Soft Rock Large Deformation Tunnel Support System and Its Construction Method

A construction method and large deformation technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as large deformation of soft rock tunnels, and achieve the effect of improving self-supporting capacity, reducing deformation, and simple and compact steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

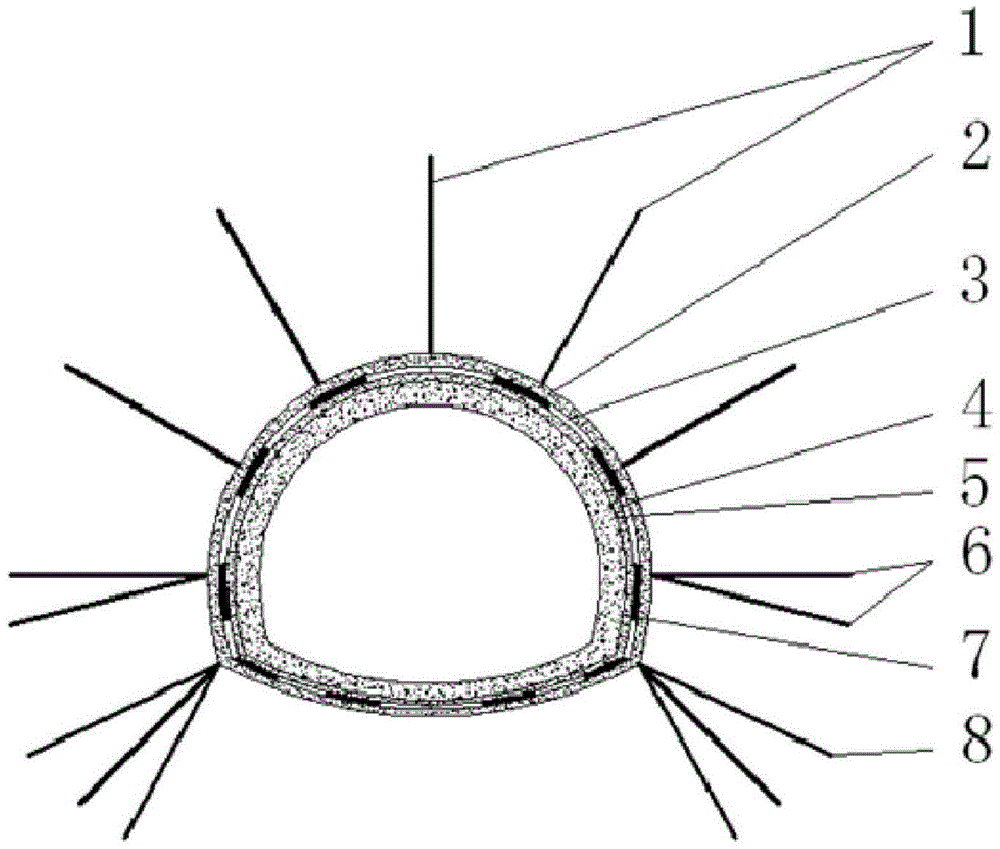

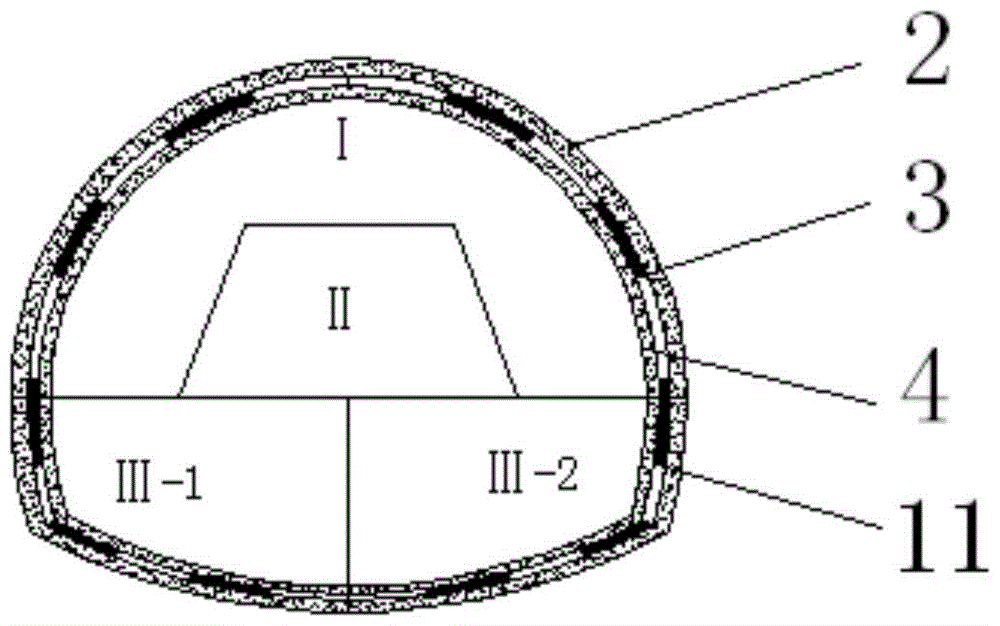

[0036] see figure 1 , the support system provided by the present invention includes: advanced support, primary support, waterproof layer 5 and secondary lining 7 arranged sequentially from outside to inside along the radial direction of the tunnel. Anchor rod 1, initial spraying layer 2, steel mesh 11, steel arch frame 3 and re-spraying layer 4.

