Patents

Literature

58results about How to "Guaranteed upright" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

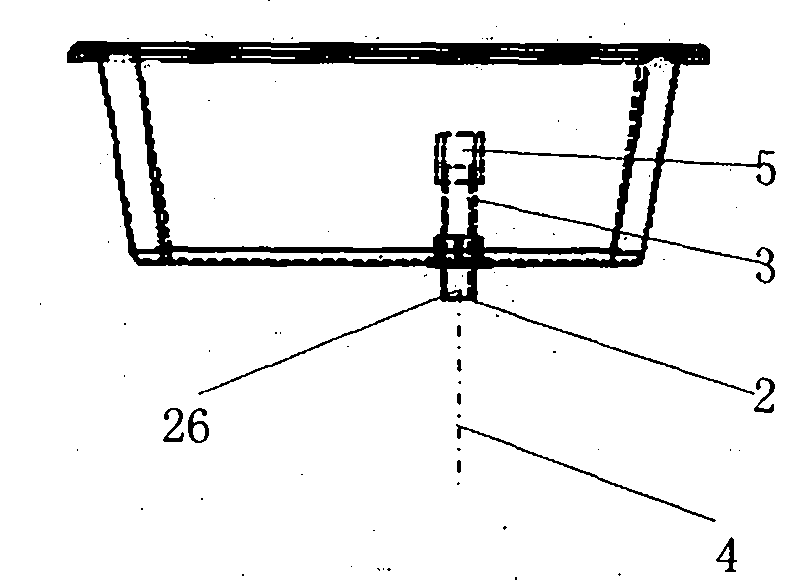

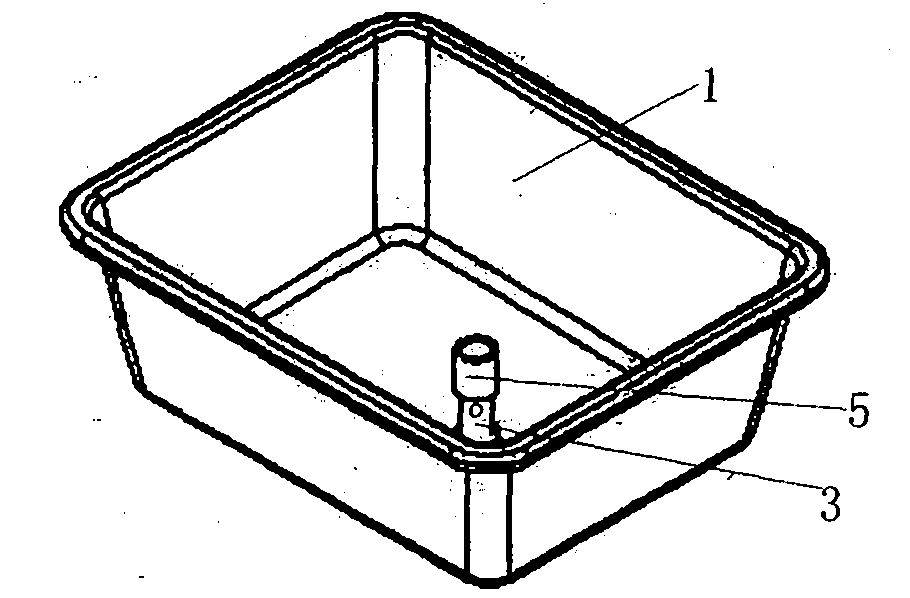

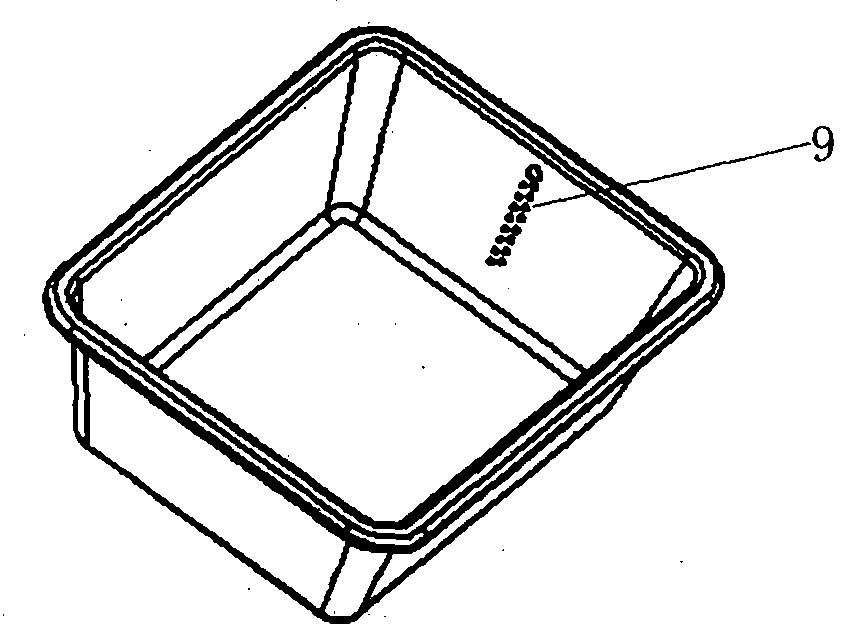

Water level adjustment method and overflowed water recovery method as well as water culture container and balcony planting device

InactiveCN102652493AGuaranteed uprightMake the most of planting spaceAgriculture gas emission reductionCultivating equipmentsWater recoveryWater pipe

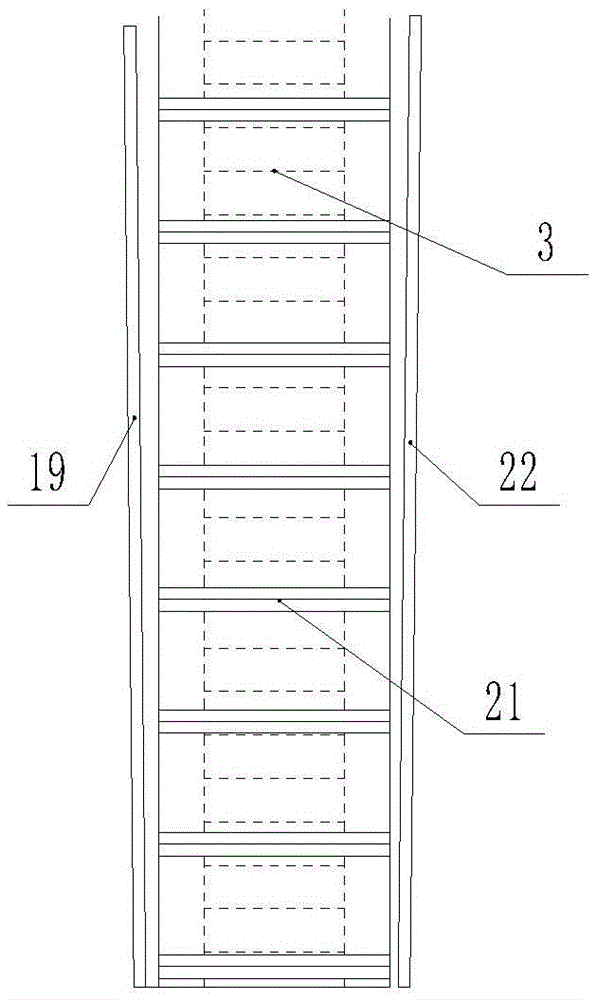

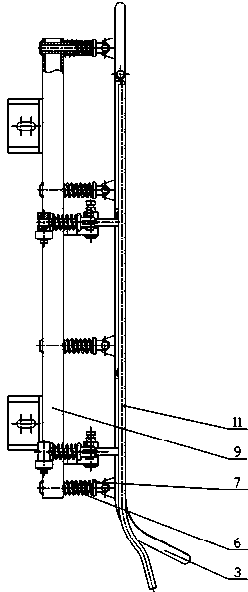

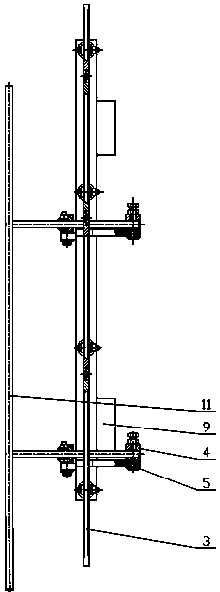

The invention provides a water level adjustment method and an overflowed water recovery method as well as a water culture container and a balcony planting device. The water level adjustment method is characterized in that a water level control duct is provided with a series of holes or is sleeved with fine adjustment ducts with different lengths, and thus the vertical height of the overflowed water can be increased or decreased by blocking and opening the hoses (9) so as to further realize the adjustment of the water level. The overflowed water recovery method is characterized in that water culture containers (23) capable of adjusting the water level are vertically placed on different layers of a goods shelf, the overflowed water vertically and downwards flows to a water culture container (23) on the next layer by the action of gravity; and finally, the overflowed water gathers to a recovery container (15), and a sealed duct is connected between the upper layer of water culture container and the lower layer of water culture container. The balcony planting device comprises the goods shelf, the water culture containers (23) capable of adjusting the water level, the recovery container (15), a water pump (16), a water pipe (17), an intellectual control module (20) and a sensor.

Owner:杨卫星

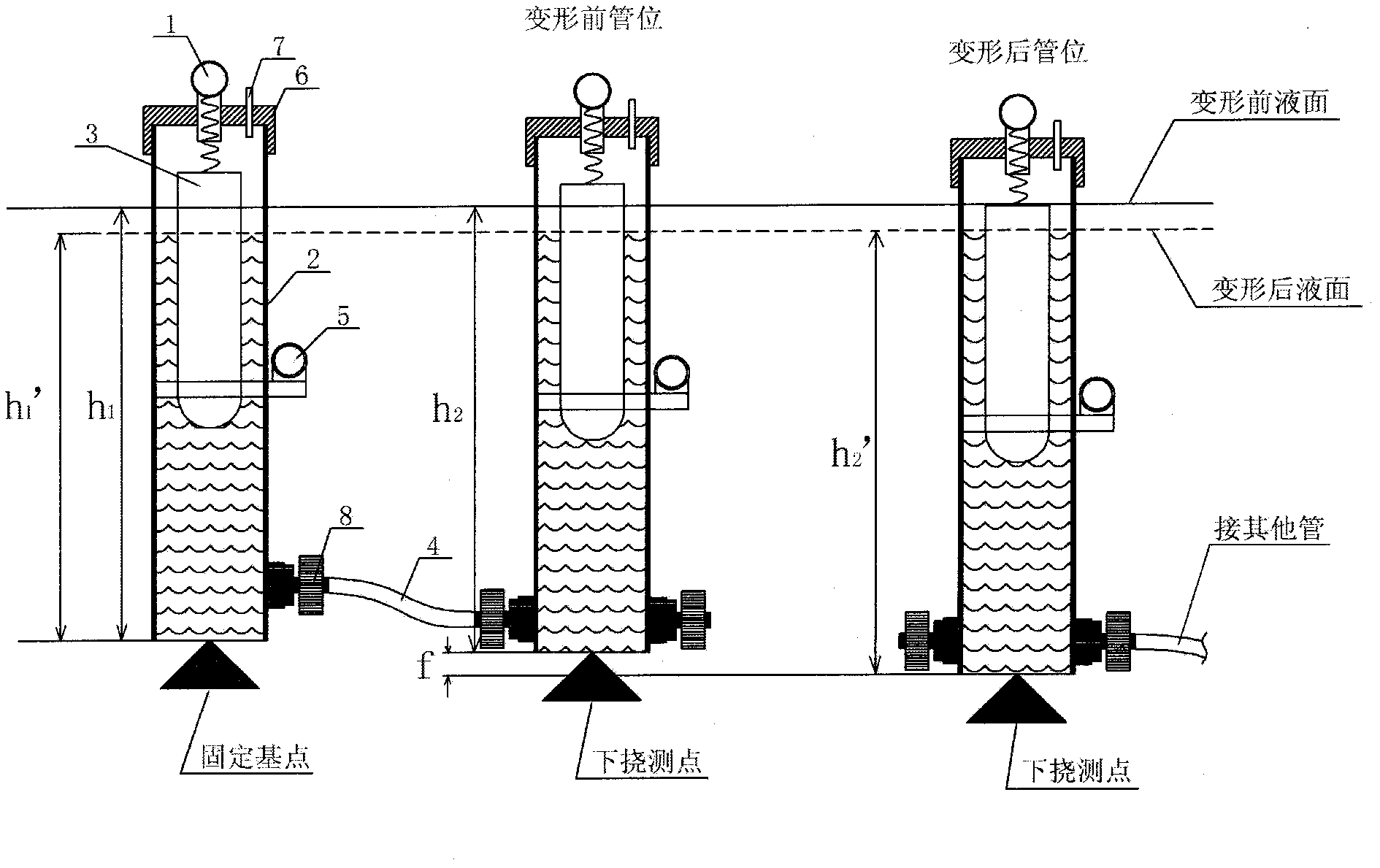

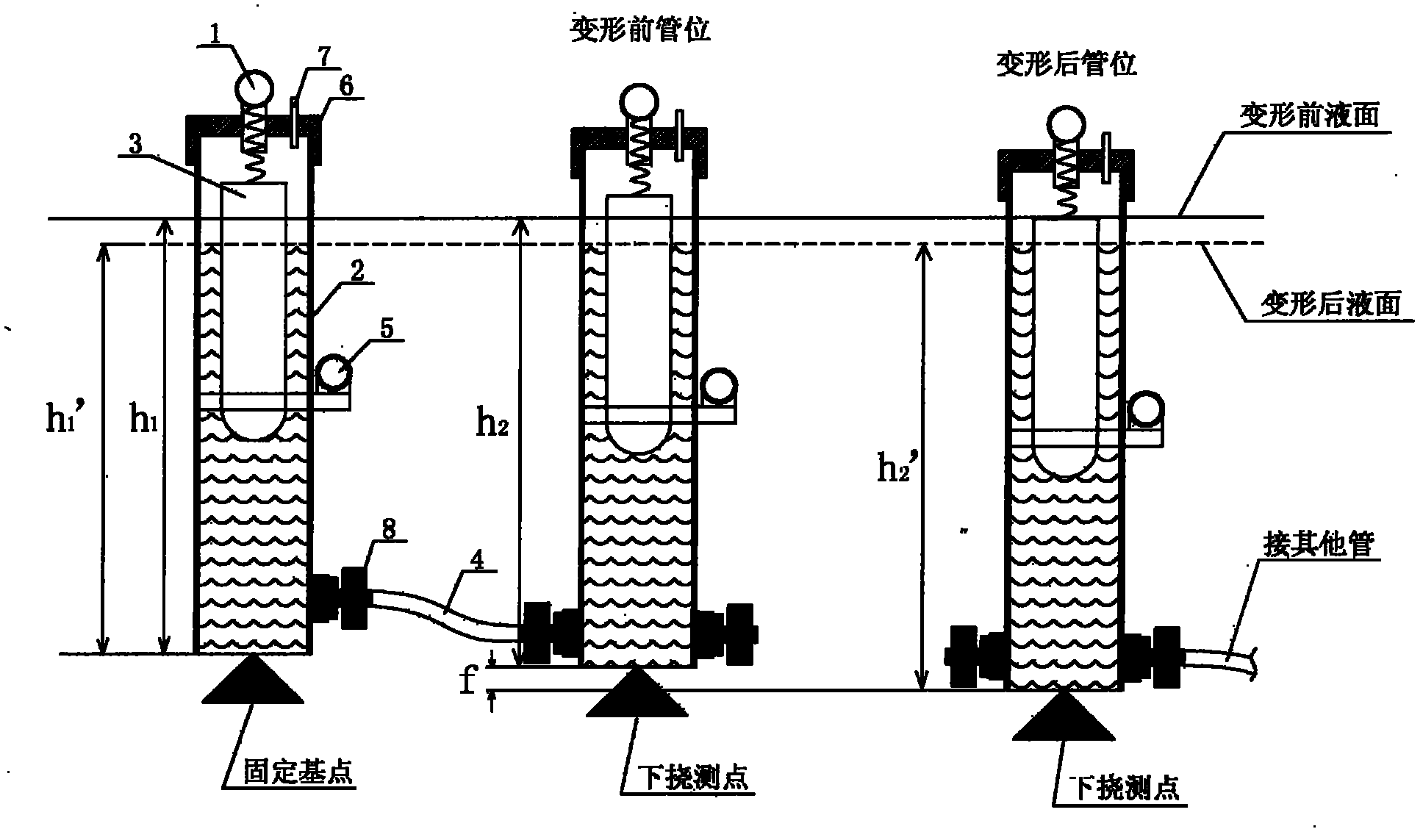

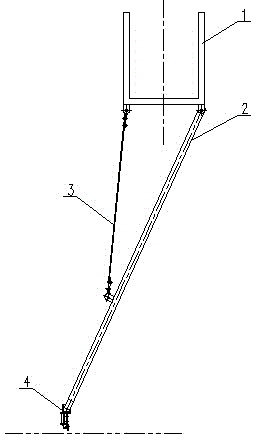

Combined multi-point deflectometer and method for measuring deflection

InactiveCN102322827AHigh precisionExtended service lifeUsing fluid meansElasticity measurementHard waterPiping

The invention discloses a combined multi-point deflectometer and a method for measuring the deflection. The novel multi-point deflectometer which can be used for high-precision displacement measurement by a tee-joint water pipe leveling principle and a mechanical elastic deformation test principle comprises a plurality of soft water pipes and hard vertical tee-joint water pipes, wherein the soft water pipes and hard vertical tee-joint water pipes can be spliced at will and are mutually communicated; the hard water pipes are provided with bubbles to ensure that the test pipes are leveled during point testing; the ends of the soft water pipes and the joint sections of the hard water pipes are connected by joints which are easy to splice and have good water tightness; the hard water pipes can be lengthened by section; and an upper section is vertically provided with an elastic deformation gauge of which the lower end is provided with a floater from the top. According to difference before and after structure deformation, the water level in each hard water pipe arranged on the specific measurement point on the structure is still kept horizontal, change happens in the pipe relatively to the horizontal water level, the floater lifts or lowers, buoyancy borne by the combined multi-point deflectometer is changed to cause the reading of the elastic deformation gauge to change, and a reading precision is high.

Owner:舒小娟

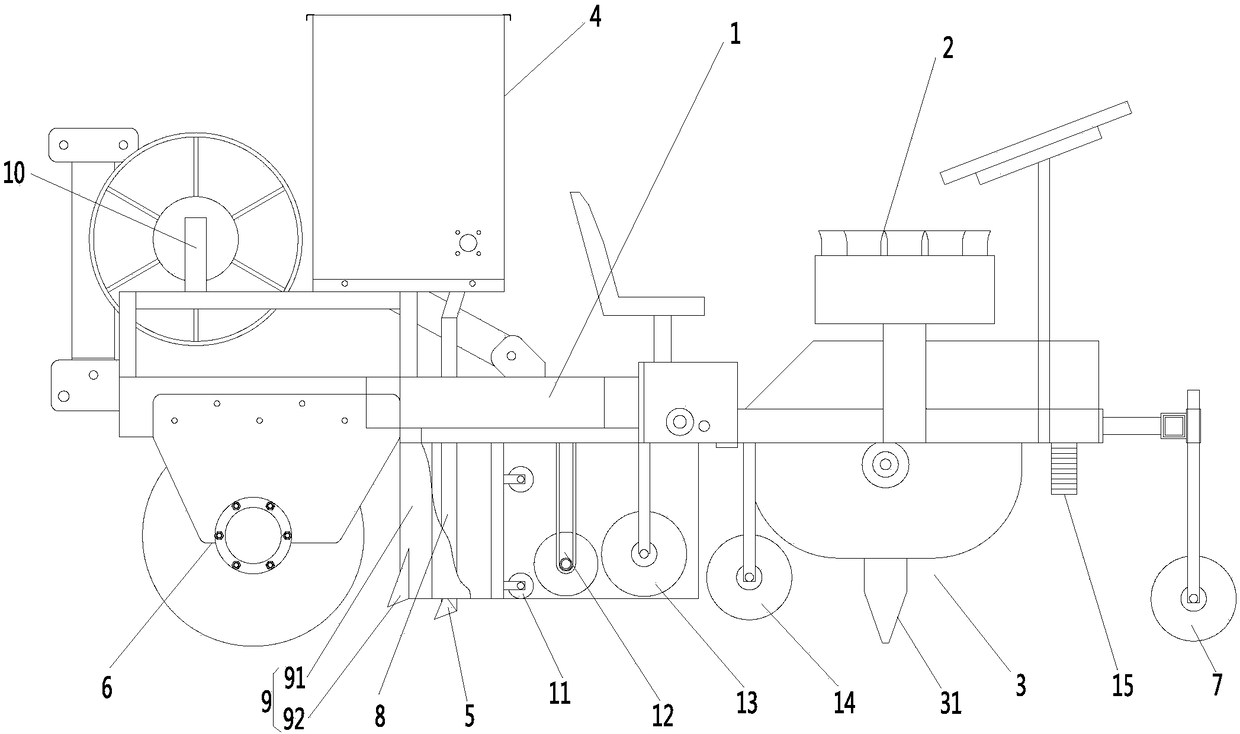

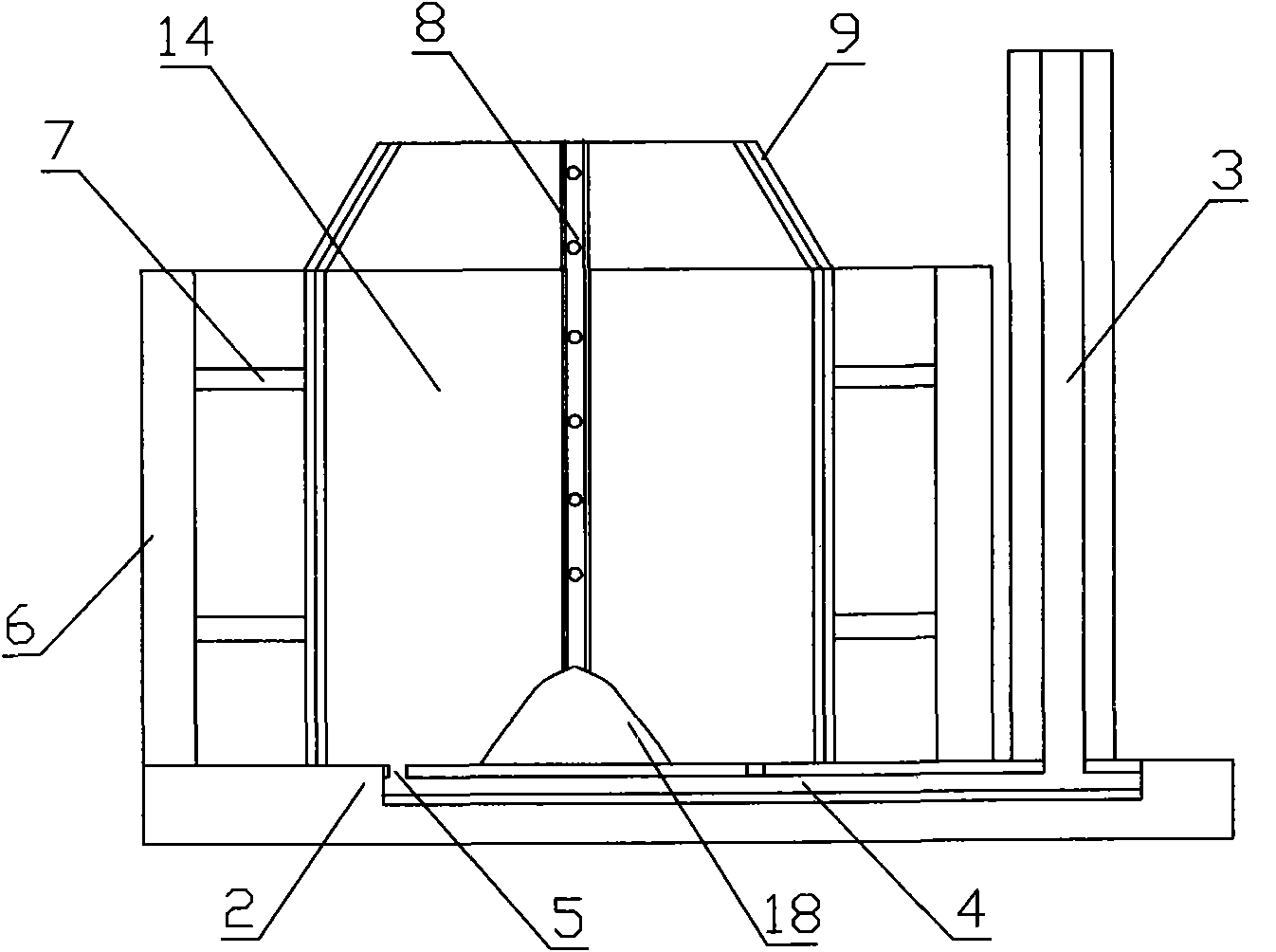

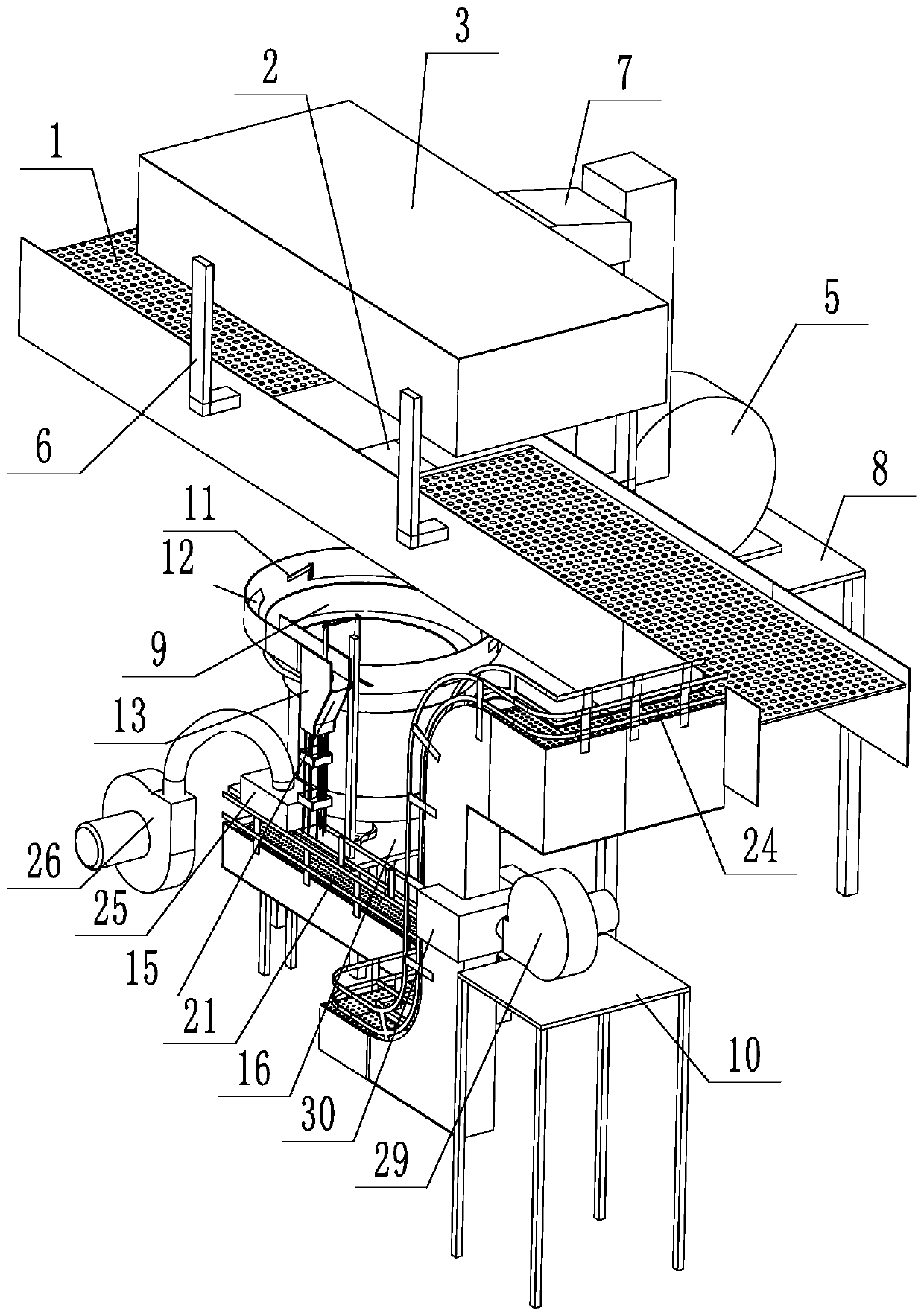

Bowl sugarcane seedling planting machine and use method thereof

PendingCN108353591AReduce labor intensityIncrease productivityWatering devicesFertiliser distributersBiologyAutomation

The invention discloses a bowl sugarcane seedling planting machine and a use method thereof. The bowl sugarcane seedling planting machine comprises a frame, a driving device, a seedling throwing device, a planting mechanism, a ditching machine, a compacting wheel, a ditcher and an earthing wheel, wherein the seedling throwing device is arranged on the upper part of the frame; the seedling throwingdevice is connected with the planting mechanism; the ditching machine is arranged on the lower part of the front end of the frame; the compacting wheel is arranged on the lower part of the rear end of the frame; the earthing wheel is located between the ditching machine and the planting mechanism; the ditcher is arranged between the ditching machine and the earthing wheel; in a direction from near to far from the ditching machine, a dropper belt guide wheel, a film hanging rod and a film pressing wheel are arranged in sequence in the ditcher; the upper part of the frame is provided with a dropper belt bracket. The invention also discloses the use method of any bowl sugarcane seedling planting machine. Compared with the prior art, the bowl sugarcane seedling planting machine has the advantages of high degree of automation and versatile functions.

