Non-electroslag remelting type clean metal ingot mould

一种金属锭、重熔的技术,应用在金属加工设备、铸锭车间、铸造熔融物容器等方向,能够解决提高成本、结晶器伤害、污染环境等问题,达到生产效率提高、节约能源、成本下降的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

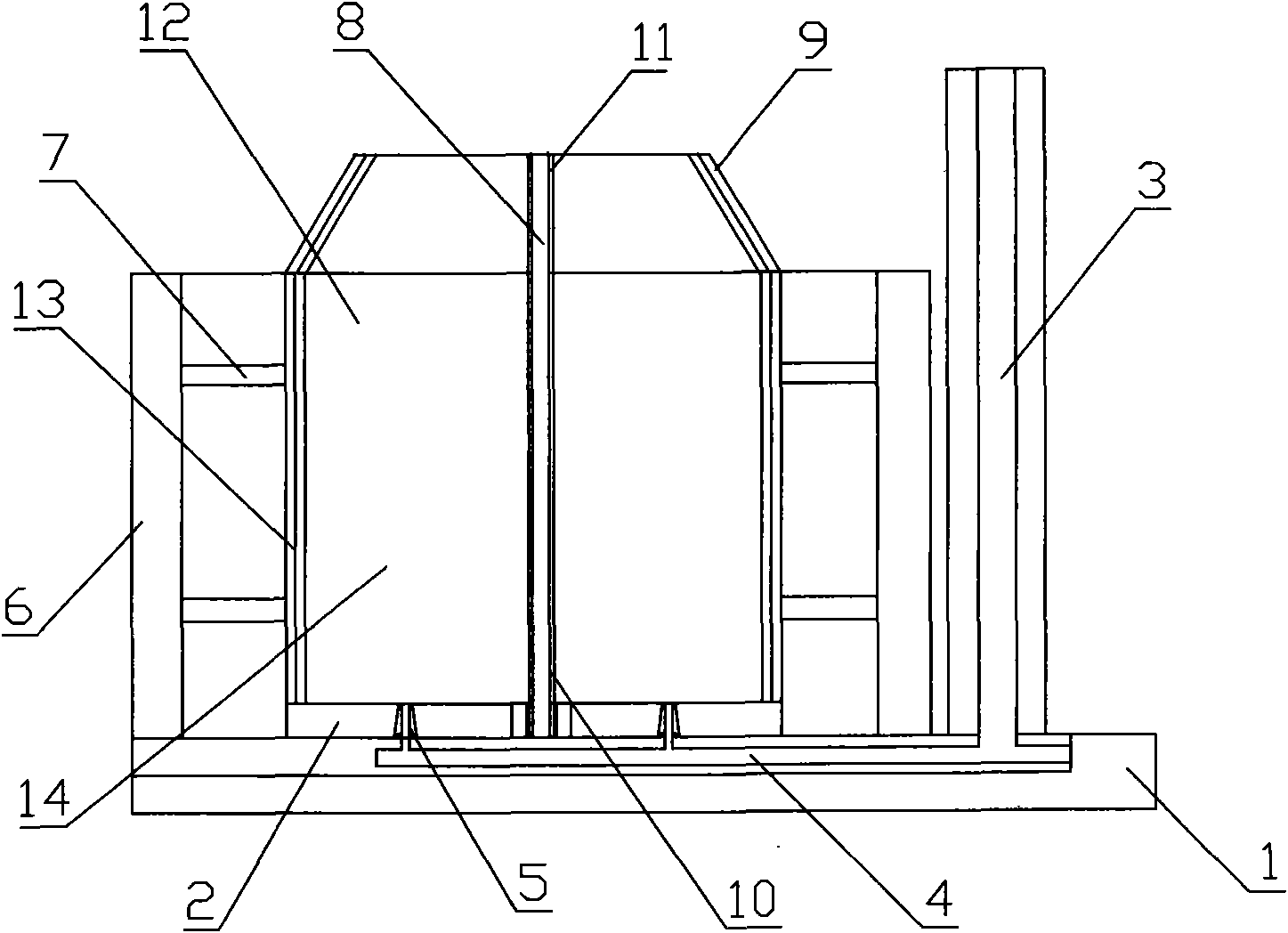

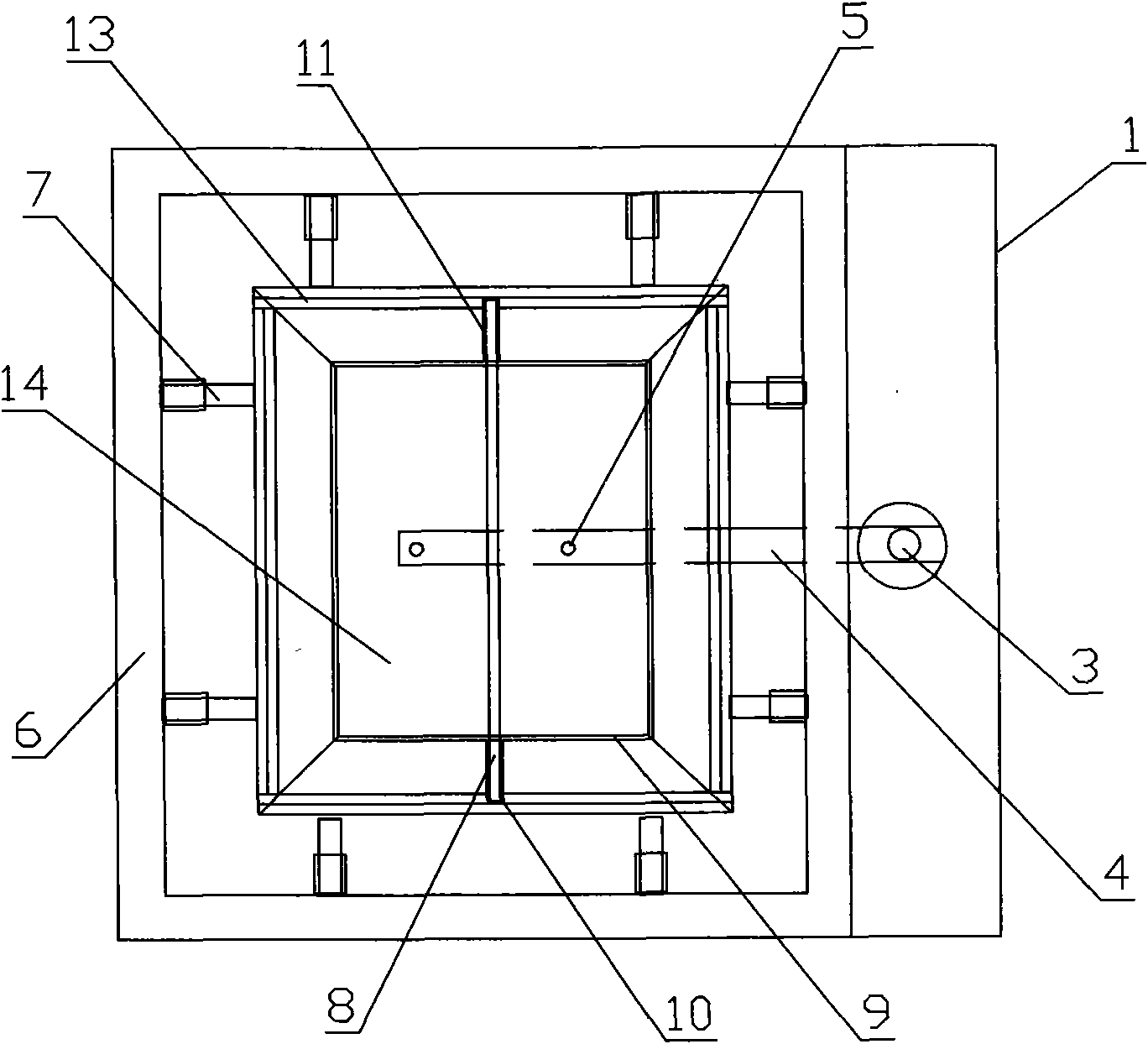

[0029] Such as figure 1 , figure 2 Shown: a non-electroslag remelting type clean metal ingot mold, set on the platen 1, including the ingot mold body 13 composed of ordinary templates and the heat preservation cap 9 arranged on the ingot mold body 13, the ingot mold The main body 13 is provided with a casting system, and the ingot mold body 13 is vertically provided with an isolation heating and heat preservation mechanism 8, and the isolation heating and heat preservation mechanism 8 divides the space inside the ingot mold body 13 into two independent cavity units 14. The mold cavity units 14 are distributed in two rows in the ingot mold body 13 . The ingot mold body 13 is composed of four vertical templates and a bottom template 2, and the vertical template is movably connected with the frame 6 arranged outside the ingot mold body 13 through a hydraulic mechanism 7 or a screw nut. The isolated heat preservation mechanism 8 is a high temperature resistant plate.

[0030] ...

