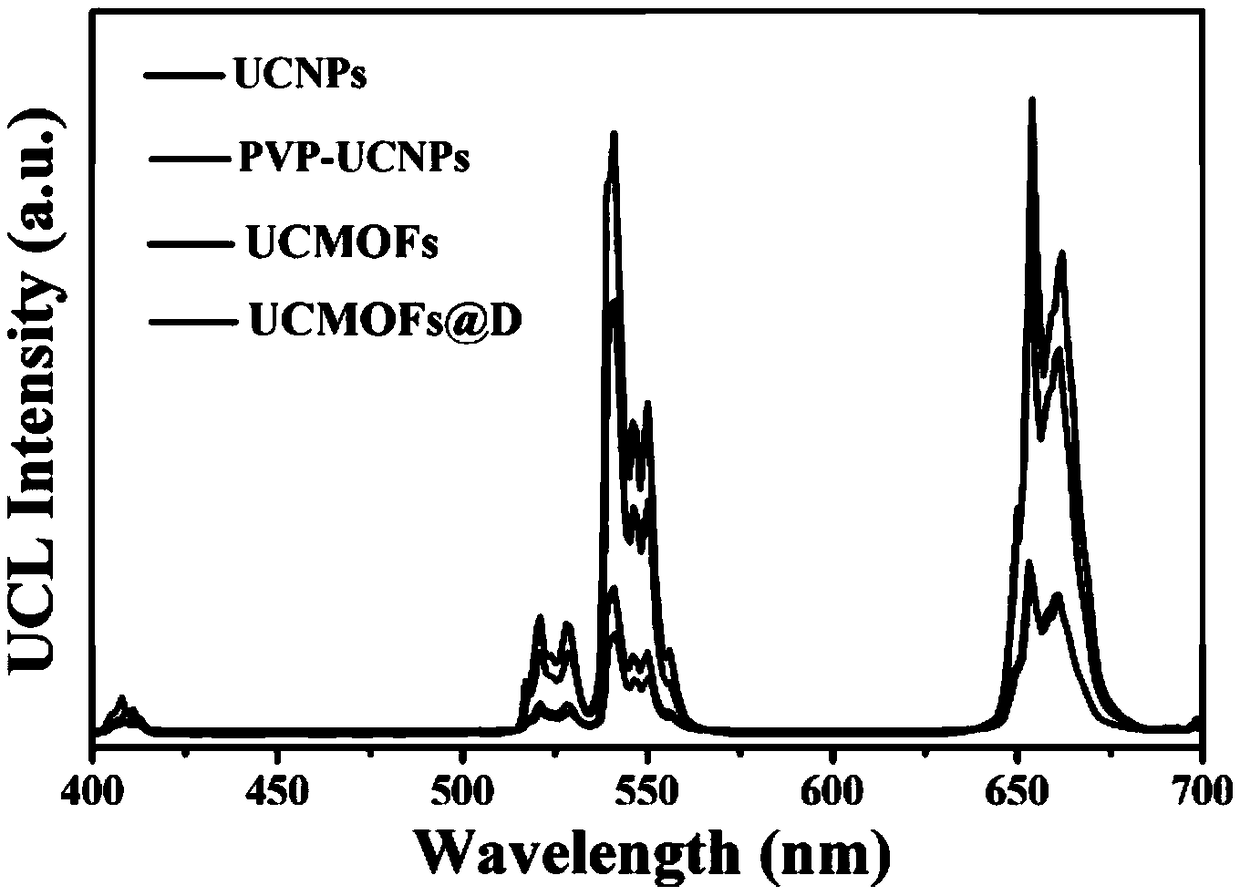

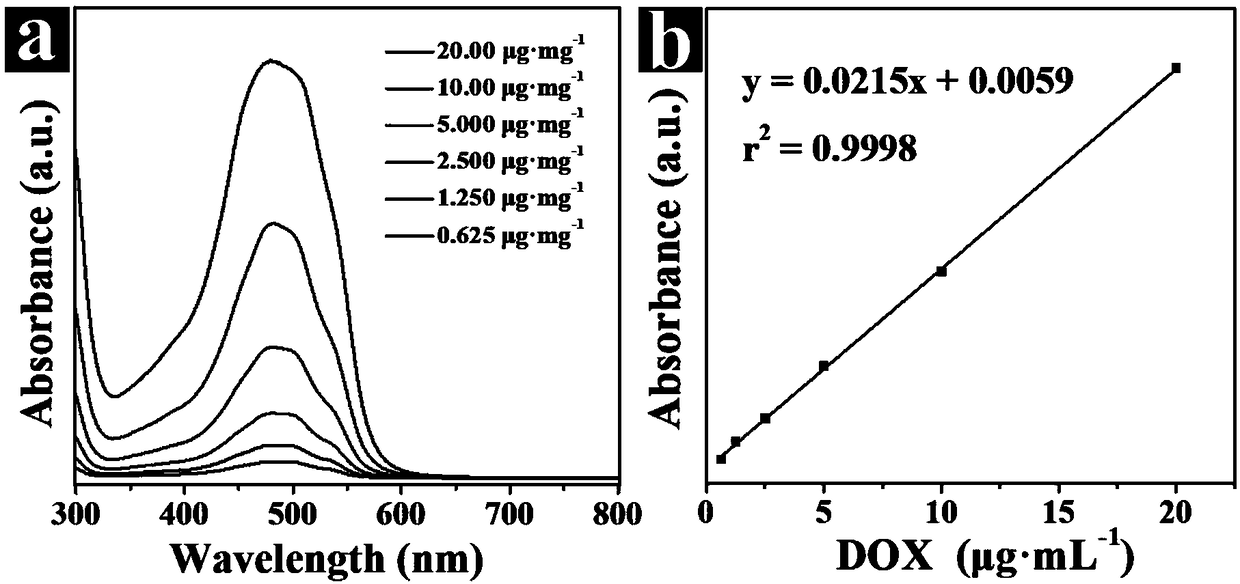

Preparation method and application of pH-responsive dual-drug-release metal-organic framework-upconversion nano-system

InactiveCN109172587AReduce forming sizeEasy to manufacturePowder deliveryOrganic active ingredientsSolubilityPolymer modified

The invention discloses a preparation method of a pH-responsive dual-drug-release metal-organic framework-upconversion nano-system. The preparation method comprises the following steps of: adopting apolymer modification method to improve the water solubility of the upconversion nano-crystal with a core-shell structure, and growing a metal-organic framework on the surface of the upconversion luminescent nano-crystal to obtain an upconversion nano-system coated with the metal-organic framework; and attaching Adriamycin hydrochloride containing amino group to the surface of the metal-organic framework, and adsorbing other anticancer drugs into the porous structure of the metal-organic framework to obtain the double-drug-loaded metal-organic framework-up-conversion nano-system. The nano system provided by the invention has good stability, good biocompatibility, simple and reliable preparation method and good repeatability. The nanosystems have tumor diagnostics-Therapeutic integration canbe used as an imaging agent for fluorescence imaging and magnetic resonance imaging, as well as drug delivery and pH-responsive dual drug release, and can be used as a drug carrier.

Owner:SHANGHAI UNIV

Diamond tool bit bevel face grinding device

ActiveCN105619204AIncrease productivityGuaranteed grinding accuracyEdge grinding machinesGrinding drivesGeneral purposeTool bit

Owner:鄂州市通磊超硬材料有限公司

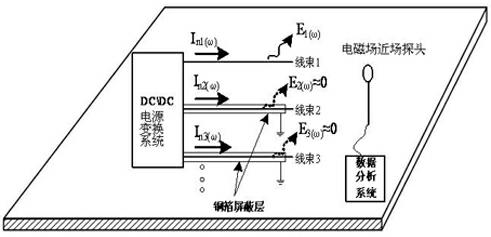

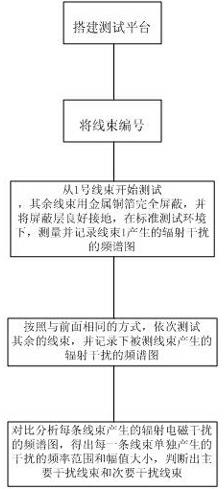

Method for detecting and analyzing radiated electromagnetic interference of wiring harnesses of power conversion system of automobile

InactiveCN102279331AEffective investigationImprove electromagnetic compatibilityElectrical testingElectromagnetic interferenceEngineering

The invention discloses a method for detecting and analyzing radiated electromagnetic interference of wiring harnesses of a power conversion system of an automobile. In the method, reasonable detecting steps are designed for detecting primary radiated interference wiring harnesses and detecting the distribution frequency band and size of the radiated electromagnetic interference generated by eachof the wiring harnesses, so as to direct engineering technical personnel to eliminate the radiated electromagnetic interference of the wiring harnesses of the power conversion system and to conveniently implement the excellent electromagnetic compatibility design for the wiring harnesses of the power conversion system. The method disclosed by the invention has the advantages that the steps are compact and the implementation is convenient.

Owner:CHONGQING UNIV

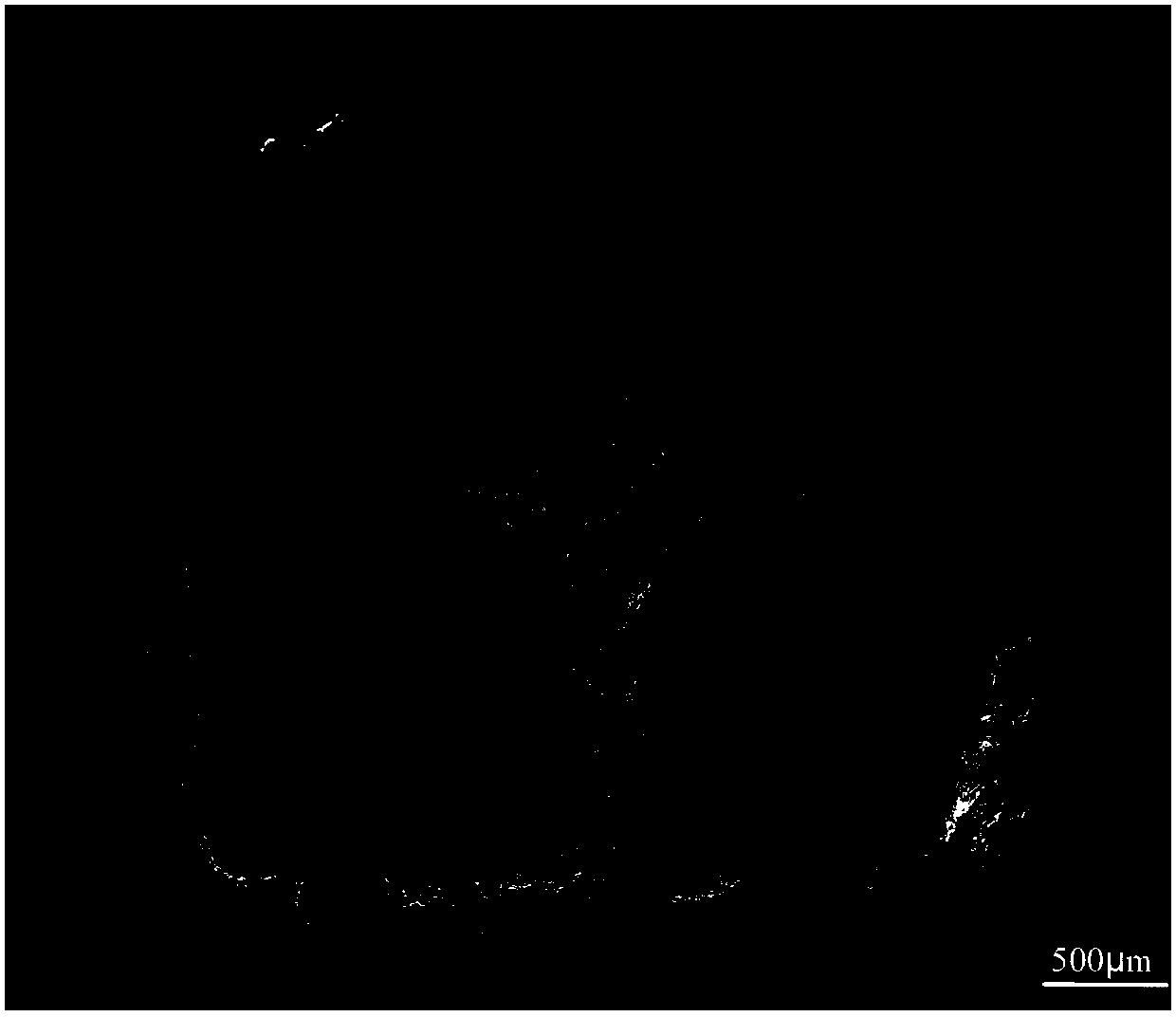

Scanning electron microscope sample table for air or moisture-sensitive sample and sample preparation method

InactiveCN107768221AEasy to carry and transferAvoid disadvantagesElectric discharge tubesMaterial analysis by measuring secondary emissionScanning electron microscopeTorsion spring

The invention discloses a scanning electron microscope sample table for an air or moisture-sensitive sample. The scanning electron microscope sample table comprises a base, a gland, a seal ring, a sample plate, torsional springs, torsional spring fixing parts, a top plate, a connection seat, a shaft, bearings and torsional spring pressure plates. A to-be-scanned air or moisture-sensitive sample issealed on the sample plate in a glove box under the protection of an inert gas and then transferred to a scanning electron microscope sample room to be scanned and observed. A sample preparation method for a scanning electron microscope for the air or moisture-sensitive sample comprises the following steps of (1) putting the sample on the sample plate under the protection of the inert gas, covering the sample with the gland and sealing the sample into a low-pressure space enclosed by the base, the gland and the seal ring; (2) transferring the sample table to the scanning electron microscope sample room and vacuumizing the sample room; (3) opening the gland under the action of the torsional springs and vacuumizing the scanning electron microscope; and (4) observing, recording and analyzingthe sample and drawing a conclusion.