Owner:高华德

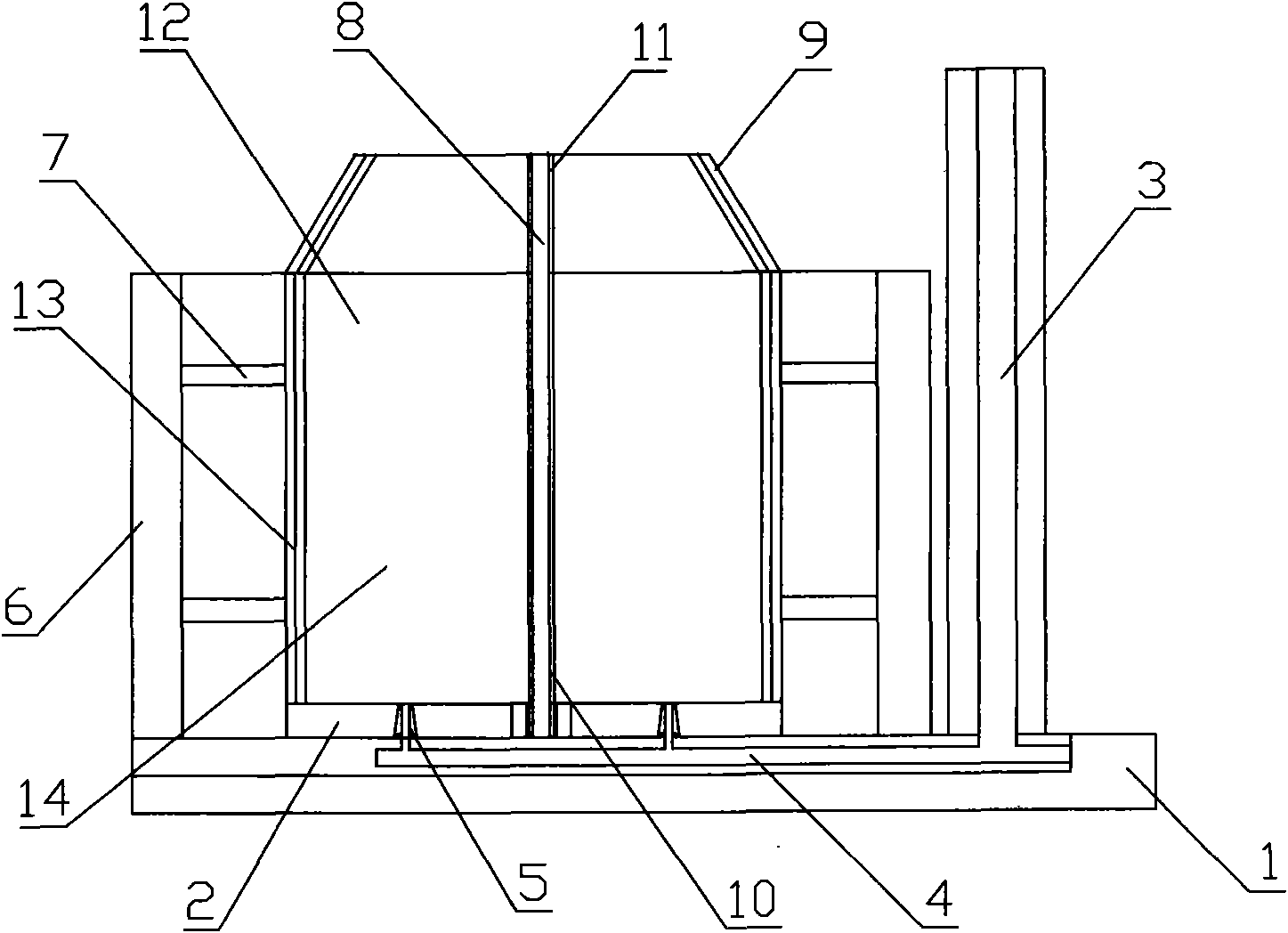

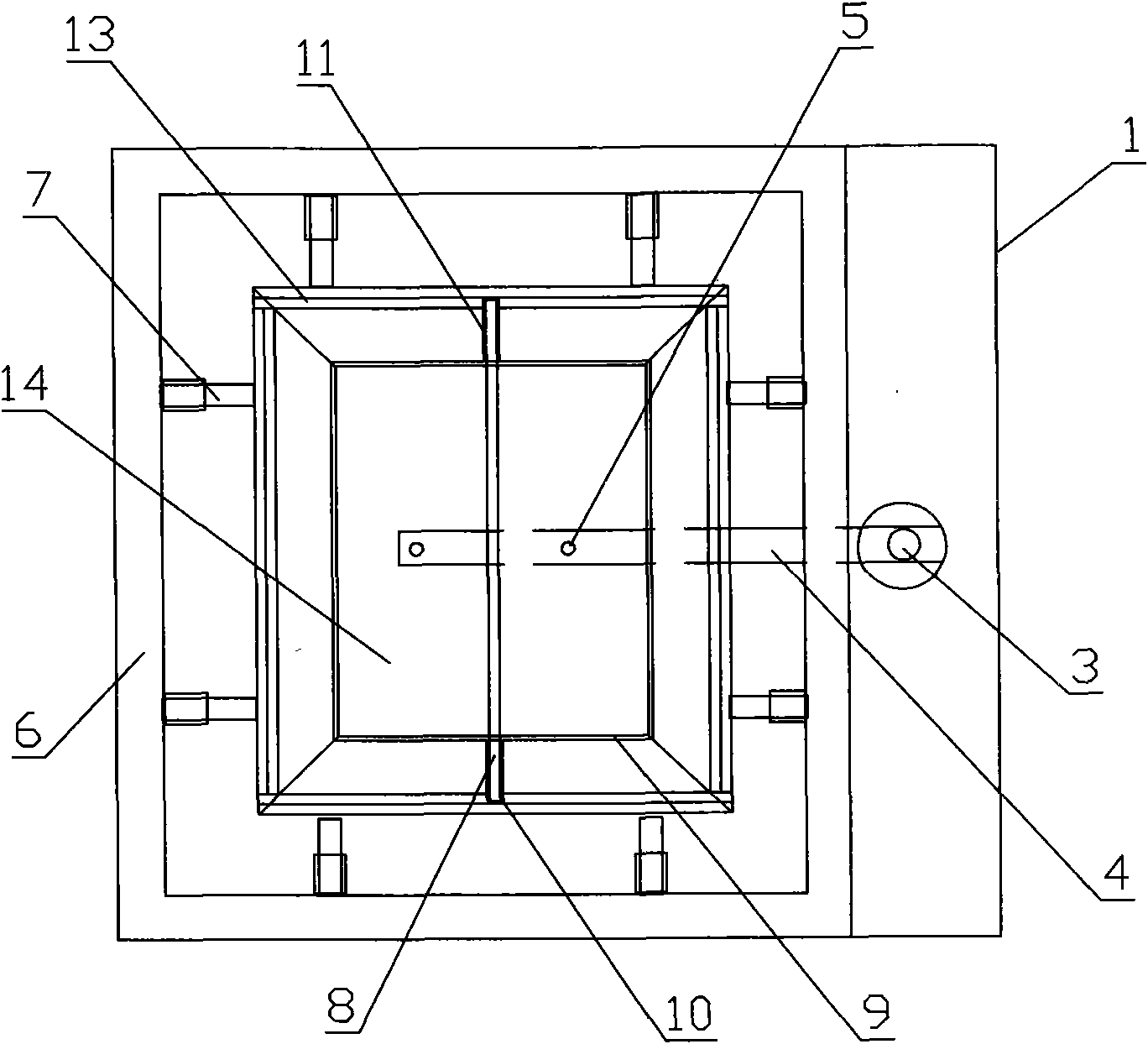

Non-electroslag remelting type clean metal ingot mould

ActiveCN101966562AAchieve removalAchieve transferMelt-holding vesselsFoundry mouldsLiquid metalDirectional solidification

The invention discloses a non-electroslag remelting type clean metal ingot mould comprising an ingot mould body and a heat preservation cap arranged on the ingot mould body; an isolation and heat insulation mechanism is vertically arranged in the ingot mould body and divides the space in the ingot mould body into a plurality of independent die cavity units; and the die cavity units are distributed in two rows in the ingot mould body. Because the isolation and heat insulation mechanism is arranged in the ingot mould body and divides the space in the ingot mould body into a plurality of independent die cavity units, most of impurities and segregates in liquid metals are enriched in the part in contact with the isolation and heat insulation mechanism in the course of directional solidification and crystallization of the liquid metals and the enriched alloy segregates and the impurities can be easily eliminated by utilizing flame or other processing methods. Thus, the transference and theelimination of the segregates and the impurities in ingots can be realized, and the purpose of purifying the ingots is reached.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD +1

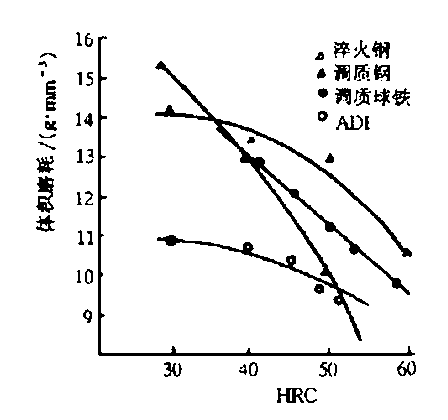

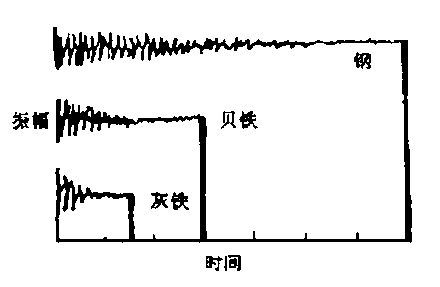

Heat treatment process of austempered ductile iron bushing

InactiveCN103276181AHigh strengthHigh hardnessFurnace typesHeat treatment furnacesBogieHeat conservation

Owner:南京雷尔伟新技术股份有限公司

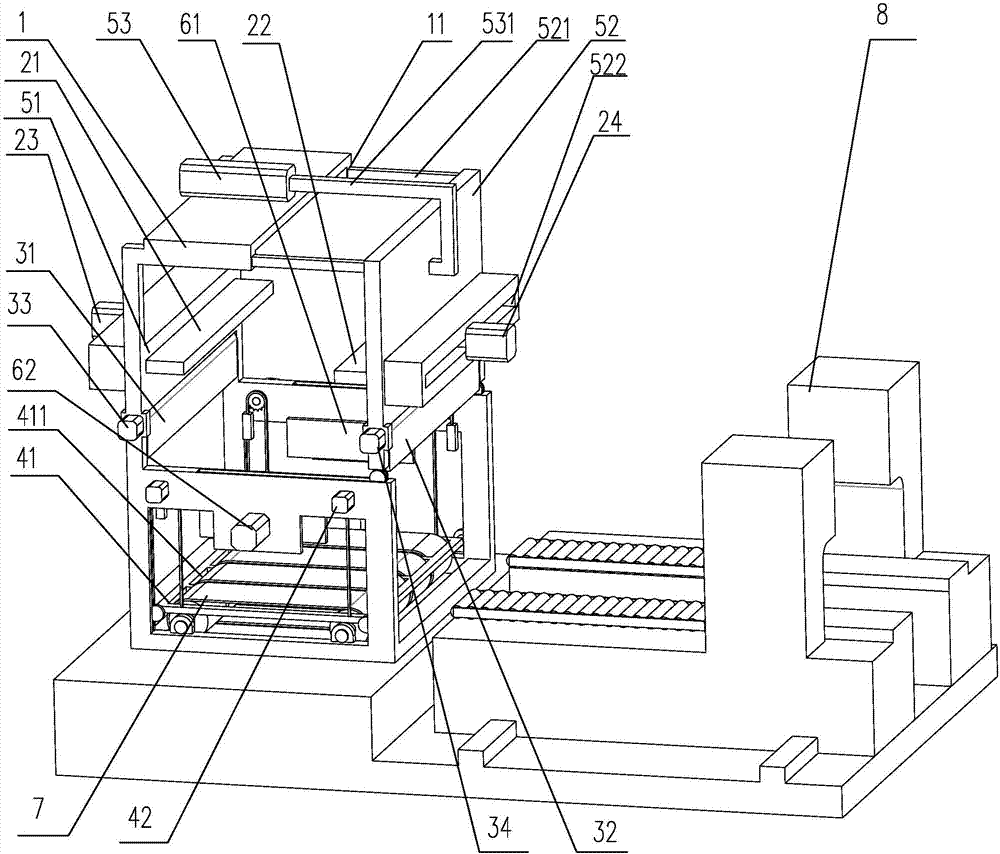

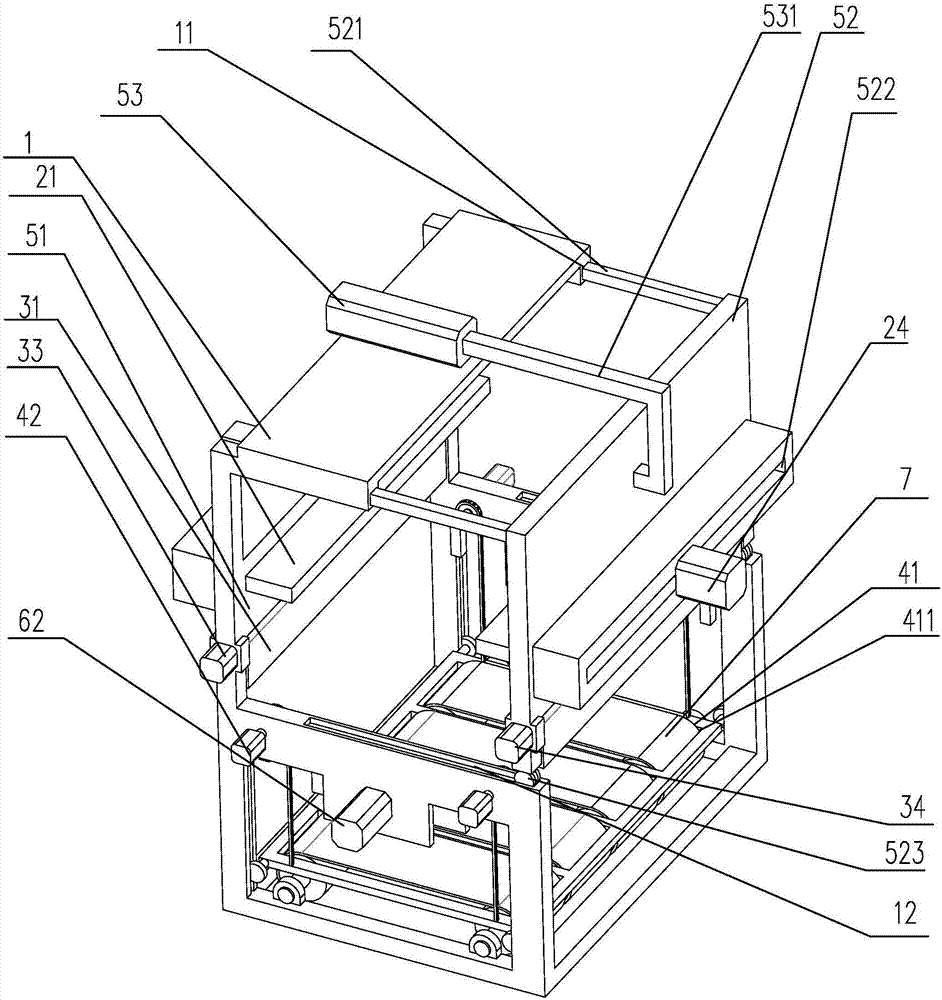

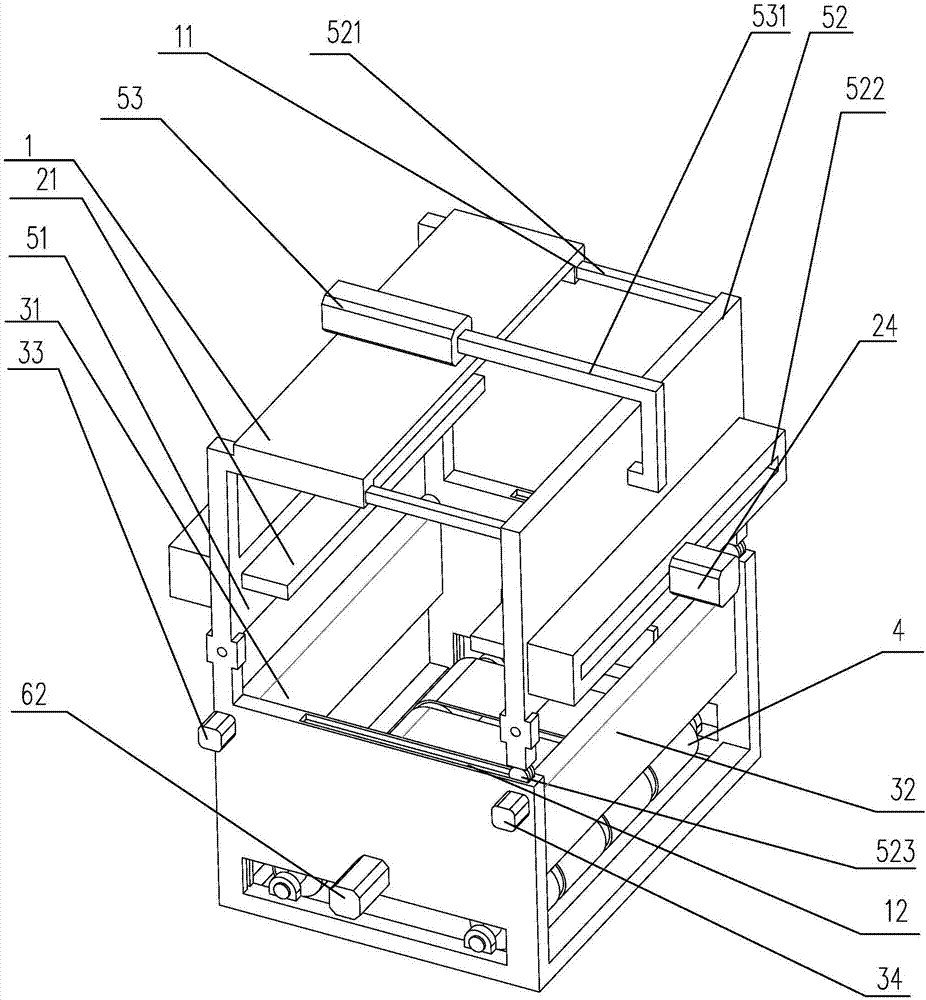

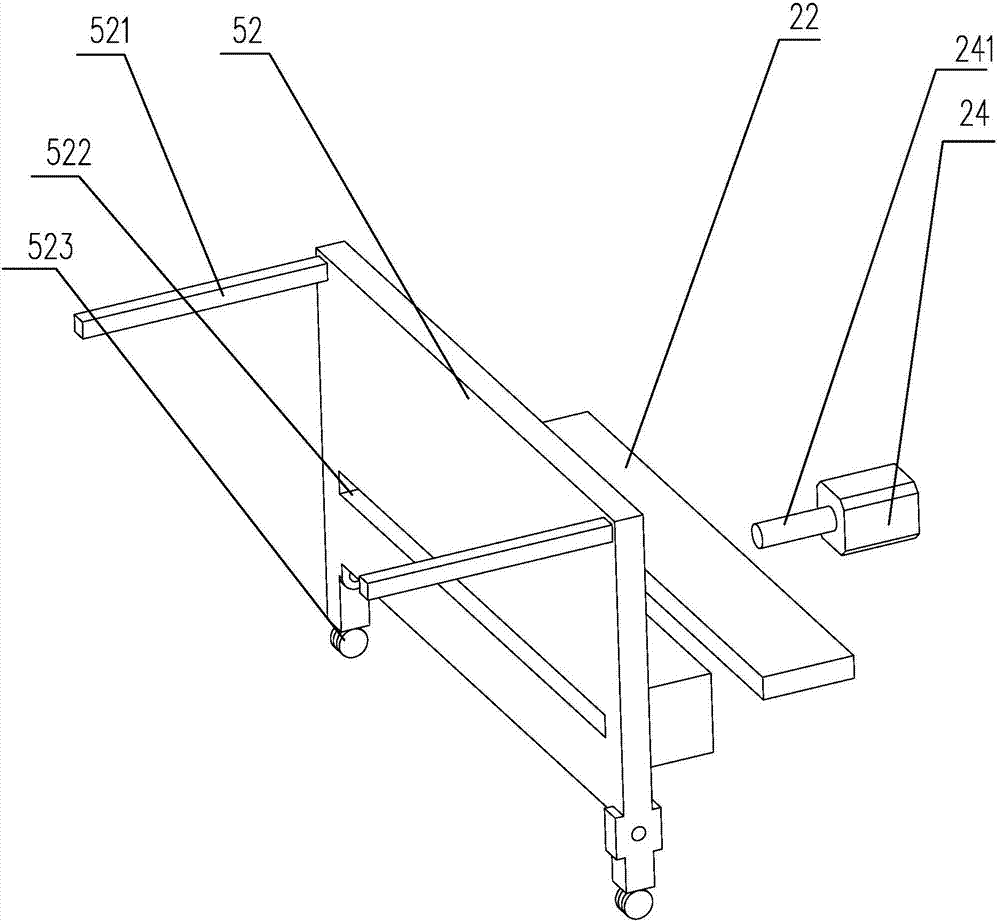

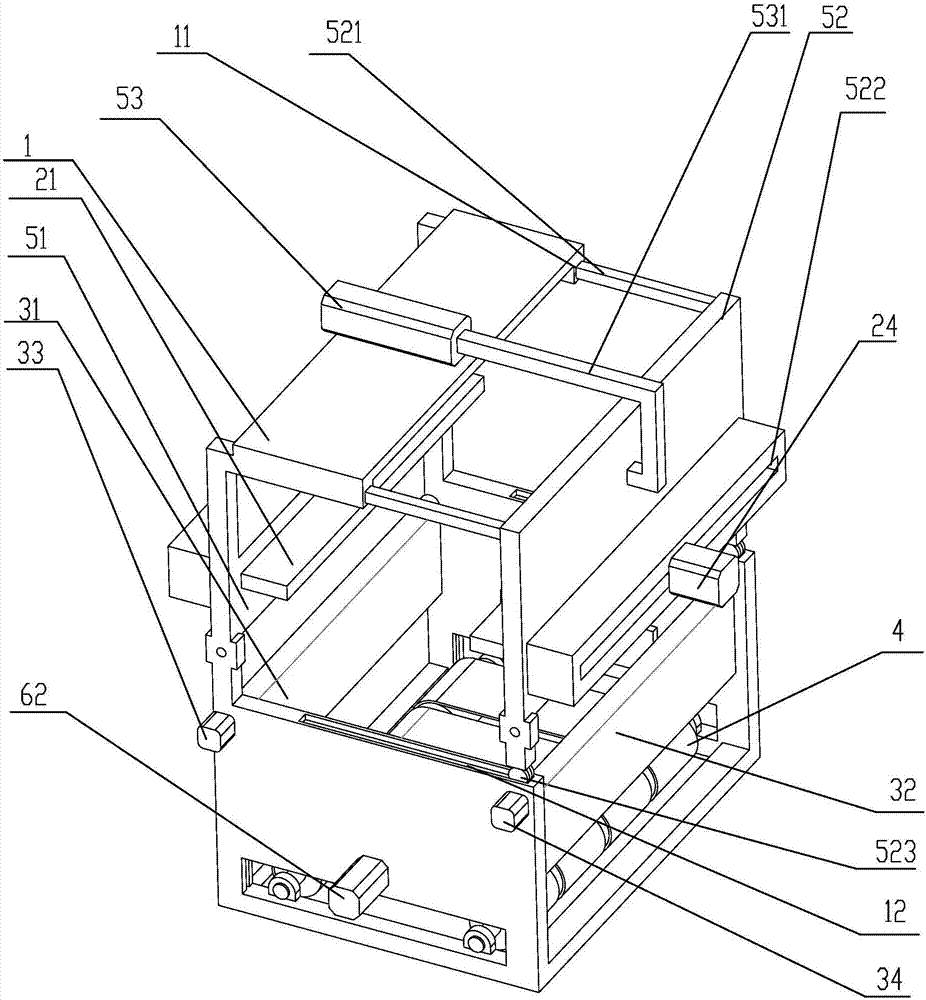

Paperboard stacking and packaging device

The invention discloses a paperboard stacking and packaging device which comprises a stacking device and a packaging device used for bundling paperboard stacks. The packaging device is arranged on the rear side of the stacking device. The stacking device comprises a support, partition plates, receiving brackets, a push plate and a lifting plate. Baffles capable of sliding front and back are arranged on the front side and the rear side of the support. The receiving brackets and the partition plates are arranged on the baffles correspondingly. The partition plates are arranged above the receiving brackets, and the lifting plate is arranged below the receiving brackets and is in sliding fit with the support. The push plate is arranged on the support, a conveying belt is arranged below the lifting plate, and the lifting plate is provided with a plurality of through grooves at intervals, wherein the conveying belt makes contact with the paperboard stacks through the through grooves. According to the paperboard stacking and packaging device, the structure is simple, paperboards with different sizes can be received, stacking is orderly, and the stacked paperboards are packaged.

