Automatic press system and method for artificial diamond production

A technology of artificial diamond and press, which is applied in chemical instruments and methods, a method of chemically changing substances by using atmospheric pressure, presses, etc., which can solve the problems of uneven experience level of workers, high-speed splashing of solid or liquid, and production efficiency. Instability and other problems, to achieve the effect of compact steps, reasonable structure design, and guaranteed synthesis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

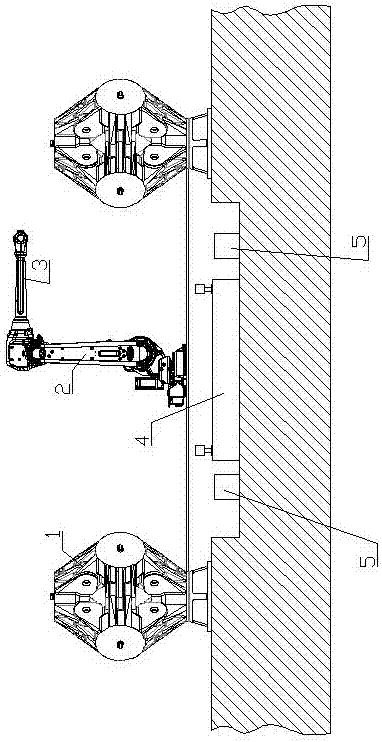

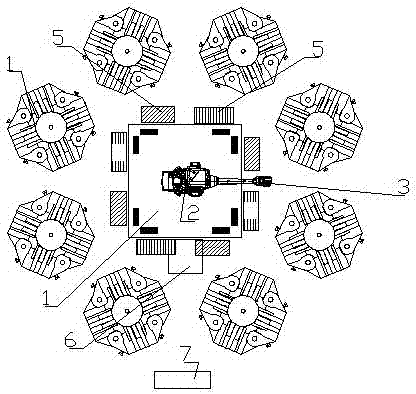

[0035] Automated press systems for synthetic diamond production, such as figure 1 , figure 2 and image 3 As shown, 8 presses 1 are included, and the 8 presses 1 are distributed in a circle.

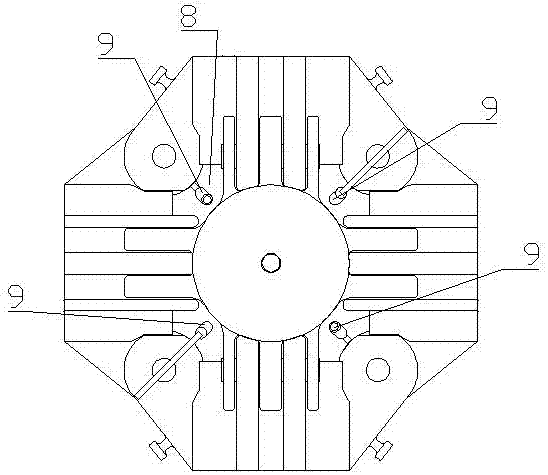

[0036] The press 1 is provided with a high-pressure oil inlet hole and a low-pressure oil inlet hole, and the press 1 is provided with a synthesis chamber, an anvil and a placement port 8 communicating with the synthesis chamber. The oil intake inside the press is realized through the high-pressure oil inlet hole and the low-pressure oil inlet hole, so as to realize the work of the top hammer in the press 1, and the synthesis block can be placed in the synthesis cavity through the placement port 8. The press 1 is provided with a high-pressure oil inlet hole and a low-pressure oil inlet hole; the synthesis cavity, top hammer and placement port in the press are mature prior art, and this application does not involve the improvement of this part.

[0037] In order to facilitate the plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com