Owner:WANXIANG 123 CO LTD +1

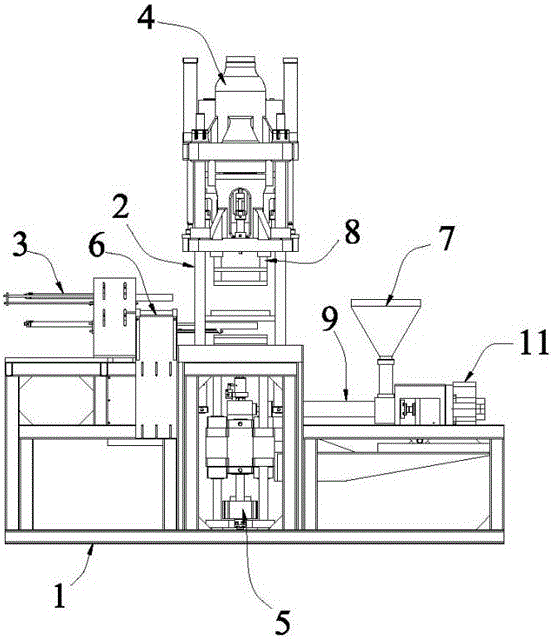

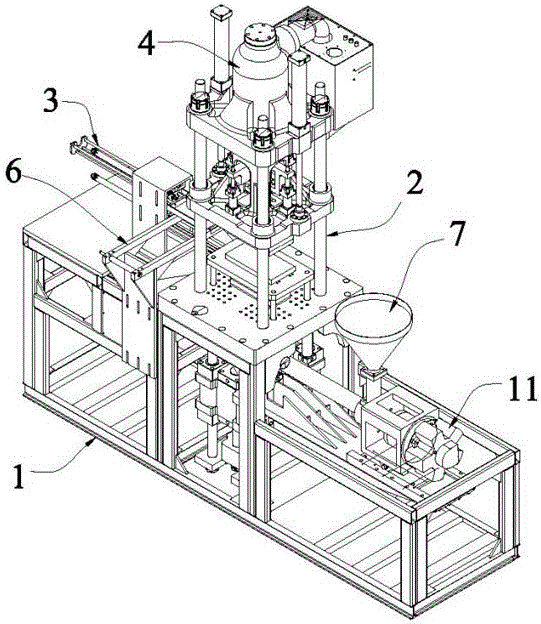

Ceramic green body injection molding machine and molding method thereof

ActiveCN106476118ACompact stepsIngenious structural designMouldsAuxillary shaping apparatusMolding machineInjection molding machine

The invention discloses a ceramic green body injection molding machine and a molding method thereof. The ceramic green body injection molding machine comprises a rack, a support, a mechanical arm, a direct pressure mold opening and closing device, a material feeding mechanism, a product conveying belt, a hopper, a molding mold, a plasticizing cylinder, a screw and a plasticizing motor; the support is vertically arranged in the middle of the rack, the molding mold and the direct pressure mold opening and closing device are arranged on the support, the material feeding mechanism is arranged at the bottom of the rack corresponding to the position below the molding mold, the plasticizing cylinder is horizontally arranged on the rack, one end of the plasticizing cylinder is connected with the material feeding mechanism, the other end of the plasticizing cylinder is provided with a hopper mounting base, one end of the screw extends into the plasticizing cylinder through the hopper mounting base, and the other end of the screw is connected with the plasticizing motor. Accordingly, the structural design is exquisite and reasonable, a traditional horizontal type is changed into a vertical type, the production efficiency is greatly improved, the produced product is good in compactness and smoothness, high in mechanical strength, high in humidity-state resistance value, not likely to break and high in product yield, and the production speed and the efficiency are high.

Owner:东莞杰宇机械有限公司

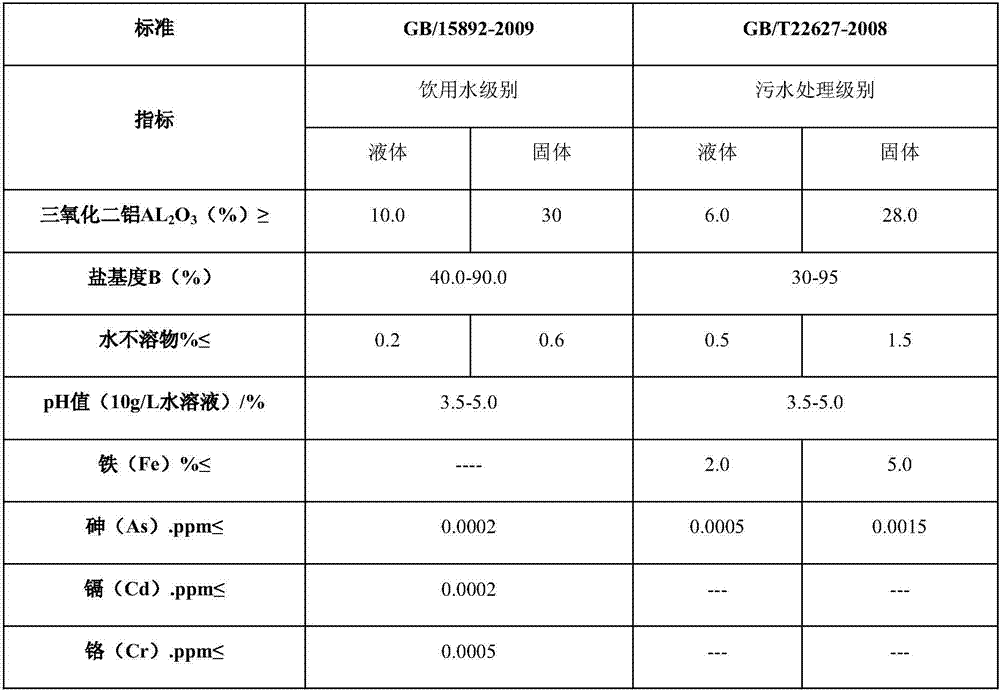

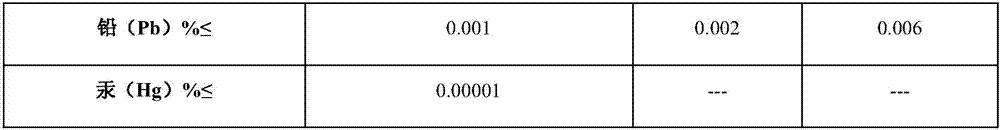

Method of producing polyaluminum chloride with wasted anthraquinone regeneration agent

ActiveCN107285355AReduce adsorptionSolve the problem of darkening and darkeningAluminium chloridesWater/sewage treatment by flocculation/precipitationActivated carbonCombustion

The invention discloses a method of producing polyaluminum chloride with a wasted anthraquinone regeneration agent. The method includes the steps of: a) mixing the wasted anthraquinone regeneration agent with activated carbon, grinding the mixture into fine powder, adding a combustion agent, and fully stirring the materials to obtain a mixture; b) performing aerobic roasting to the mixture in the step a) to obtain a roasted material; c) mixing the roasted material with hydrochloric acid to dissolve-out the aluminum oxide to obtain a dissolving-out solution; d) slowly adding hydrochloric acid dropwise to the dissolving-out solution, uniformly stirring the solution, after the hydrochloric acid is all added, adding a NaOH solution to regulate the pH value, and performing hydrolytic polymerization aging to obtain a polyaluminum chloride solution; and e) diluting and filtering the polyaluminum chloride solution, evaporating and concentrating the solution, and drying the solution to obtain solid polyaluminum chloride. The method has simple process and fewer steps, is low in investment and cost, and has promoting significance.

Owner:GUANGXI XINJING TECH

Compound herbal arnebia root ointment and preparation method thereof

InactiveCN110354047AEnhanced barrier functionPromote new metabolismCosmetic preparationsToilet preparationsBiotechnologyGrape seed

The invention discloses a compound herbal arnebia root ointment. The compound herbal arnebia root ointment is prepared from, by weight, 3-5 parts of an amebia enchroma extract, 1-3 parts of petrolatum, 2-4 parts of grape seed oil, 1-3 parts of camellia seed oil, 2-5 parts of cera alba and 1-4 parts of cocoa seed butter. The preparation method of the compound herbal arnebia root ointment comprisesthe following steps that S1, the amebia enchroma extract, the petrolatum, the cocoa seed butter and the cera alba are obtained to be mixed with the grape seed oil; S2, the camellia seed oil, fructus hippophae seed oil, peppermint leaf oil, melaleuca alternifolia cheel leaf oil, lavender oil, eucalyptus globulus oil, bisabolol and tocopherol are obtained to be stirred and mixed; S3, the mixture 1 is added to the mixture 2 for stirring. The invention further discloses a preparation method of the compound herbal arnebia root ointment. The compound herbal arnebia root ointment has good effects ofremoving wet itching and mosquito bites, further has the curative effects of antiphlogosis, astriction and moisturizing, and has the effects of whitening, spot-fading, moisturizing, regeneration and ageing resistance on the skin, and the effects are significant.

Owner:清远市族原生物科技有限公司

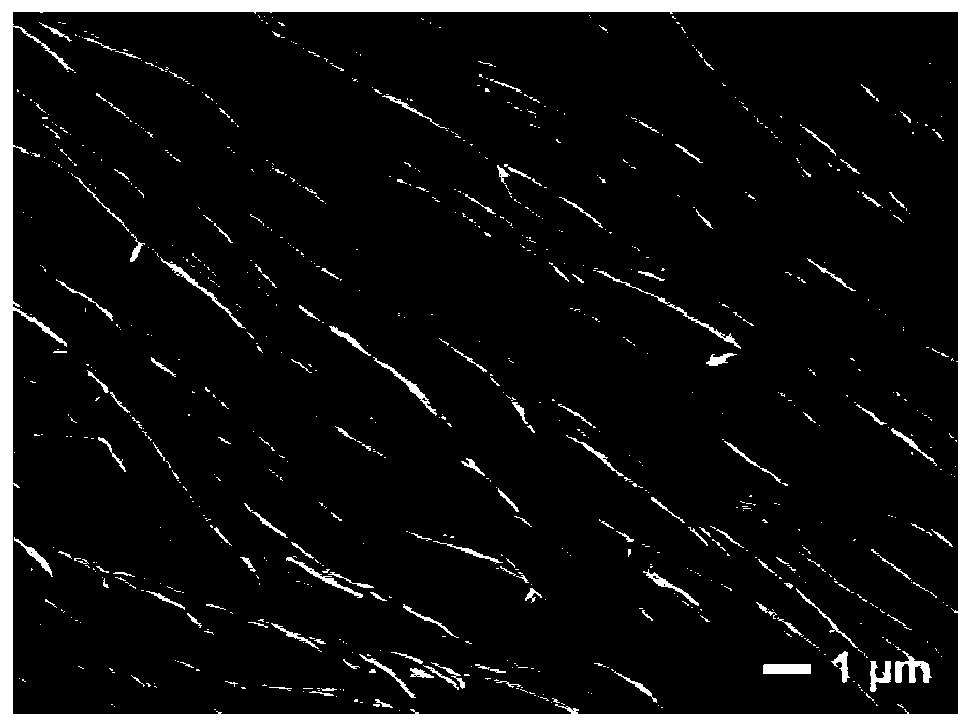

Preparation method of conducting lubricating grease

PendingCN107574000AConductiveMaintain two-dimensional anti-wear lubricationLubricant compositionGraphiteBase oil