Owner:ZHEJIANG DONGJIN TECH CO LTD

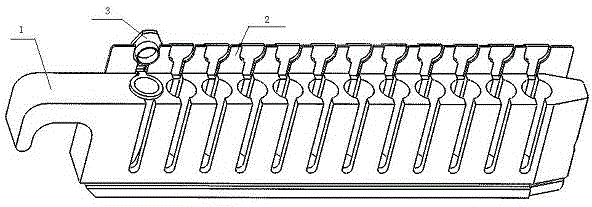

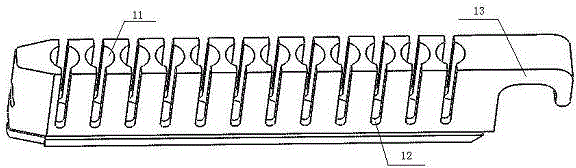

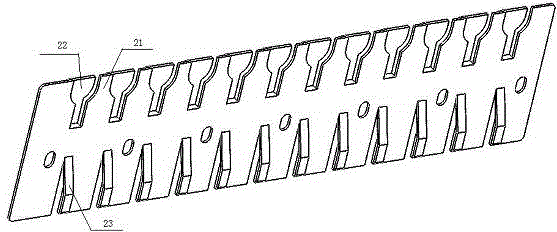

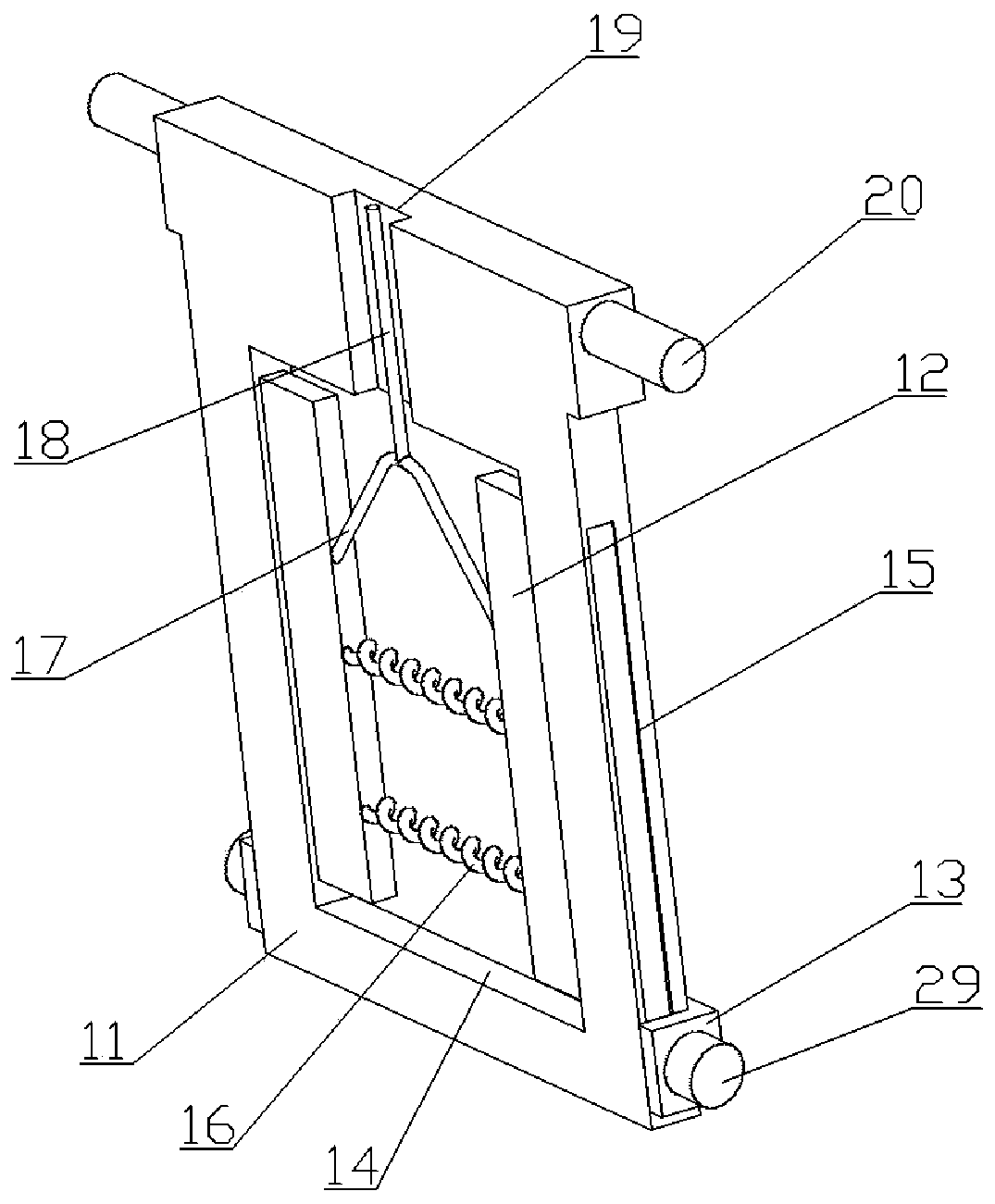

Sample frame

The invention provides a sample frame, which can adapt to test tubes and centrifuge tubes with different specifications, and aims at providing the sample frame which is simple in structure, high in practicability and suitable for full-automatic inspection equipment. The sample frame comprises two parts, namely a main carrier body and a baffle plate; the baffle plate is arranged on the side surface of the main carrier body; a plurality of round holes for arranging the test tubes are formed in the main carrier body; a spring sheet is arranged at the lower end of the baffle plate; and a seal cover fixing structure is arranged at the upper end of the baffle plate. The sample frame is simple in structure, relatively low in cost and high in practicability; the problem that an existing sample frame cannot hold the test tubes or centrifuge tubes with various specifications is solved; and the automatic degree of an instrument is improved.

Owner:ZHANGQIU YIHONGGUANG MEDICAL DEVICE

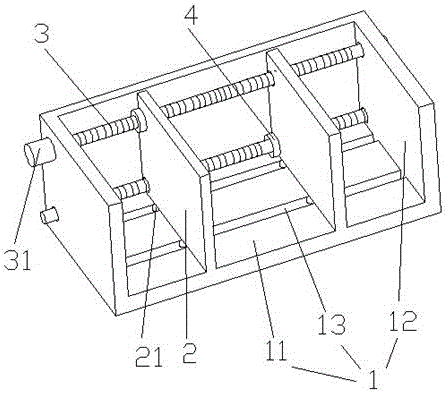

Book end

The invention discloses a book end comprising a fixed pedestal and two movable clamping plates, wherein the fixed pedestal comprises a base plate and side vertical plates vertically arranged on two sides of the base plate; two sliding chutes are crosswise arranged at the bottom of the base plate in parallel; the two movable clamping plates are arranged on the fixed pedestal, and two idler wheels are arranged at the bottom of each movable clamping plate corresponding to the sliding chutes, two screws are arranged on the inner side of the fixed pedestal and between the two side vertical plates, and each screw is provided with a screw nut fixedly connected with the corresponding movable clamping plate. The movable clamping plates can be moved by rotating rotary knobs, thus being convenient to move and doing not randomly change positions, so that books can be well clamping to ensure standing upright and meanwhile is also convenient to take out; and after the book is taken out, the residual books can be clamped again by rotating the rotary knobs.

Owner:张四清

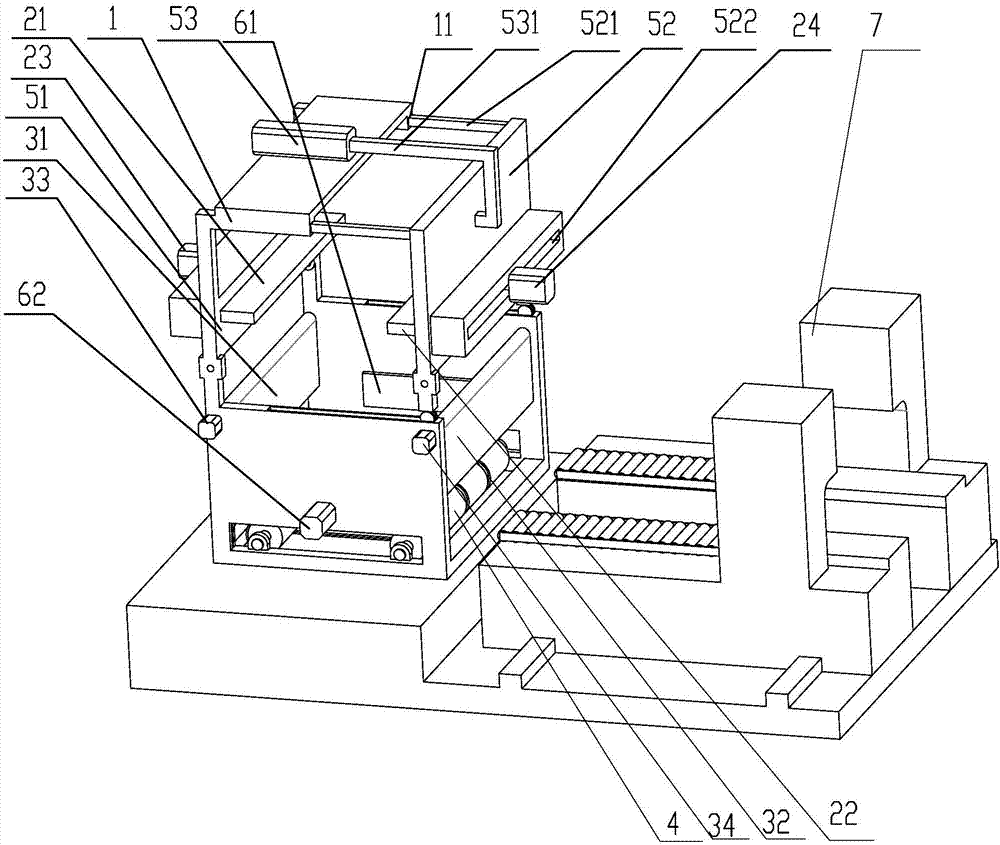

Paperboard stacking device

The invention discloses a paperboard stacking device. The paperboard stacking device comprises a bracket, a partition board, a collecting carrier, a pushing plate and a lifting plate, wherein baffles capable of sliding forwards and backwards are arranged at the front and rear sides of the bracket; both the collecting carrier and the partition board are arranged on the baffles; the partition board is arranged above the collecting carrier; the lifting plate is arranged below the collecting carrier and is in sliding fit with the bracket; and the pushing plate is arranged on the bracket, a conveyor belt is arranged below the lifting plate, and a plurality of through grooves for helping the conveyor belt be in contact with a paperboard stack are arranged in the lifting plate at intervals. The paperboard stacking device is simple in structure and can collect paperboards with different sizes and at the same time tidily stack the paperboards, thereby facilitating the following operation.

Owner:ZHEJIANG DONGJIN TECH CO LTD

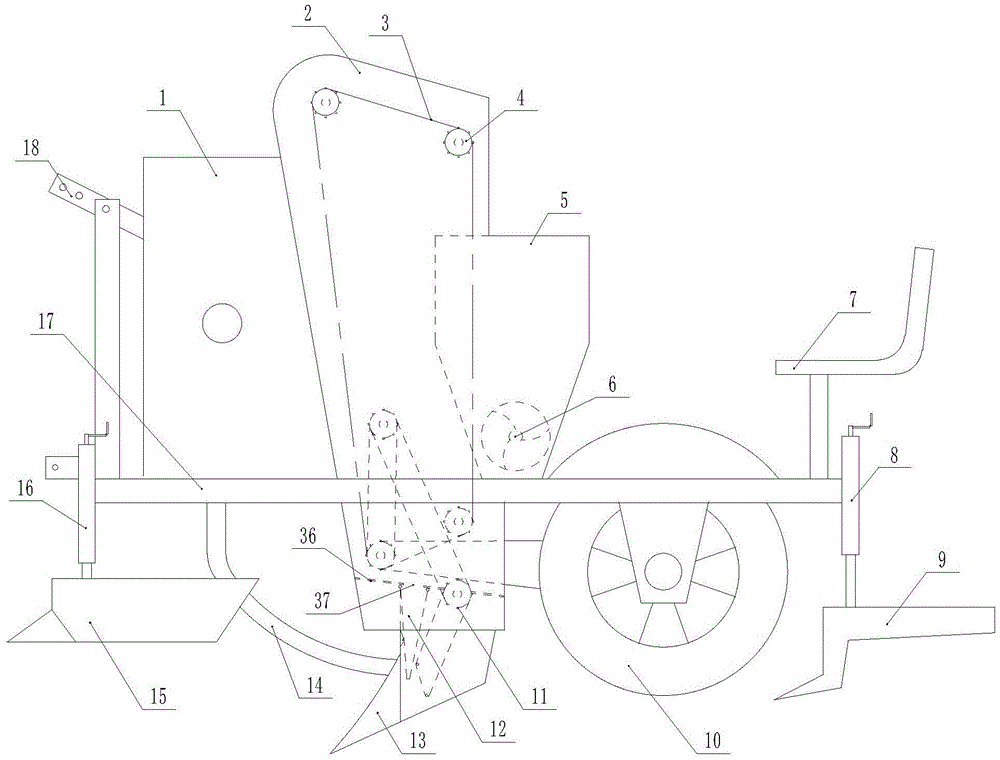

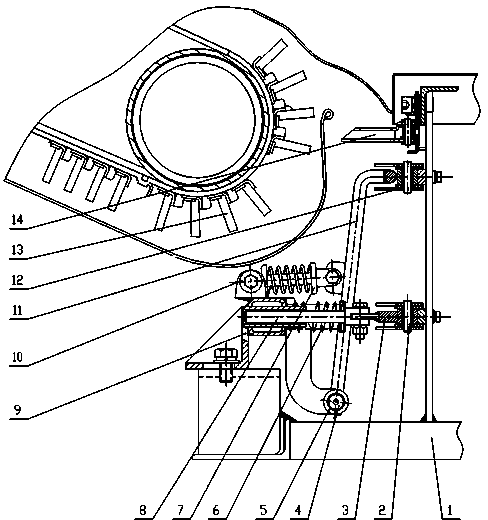

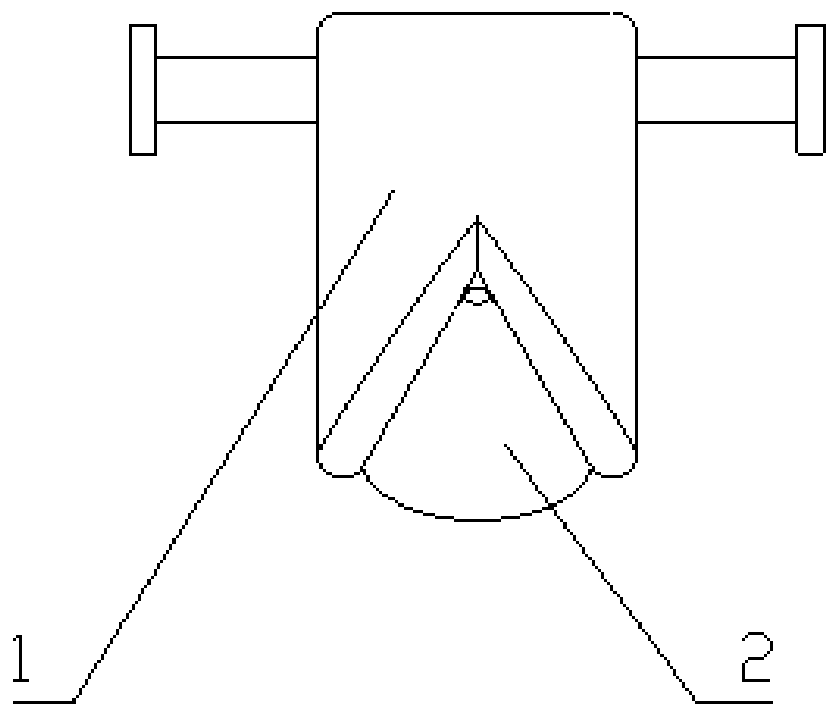

Garlic sowing machine

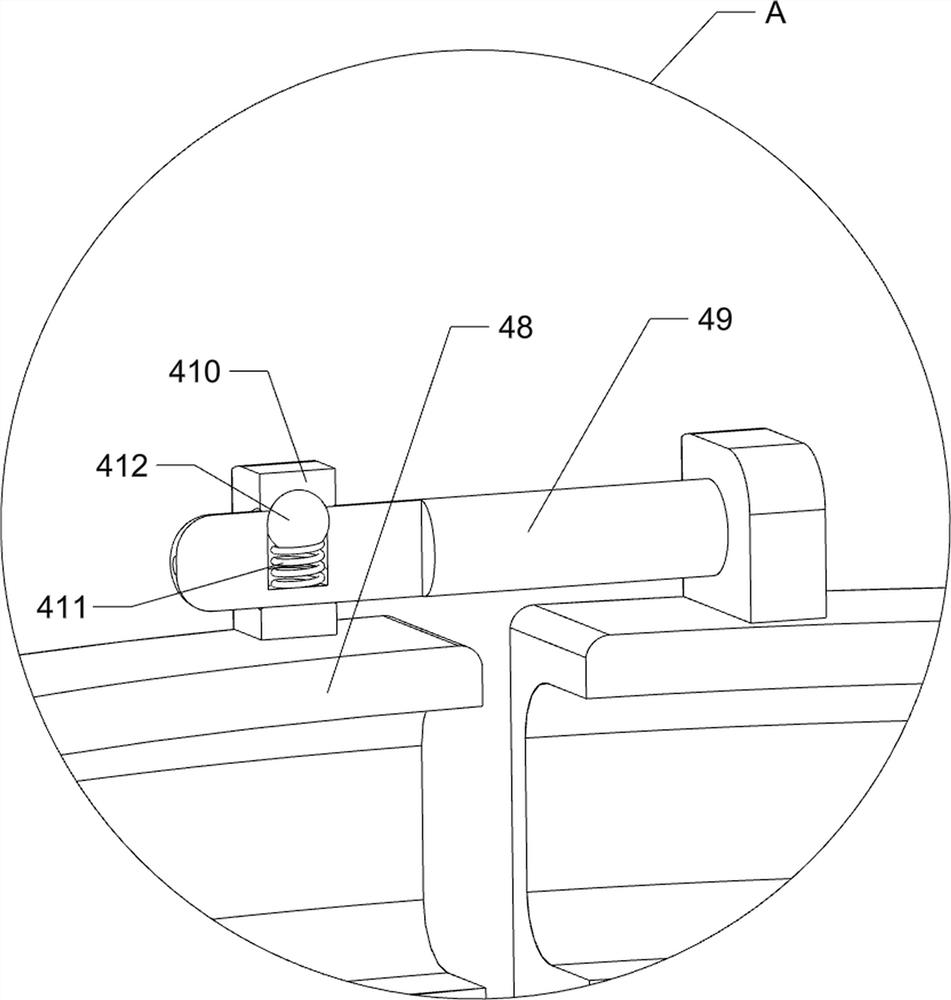

ActiveCN105580545AGuaranteed uprightIncrease success rateFertiliser distributersPotato plantersSeederGear wheel

The invention discloses a garlic sowing machine and belongs to the field of agriculture machinery. The garlic sowing machine is applied to mechanized garlic sowing and comprises a rack, wherein the rack is equipped with travelling wheels and a drawing mechanism, a sowing box, an aligning mechanism and a garlic clove furrow opener are further mounted on the rack, the aligning mechanism comprises transmission gears and a conveying chain, and support plates are arranged on the conveying chain; an aligning baffle plate A and an aligning baffle plate B with porous structures are arranged on two sides in the downlink direction of the conveying chain respectively and arranged on a chain baffle plate, space between the aligning baffle plate A and the aligning baffle plate B is gradually reduced, and the aligning baffle plate A, the aligning baffle plate B and the chain baffle plate constitute a channel allowing the conveying chain and the support plates to move; a sowing baffle plate is arranged below the aligning mechanism, and sowing ports are formed in the sowing baffle plate. With the adoption of the technical scheme, the defects that the planting requirement cannot be met due to the fact that the garlic sowing machine cannot guarantee that the garlic clove bulbils are upward during sowing in the prior art is overcome.

Owner:临沂华翔鑫农业机械科技有限公司

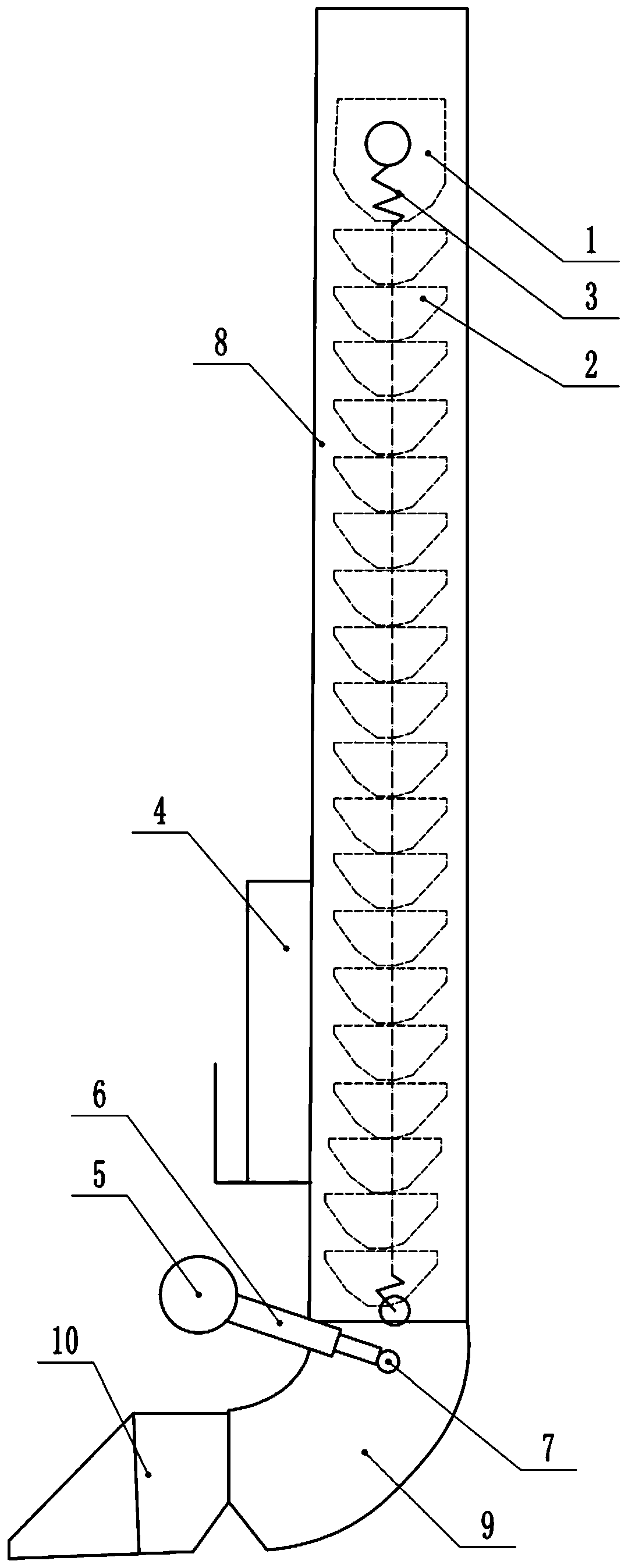

Vacuum feeding method of rotary disc screw feeding device

InactiveCN105858223AGuaranteed uprightAvoid material jamsBulk conveyorsConveyor partsVacuum pumpingSuction stress

The invention provides a vacuum feeding method of a rotary disc screw feeding device. The method comprises the following steps that (1) a drive device drives a second disc body to rotate, and screws on the second disc body begin to be stirred along with the second disc body; (2) a vacuumizing source conducts vacuum pumping inside a long groove from a first through hole; (3) a second through hole generates suction for the screws once being vacuumized, and the screws are sucked into the second through hole; and (4) an external fetching device fetches away the screws from the second through hole. Feeding of the screws of small sizes is achieved, feeding accuracy is ensured, and the clamping phenomenon of the screws is effectively prevented.

