Polymer composite material containing boron nitride aerogel and preparation method and application thereof

A technology of composite materials and boron nitride, which is applied in the field of stimulating thermal response composite materials, can solve the problems of inability to apply intelligent drivers and sensors, unsuitability for thermal response composite materials, and high requirements for preparation equipment, and achieve easy industrialized large-scale production, Good elasticity and the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

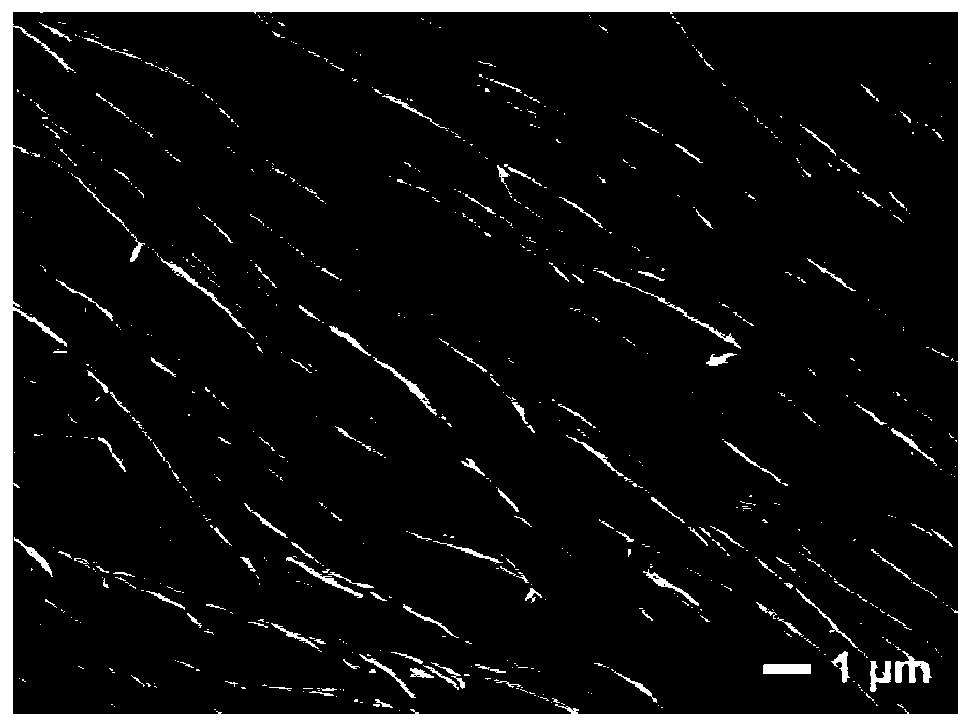

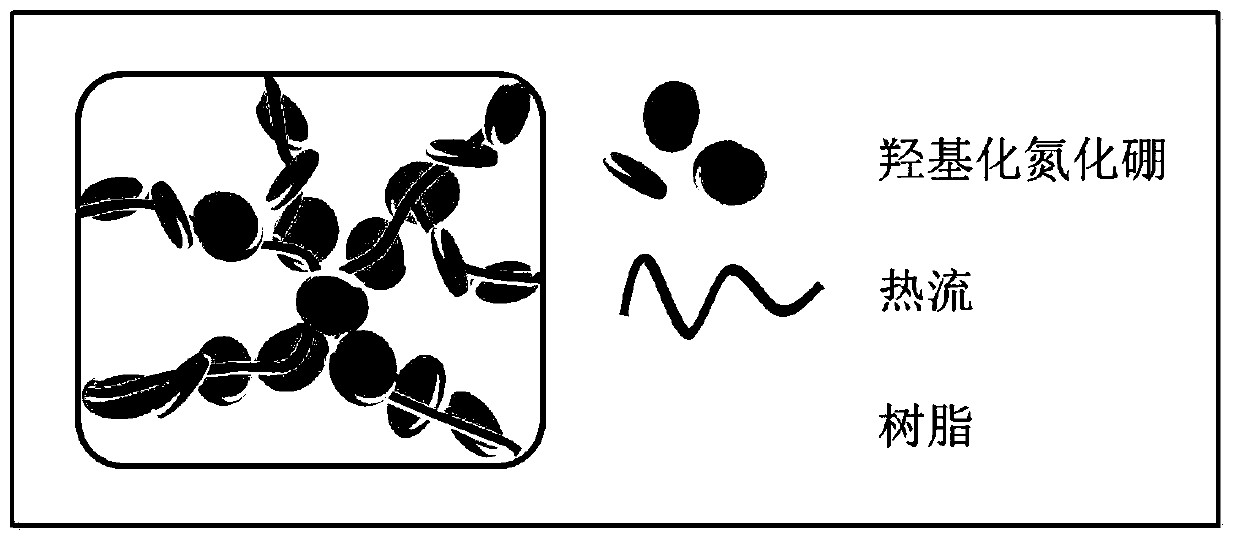

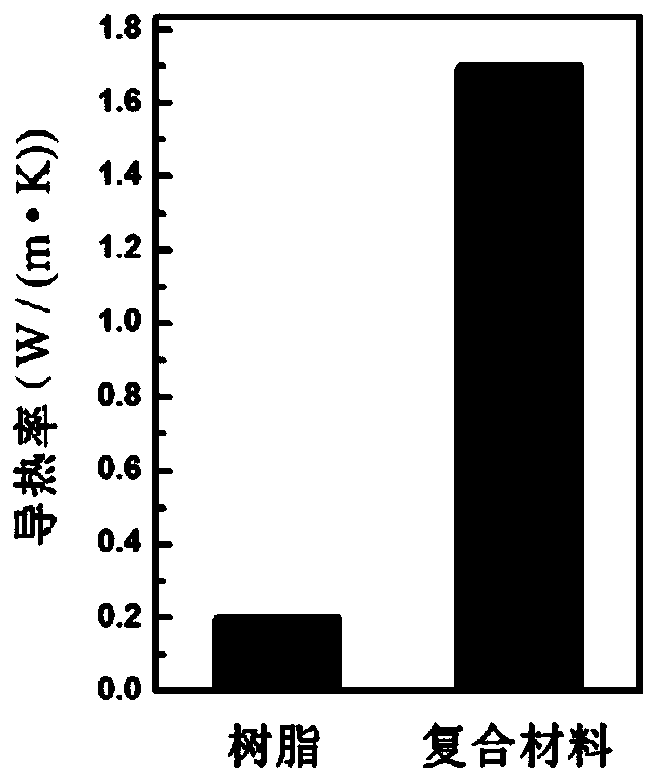

[0028] Reference attached Figure 1~4 , the polymer composite material containing boron nitride airgel provided in this embodiment is prepared from boron nitride airgel and resin in a molten state, and the component distribution ratio according to weight percentage is: boron nitride gas Gel 1-20%, resin 80%-99%.

[0029] Wherein, the boron nitride aerogel is a double-crosslinked elastic boron nitride aerogel, which is made by the following steps:

[0030] (1) Preparation of hydroxylated boron nitride: disperse 0.1 to 2 g of boron nitride powder into an aqueous solution of sodium cholate with a mass fraction of 0.05, disperse ultrasonically, and prepare a hydroxylated boron nitride with a concentration of 1 mg / ml to 20 mg / ml. boron nitride solution;

[0031] (2) Preparation of double-crosslinked elastic boron nitride airgel: the chemical crosslinking agent 1,4-butanediol diglycidyl ether, the accelerator benzyltriethylammonium chloride and the above steps (1) Mix the obtaine...

Embodiment 2

[0039] The polymer composite material containing boron nitride aerogel, preparation method and application provided in this example are basically the same as those in Example 1, except that:

[0040] A method for preparing a polymer thermoresponsive composite material containing boron nitride airgel, specifically comprising the following steps:

[0041](1) Preparation of hydroxylated boron nitride: disperse 1 g of boron nitride powder into an aqueous solution of sodium cholate with a mass fraction of 0.05, ultrasonically disperse, and prepare a hydroxylated boron nitride solution with a concentration of 10 mg / ml;

[0042] (2) Preparation of double-crosslinked elastic boron nitride airgel: the chemical crosslinking agent 1,4-butanediol diglycidyl ether, the accelerator benzyltriethylammonium chloride and the above steps (1) The obtained hydroxylated boron nitride solution was mixed, hydrochloric acid was added dropwise under stirring and the temperature was raised to react for ...

Embodiment 3

[0046] The polymer composite material containing boron nitride aerogel, preparation method and application provided in this example are basically the same as those in Examples 1 and 2, except that:

[0047] A method for preparing a polymer thermoresponsive composite material containing double-crosslinked elastic boron nitride airgel, comprising the following steps:

[0048] (1) Preparation of hydroxylated boron nitride: disperse 1.5 g of boron nitride powder into an aqueous solution of sodium cholate with a mass fraction of 0.05, ultrasonically disperse, and configure a hydroxylated boron nitride solution with a concentration of 15 mg / ml;

[0049] (2) Preparation of double-crosslinked elastic boron nitride airgel: the chemical crosslinking agent 1,4-butanediol diglycidyl ether, the accelerator benzyltriethylammonium chloride and the above steps (1) The obtained hydroxylated boron nitride solution was mixed, hydrochloric acid was added dropwise under stirring and the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com