The invention discloses a preparation method of conducting lubricating grease. The preparation method comprises the following steps: A, carrying out microwave heating on expandable graphite, raising temperature and expanding the expandable graphite to obtain graphite nano-sheets; B, mixing the graphite nano-sheets in step A with ionic liquid according to the dosage relation of (80mg to 120mg) to (50mL to 500mL); pressurizing and grinding the mixture at 150 DEG C to 250 DEG C; then carrying out ultrasonic treatment on suspension liquid obtained by grinding; after finishing the ultrasonic treatment, centrifuging for 0.5h to 2h; taking supernatant liquid to obtain a conducting lubricating grease additive; C, mixing the conducting lubricating grease obtained by step B with base oil and a thickener according to the ratio of (5 to 10) to (75 to 85) to (10 to 15) and uniformly mixing to obtain the conducting lubricating grease. The preparation method disclosed by the invention has the advantages of simple technological process, compact steps, less investment and low cost; the lubricating grease which has better conducting and lubricating functions at the same time is prepared.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

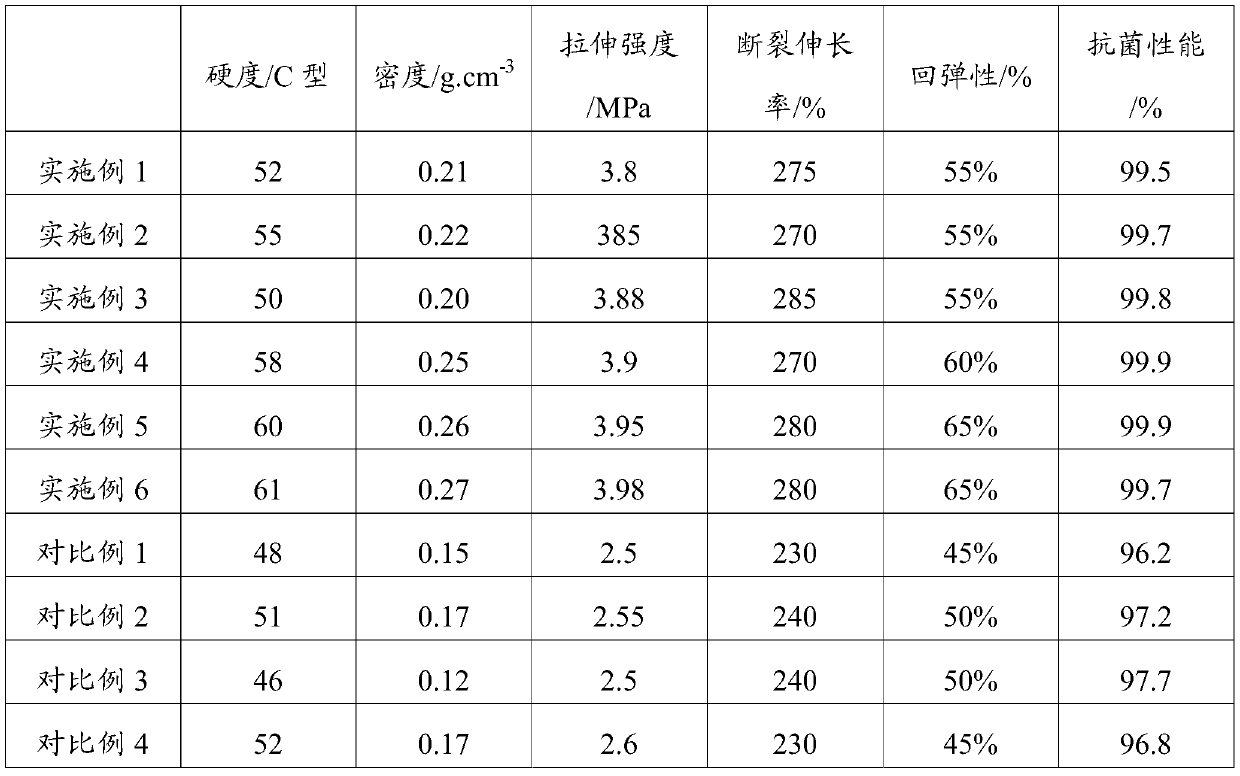

Durable elastic floating body and preparation method thereof

The invention discloses a durable elastic floating body and a preparation method thereof, and belongs to the technical field of high polymer materials. The durable elastic floating body comprises an ethylene-vinyl acetate copolymer, a thermoplastic elastomer TPE, a filler, a foaming agent, a foaming aid, a lubricant, a coupling agent modified anti-ultraviolet agent, a coupling agent modified antioxidant, a coupling agent modified antibacterial agent, a cross-linking agent and a pigment. According to the durable elastic floating body, the surfaces of the anti-ultraviolet agent, the antioxidantand the antibacterial agent are changed into hydrophobicity from hydrophilcity through modification of the coupling agent, the dispersity of an inorganic auxiliary agent in an organic material is improved, the binding force of the inorganic auxiliary agent and the organic material is enhanced, the effect of the inorganic auxiliary agent can be fully exerted, the obtained elastic floating body hasexcellent wear resistance, rebound resilience, antibacterial property and aging resistance at the same time. The preparation method is simple in step and easy to operate, and the elastic floating bodyis formed through one-time foaming, compact in texture, smooth and thorn-free in surface and excellent in quality.

Owner:福建创合新材料科技有限公司

Soft Rock Large Deformation Tunnel Support System and Its Construction Method

InactiveCN104847374BEnsure safetySmall overall deformationUnderground chambersTunnel liningSupporting systemLarge deformation

A support system and construction method for large deformation tunnels in soft rock, including main structures such as advance support, primary support, waterproof layer and secondary lining, and each structure is constructed sequentially following the construction process. The advance support is to strengthen the surrounding rock through the advance small conduit grouting. The initial support consists of an extended anchor rod, a primary spray layer, a steel arch frame and a respray layer. There are also lock foot anchor rods and steel arches at the upper steps and arch feet. Frames are welded, adjacent steel arches are connected by longitudinal connecting bars, and finally secondary lining is applied to form a supporting system. The steps of the invention are simple and interlocking, avoiding the problem of support delay caused by idle work, and have beneficial effects on controlling the large deformation of the tunnel.

Owner:CHANGAN UNIV

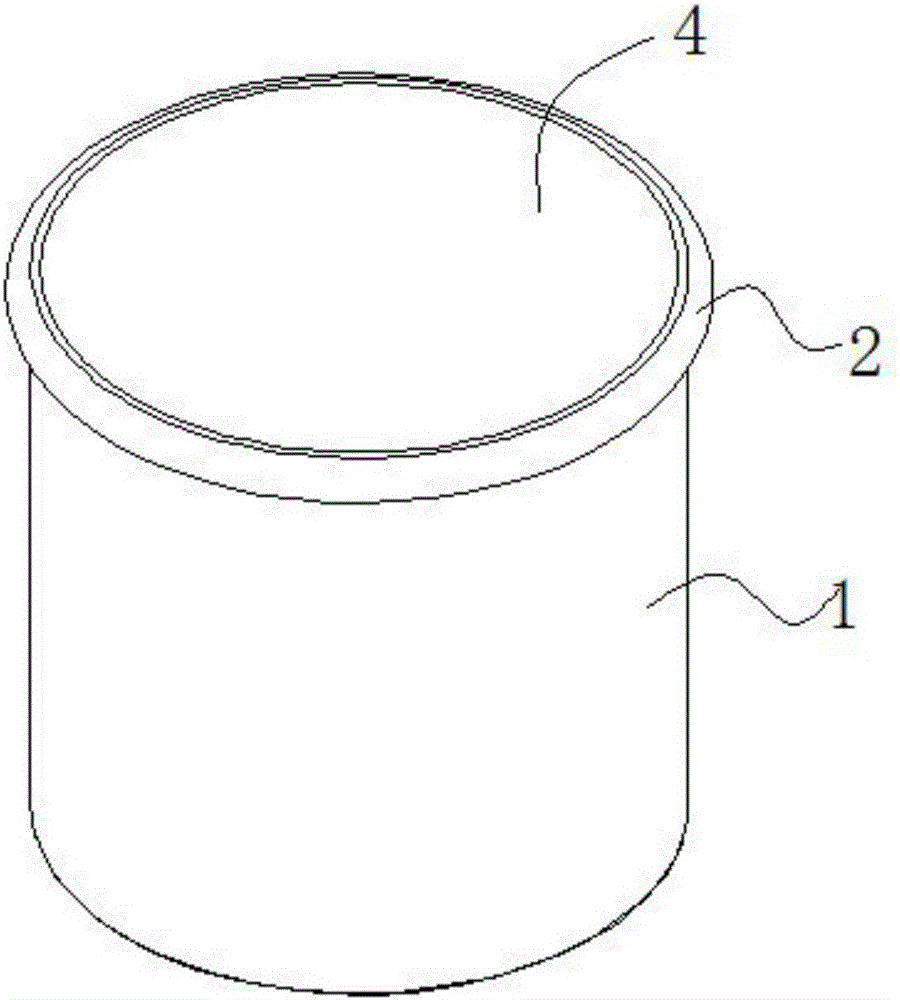

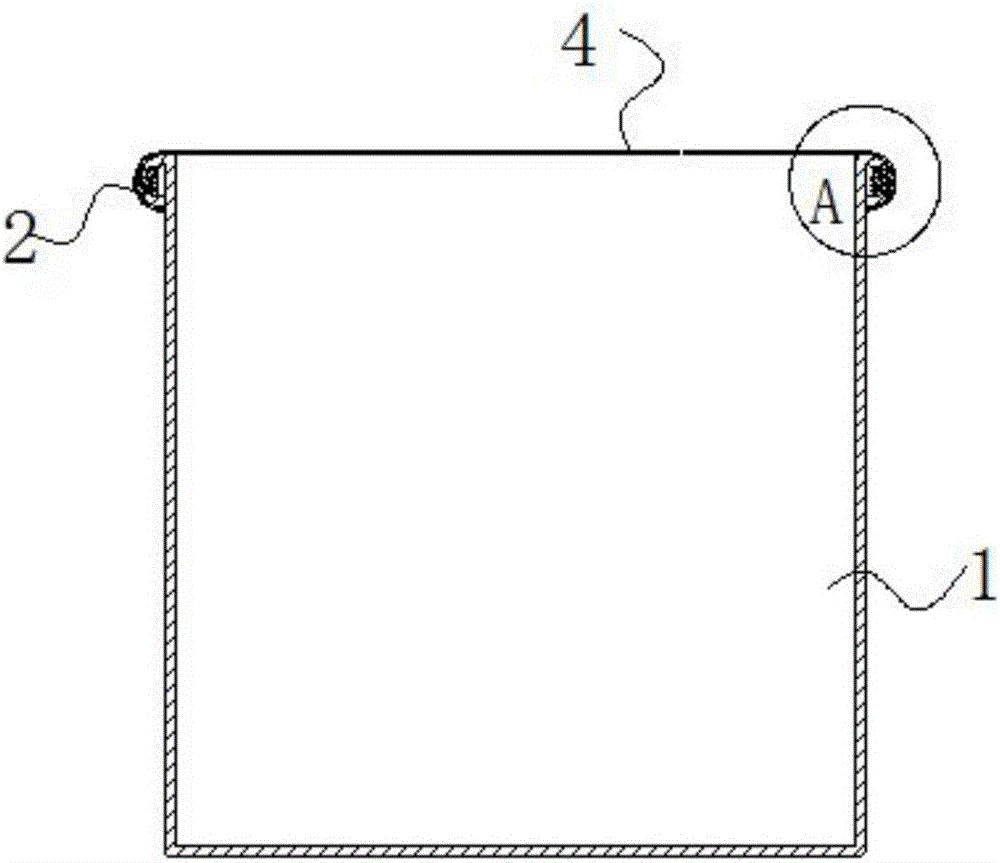

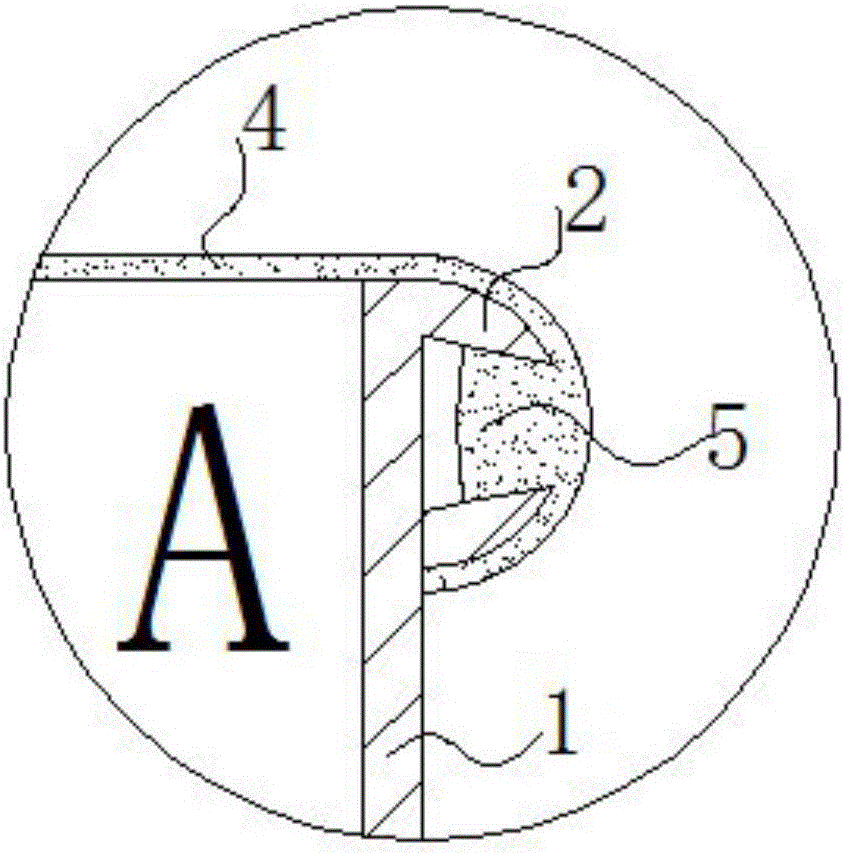

Degradable sealing membrane material preparing method, product and sealed container