Owner:SUZHOU LONGYU ELECTRONICS EQUIP

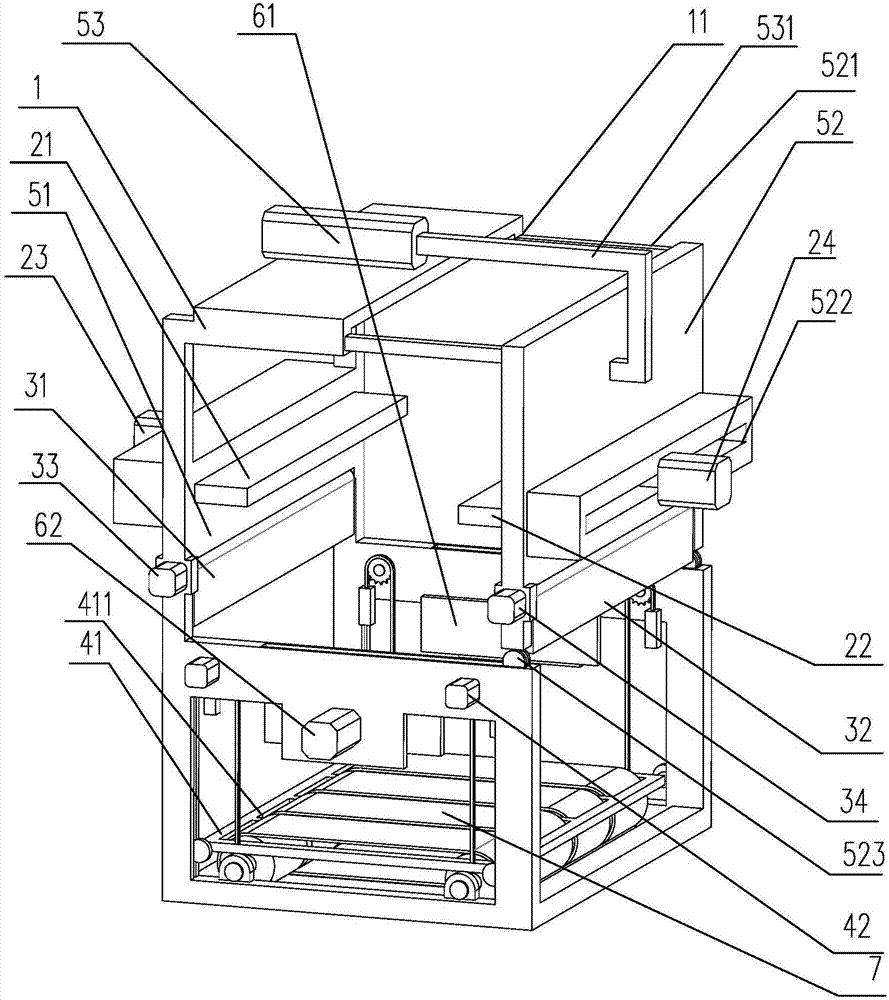

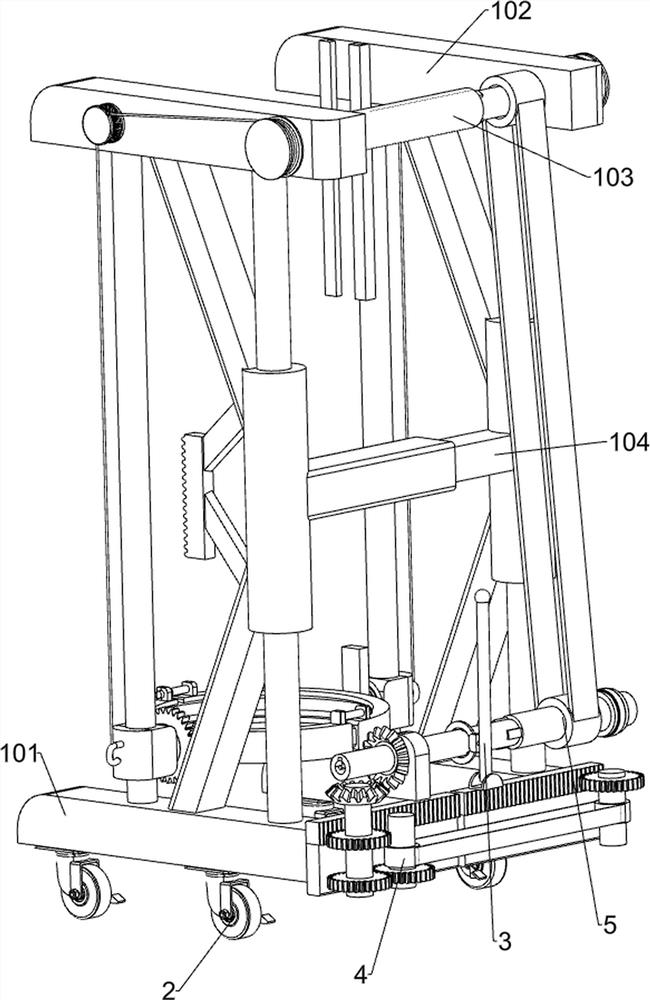

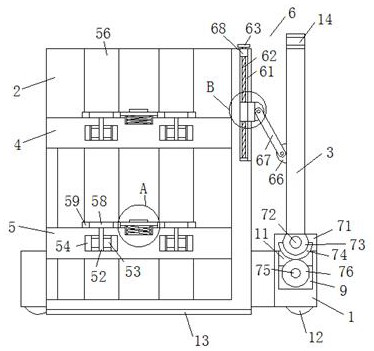

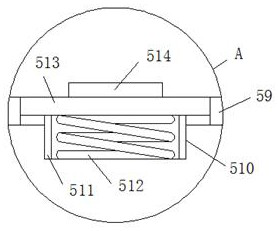

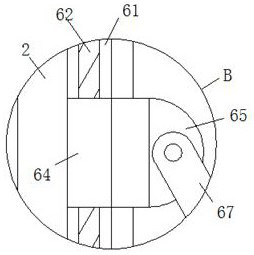

Barreled water placement equipment

InactiveCN112278830AGuaranteed uprightAvoid damageConveyorsConveyor partsStructural engineeringControl theory

The invention relates to placement equipment, in particular to barreled water placement equipment. The technical problem is to provide the barreled water placement equipment which can automatically place barreled water on a water dispenser and is safe and stable. The barreled water placement equipment comprises a mounting frame, a right support, a left support, a circular telescopic rod, a squaretelescopic rod, wheels, a power assembly, a clamping assembly, a lifting assembly and a rotating assembly; the right support is mounted on the mounting frame in a sliding manner; the left support is mounted on the mounting frame in a sliding manner; the circular telescopic rod is mounted between the right support and the left support in a rotational manner; the square telescopic rod is mounted between the right support and the left support; the wheels are mounted on the two sides of the right support, the two sides of the left support and the two sides of the mounting frame in a rotational manner; the power assembly is mounted on the mounting frame; the clamping assembly is mounted on the mounting frame and between the right support and the left support; the lifting assembly is mounted between the right support and the left support; and the rotating assembly is mounted on the right support. The barreled water placement equipment is provided with a guide assembly, so that the water dispenser is prevented from being damaged by inaccurate placement position of the barreled water.

Owner:赵中会

Stacking device for paperboards

Owner:ZHEJIANG DONGJIN TECH CO LTD

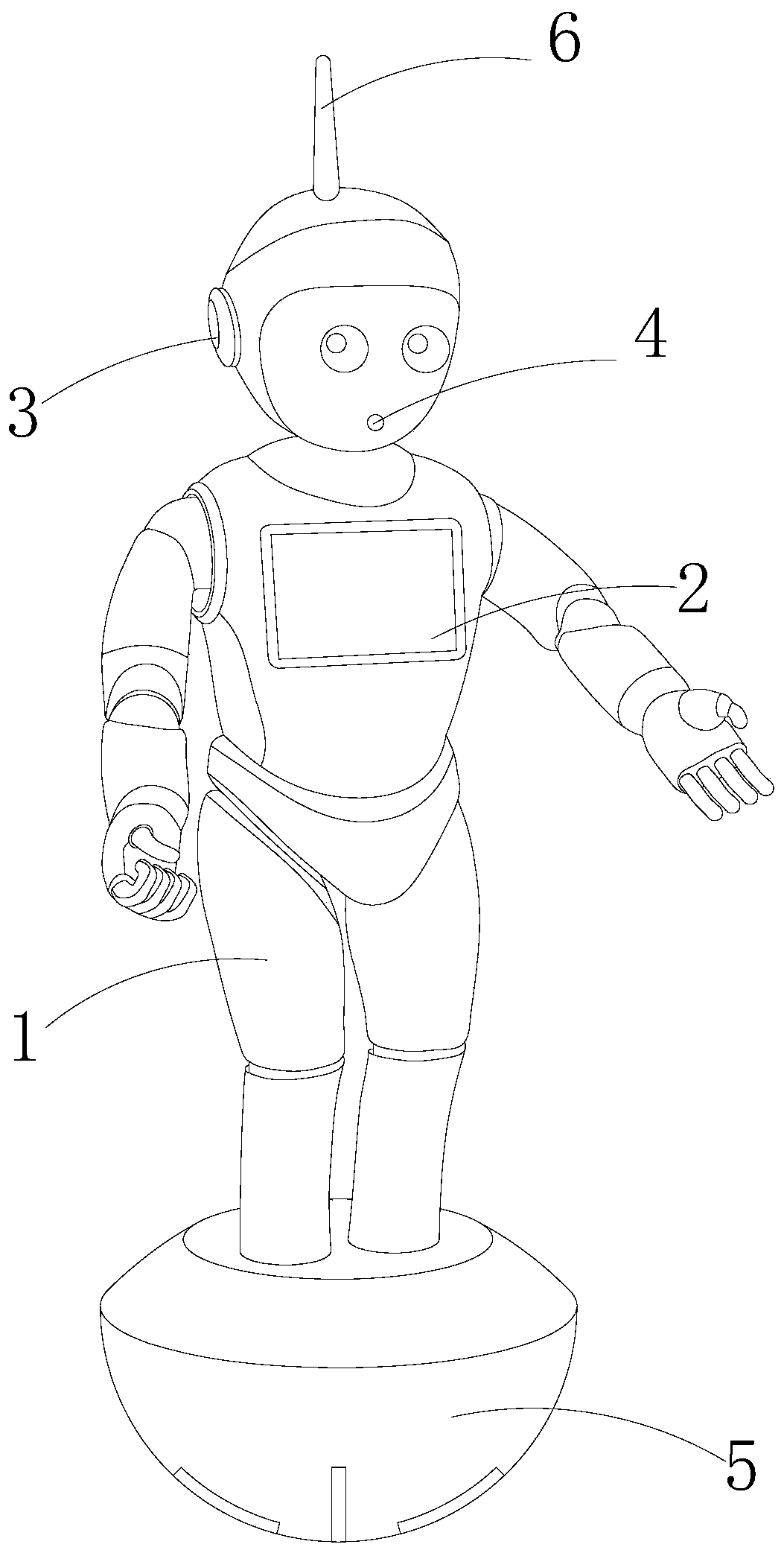

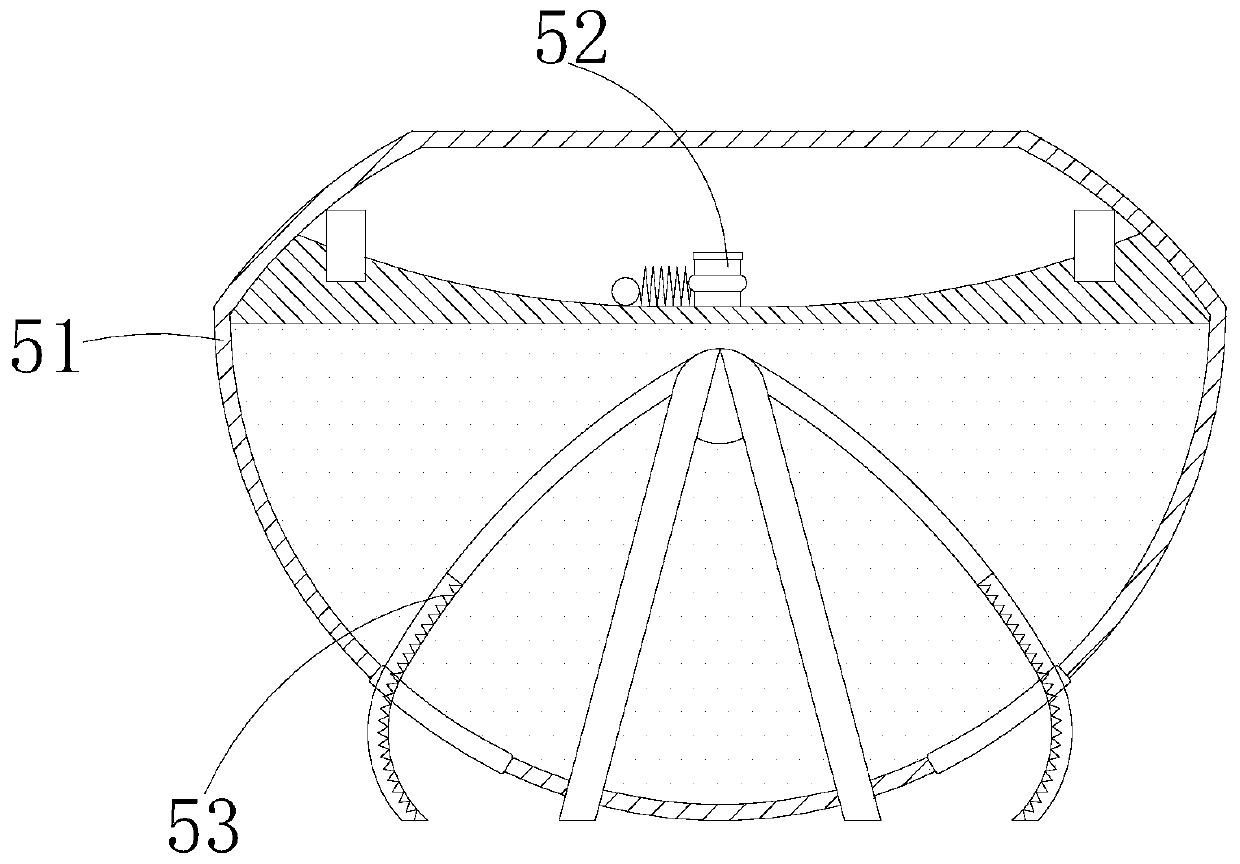

Intelligent robot learning toy

ActiveCN109999512APrevent knocking downGuaranteed uprightDollsGavity operated toysComputer scienceIntelligent robots

The invention discloses an intelligent robot learning toy. The toy structurally includes a robot body, a display screen, speech receiving systems, a speech playing system and a stand anti-falling device. The display screen is embedded on the front surface of the robot body, the speech receiving systems are arranged on both sides of the upper part of the robot body, and the speech playing system isarranged on the upper end of the robot body. Through arrangement of the stand anti-falling device, a claw-shaped structure is used to support the robot toy to ensure a standing state; and by using ofthe principle of "tumbler", the robot toy can rapidly recover the standing state when toppled by a larger external force, and fragile parts, such as the display screen arranged on the upper part of the robot toy can be prevented from falling down to the ground, so that the fragile parts are protected; and the robot toy maintaining the standing state occupies less space and is convenient to clearup and store.

Owner:深圳纳锐创新科技有限公司

Posture-correcting integrated campus desk and chair capable of being adjusted in multiple directions

The invention relates to the technical field of campus facilities, in particular to a posture-correcting integrated campus desk and chair capable of being adjusted in multiple directions. The integrated campus desk and chair includes an arm chair device, the arm chair device comprises a backrest; a bottom plate is arranged at the bottom end of the backrest; a cushion is arranged at the top end ofthe bottom plate, two sets of inserting rods are fixedly connected to the bottom end of the cushion, tooth blocks are evenly and fixedly connected to one sides of the inserting rods on the back face,a shaft rod is arranged at the top end of the bottom plate, the front side and the rear side of the shaft rod are connected with the inner wall of the bottom plate through embedded bearings, and the surface of the shaft rod is sleeved with a first gear. When a student sits down, the waist of the student can be automatically corrected, hunchback caused by long-time bending of the waist of the student is avoided, when the student reads a book, the inclination angle of the rotating plate can be freely adjusted according to the body shape of the student, the shoulders of the student are propped against and supported through the supporting rods, and the student is helped to build a healthy body shape.

