Production and manufacturing method of activated carbon cigarette filters

A manufacturing method and technology of activated carbon, which are applied in the fields of smoke oil filter, manufacture of cigarettes, tobacco, etc., can solve the problems of high price of cigarette activated carbon filter, low production efficiency and high labor cost, and achieve scientific and reasonable manufacturing method and compact steps. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

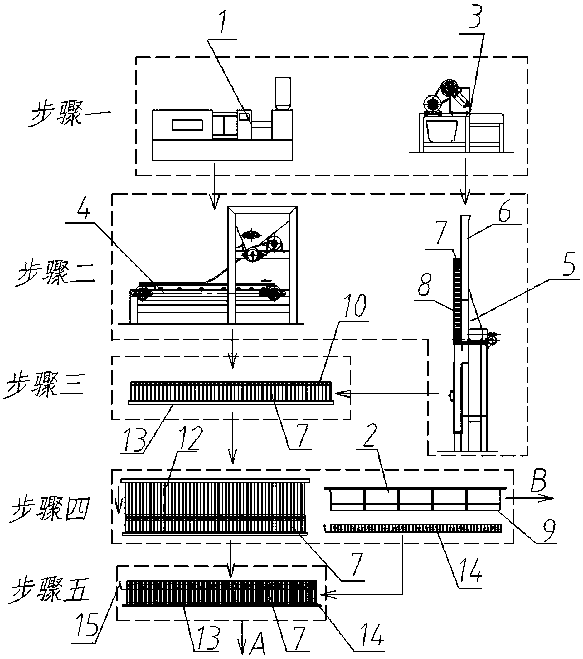

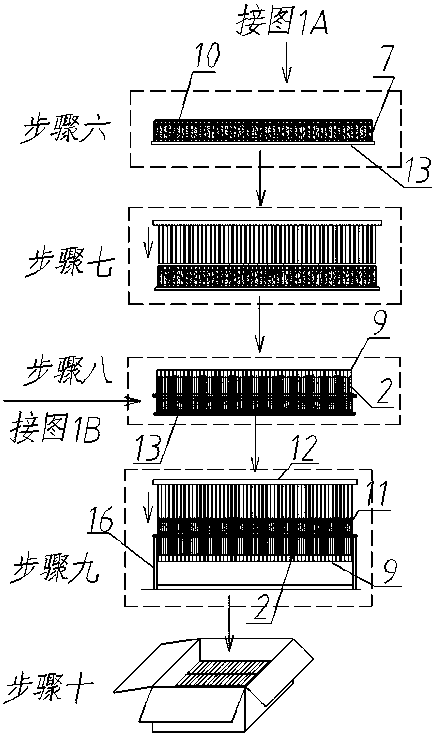

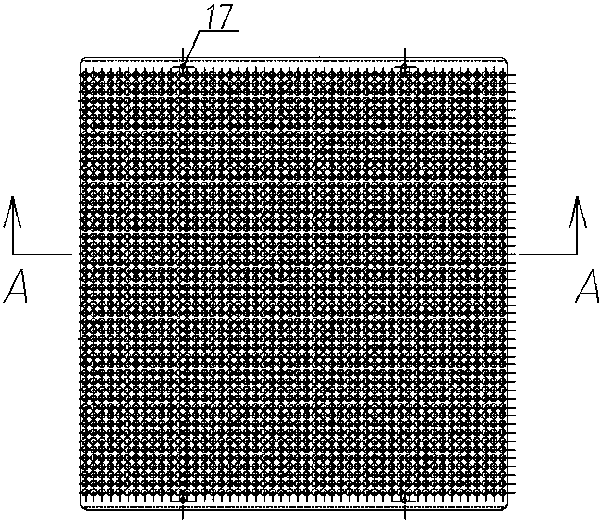

[0020] Can find out from the accompanying drawing of above specific production process and schematic drawing thereof and relevant special device, the concrete production method of cigarette activated carbon filter tip of the present invention is as follows:

[0021] Step 1: Use the injection molding machine 1 to produce the plugs 19 and simultaneously use the paper tube machine 3 to pick up the tubes 20; Step 2: Use the plug self-arrangement array machine 4 to automatically discharge the plugs 19 to the plug array orifice plate 10 in a horizontal and vertical arrangement In order to insert the plug 19 into one end of the paper tube 20, at the same time put the paper tube array orifice plate 7 into the frame rail 8 of the paper tube self-arraying machine 5 and place the twisted paper tubes 20 in a longitudinal arrangement In the paper tube hopper 6 of the paper tube self-arraying machine 5, the paper tube self-arranging machine is turned on, and the machine automatically inserts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com