ActiveCN105885278AModerate softnessModerate intensityCans/barrels/drumsDomestic articlesThermal stabilityUltimate tensile strength

The invention discloses a degradable sealing membrane material preparing method and a product. The degradable sealing membrane material can be degraded in the natural environment after being discarded; furthermore, the material has moderate flexibility and strength, is not prone to breaking, has high flame retardation, adhesive property and thermal stability and excellent heat sealing processability, and has a wide application range; heat sealing can be well achieved between the material and metal especially, and disengagement can not be caused easily. The invention further discloses a method for preparing a metal sealed container made of the degradable sealing membrane material and a product. Through improvement in both technology and structure, heat sealing between a metal container body and a sealing membrane can be well achieved in adhering, hooping and buckling modes, and the condition in the container can be observed more or less due to the semitransparent property.

Owner:英联金属科技(汕头)有限公司

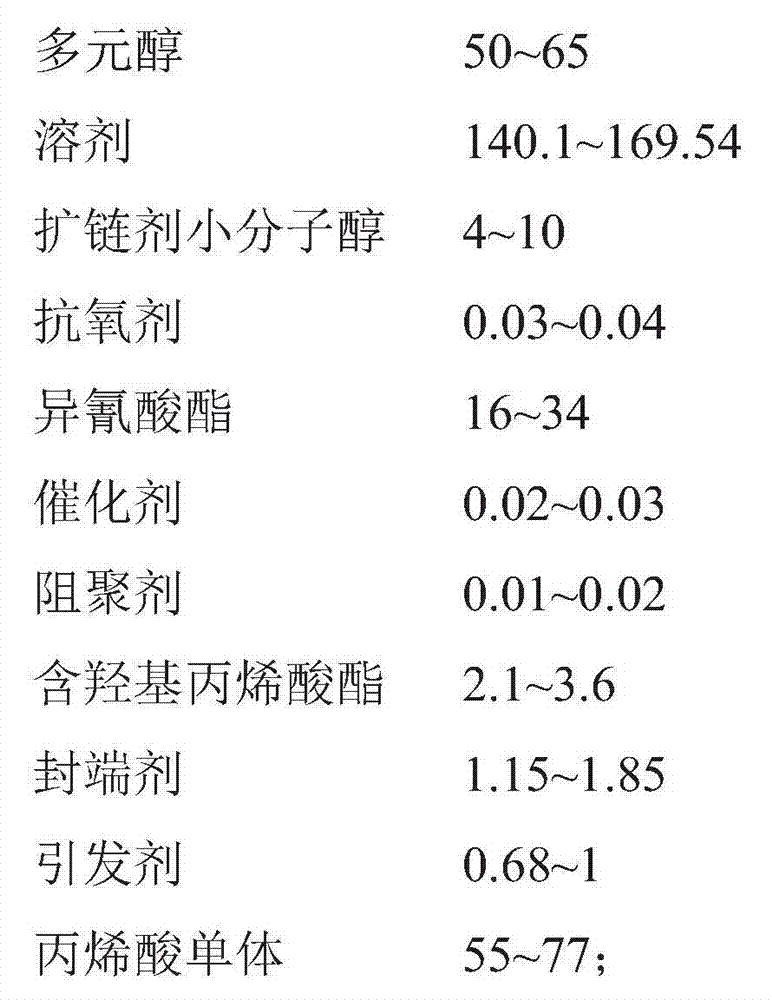

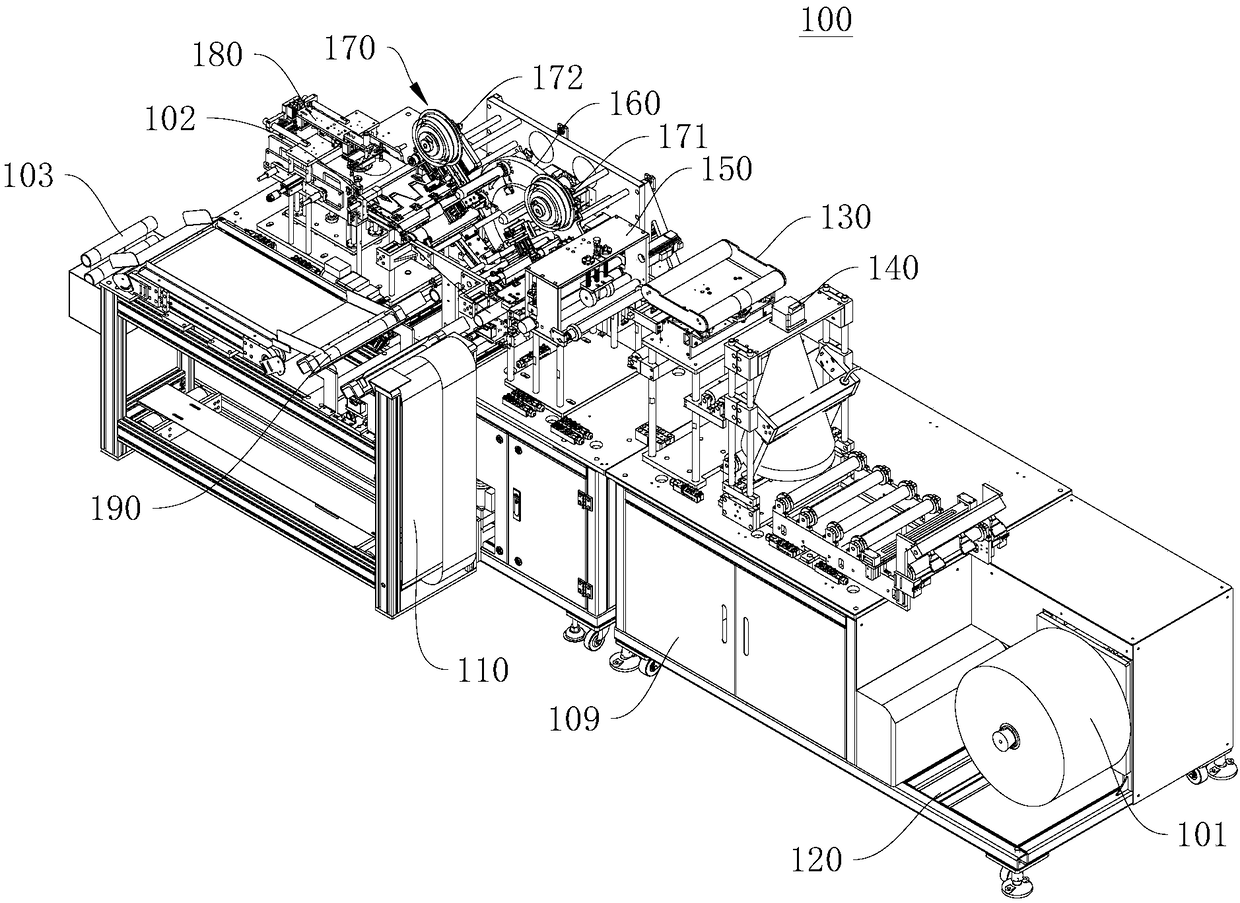

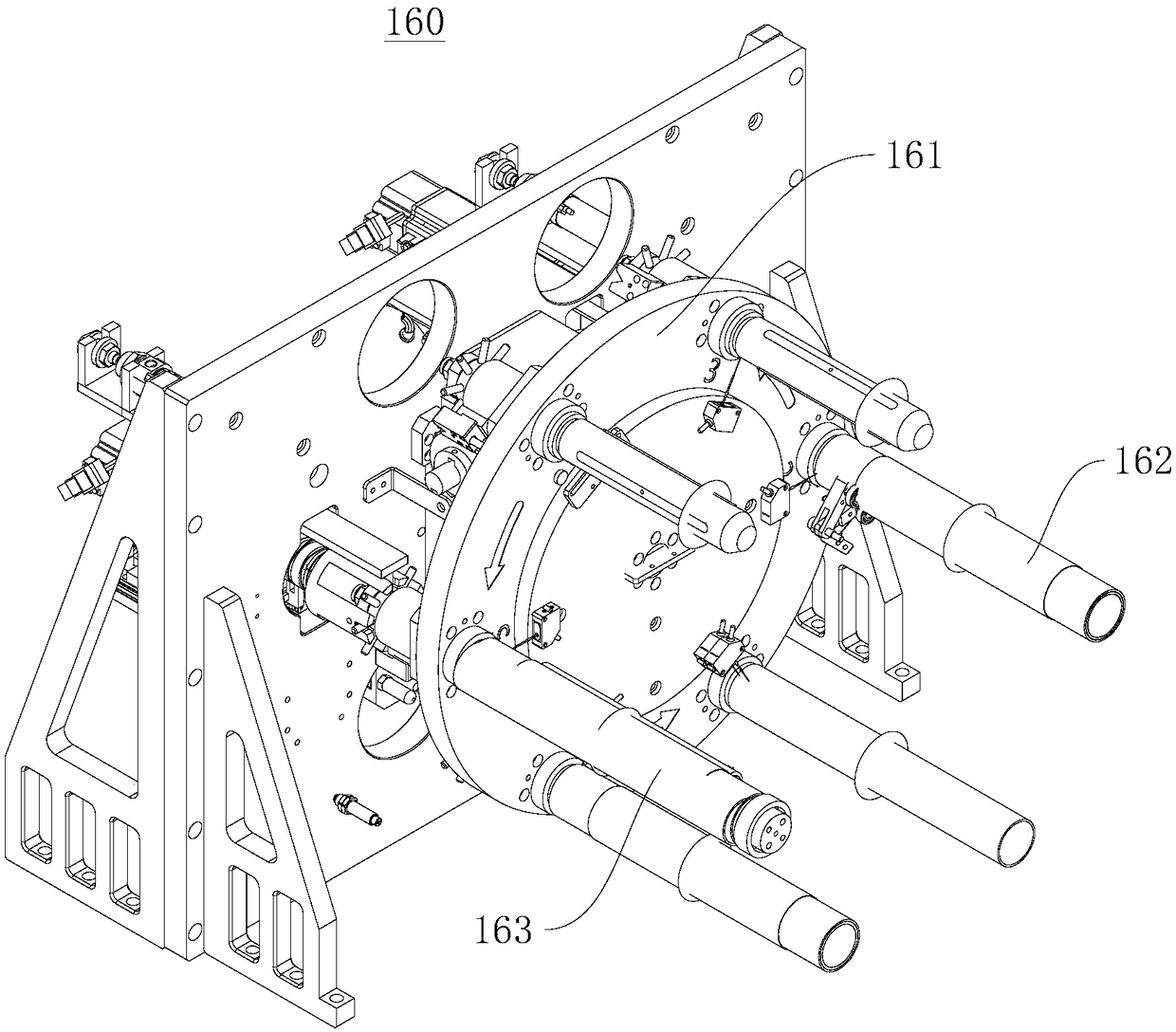

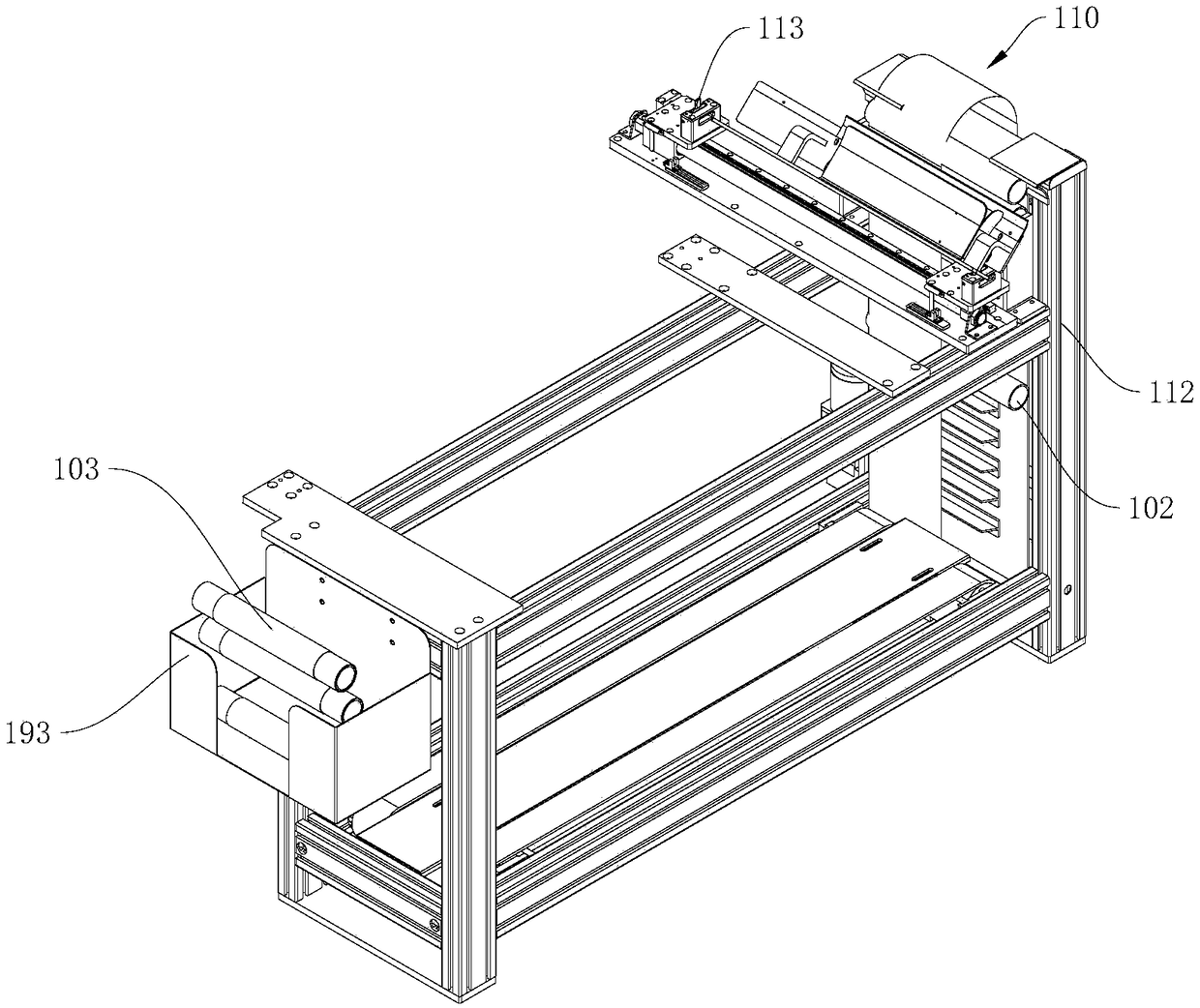

Rotating disc type roll paper packaging machine and control method thereof

ActiveCN108516391AIncrease productivityReduce manual labor intensityPaper article packagingArticle deliveryRolling paperPulp and paper industry

The invention provides a rotating disc type roll paper packaging machine and a control method thereof, and relates to the technical field of roll paper packaging machines. The rotating disc type rollpaper packaging machine comprises a paper tube core feed and push-in mechanism, a roll containing and tension mechanism, a paper feeding and slitting mechanism, a rotating disc tool mechanism, a gluing mechanism, a color page separating and conveying mechanism, a finished product push-out and discharge mechanism and a controller. Under the control action of the controller, the paper tube core feedand push-in mechanism, the roll containing and tension mechanism, the paper feeding and slitting mechanism, the rotating disc tool mechanism, the gluing mechanism, the color page separating and conveying mechanism and the finished product push-out and discharge mechanism can roll large roll paper into small paper tube cores, preliminary finished products are formed through cutting, color page bonding is further carried out to form products, production efficiency is high, and the manual operation intensity is low.

Owner:XIAMEN YOUXIN INFORMATION TECH CO LTD

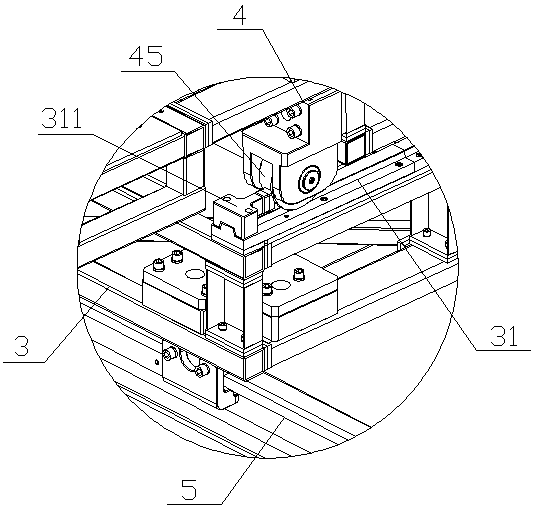

General assembly line body for vacuum pump assembly line