Owner:丘远光

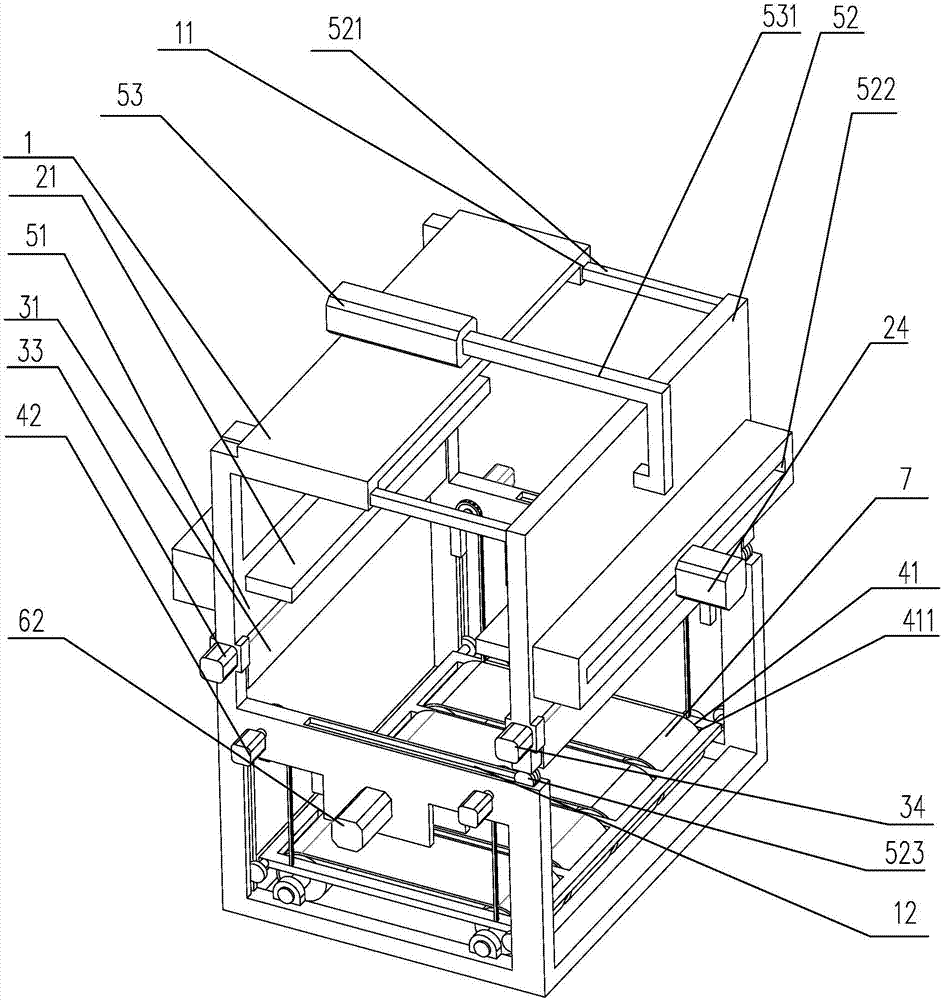

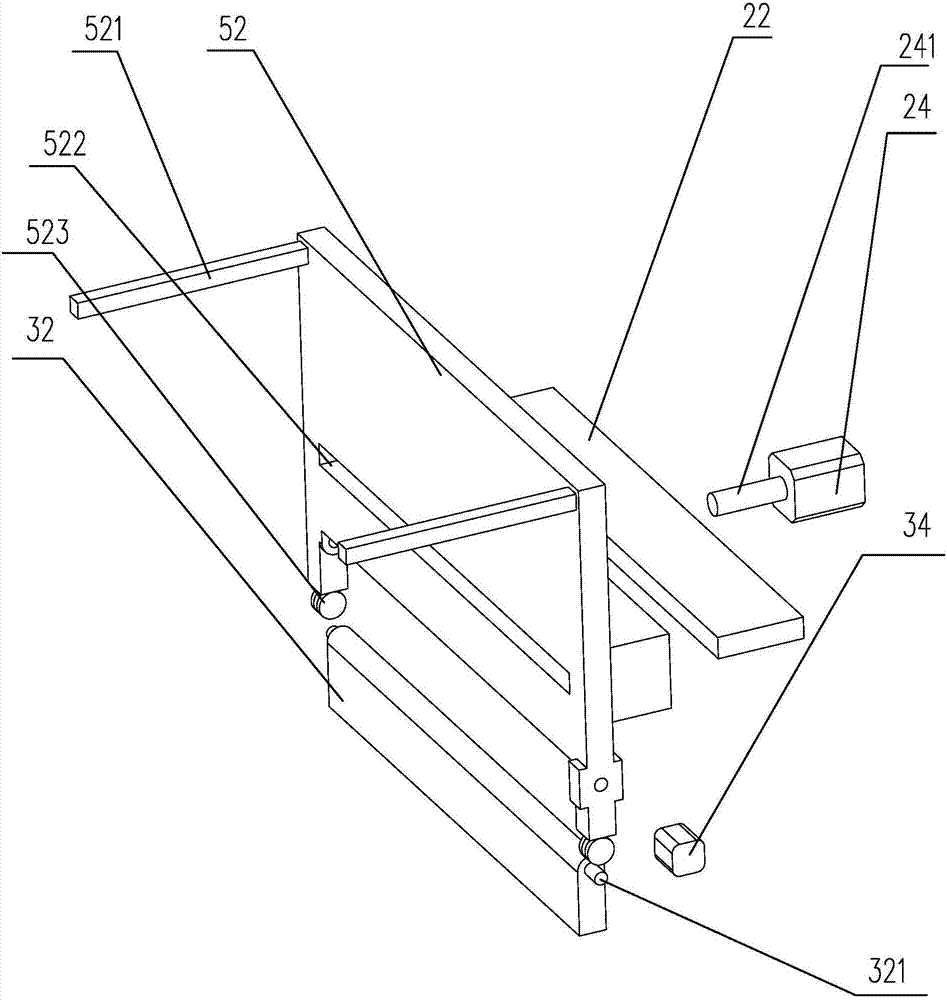

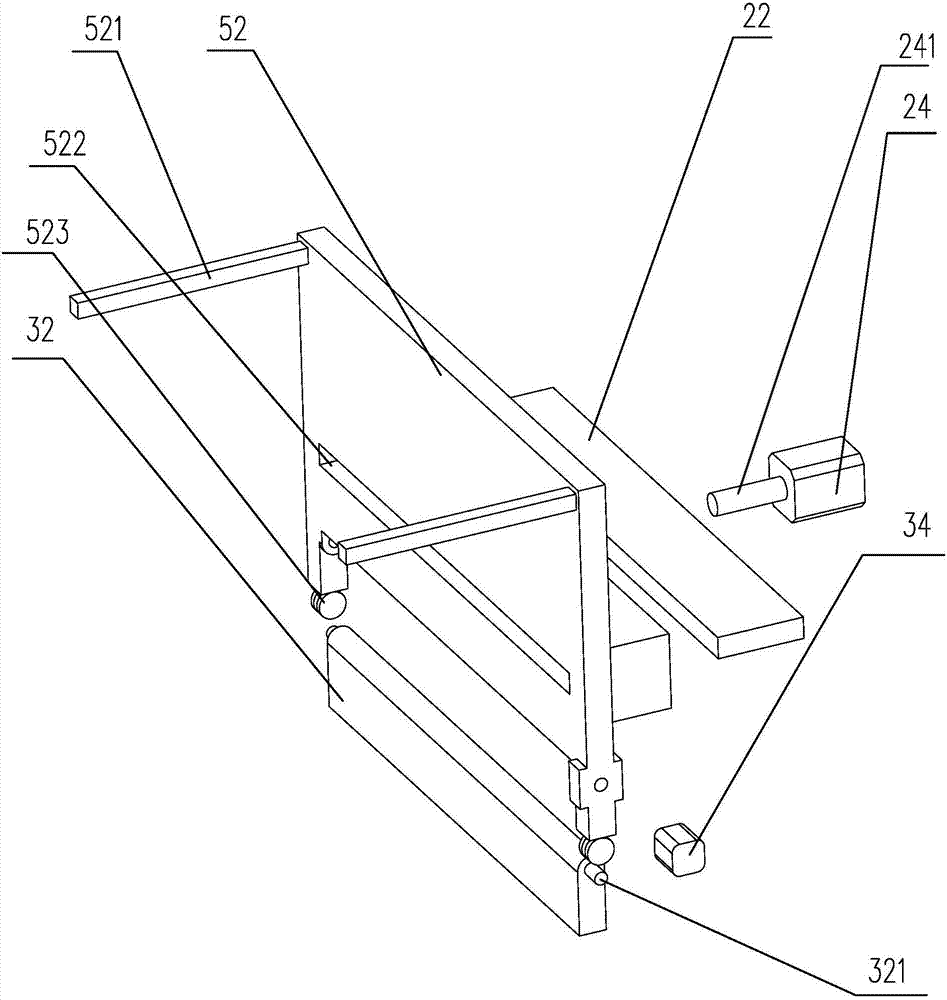

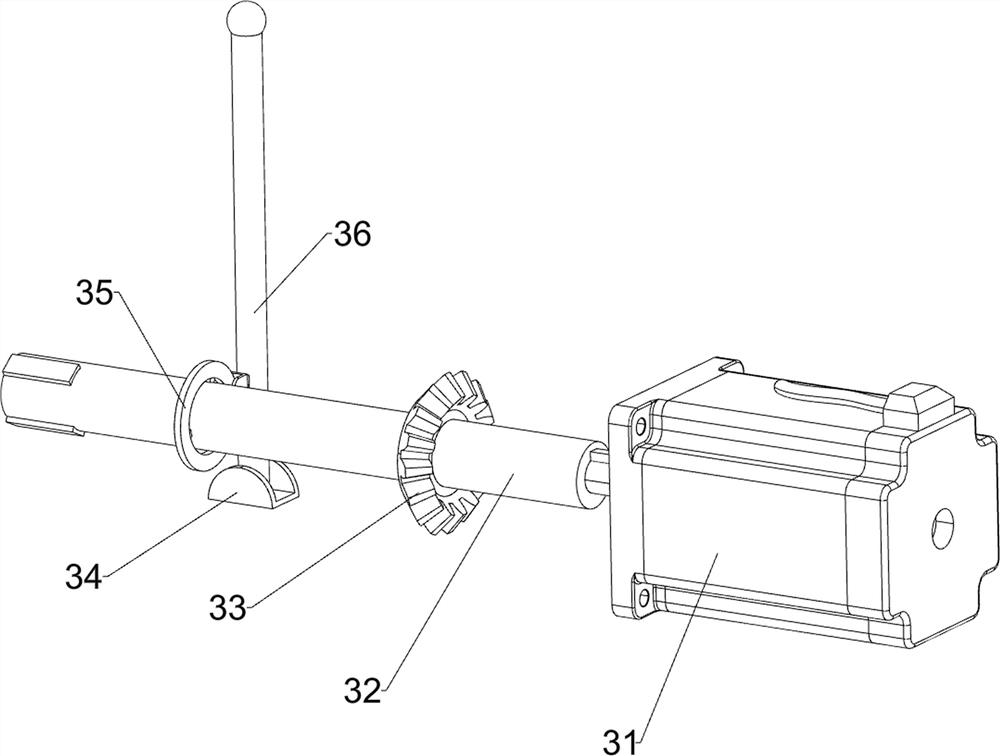

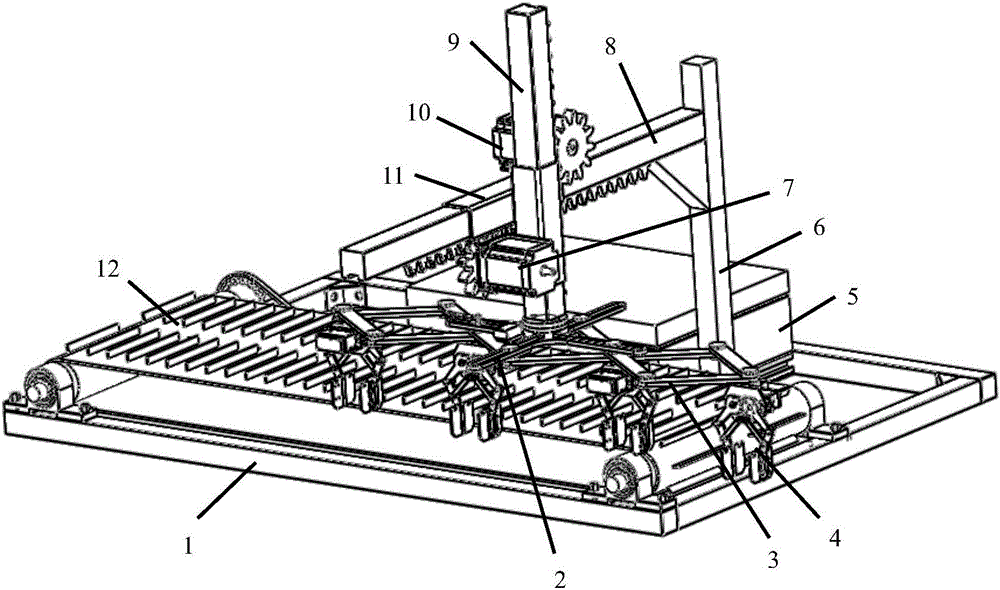

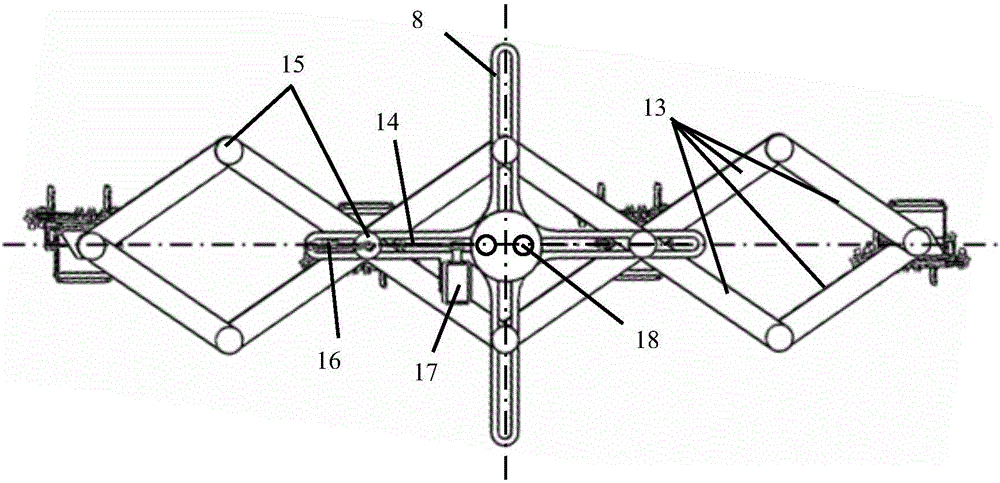

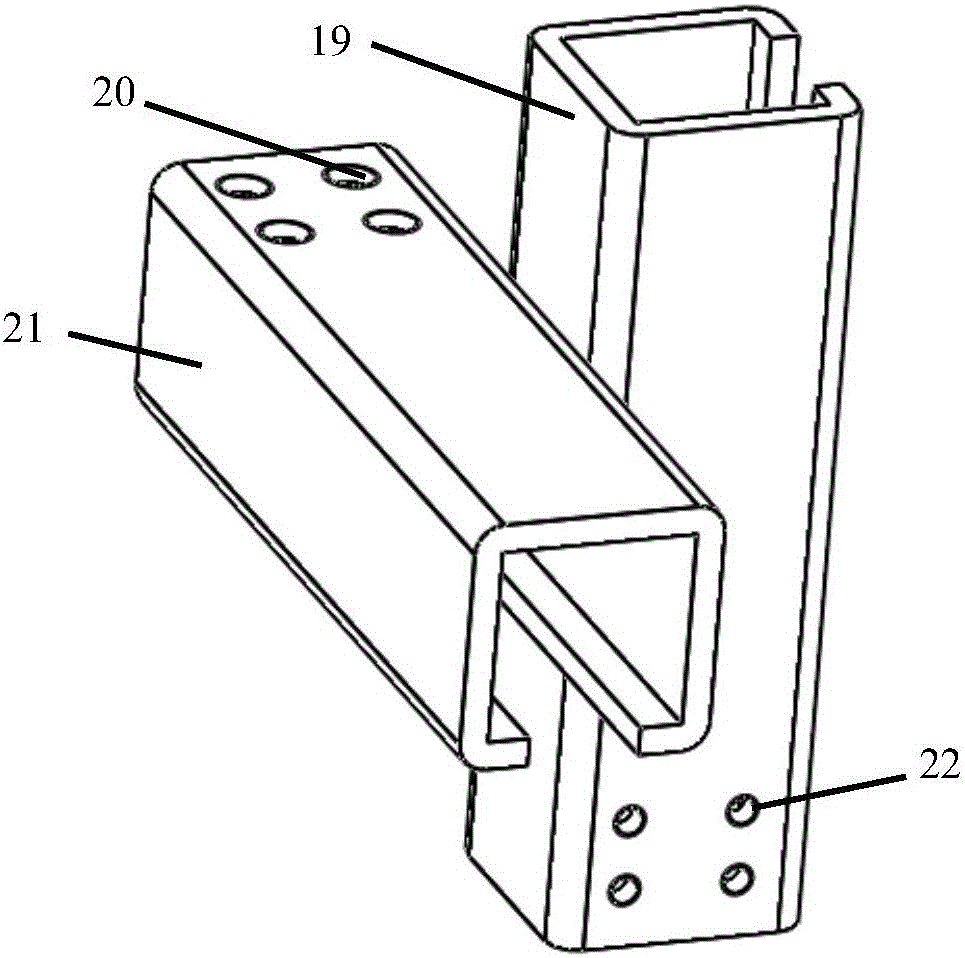

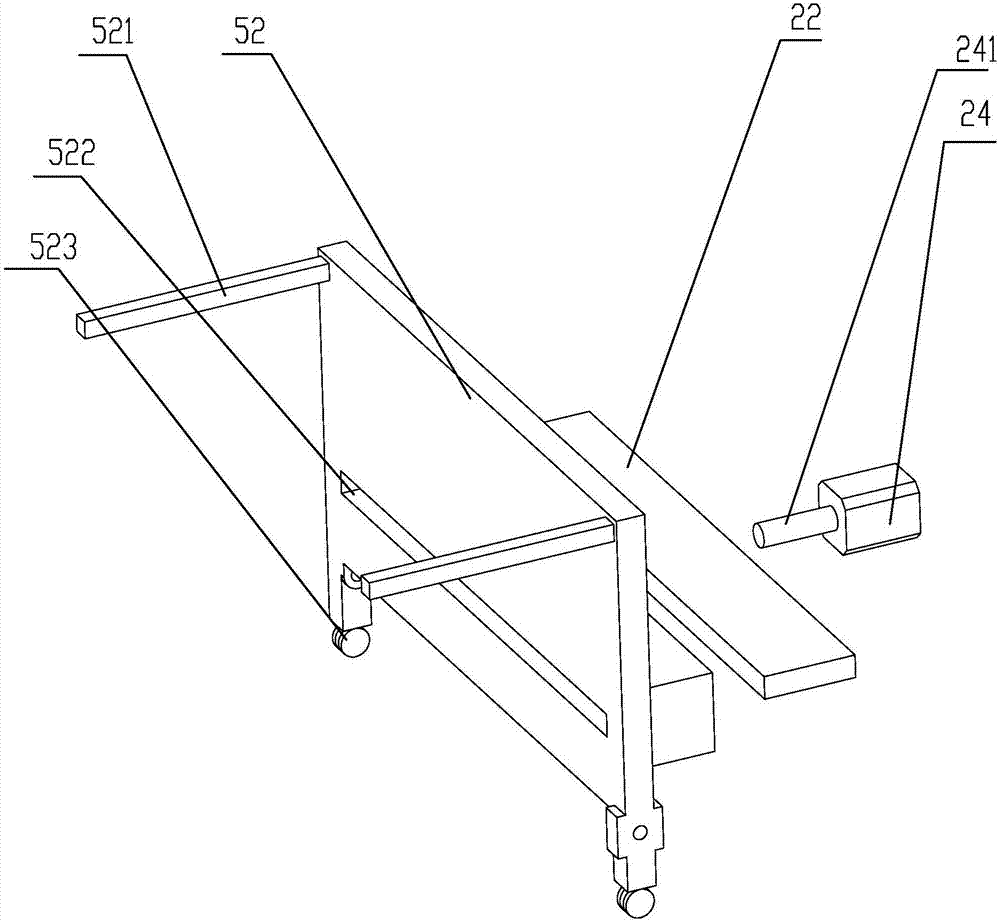

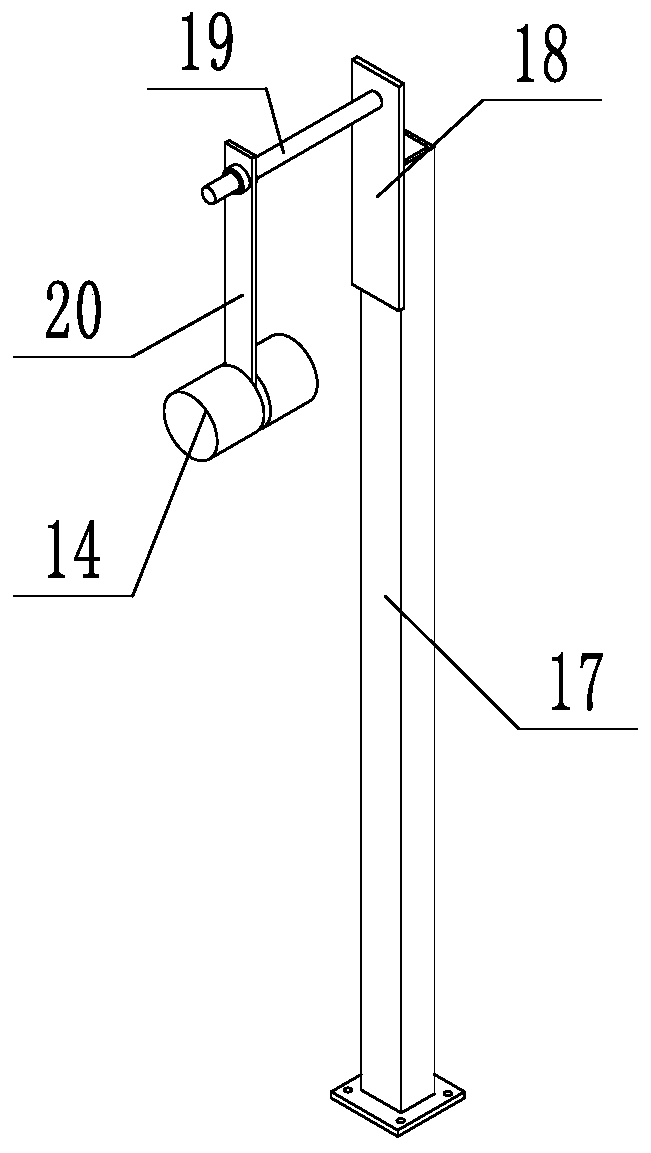

Intelligent multi-row seed clove box grabbing and releasing device

PendingCN106717363AGuaranteed uprightImprove productivityPotato plantersProduction rateControl system

The invention relates to an intelligent multi-row seed clove box grabbing and releasing device. The device comprises a rack, and a seed clove box conveying mechanism, a guide rail, a cross guide rail, a telescopic arm, mechanical arms and a control system which are arranged on the rack, wherein the seed clove box conveying mechanism comprises a conveying belt and a seed clove box; the guide rail comprises an assembly seat, a horizontal guide rail, a vertical guide rail, a sliding sleeve, a stepped motor I and a stepped motor II; the sliding sleeve comprises two sleeves which are vertical to each other and are fixedly arranged together; one sleeve of the sliding sleeve is connected on the horizontal guide rail in a sleeving manner, and the vertical guide rail is movably arranged in the other sleeve of the sliding sleeve; the center of the cross guide rail is fixedly arranged right under the vertical guide rail; the telescopic arm comprises multiple groups of parallel four-link mechanisms; the mechanical arms are arranged under the center peak of the parallel four-link mechanisms; and the control system comprises a single chip microcomputer and a motor driver. The intelligent multi-row seed clove box grabbing and releasing device can be used for automatically grabbing and releasing seed clove boxes, ensures the vertical state of garlic roots after planting, and has uniform row spacing and high production efficiency.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

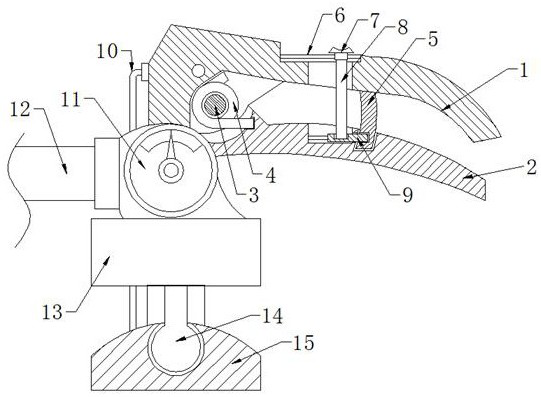

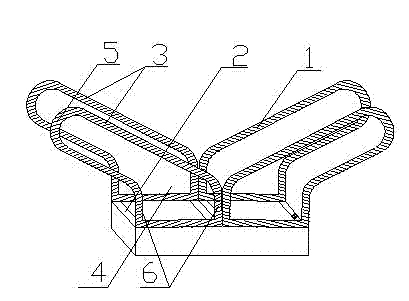

Double straw clamping rods for half-feed combine harvester

InactiveCN103355061ARealize double clampingGuaranteed uprightThreshersAgricultural engineeringThreshing

The invention discloses double straw clamping rods for a half-feed combine harvester. The double straw clamping rods are used for the half-feed combine harvester to clamp straws in the conveying and threshing of harvesting operation. A straw clamping rod I obtains corresponding initial pre-tightening force through a spring compressed to a certain extent and mounted in the middle of a pin shaft base, is clung onto a roller of a lower feeding straw chain, can perform backward rectilinear motion after being squeezed by straws in the harvesting process to continue to compress the spring and make room for the passing of straws; A straw clamping rod II obtains corresponding initial pre-tightening force through a spring compressed to a certain extent and mounted at the upper part of the pin shaft base, is clung onto a roller of a middle feeding straw chain, can rotate and swing backwards after being squeezed by straws in the harvesting process to continue to compress the spring and make room for the passing of straws; the straw clamping rod I is away from the straw clamping rod II at a certain distance, and can firmly clamp both ends of the conveying straws simultaneously.

Owner:培禾新地科技股份有限公司

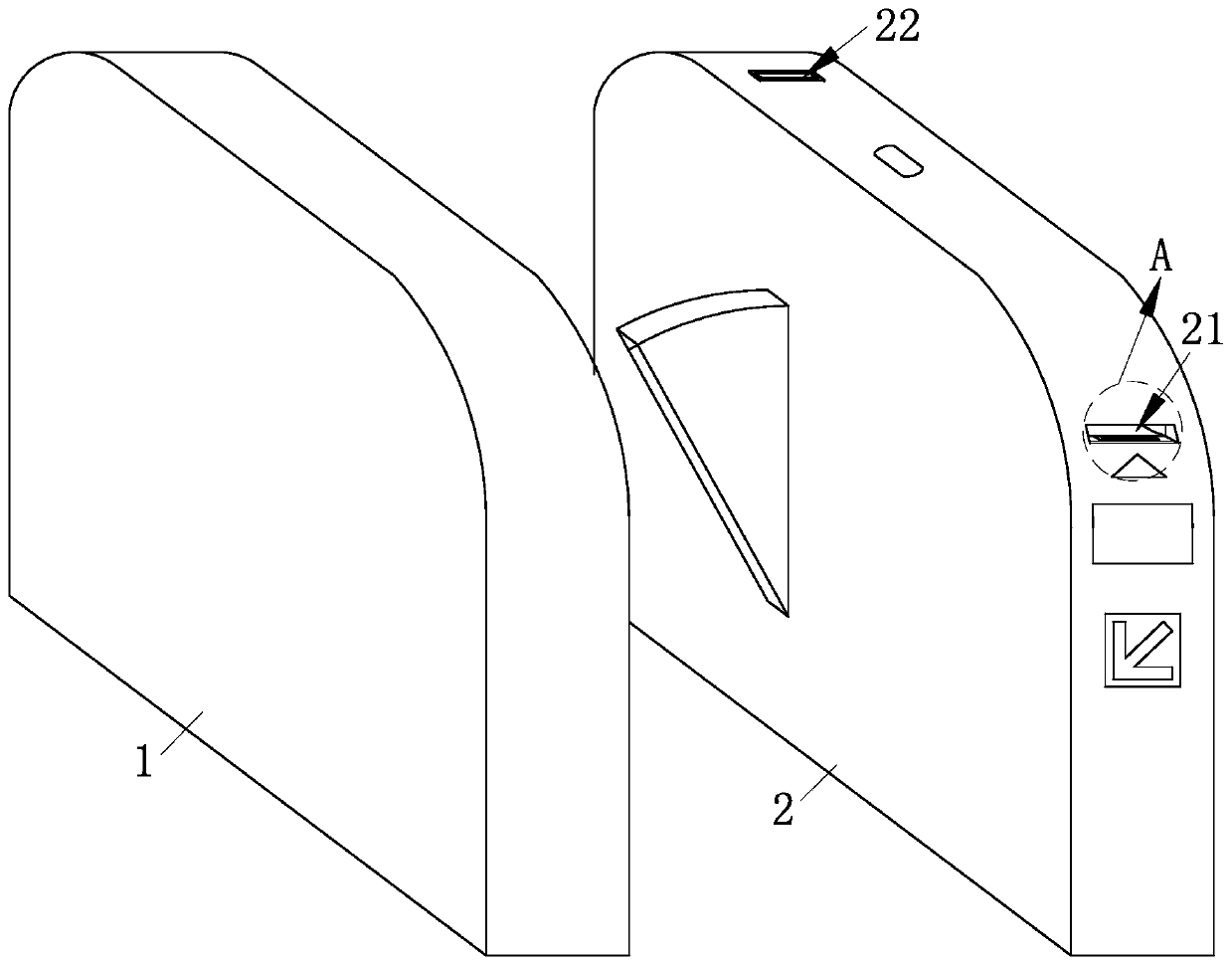

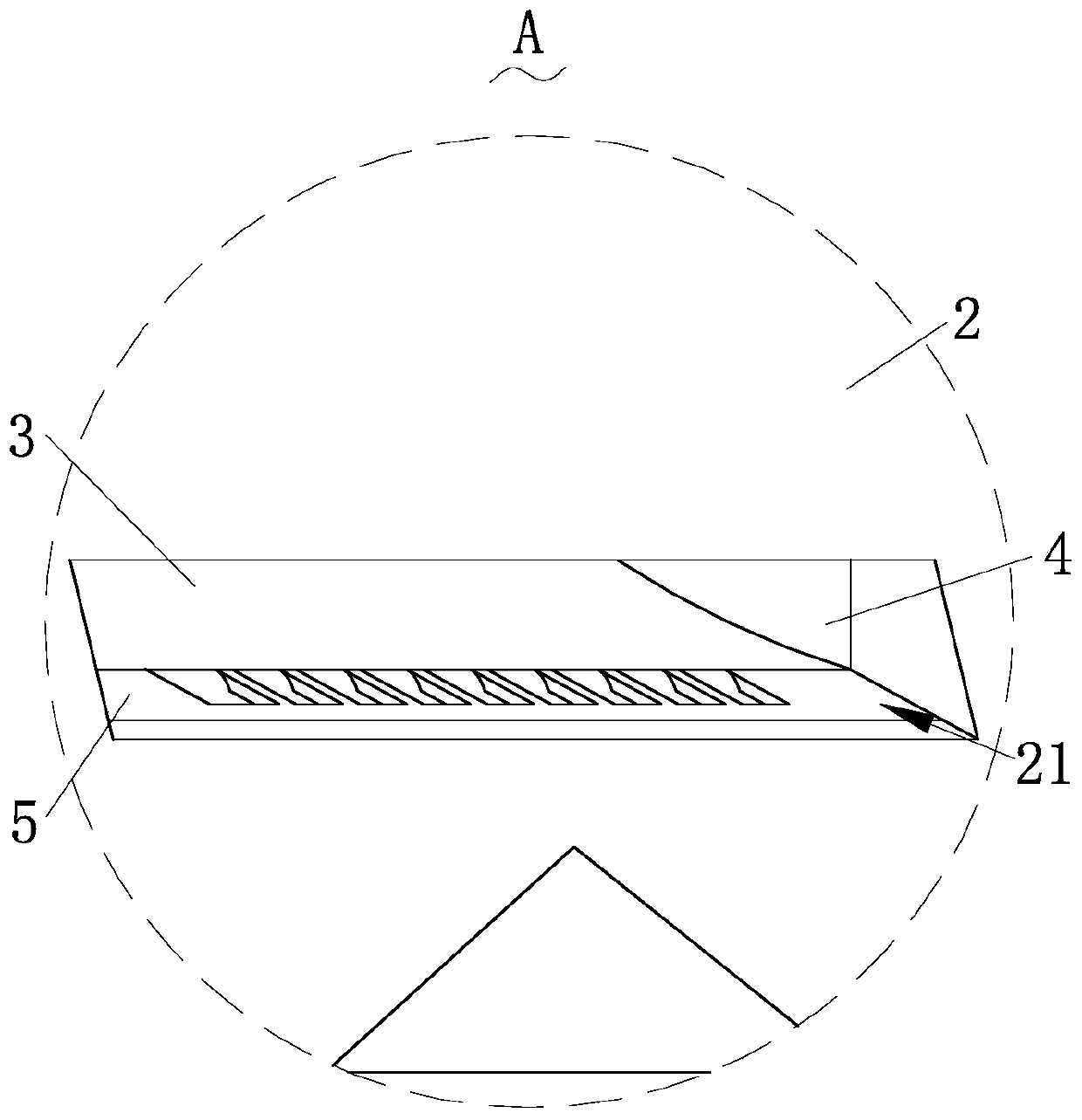

Subway and high-speed train ticket checking equipment

The invention relates to the field of ticket checking equipment, in particular to a subway and high-speed train ticket checking equipment. The equipment comprises a shell, a ticket checker body, a first transmission mechanism, a guide mechanism, a first connecting plate, a second transmission mechanism, a cleaning mechanism, a second connecting plate and a collection mechanism. The guide mechanismfor guiding tickets entering the ticket checker body is connected with the ticket checker body for ticket checking. Thus, when a ticket is not placed in the right position, the guide mechanism can guide the ticket and ensure that the ticket is placed in the right position, so as to facilitate the transmission of the ticket on the first transmission mechanism and on the second transmission mechanism and the cleaning of the ticket. Moreover, the ticket can pass through the second connecting plate easily, the solid dirt at the bottom of the ticket can be cleaned through the pushing force appliedto the ticket by the first transmission mechanism when the solid dirt is stuck in the through hole of the second connecting plate, and the transmission of the ticket is facilitated.

