Mud scraping mechanism of radial-flow-type mud scraper

A mud scraper and radial flow technology, applied in the field of mud scraper mechanism of radial flow mud scraper, can solve the problems of sewage treatment process, negative impact of sewage treatment plant, instability of sludge output from secondary sedimentation tank, etc., to reduce The effect of production cost and difficulty, simple structure and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

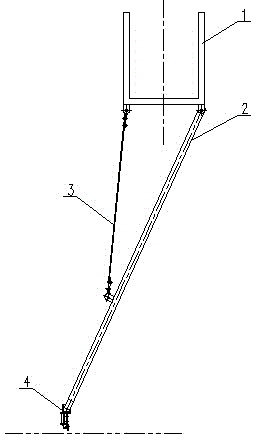

[0010] The mud scraping mechanism of the radial flow mud scraper, the mud scraping mechanism includes a working bridge 1, a scraping arm 2, a steel wire rope 3 and a scraper 4, the lower end of the working bridge 1 is provided with two lugs, and the steel wire rope 3 The upper end of the scraper arm 2 and the upper end of the scraper arm 2 are respectively connected to the two lugs at the lower end of the working bridge 1 through pin shafts, the lower end of the steel wire rope 3 is connected to the scraper arm 2, and the scraper 4 is fixedly connected by fasteners At the lower end of the scraping arm 2, one end of the working bridge 1 is installed on the central support, and the other end is installed on the traveling end beam. The traveling end beam walks around the pool, and the working bridge rotates around the central support. The working bridge 1 It is a full-bridge or half-bridge type, and the scraper 4 is arranged in a logarithmic helix, and 1-3 pieces are arranged at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com