The invention discloses a general assembly line body for a vacuum pump assembly line. The general assembly line body comprises a vertical bearing frame, wherein the vertical bearing frame is horizontally provided with a first sliding rail and a second sliding rail which are parallel to each other; a first conveying belt vertical to the transmission direction of the first sliding rail is connected beside the feeding end of the first sliding rail, and a second conveying belt is connected between the discharging end of the first sliding rail and the feeding end of the second sliding rail; the first conveying belt, the first sliding rail, the second sliding rail and the second conveying belt are slidably provided with a station plate, and the station plate is used for bearing parts of a vacuum pump and is capable of sliding relative to the vertical bearing frame under the drive of the first sliding rail and the second sliding rail; and the first sliding rail is driven by a first traversing mechanism, and the second sliding rail is driven by a second traversing mechanism. The general assembly line body has the beneficial effects that the parts of the vacuum pump are sequentially conveyed in all steps for preparing the vacuum pump, and meanwhile the general assembly line body is mounted in a relatively narrow production workshop.

Owner:CHONGQING YUNHAI MACHINERY MFG

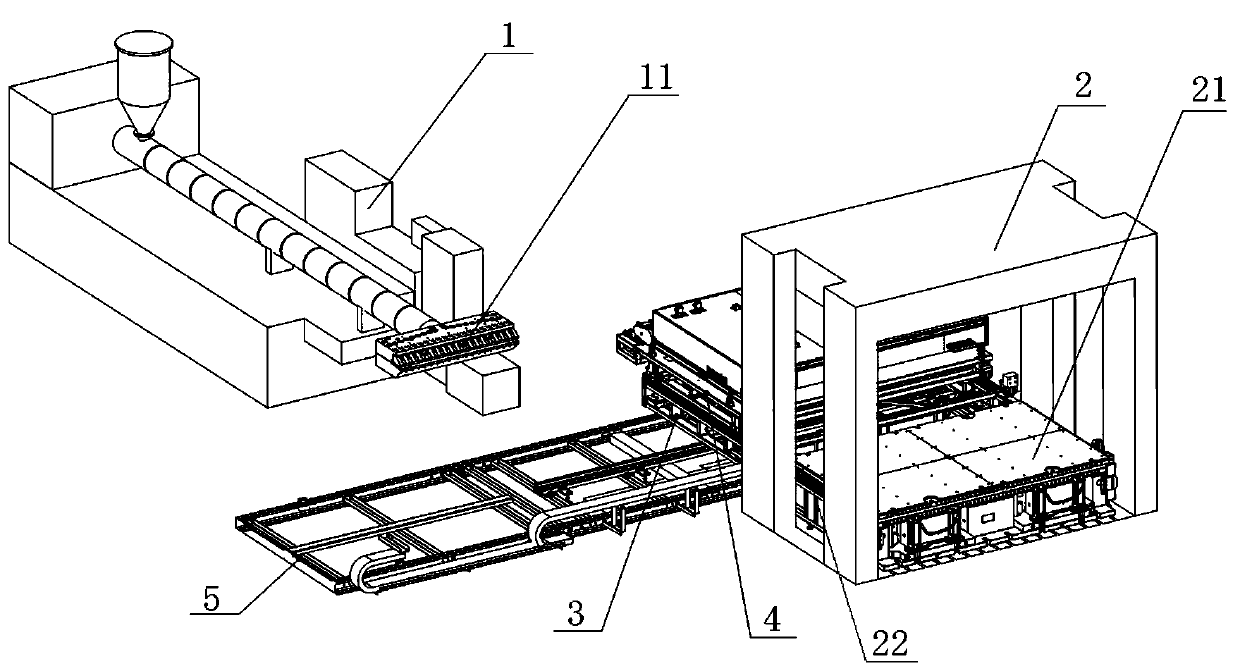

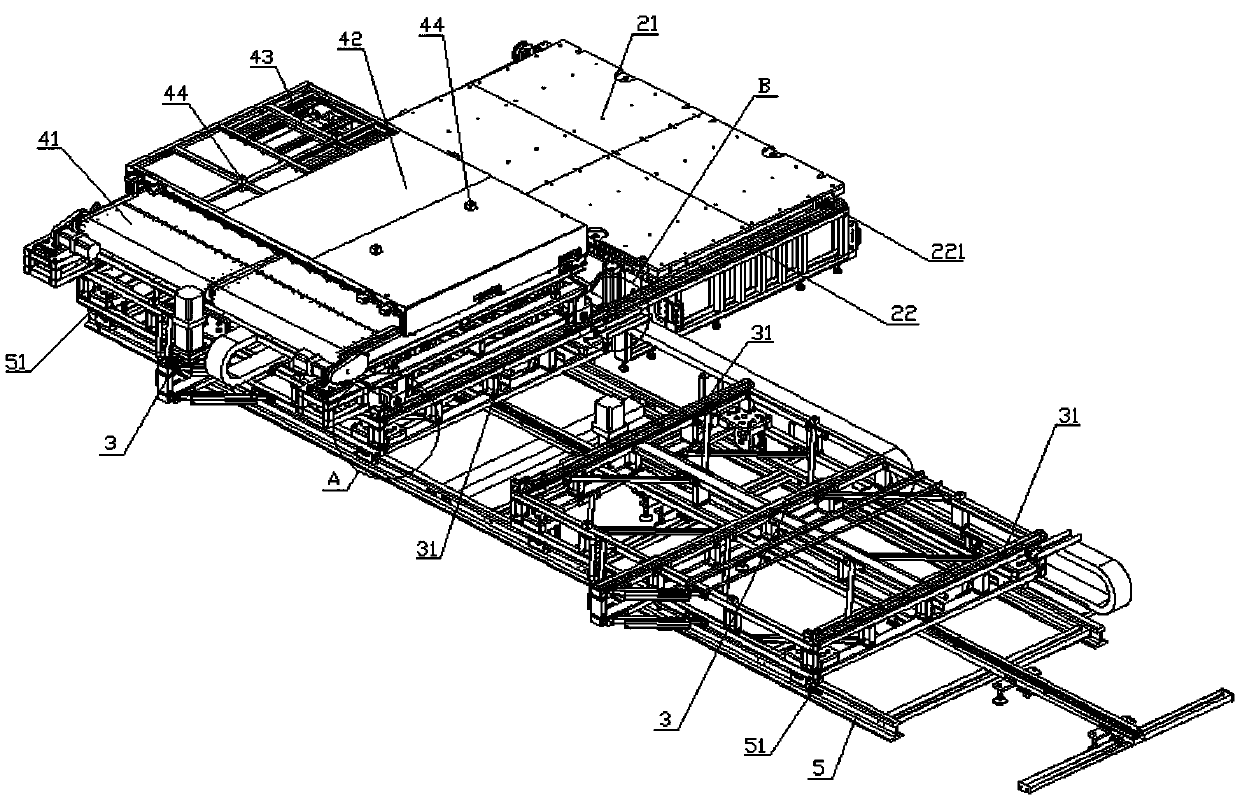

Base plate production system and base plate production process

The invention relates to the technical field of base plate production, and particularly relates to a base plate production system and a base plate production process. The base plate production systemcomprises an extruder, a hydraulic machine, a transport trolley, a discharging trolley and a third conveying rail assembly, wherein an extrusion die is installed on the extruder; a die pressing die and a first conveying rail assembly are installed on the hydraulic machine; a second conveying rail assembly is installed on the transport trolley; a conveying mechanism used for conveying base plates and a heat preservation mechanism used for heat preservation of the base plates are installed on the discharging trolley; and the transport trolley moves in a reciprocating mode along the third conveying rail assembly so that the discharging trolley can bear the base plates extruded by the extrusion die and send the base plates into the die pressing die. The base plate production system and the base plate production process have the beneficial effects that the production and machining of the base plates are realized through the cooperation of the extrusion die and the die pressing die, the production quality and the production efficiency are improved, the temperature of the molten blocky base plates in the conveying process is guaranteed, the requirement for the production environment is reduced, the occupied space is small, and the transportation is convenient.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