Owner:EASYWAY SUZHOU ELECTRONICS TECH

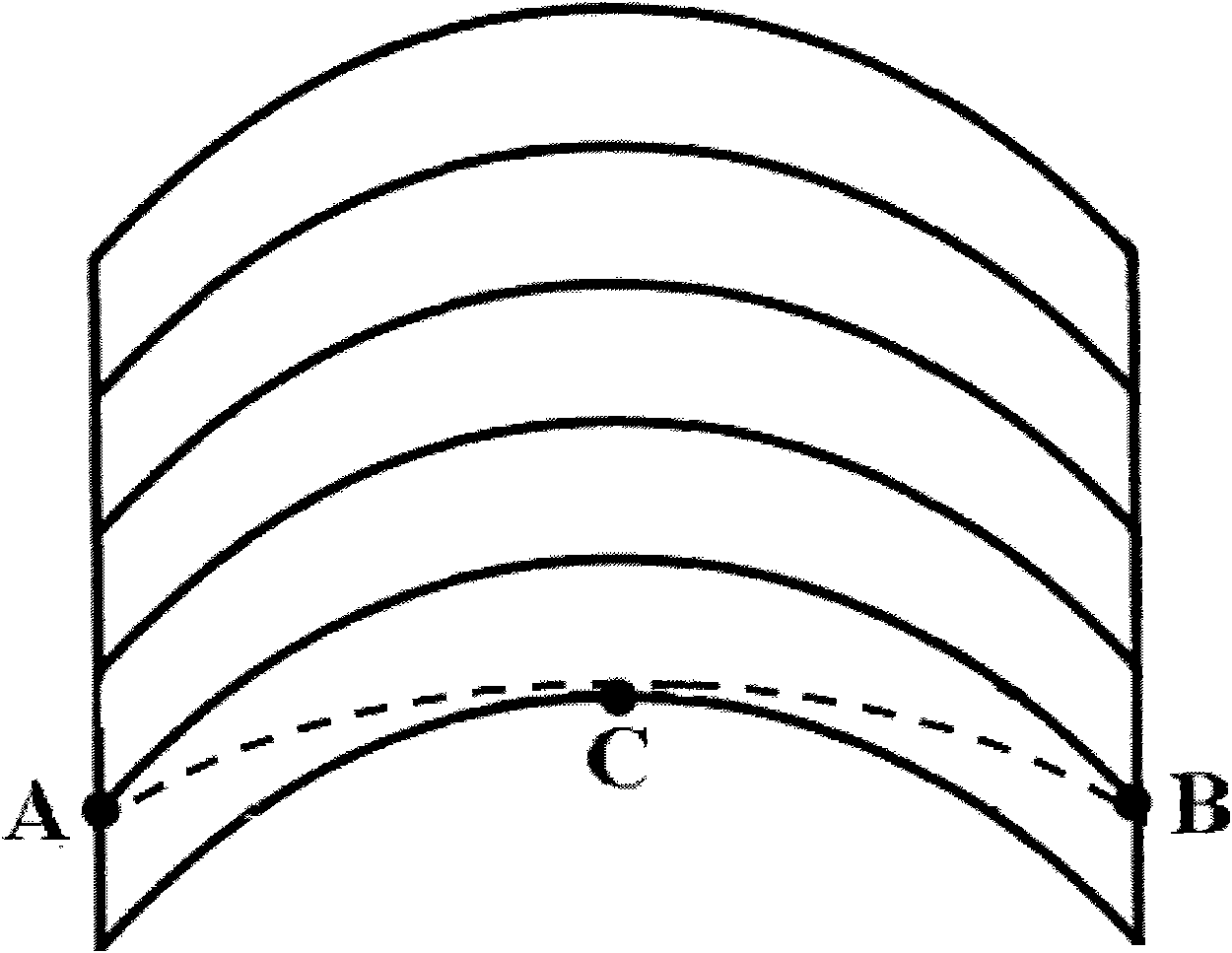

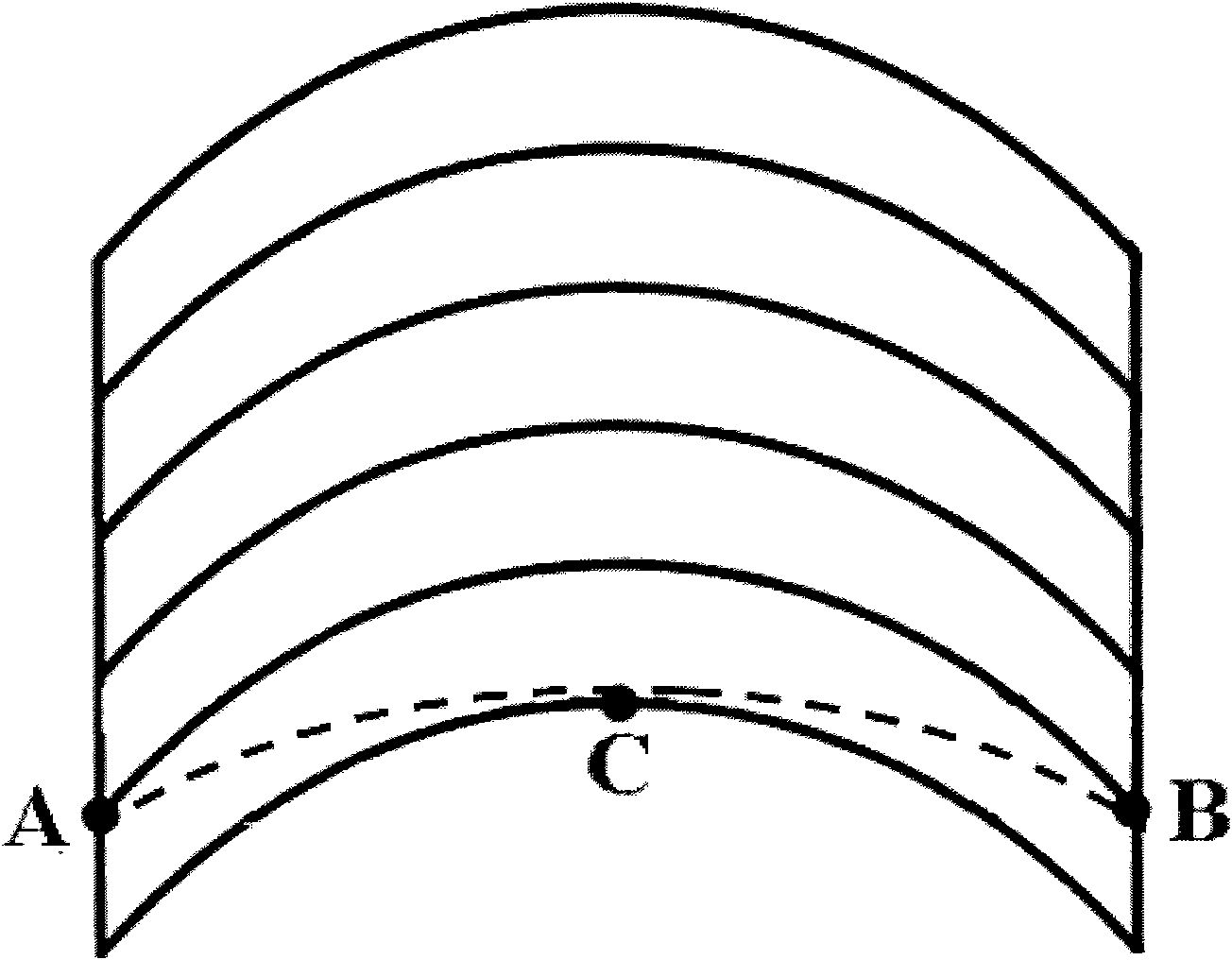

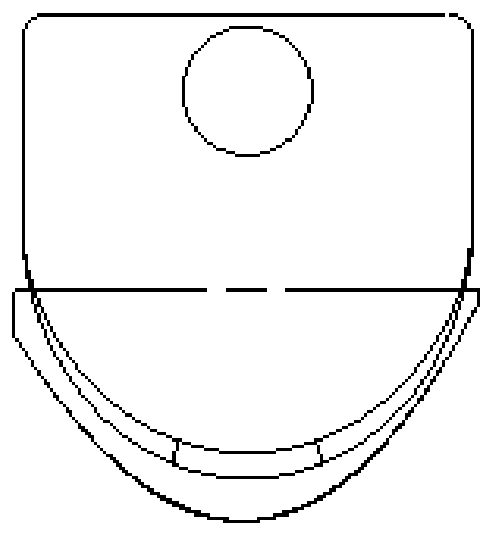

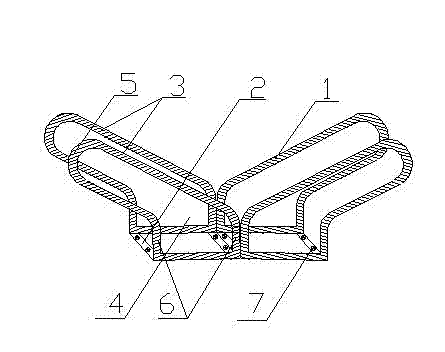

Arc-shaped slot cubbyhole

The invention relates to a cultural tool, in particular to an arc-shaped slot cubbyhole. The traditional cubbyhole capable of vertically placing files is arranged by checks, is convenient to place magazines or thinner books and required books are also easy to find. The traditional cubbyhole is always put on a desk or a family writing desk, but the lower half part of the file is always bent when the traditional cubbyhole stores the file with several pieces of paper, especially the file with a single piece of paper, the file deforms and is uneven in a long time, and especially each file check is not full of files, i.e. thinner paper files are difficult to stand straight. In the invention, the arc-shaped slot cubbyhole which can cause the single piece of paper to stand straight in the cubbyhole to be stored is designed. The arc-shaped slot cubbyhole is very convenient to draw files.

Owner:李畅

Paperboard stacking and packing device

The invention discloses a paperboard stacking and packing device. The paperboard stacking and packing device comprises a stacking device and a packing device used for bundling paperboard piles, and the packing device is arranged on the rear side of the stacking device; and the stacking device comprises a support, partition plates, receiving brackets and push plates, wherein baffles capable of sliding forwards and backwards are arranged on the front side and the rear side of the support, the receiving brackets are arranged on the support, each partition plate is arranged on the corresponding baffle and arranged above the corresponding receiving bracket, the push plates are arranged on the support, and conveyor belts are arranged below the push plates. The paperboard stacking and packing device is simple in structure and can be used for receiving paperboards with different sizes; meanwhile, the paperboards can be stacked regularly, and the stacked paperboards can be packed.

Owner:ZHEJIANG DONGJIN TECH CO LTD

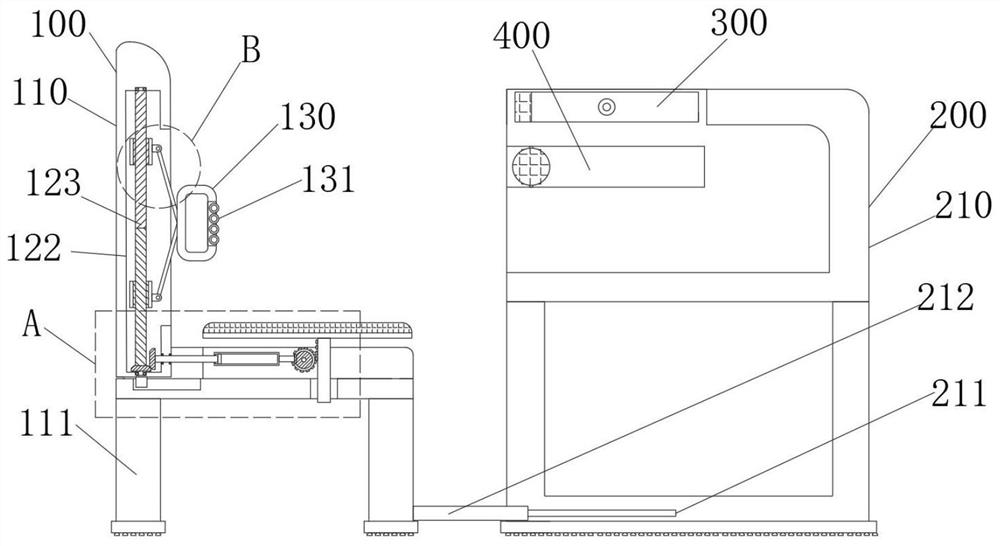

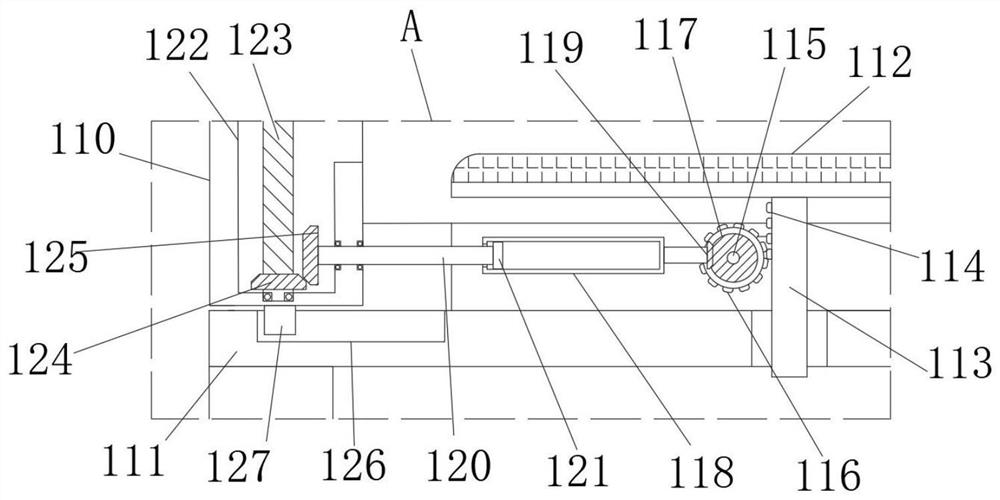

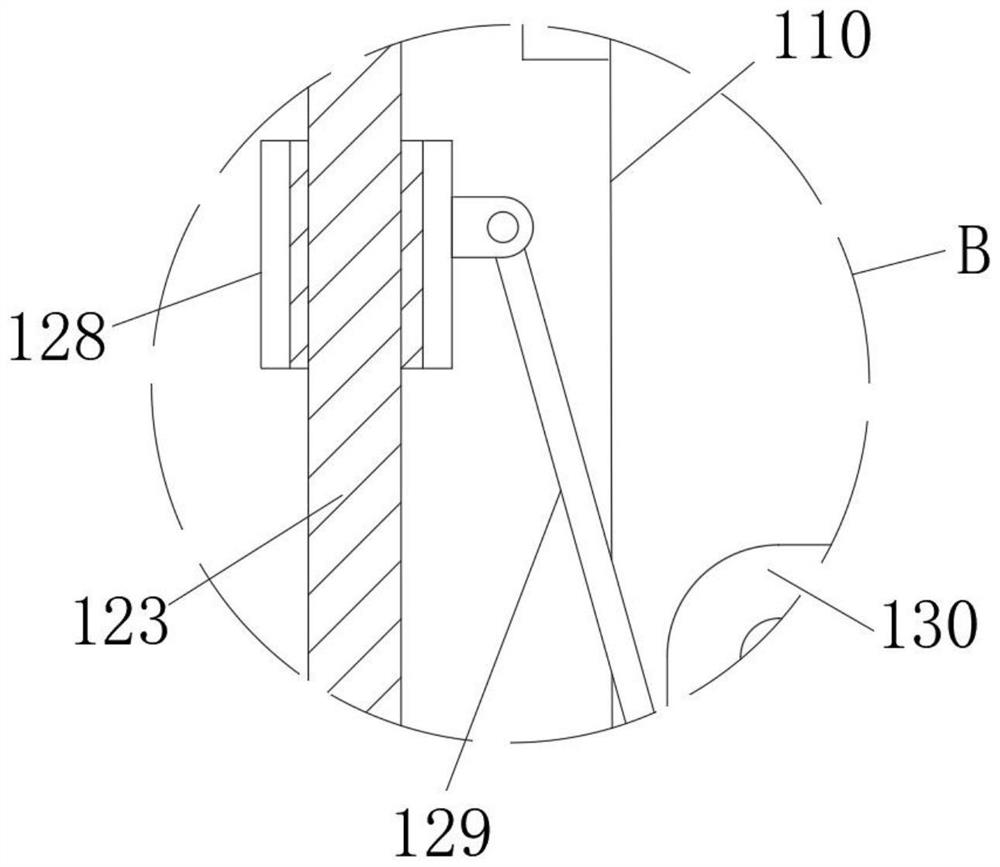

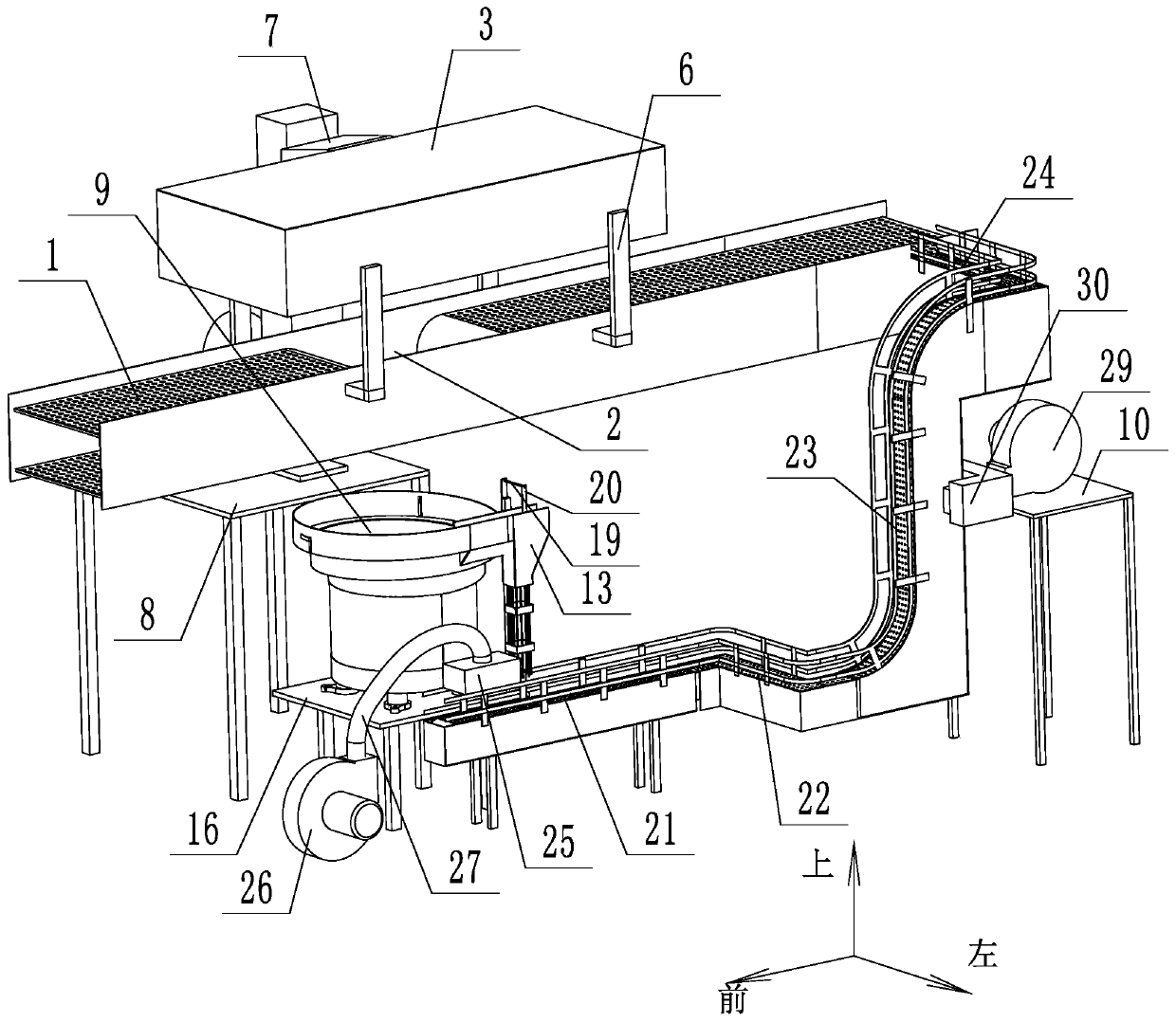

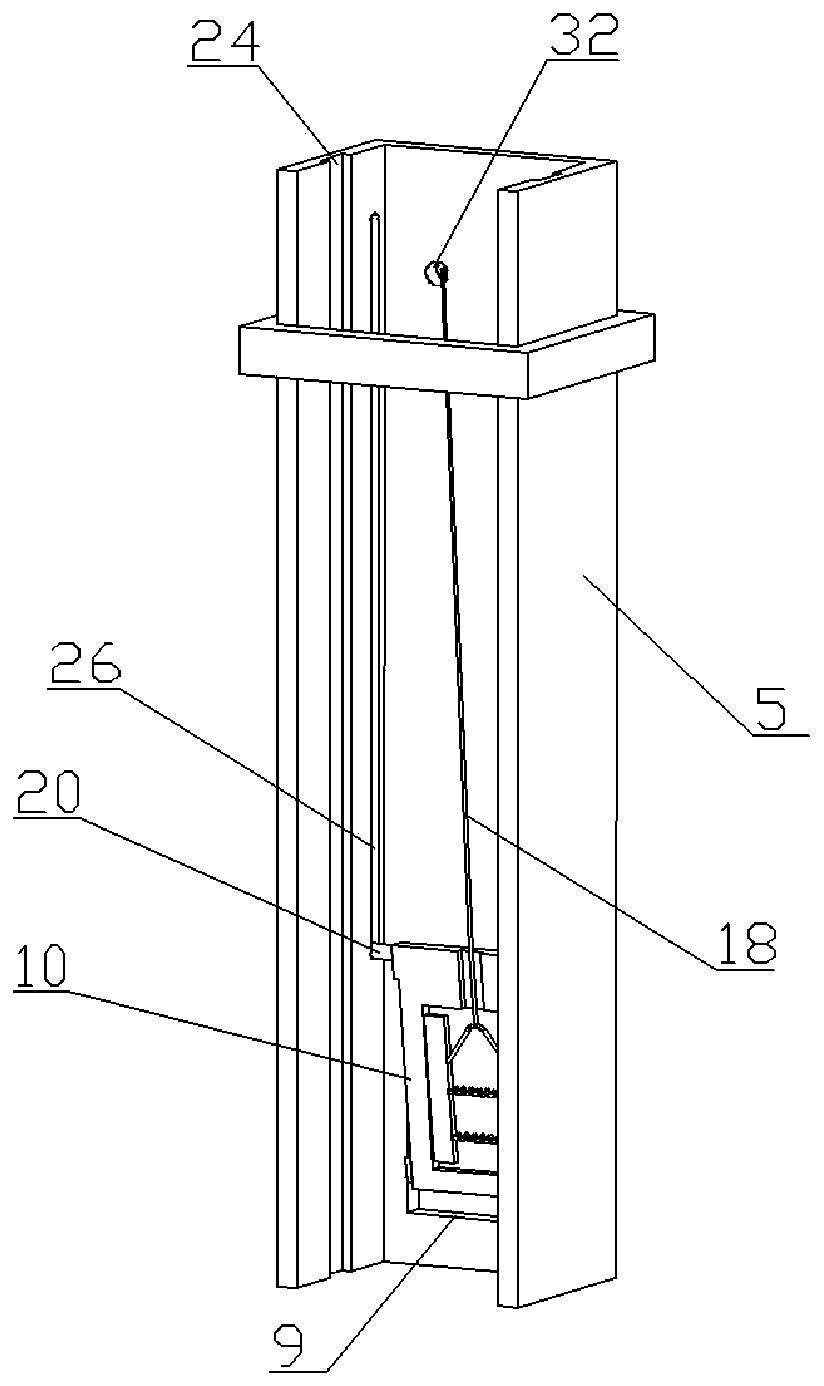

Fallen can automatic reset and transfer machine of zip-top can conveyor belt

ActiveCN110482196AHigh degree of automationGood practicalityConveyorsConveyor partsTransfer mechanismEngineering

The invention discloses a fallen can automatic reset and transfer machine of a zip-top can conveyor belt. The fallen can automatic reset and transfer machine comprises a first conveyor belt. An opening is formed in the first conveyor belt. A zip-top can discharge mechanism is arranged at the upper end of the opening. A zip-top can reset mechanism is arranged below the zip-top can discharge mechanism. A zip-top can transfer mechanism is arranged between the output end of the zip-top can reset mechanism and the conveyor belt. When zip-top cans pass through the zip-top can discharge mechanism, the fallen zip-top cans can drop down and are then corrected through the zip-top can reset mechanism, the corrected zip-top cans are then transferred to the first conveyor belt through the zip-top can transfer mechanism to continue to be conveyed, automatic collection, reset and transfer of the fallen cans are achieved, the automation degree is high, practicability is good, and the labor intensity is lowered.

Owner:济南联合制罐有限公司

Layered detection device for road subsidence

The invention discloses a layered detection device for road subsidence. The detection device includes a pair of support bodies, each supporting main body is provided with an extending part I used forfixing, the outer wall of each supporting main body is provided with a fixing ring, a detection main body used for subsidence detection is clamped in each fixing ring in a lifting mode, and each detection main body comprises a supporting arm I, a supporting arm II clamped on the inner side of the supporting arm I in a lifting mode and a supporting arm III clamped on the inner side of the supporting arm II in a lifting mode. The roadbed subsidence detection device has the following beneficial effects: real-time subsidence detection is carried out on roadbed supporting soil layers with differentdepths through the detection device, so that a road detection worker can discover a soil layer with a subsidence condition in time, the detection efficiency of road subsidence is improved, and the subsidence soil layer is convenient to fill and repair in time.