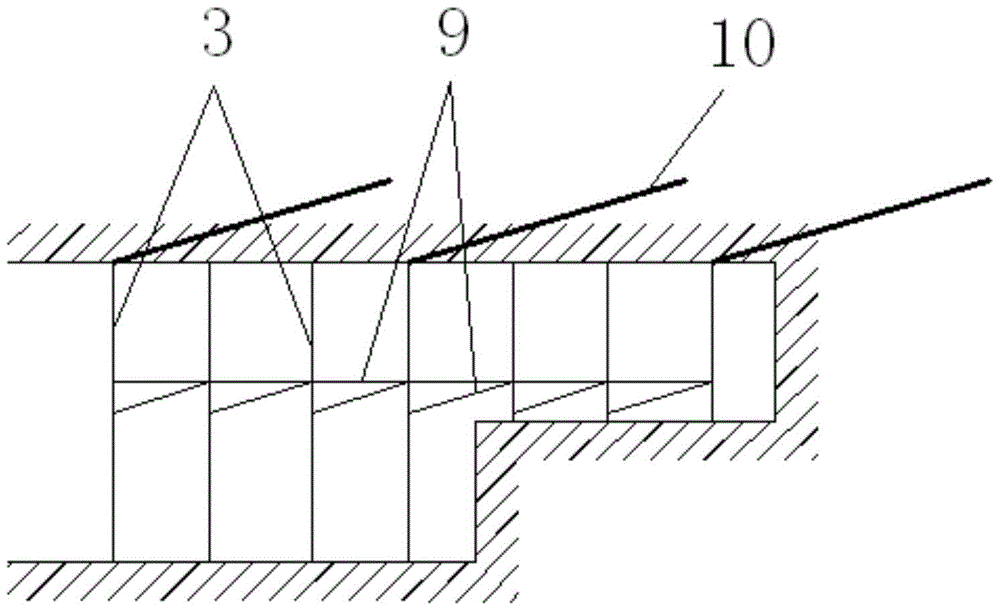

[0037] The advance support is formed by grouting the advance small conduit 10, which is an important measure for pre-reinforcement. see Figure 4 , the advanced small catheter 10 is constructed along the circumferential direction of the tunnel within 120° of the vault at the tunnel face, the circumferential distance of the advanced small catheter 10 is 30-50cm, the extrapolation angle is 3-5°, and the length is 6-8m .

[0038]The extended anchor 1 adopts self-advancing grouting anchor, and the length of the anch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com