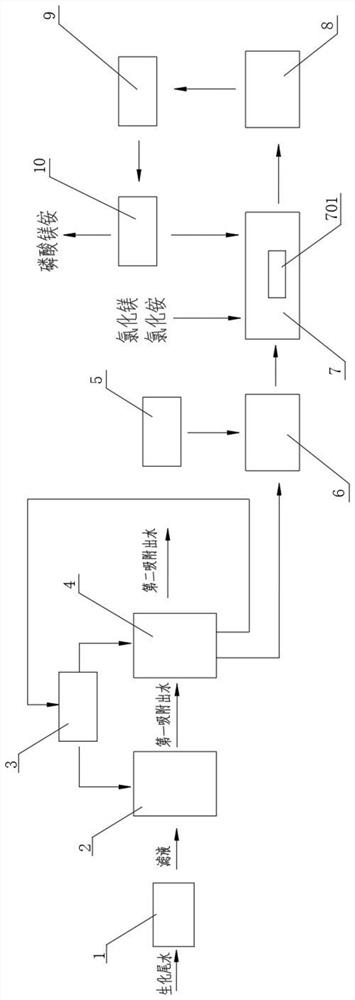

Method for deep purification and efficient recovery of trace phosphorus in biochemical tail water

ActiveCN111892229ACompact stepsLow running costTreatment involving filtrationWater/sewage treatment by ion-exchangeMagnesium ammonium phosphateEnvironmental chemistry

The invention relates to a method for deep purification and efficient recovery of trace phosphorus in biochemical tail water. The method comprises the following steps: removing organic matters in thebiochemical tail water by using high-crosslinking adsorption resin, and adsorbing phosphorus in the biochemical tail water by using a selective phosphorus removal composite material, thereby implementing deep removal of trace phosphorus in the biochemical tail water. Phosphorus-rich desorption liquid containing high-concentration phosphorus is obtained by desorbing the phosphorus removal compositematerial which is saturated through adsorption, phosphorus is converted into magnesium ammonium phosphate through crystallization and precipitation, magnesium ammonium phosphate is separated out, andtherefore trace phosphorus in biochemical tail water is efficiently recycled. By using the method, deep removal of trace phosphorus in the biochemical tail water can be realized, and the recovered magnesium ammonium phosphate has higher purity, can be used as an agricultural fertilizer, and can generate better environmental benefits and economic benefits.

Owner:JIANGSU QICHUANG ENVIRONMENTAL SCI & TECH

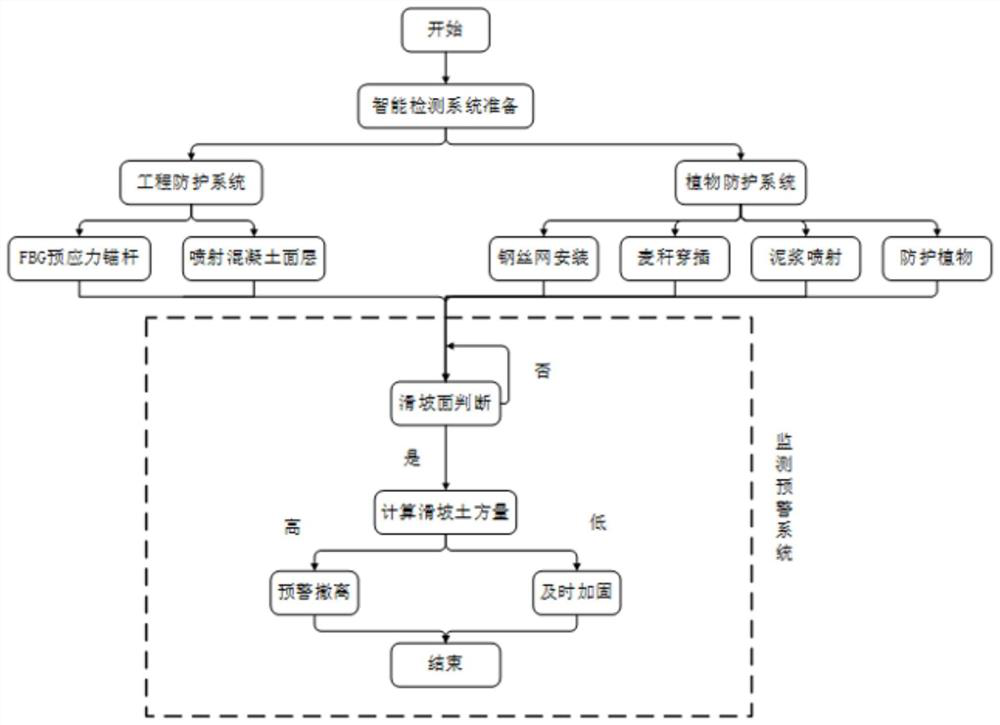

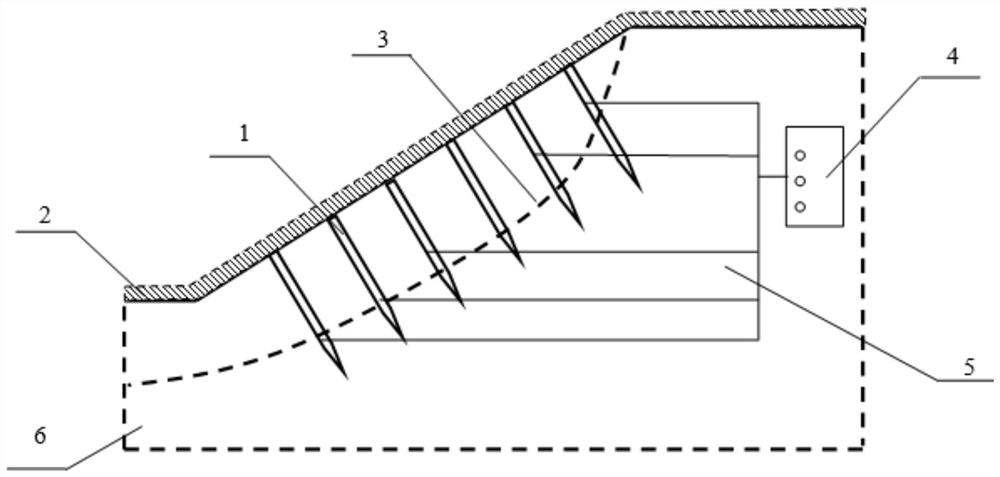

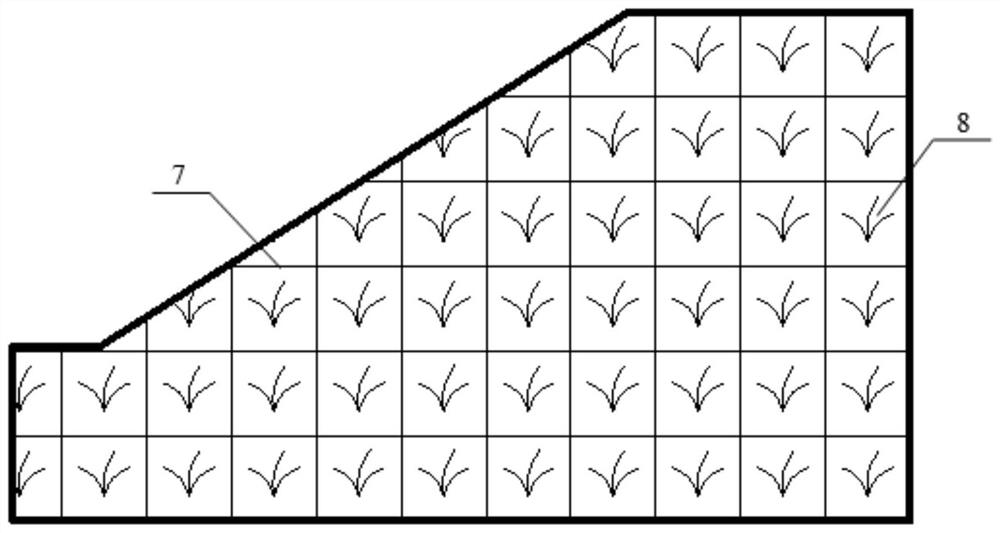

Slope reinforcement construction method with intelligent monitoring system

The invention discloses a slope reinforcement construction method with an intelligent monitoring system. The slope reinforcement construction method comprises a monitoring and early warning system, an engineering protection system and a plant protection system, the problem that the previous reinforcement engineering is lack of the monitoring and early warning system is solved, and the problem of slope instability can be effectively solved and the landslide surface is predicted, thereby ensuring the slope safety and the later operation safety, monitoring and reinforcement are combined, a large amount of slope landslide data can be collected, meanwhile, the slope reinforcement practical significance is achieved, the collected data can provide design parameters for follow-up similar projects, and project waste of saturated design of the similar slope projects is avoided.

Owner:CHINA RAILWAY 16TH BUREAU GRP ROAD & BRIDGE ENG CO LTD +1

Preparation method, product and application of nano aluminum oxide material

ActiveCN104445316AProcess ScienceCompact stepsMaterial nanotechnologyAluminium oxides/hydroxidesBriquetteNanometre

The invention discloses a preparation method of a nano aluminum oxide material. The preparation method is characterized by comprising the following steps: (1) preparing a precursor, namely uniformly mixing micron-scale aluminum oxide powder with carbon powder in a molar ratio of 1:(0.5-2), and then pressing into a briquette; (2) preparing sub-aluminum oxide, namely performing heating and heat preservation on the pressed briquette under a vacuum condition with the pressure of 10<-1>-10<-4> Pa until the aluminum oxide reacts with the carbon powder according to 2C+Al2O3=Al2O+2CO and gaseous sub-aluminum oxide starts to be generated; and (3) forming the nano aluminum oxide material, namely lowering the temperature in the step (2), then introducing air, discharging carbon monoxide at the same time to ensure that the gaseous aluminum oxide under the vacuum condition is converted into the nano aluminum oxide material, and collecting nano powder obtained under the vacuum condition, thereby obtaining the nano aluminum oxide material. The invention also discloses the nano aluminum oxide material prepared by the method, and an application of the nano aluminum oxide material in doping of a positive electrode material of a lithium ion battery.