Owner:浙江义达建设管理有限公司

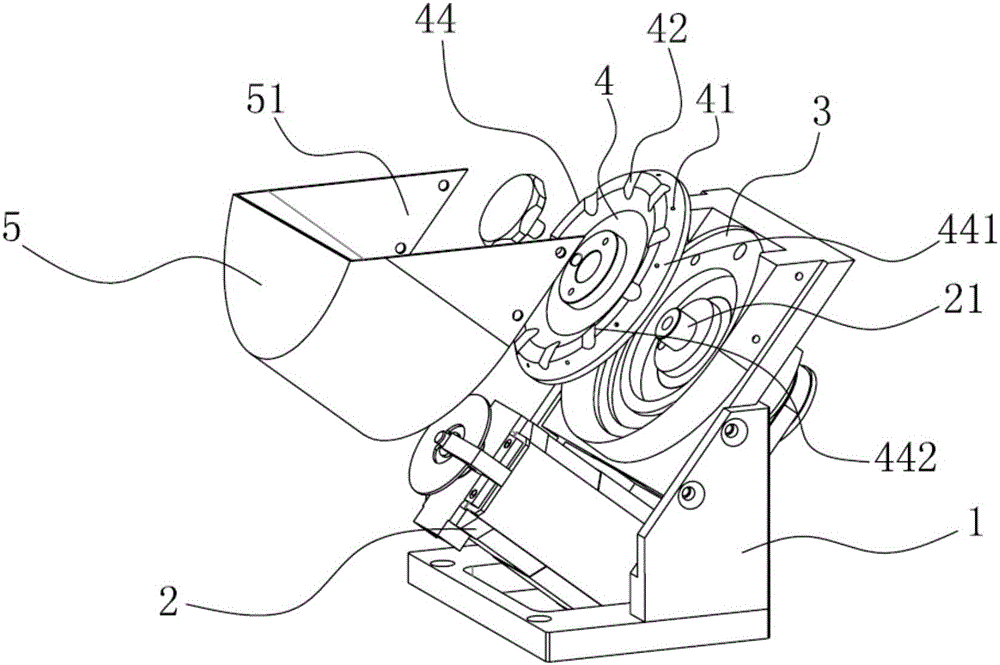

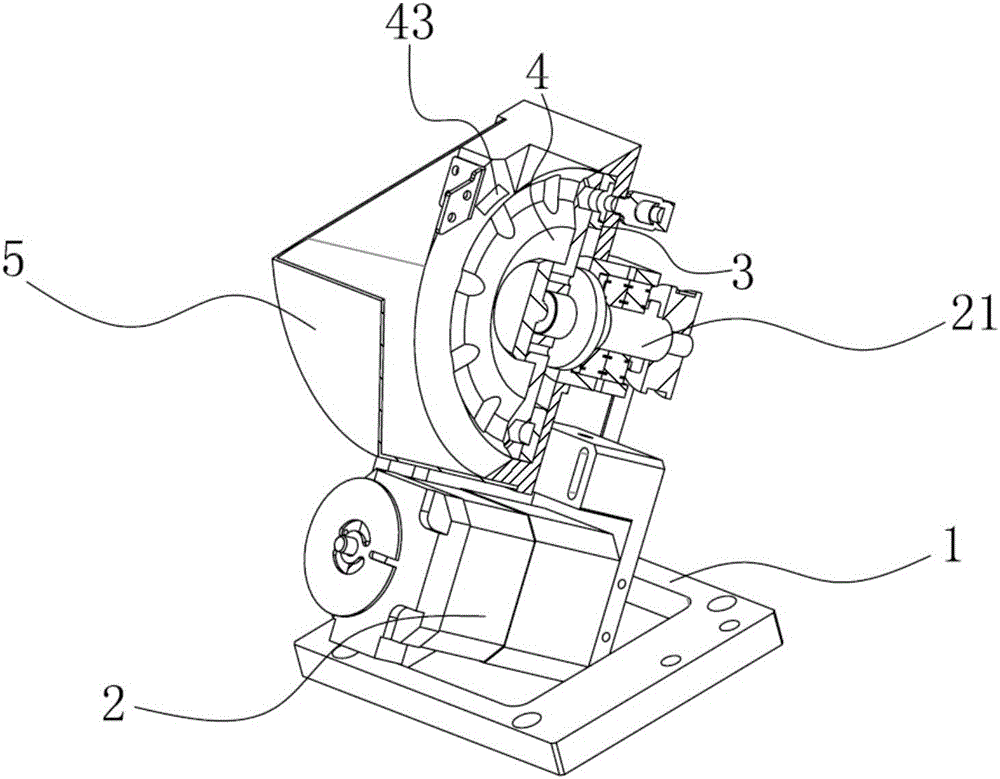

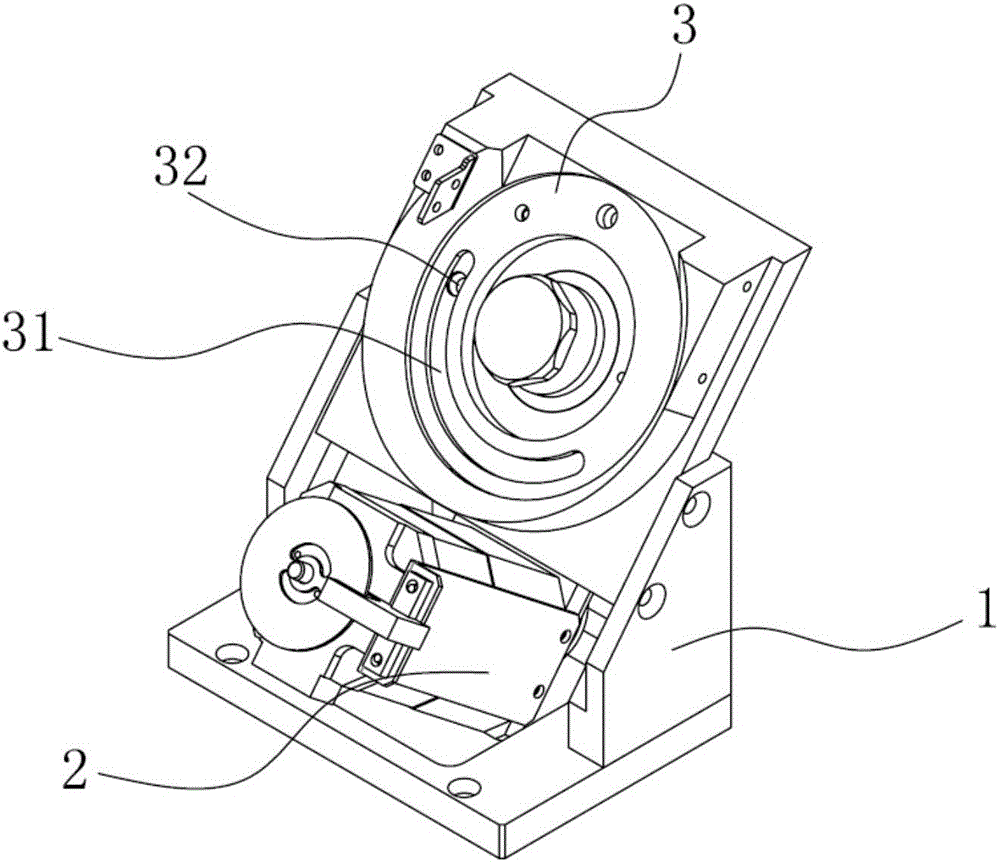

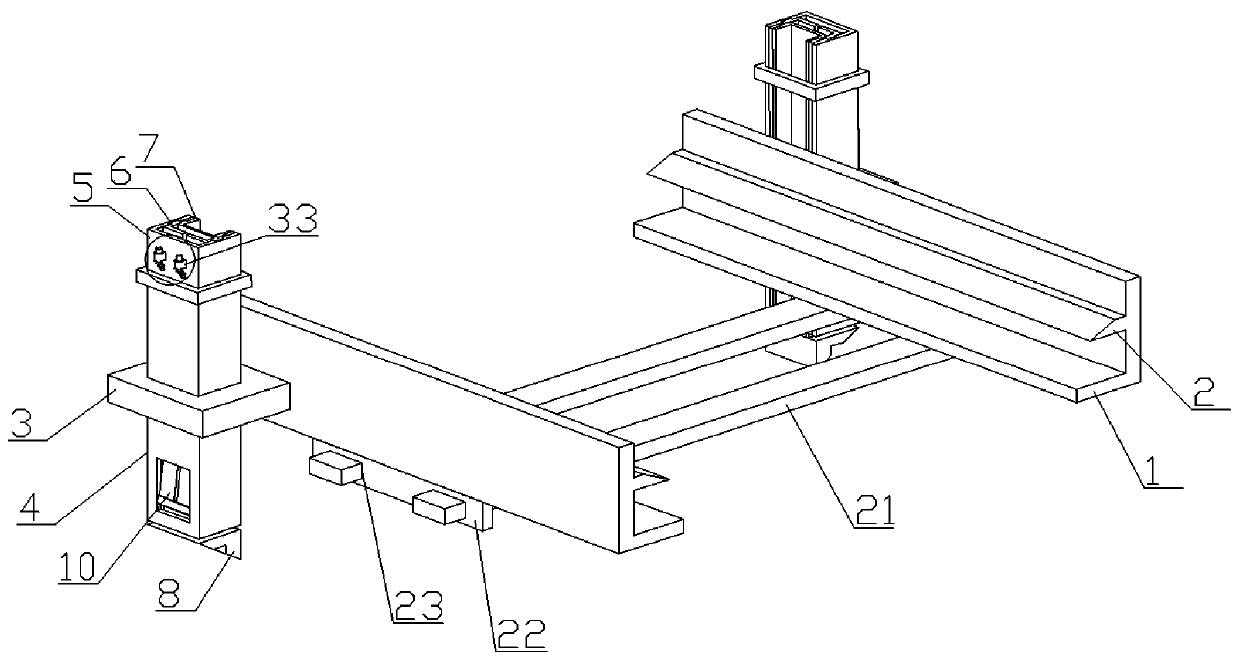

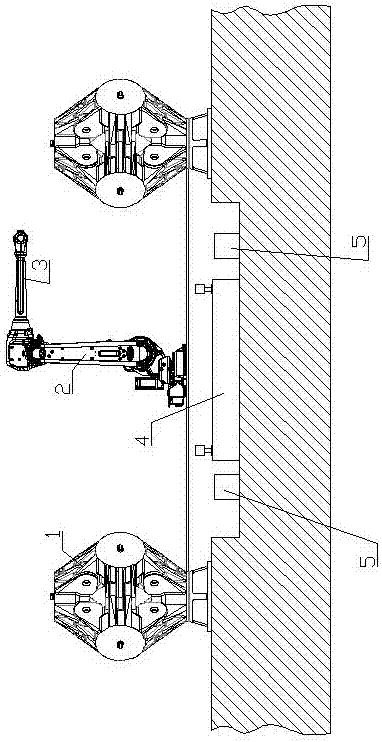

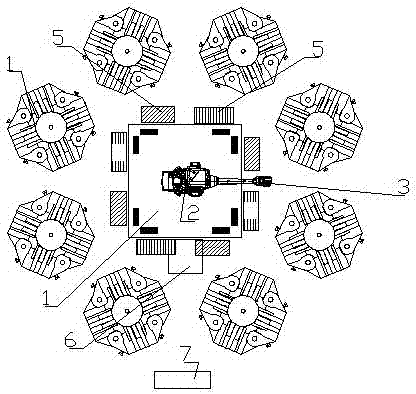

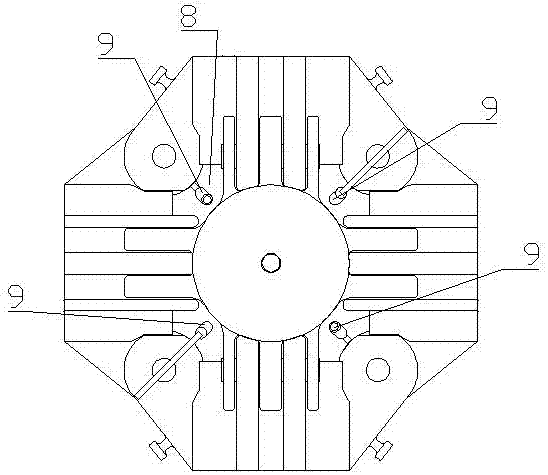

Automatic press system and method for artificial diamond production

PendingCN106902709ARealize automatic synthesisAchieve grippingUltra-high pressure processesShaping pressElectric controlManipulator

Provided are an automatic press system and method for artificial diamond production. The system includes an electric control cabinet, a robot and two or more circumferentially distributed presses; the robot includes a mechanical arm and a mechanical hand which is arranged on the mechanical arm, distances between the mechanical arm and the presses are equal, and the working diameter of the mechanical arm is greater than the distances between the mechanical arm and the presses; synthesis cavities and holding-up hammers which are arranged towards the synthesis cavities are arranged in the presses, placement openings for being communicated with the synthesis cavities are formed in the presses, and the placement openings of all the presses are all arranged towards the mechanical arm; a press working parameter collection unit and a processing unit are arranged in the electric control cabinet; the press working parameter collection unit is used for transmitting collected working parameters to the processing unit, and the processing unit separately outputs signals to control the operation of the presses, the mechanical hand, the mechanical arm and hydraulic assemblies; the hydraulic assemblies for providing hydraulic oil for the operation of the presses are arranged under the presses and the electric control cabinet. According to the method, the automatic synthesis of synthesized pieces is achieved, procedures are compact, and the quality of produced artificial diamonds is uniform.

Owner:ZHENGZHOU SINO CRYSTAL DIAMOND

Garlic conveying device and sowing machine

PendingCN110476555AIntegrity guaranteedPromote growthPotato plantersFurrow making/coveringEngineeringUltimate tensile strength

The invention discloses a garlic conveying device and a sowing machine. The garlic conveying device comprises a vertical section, an arc section and a horizontal section which are communicated with one another in sequence, wherein the vertical section comprises a conveying cylinder of which the cross section is oval, and a seed pressing block is cooperatively arranged in the conveying cylinder, cooperatively provided with a tension spring, and used for pushing garlic seeds in the conveying cylinder to the arc section under the effect of the tension spring; a seed putting port is formed in theend, close to the arc section, of the horizontal section, the arc section is cooperatively provided with a seed collecting claw, and the seed collecting claw is used for conveying the garlic seeds inthe conveying cylinder into the seed putting port. Through the arrangement of a pushing device, garlic can be planted in the way that bulbil faces upwards, and the backs have the same orientation. Theproblems in the prior art that garlic is manually planted with a squatting gesture, and therefore, the efficiency is low, and the work intensity is large are solved.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

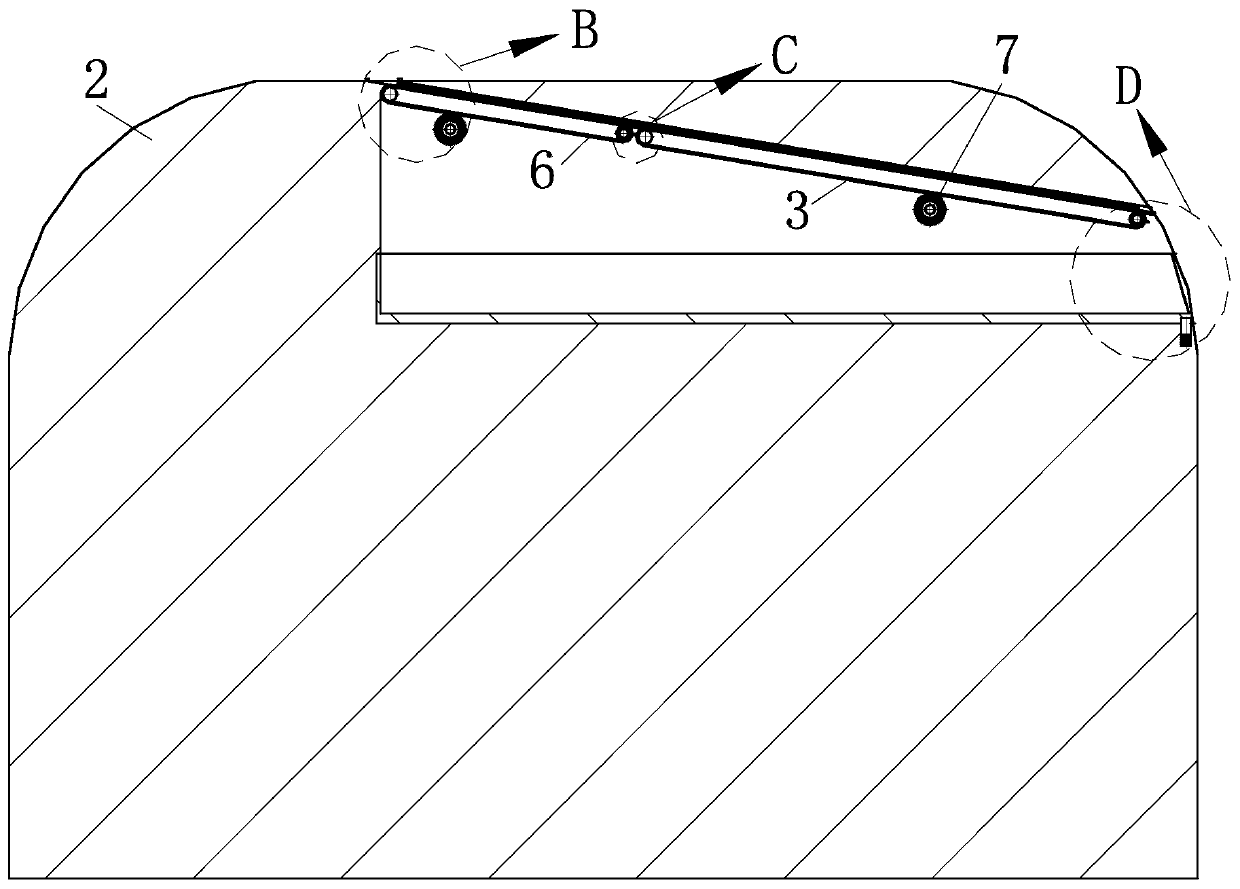

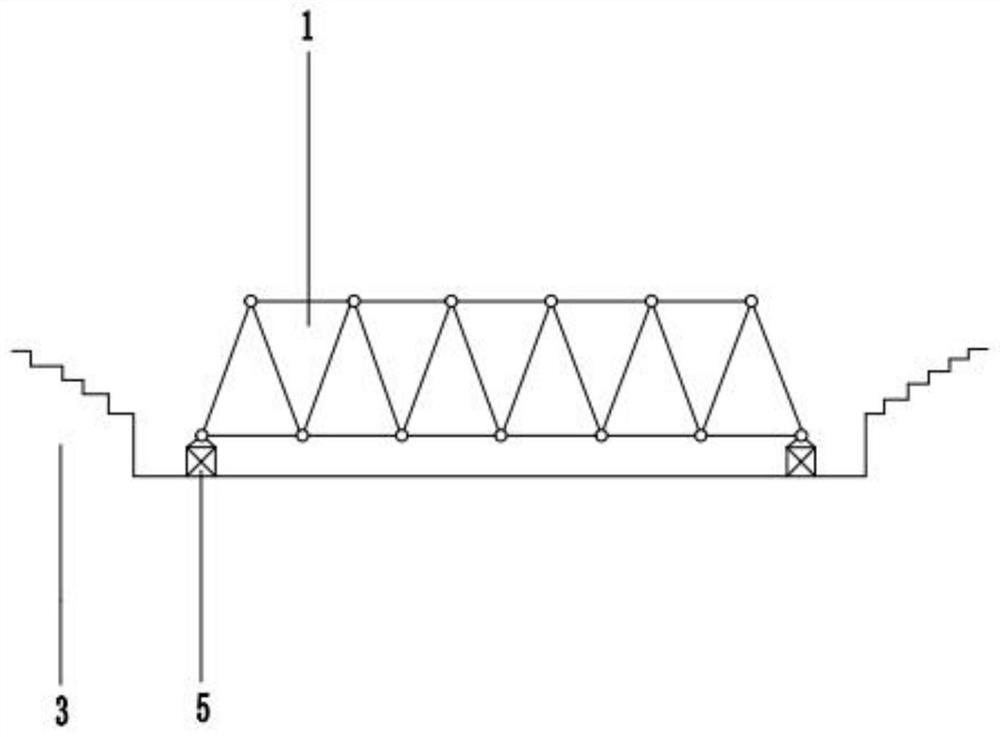

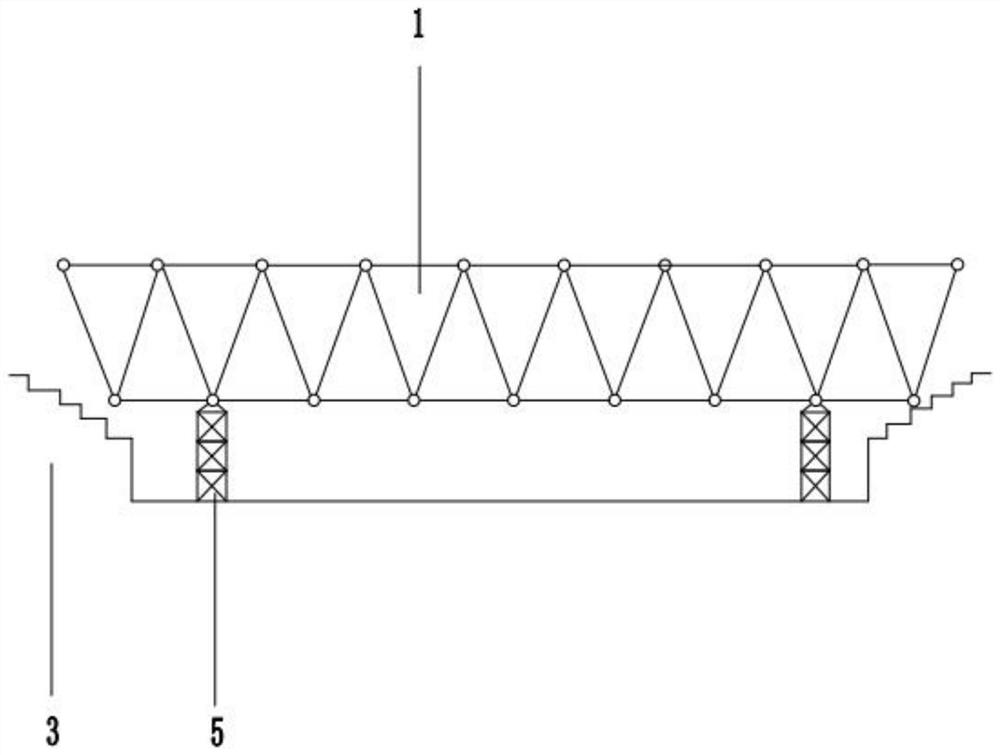

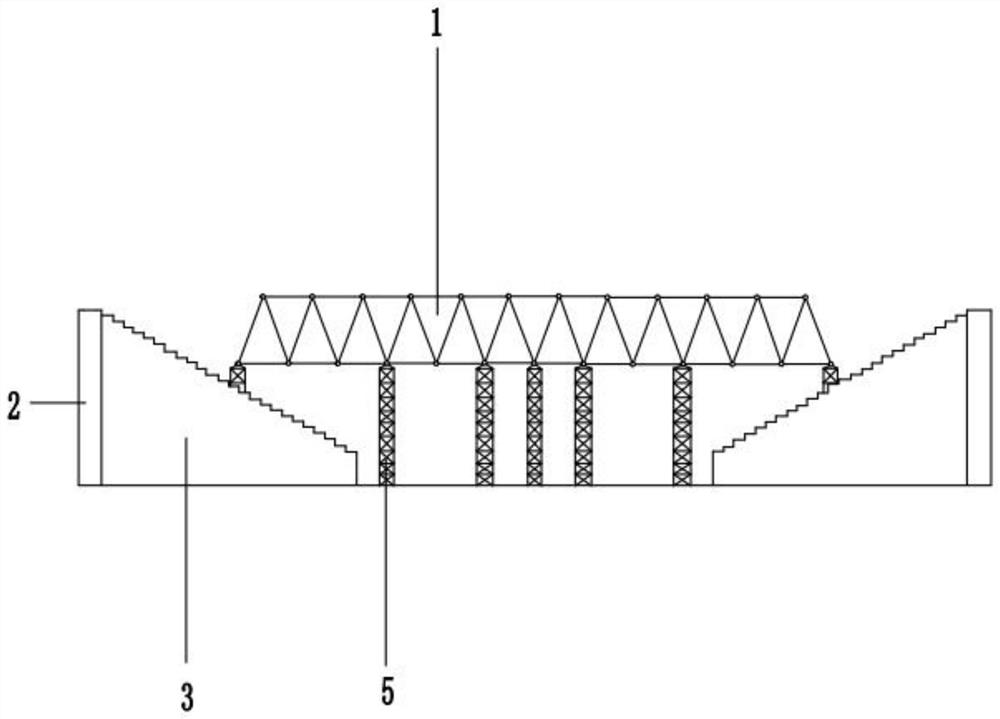

Stadium net rack construction method

PendingCN114164945AAchieve coverageResolution progressExtraordinary structuresBuilding material handlingArchitectural engineeringEngineering

Owner:中铁二十一局集团第二工程有限公司

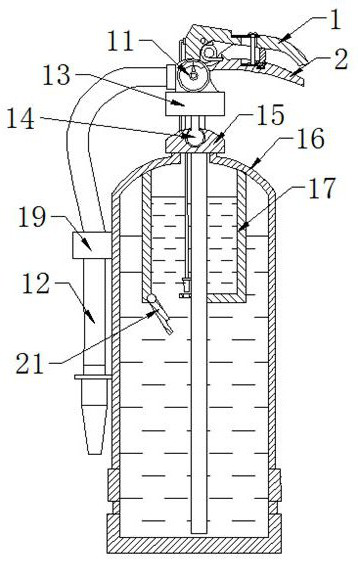

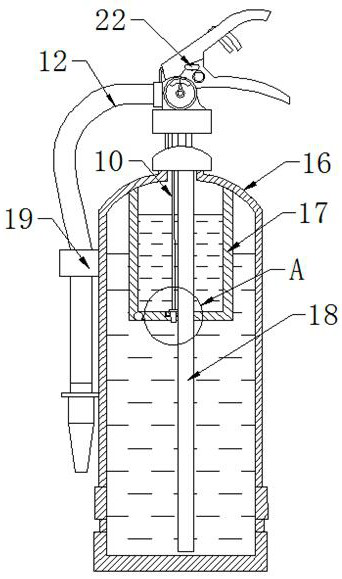

Pressure storage type portable air foam fire extinguisher

The invention relates to the technical field of fire extinguishers, and discloses a pressure storage type portable air foam fire extinguisher which comprises a pressing rod, a grip and a pressure tank. A rotating shaft is movably riveted to the joint of the pressing rod and the grip, the shaft wall of the rotating shaft is in cup joint with a torsion spring, one end of the torsion spring is fixedly connected to the inner side wall of the pressing rod, and the other end of the torsion spring is fixedly connected to the inner side wall of the grip. A first inserting rod is fixedly connected to the side wall of the lower end of the pressing rod, a first groove is formed in the upper end face of the pressing rod, a sliding rod is fixedly connected into the first groove, a sliding block is slidably connected to the rod wall of the sliding rod, and a rectangular hole is formed below the first groove. The lower end face of the sliding block is fixedly connected with a limiting rod, and the limiting rod is slidably connected to the side wall of the rectangular hole. The fire extinguisher can be kept in a vertical state all the time, the situation that the fire extinguisher cannot be used due to inclination is avoided, and more labor is saved during use.

