Sample frame

A sample rack and carrier technology, applied in the field of sample racks, can solve the problems of increasing the risk of infection of experimental personnel, affecting the sampling of sampling needles, and limited space for fully automatic inspection equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

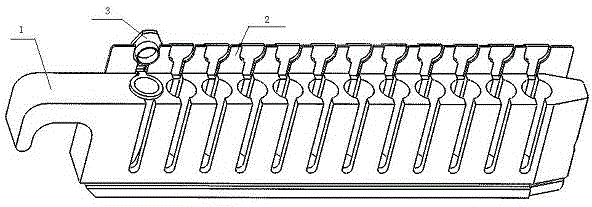

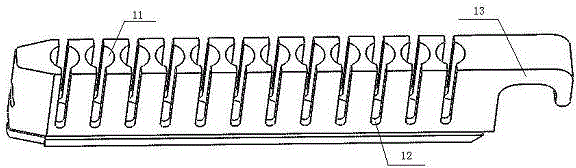

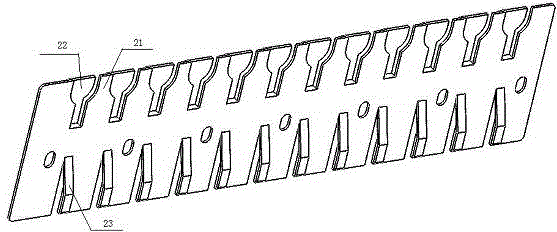

[0018] Such as Figure 1-Figure 4 As shown, the sample rack includes a carrier body 1 and a baffle plate 2, which are connected by screws and have a simple structure. The main body 1 of the carrier is provided with a round hole 11 for placing test tubes. Both sides of the round hole 11 are provided with strip-shaped slots 12. One end of the main body 1 of the carrier is provided with a handle 13 for easy access. The lower end of the baffle plate 2 is provided with a shrapnel 23, and the upper end baffle includes two parts, the front baffle 21 and the rear baffle 22. The front baffle 21 is provided with a semicircular hole consistent with the shape of the sealing cover of the centrifuge tube, and the rear baffle 22 is vertical to the rear. Stand upright after bending, the distance between the front blocking piece 21 and the rear blocking piece 22 is just the thickness of the edge of the sealing cover.

[0019] Specifically, the diameter of the round hole on the main body 1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com