Owner:东莞市鸿德电池有限公司

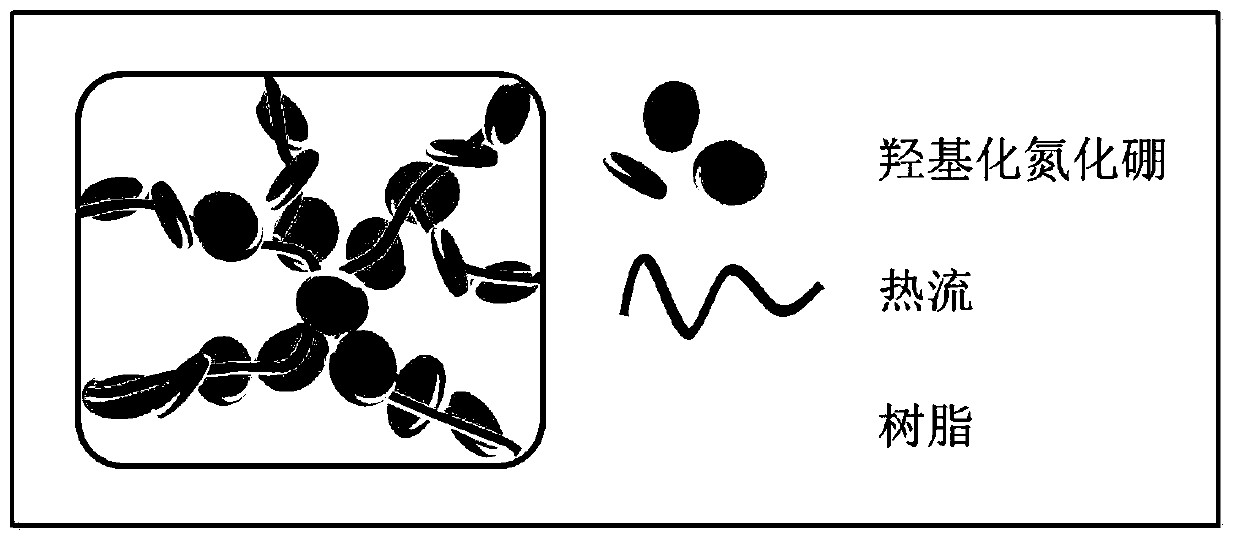

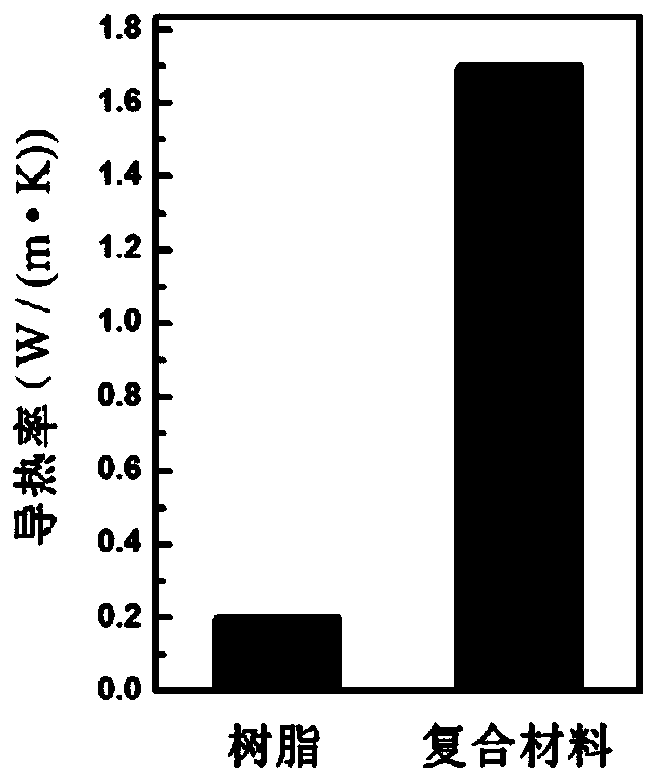

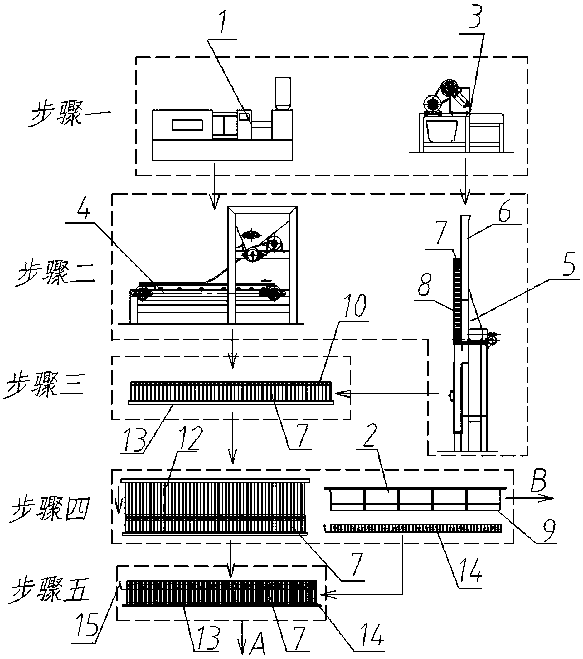

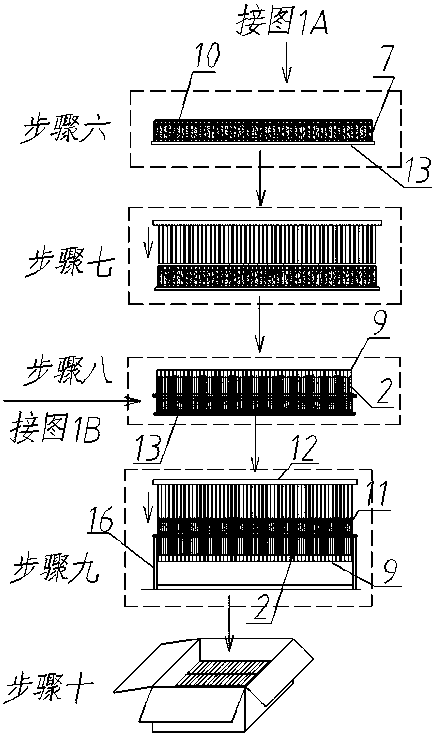

Polymer composite material containing boron nitride aerogel and preparation method and application thereof

ActiveCN110938297AImprove thermal conductivityImprove mechanical propertiesNitrogen compoundsBulk chemical productionBoron nitrideThermo responsive

The invention discloses a polymer composite material containing boron nitride aerogel, and a preparation method and application thereof. The polymer composite material is prepared from 1-20 wt% of theboron nitride aerogel and 80-99wt% of resin. The preparation method comprises the following steps: preparing hydroxylated boron nitride through assisted stripping of sodium cholate, then preparing anelastic boron nitride aerogel through a double-crosslinking reaction, and finally performing vacuum infusion to obtain the polymer thermal-response composite material containing the double-crosslinked elastic boron nitride aerogel. At present, research on application of a three-dimensional boron nitride / polymer composite material with high thermal conductivity and mechanical strength to a thermalresponse composite material has not been reported. The polymer composite material containing the boron nitride aerogel provided by the invention has good elasticity, the mechanical strength of thermal response compounding is improved, a continuous three-dimensional heat conduction path is constructed, and the heat conduction performance of the thermal-response composite material is improved. Thecomposite material disclosed by the invention can be used as a thermal-response composite material in a stimuli-responsive material and is used for preparing an intelligent driver and a sensor.

Owner:SHANGHAI UNIV

Construction method for efficient layered backfilling of earthwork

InactiveCN109778878AGuaranteed uniformityImprove compactionExcavationsWater contentEnvironmental geology

The invention discloses a construction method for efficient layered backfilling of earthwork, and relates to the technical field of backfilling construction of earthwork. The construction method comprises the following steps: (1) substrate treatment; (2) layered filling: before filling compaction, the loose laying thickness is not greater than 25 cm and not less than 12 cm; (3) paving and leveling: earthwork is transported from an excavation area to a soil filling area; (4) watering and drying in the sun: the water content of a filler measured on site is compared with an optimal water content,and when the water content exceeds + / -2%, the filler is watered or dried in the sun; (5) rolling: in a rolling process, a road roller is used for conducting prepressing once in a mode of first lightpressing and then heavy pressing from a low position to a high position and from a side to the middle, then flattening is carried out by a bulldozer and then rolling is carried out; (6) detecting: thewater content and the compaction degree of the filled soil are detected; and (7) filling construction of an uppermost layer of soil: an accurate virtual height is reserved according to the field soiltexture and the field pressure test condition. The method has the advantages that the overall construction is standard, the rework probability is greatly reduced, and the construction efficiency is high.

Owner:中冶成都勘察研究总院有限公司

Production and manufacturing method of activated carbon cigarette filters

ActiveCN108338407ACompact stepsThe production method is scientific and reasonableCigarette manufactureTobacco smoke filtersActivated carbonPulp and paper industry

The invention relates to a production and manufacturing method of activated carbon cigarette filters. The method is characterized by including the process steps of performing injection molding of sealplugs, making paper tubes by twisting, automatically arranging the seal plugs into an array, automatically arranging the paper tubes into an array, positioning and combining a seal plug array pore plate and a paper tube array pore plate, pressing the seal plugs into the paper tubes, positioning and combining a measure hopper array device and the paper tube array pore plate, filling the paper tubes with activated carbon, positioning and combining the seal plug array pore plate and the paper tube array pore plate secondarily, pressing the seal plugs into the paper tubes secondarily, boxing activated carbon cigarette filter finished products, performing encasing and the like. The production and manufacturing method of activated carbon cigarette filters is scientific and reasonable and has high efficiency, and the steps are compact.