Owner:陕西沅安科技发展有限公司

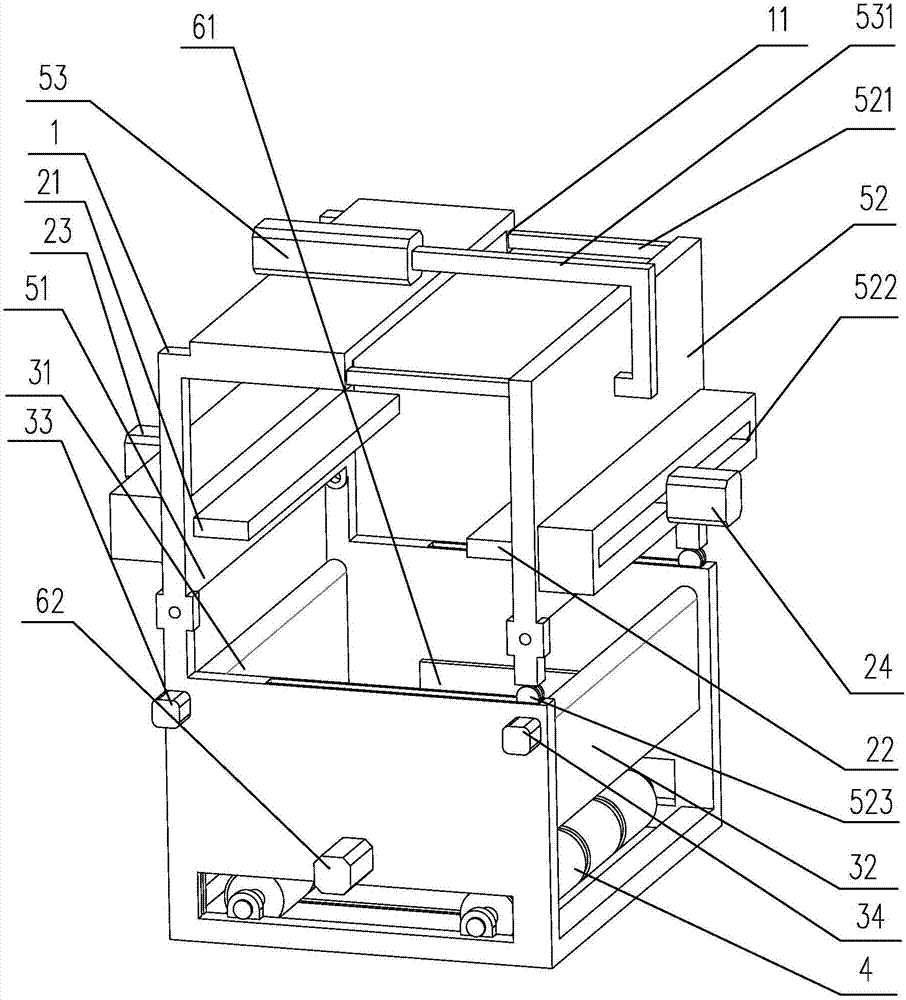

Environment-friendly liquid nitrogen container transportation and storage device

InactiveCN112660220AEasy to pullPrevent tiltingLifting framesHand carts with multiple axesLiquid nitrogen containerThermodynamics

The invention relates to the field of environment-friendly liquid nitrogen container transportation, in particular to an environment-friendly liquid nitrogen container transportation and storage device which comprises a dragging support, a transportation box, a pulling rod, a fixing plate, a fixing mechanism, a driving mechanism, a linkage mechanism, a lifting mechanism and universal wheels. The dragging support has a U-shaped structure. The universal wheels are fixedly connected with four corners of the lower end of the dragging support. And a transportation box is connected into the dragging bracket in a sliding manner. The driving mechanism drives the rotating rod to rotate to enable the pulling rod to rotate, so that the whole transportation box is pulled conveniently, and the driven gear and the driven rotating shaft of the lifting mechanism can be driven to rotate through transmission of the driving rotating shaft and the driving gear of the transmission mechanism, so that the transportation box can be located in the dragging support to ascend vertically. According to the environment-friendly liquid nitrogen container transportation and storage device, the situation that the liquid nitrogen tank inclines when the liquid nitrogen tank is pulled for transportation is effectively avoided, it can be guaranteed that the liquid nitrogen tank is kept upright in the transportation process, and therefore the transportation safety of the liquid nitrogen tank can be guaranteed.

Owner:张守虎

Mud scraping mechanism of radial-flow-type mud scraper

InactiveCN106139653AExtended service lifeAvoid standing uprightSettling tanks feed/dischargeArchitectural engineeringEngineering

The invention relates to a mud scraping mechanism of a radial-flow-type mud scraper. The mud scraping mechanism includes a work bridge, a scraping arm, a steel wire rope and a scarping plate. Two support lugs are arranged on the lower end of the work bridge. The upper end of the steel wire rope and the upper end of the scraping arm are respectively connected to the two support lugs on the lower end of the work bridge by means of pin shafts. The lower end of the steel wire rope is connected to the scraping arm. The scarping plate is fixedly connected to the lower end of the scraping arm through a fastener. The mud scraping mechanism has simple structure, low production cost and maintenance cost, can prolong the service life of the scarping plate and works stably. The scarping plate is totally lift up from the bottom of a tank, wherein a rubber board on the bottom of the scarping plate is not contacted with the cement bottom of the tank anymore and friction surface does not exist, so that the scarping plate is prolonged in service life and the maintenance cost is reduced. A roller pair of the scarping plate is avoided, so that production cost and difficulty are reduced at certain degree, and a problem or shutdown of the whole primary settlement tank or secondary settlement tank due to the problem of the roller pair is solved. The scraping arm is hoisted by the steel wire rope, so that the scarping plate can vertically stand on the bottom of the tank, and the distance between the scarping plate and the bottom of the tank can be adjusted at certain degree.

Owner:JIANGSU TIANHE WATER EQUIP

Anti-dumping retaining jiffy stand

InactiveCN102951225AGuaranteed uprightMake sure to tilt slightlyCycle standsMarine engineeringStructural engineering

The invention discloses an anti-dumping retaining jiffy stand which comprises two retaining structures with the same shape; the two retaining structures are arranged reversely and symmetrically; each retaining structure comprises a fixing device and retaining devices, wherein the retaining devices are arranged above the fixing device and two retaining devices are respectively arranged on two symmetric sides of the fixing device; one oblique end of each retaining device is open-ended and the other end of the retaining device is in a closed shape; each open end is arranged below the corresponding closed end; and each open end is provided with a bulge which is connected with the corresponding fixing device. The anti-dumping retaining jiffy stand has the beneficial effects that according to the anti-dumping retaining jiffy stand, an original jiffy stand is changed into a symmetric structure, and the left and right retaining structures can make sure that a vehicle is upright or slightly oblique after the wheels of a bicycle or an electric vehicle are arranged in the jiffy stand; and even if the number of vehicles is large, the orderly placement of the vehicles can be maintained.

Owner:无锡常安通用金属制品有限公司

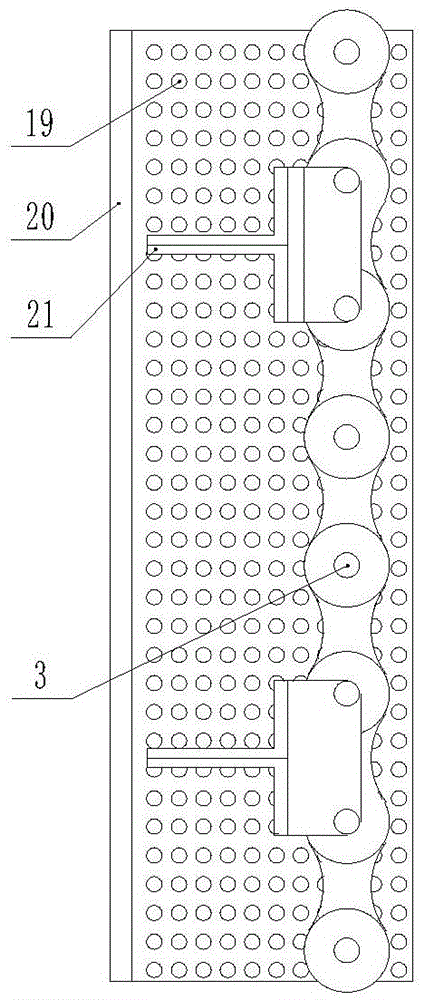

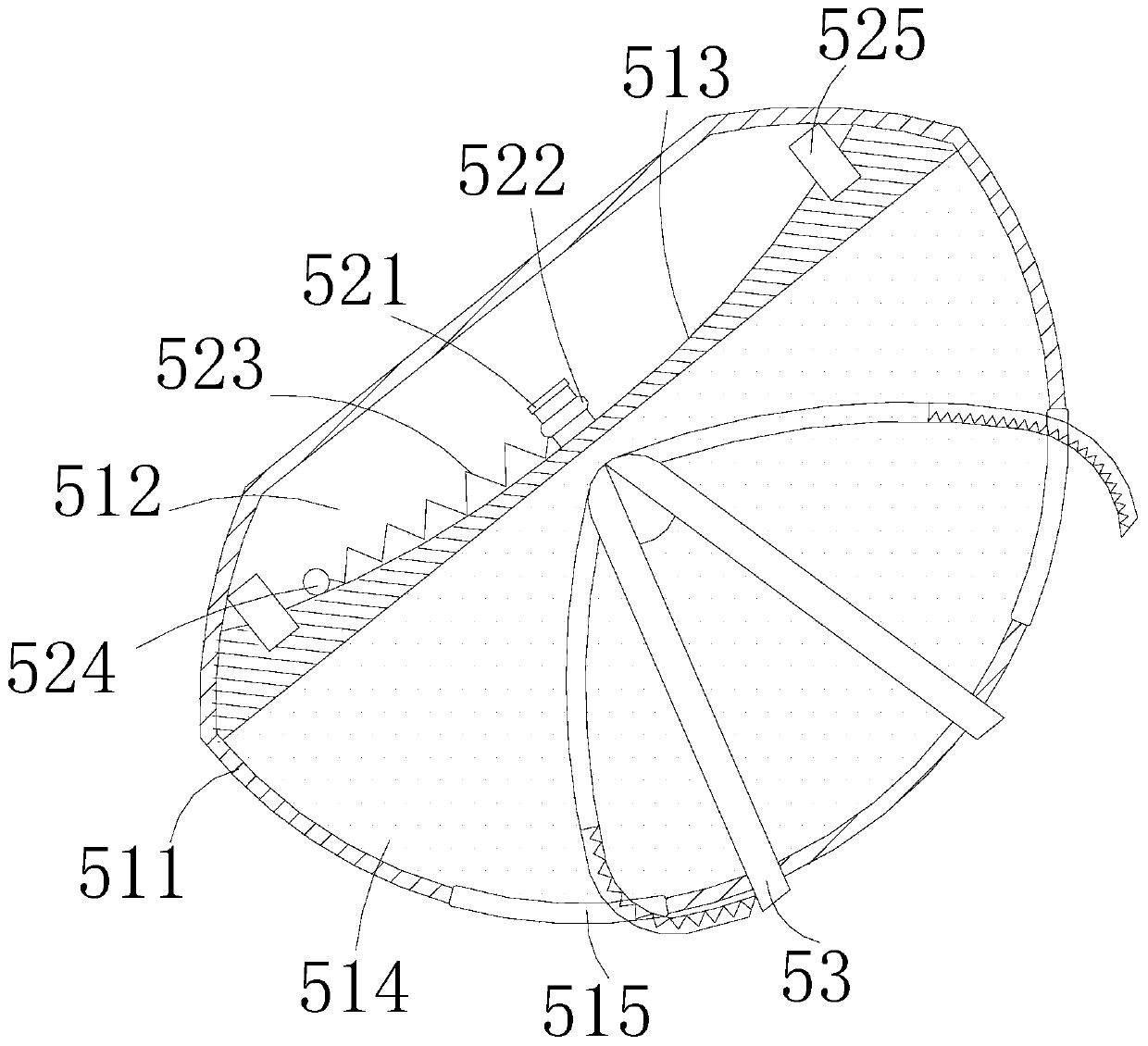

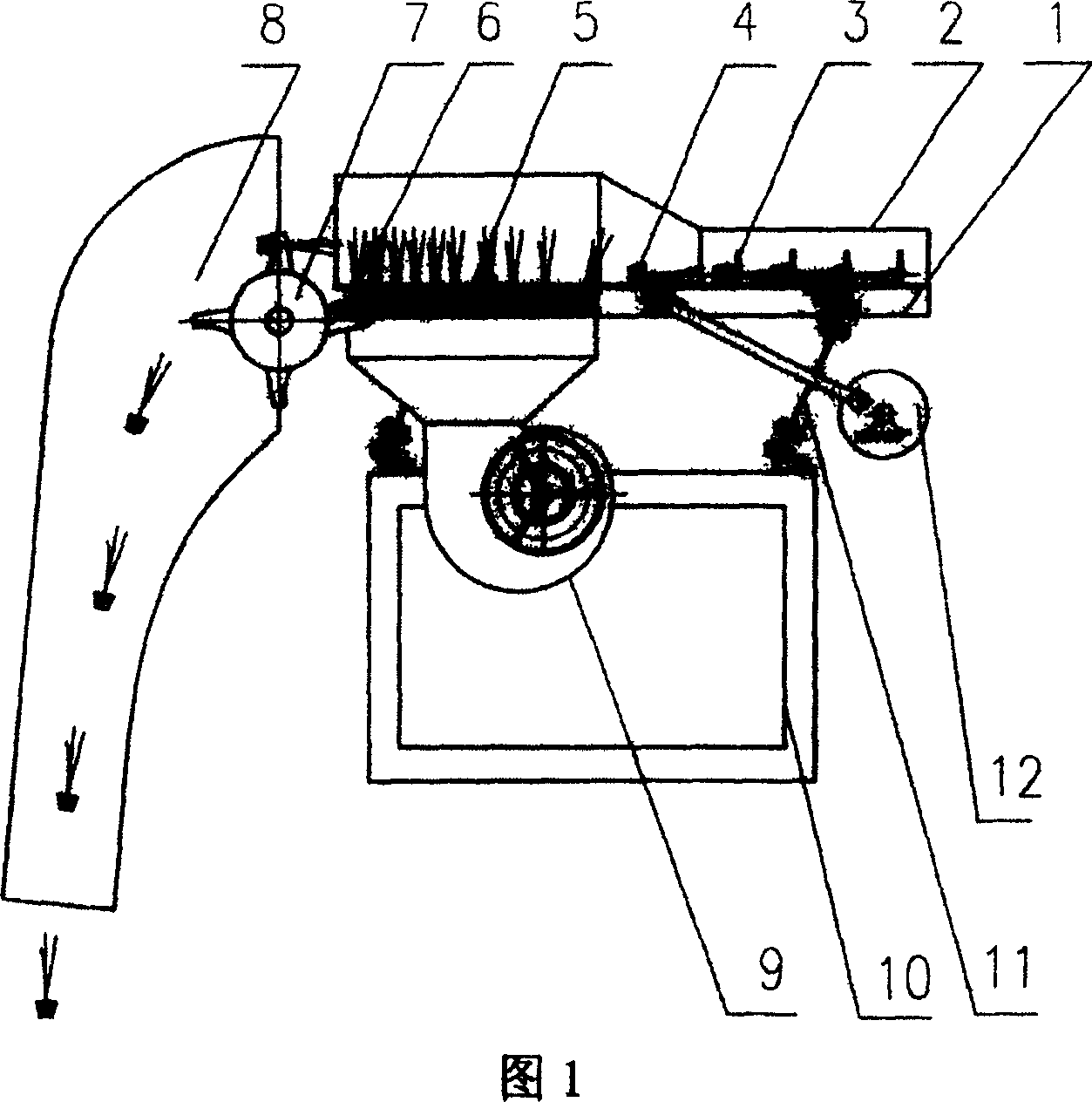

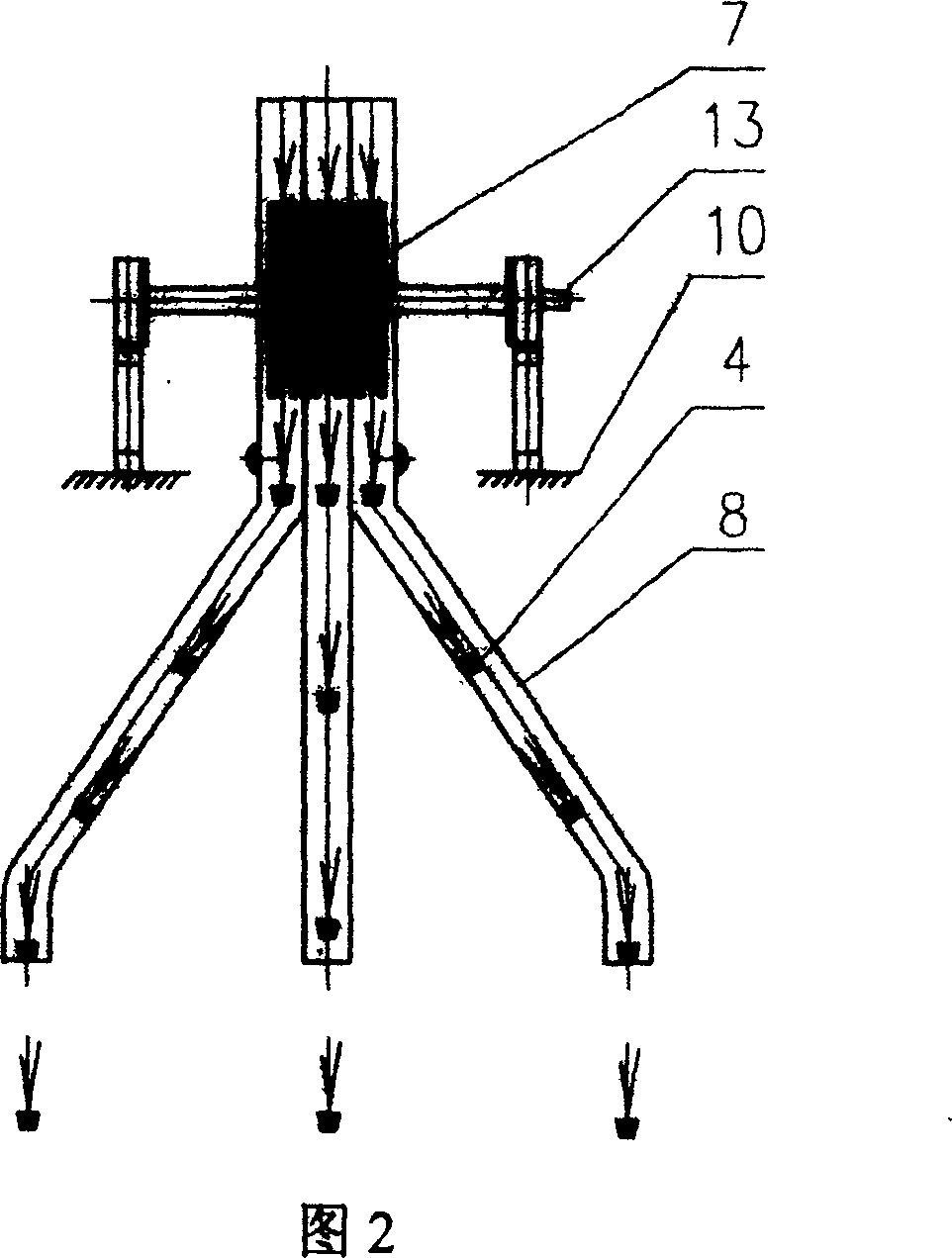

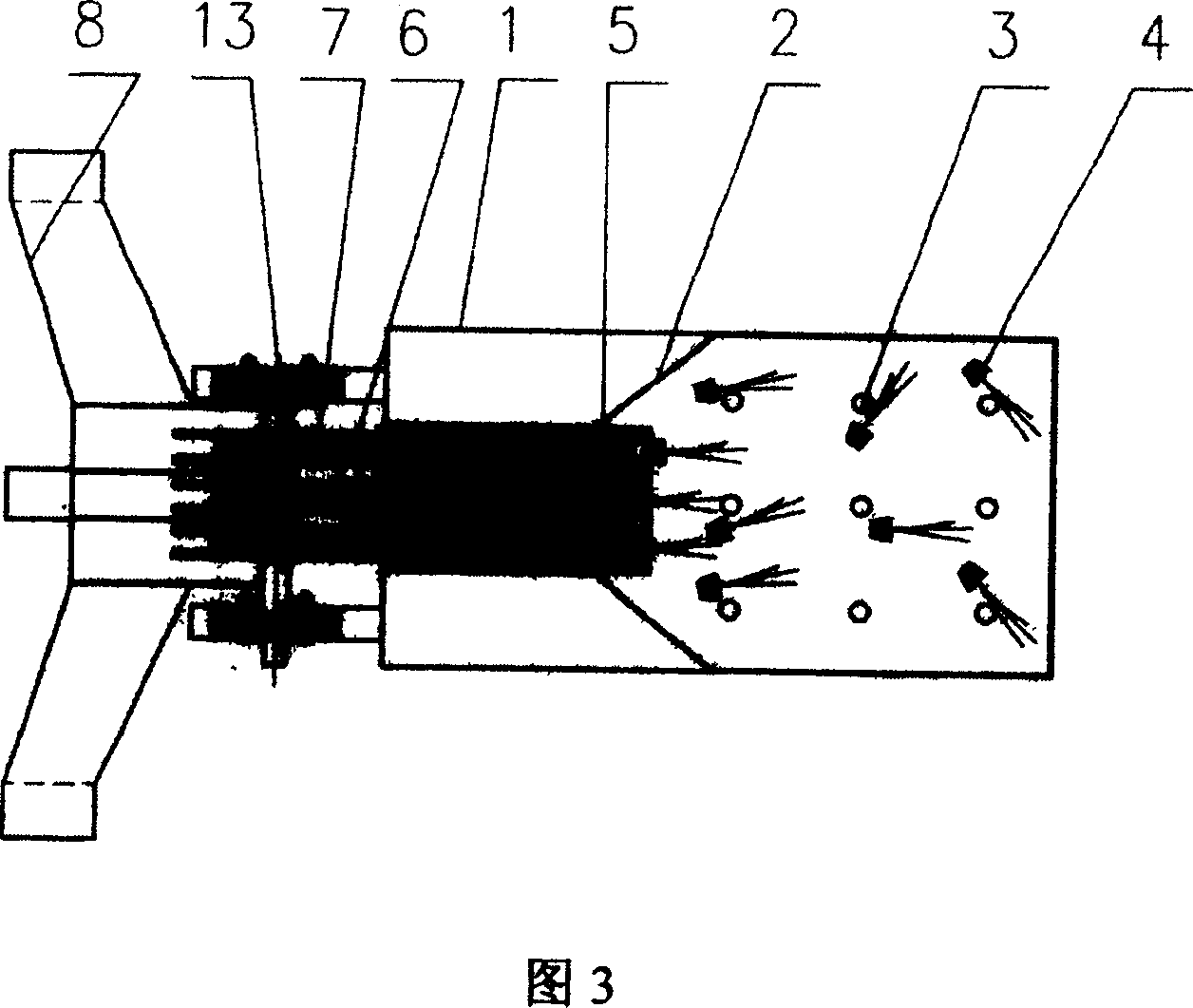

Airflow vibrating type ordered seedling throwing and separating mechanism

The invention discloses a pneumatic-vibratory device for ordered rice transplanting and separating, which comprises a vibrating-mechanism driving vibrating conveying board which is mounted in the frame by flat spring, the surface for potted seedling feeding of the vibrating conveying board having spike-tooth which can adjust the direction of potted seedling with the action of effective force, the side shield of the vibrating conveying board is wider in the initial part and then gradually becomes narrower, then followed by the leaf grating for the air flow passage and keeping the potted seedling upright, the lower part of the leaf grating is connected with air supply, the lateral section is groove which is similar to the spotted seedling stoup in the shape, blocks are equipped in each exit of the groove, the front end of the block is equipped with seedling-shifting wheel whose number equals to the groove and is driven by shifting wheel axle, each connected with introductory pipe in the front of the seedling-shifting wheel. The device combines the vibrating conveying with air flow, the vibration can make the spotted seedling moving on the vibrating board, while the air flow cam keep the spotted seedling upright, which can realize automatic ordering, and can grow seedling with seedling tray used in traditional artificial rice transplanting.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com