Embodiment 2

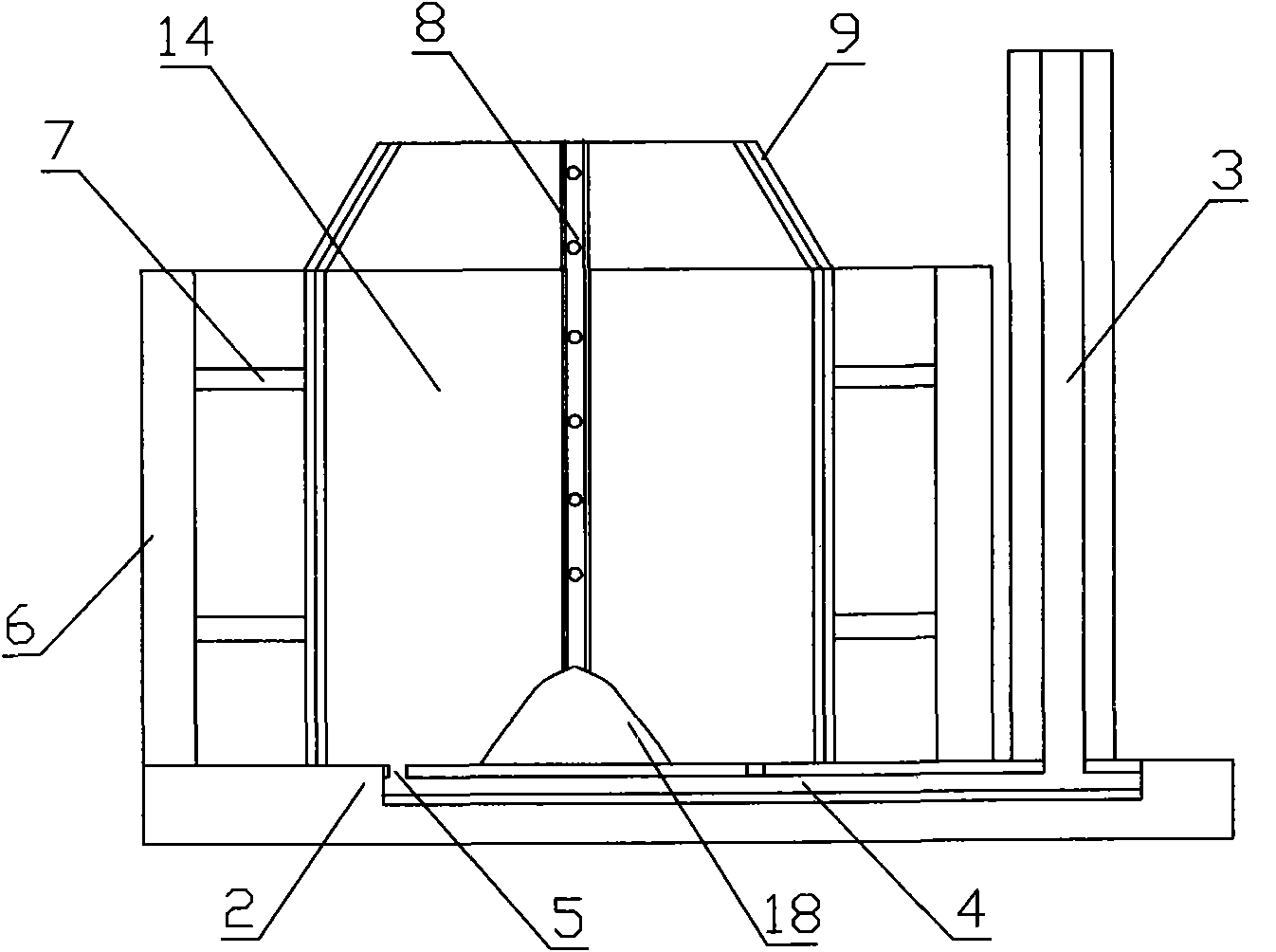

[0032] Such as image 3 Shown: a non-electroslag remelting type clean metal ingot mold, including an ingot mold body 13 composed of water-cooled templates and an insulation cap 9 arranged on the ingot mold body 13, and a casting system is arranged on the ingot mold body 13, The ingot mold body 13 is vertically provided with an isolated heating and heat preservation mechanism 8, which includes a high temperature resistant plate and a strong heating component arranged inside the high temperature resistant plate, such as a voltage heating component or a gas heating component. The isolation, heating and heat preservation mechanism 8 divides the space inside the ingot mold body 13 into two independent cavity units 14 , and the cavity units 14 are distributed in two rows in the ingot mold body 13 . The ingot mold body 13 is composed of four vertical water-cooled templates and a water-cooled bottom template 2, and the vertical water-cooled template is movably connected with the frame...

Embodiment 3

[0035] Such as Figure 4Shown: a non-electroslag remelting type clean metal ingot mold, set on the platen 1, including the ingot mold body 13 composed of water-cooled formwork and the heat preservation cap 9 arranged on the ingot mold body 13, the ingot mold The main body 13 is provided with a casting system, and the ingot mold body 13 is vertically provided with an isolation heating and heat preservation mechanism 8, and the isolation heating and heat preservation mechanism 8 includes a high temperature resistant plate and a strong heating component arranged inside the high temperature resistant plate, such as a voltage heating component Or gas heating components. The two horizontally and vertically intersecting isolated heating and heat preservation mechanisms 8 divide the inner space of the ingot mold body 13 into four independent cavity units 14 , and the cavity units 14 are distributed in two rows in the ingot mold body 13 . The ingot mold body 13 is composed of four ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com