Owner:鄂西卷烟材料厂

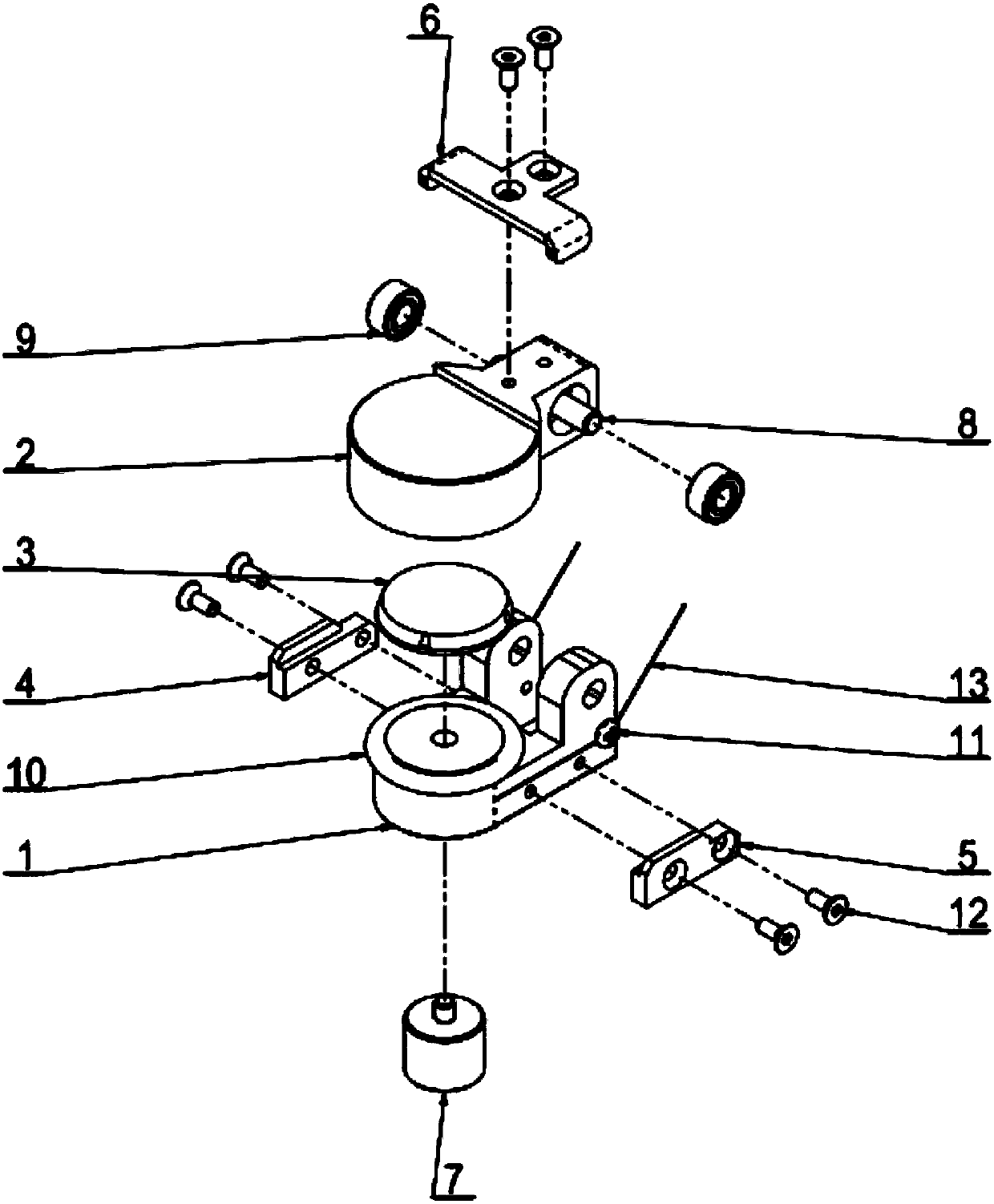

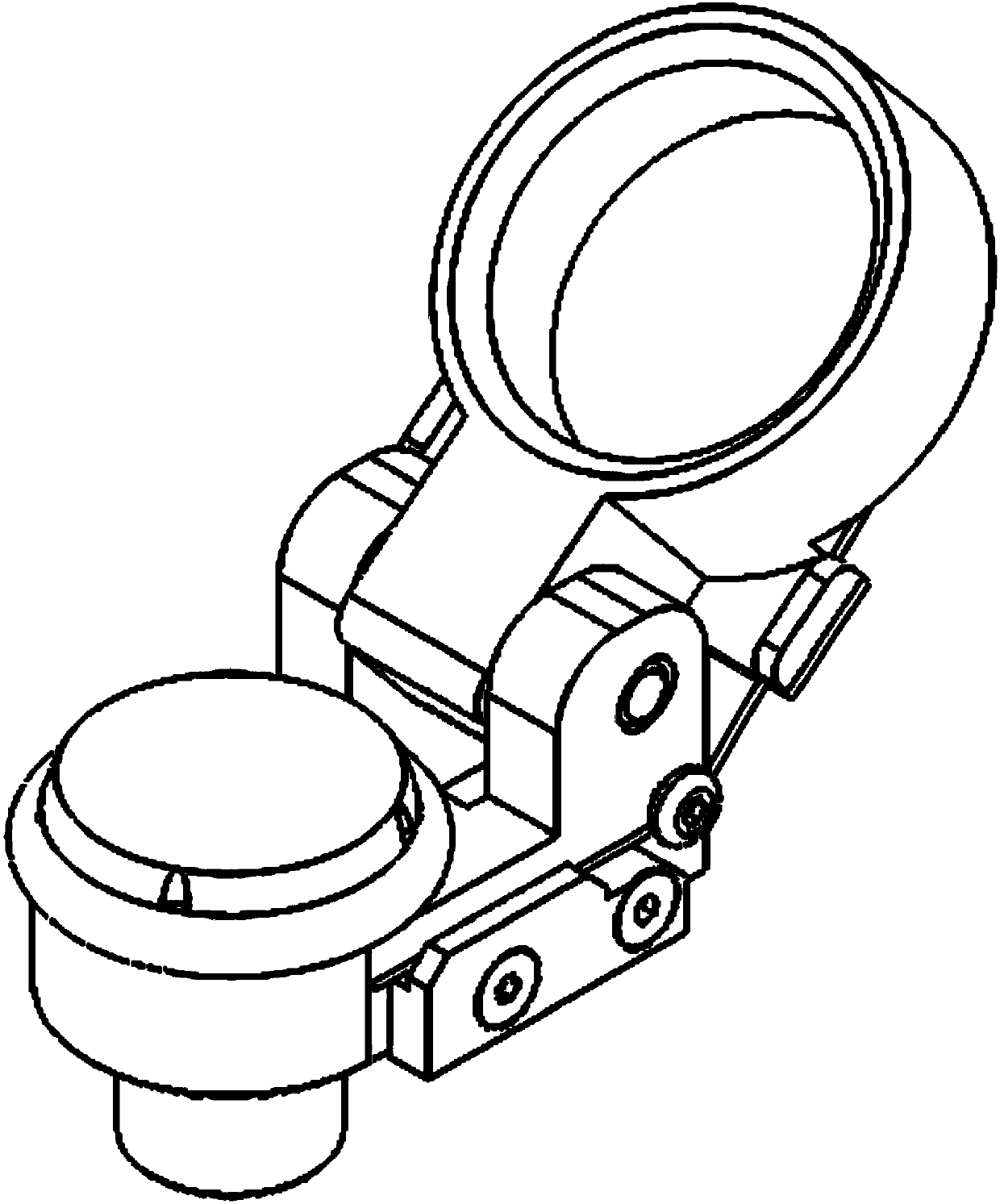

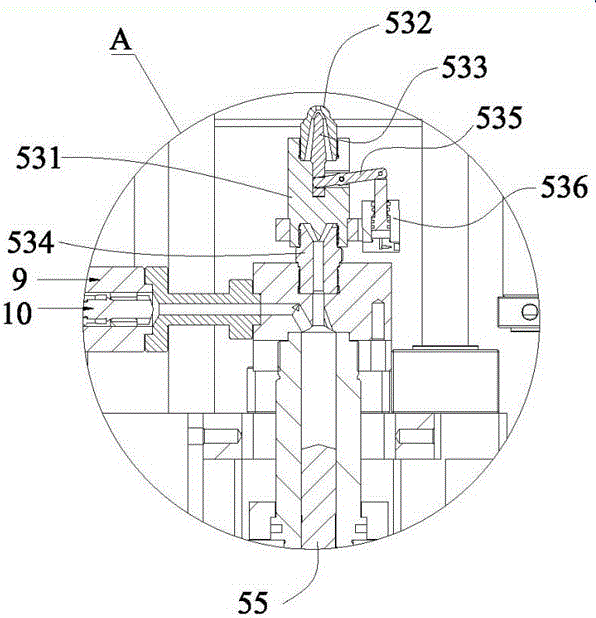

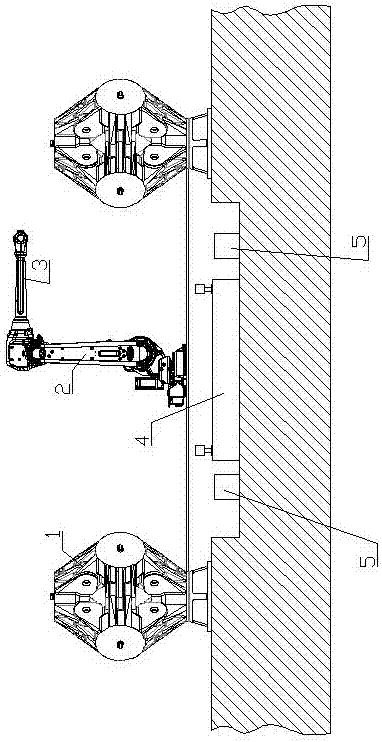

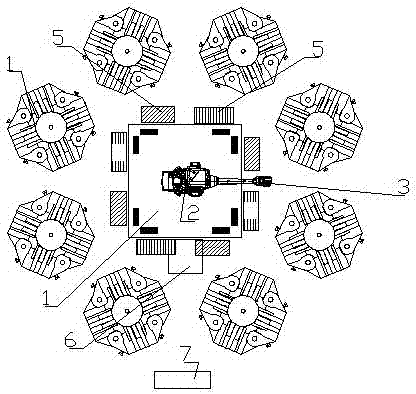

Automatic press system and method for artificial diamond production

PendingCN106902709ARealize automatic synthesisAchieve grippingUltra-high pressure processesShaping pressElectric controlManipulator

Provided are an automatic press system and method for artificial diamond production. The system includes an electric control cabinet, a robot and two or more circumferentially distributed presses; the robot includes a mechanical arm and a mechanical hand which is arranged on the mechanical arm, distances between the mechanical arm and the presses are equal, and the working diameter of the mechanical arm is greater than the distances between the mechanical arm and the presses; synthesis cavities and holding-up hammers which are arranged towards the synthesis cavities are arranged in the presses, placement openings for being communicated with the synthesis cavities are formed in the presses, and the placement openings of all the presses are all arranged towards the mechanical arm; a press working parameter collection unit and a processing unit are arranged in the electric control cabinet; the press working parameter collection unit is used for transmitting collected working parameters to the processing unit, and the processing unit separately outputs signals to control the operation of the presses, the mechanical hand, the mechanical arm and hydraulic assemblies; the hydraulic assemblies for providing hydraulic oil for the operation of the presses are arranged under the presses and the electric control cabinet. According to the method, the automatic synthesis of synthesized pieces is achieved, procedures are compact, and the quality of produced artificial diamonds is uniform.

Owner:ZHENGZHOU SINO CRYSTAL DIAMOND

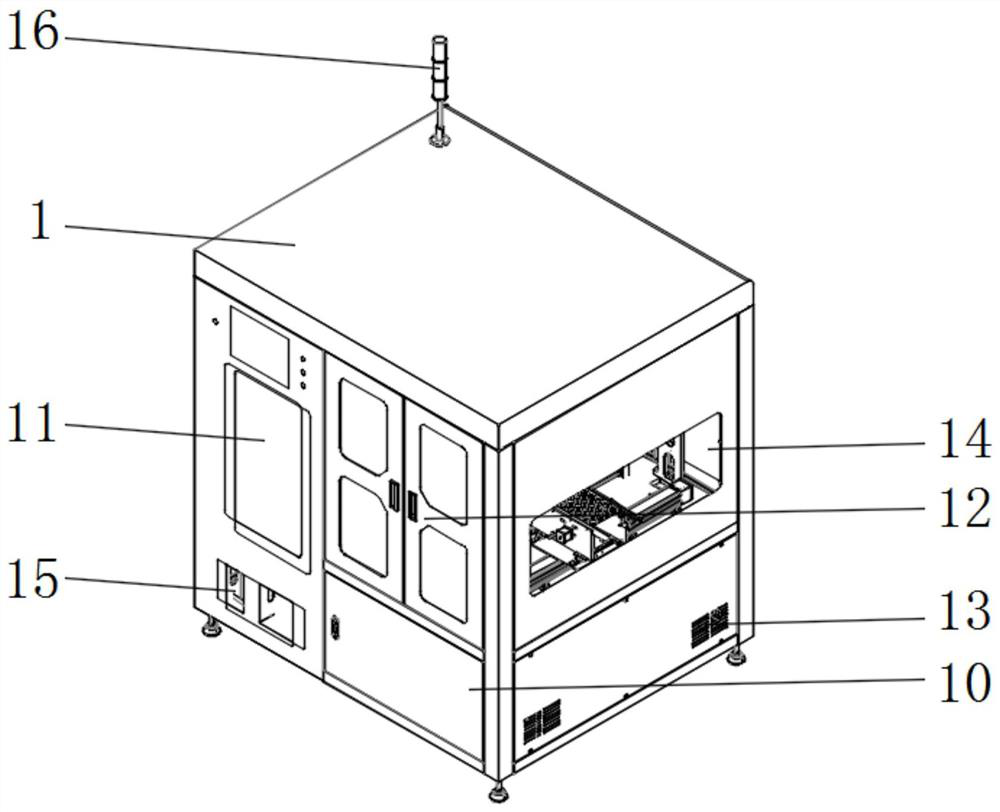

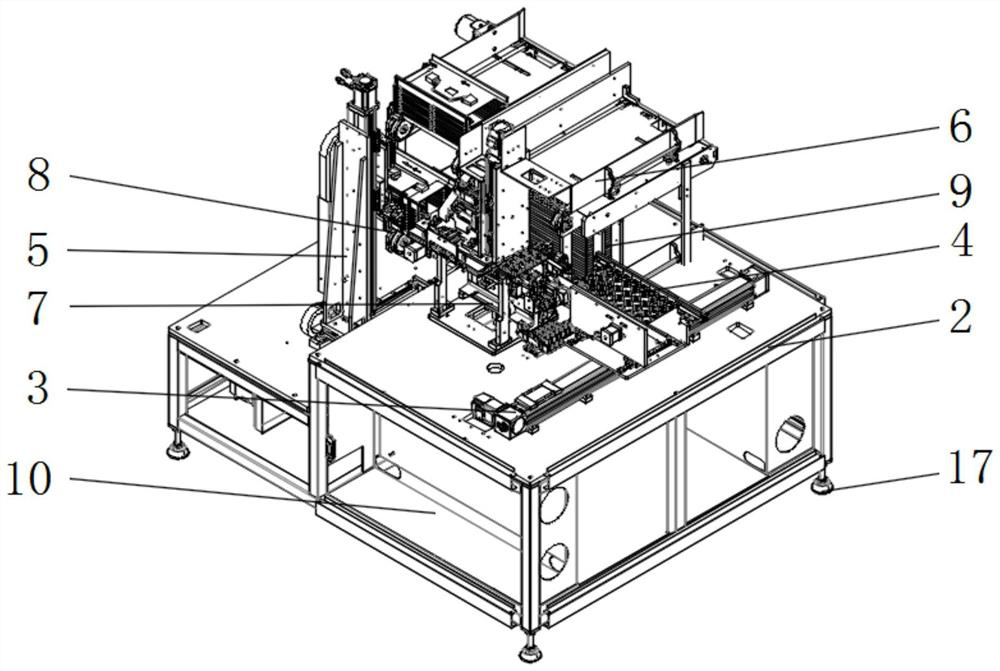

Cover discharging discharging machine

ActiveCN112645039ACompact stepsSimple and fast operationConveyor partsStructural engineeringMechanical engineering

A cover discharging discharging machine comprises a device body; a mounting frame is arranged on the inner side of the device body; a guide rail is arranged on the outer surface of the upper end of the mounting frame; a plate collecting mechanism is arranged at the upper end of the guide rail; a material box carrying mechanism is arranged on the outer surface of the upper end of the mounting frame; a cover plate carrying mechanism is arranged at the upper end of the plate collecting mechanism; a cover plate collecting platform is arranged on one side of the plate collecting mechanism; a material box conveying flow channel is arranged on one side of the material box carrying mechanism; and a cover plate stock bin is arranged at the lower end of the cover plate carrying mechanism. According to the cover discharging discharging machine, through the cover plate carrying mechanism, the cover plate collecting platform and the material box conveying flow channel, the steps can be compact, manual operation needing to be carried out can be reduced, operation is easy and convenient, and the cover discharging discharging machine is more intelligent and more practical.

Owner:象平半导体设备(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com