Barreled water placement equipment

A technology for bottled water and equipment, which is applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of bottled water that consumes physical strength, is difficult to place, and that the bottled water falls and hurts people. Improper placement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

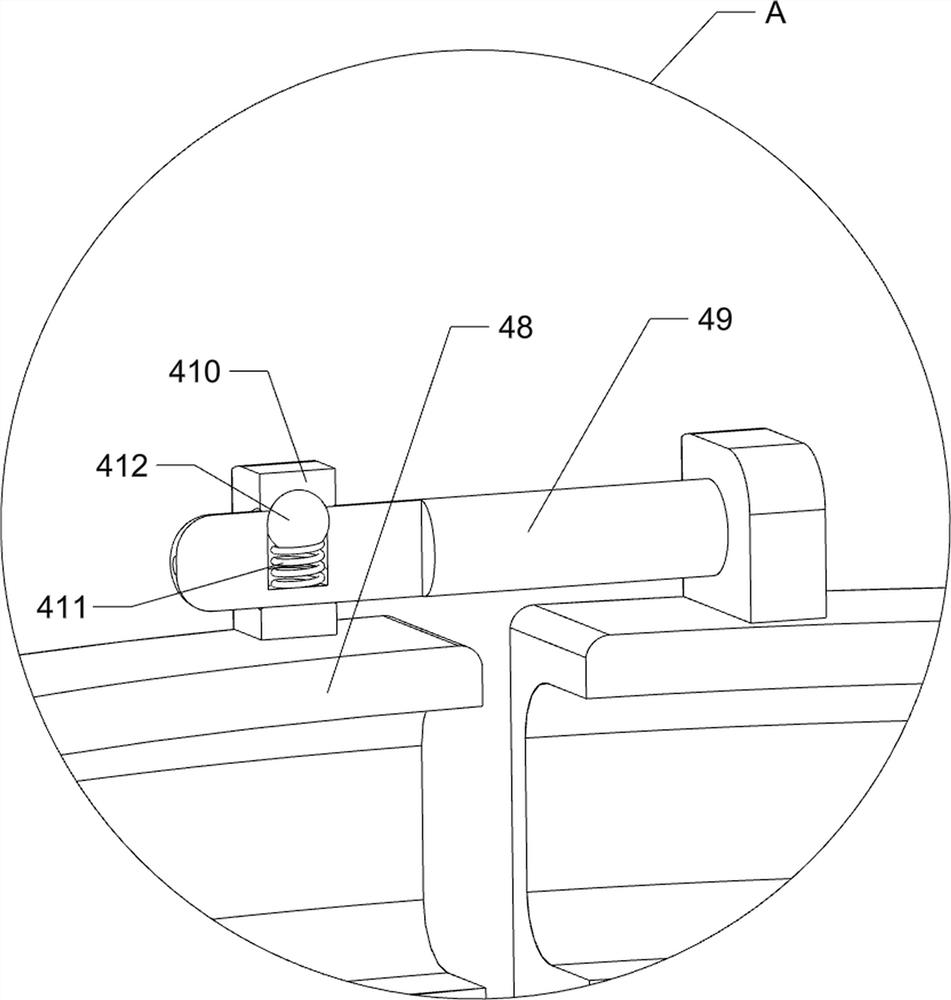

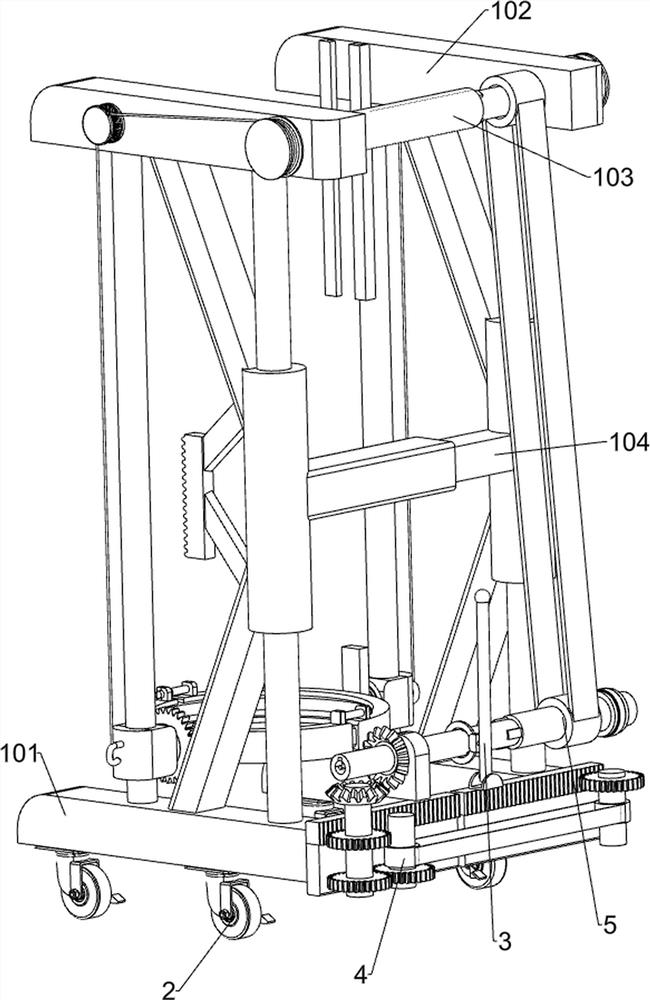

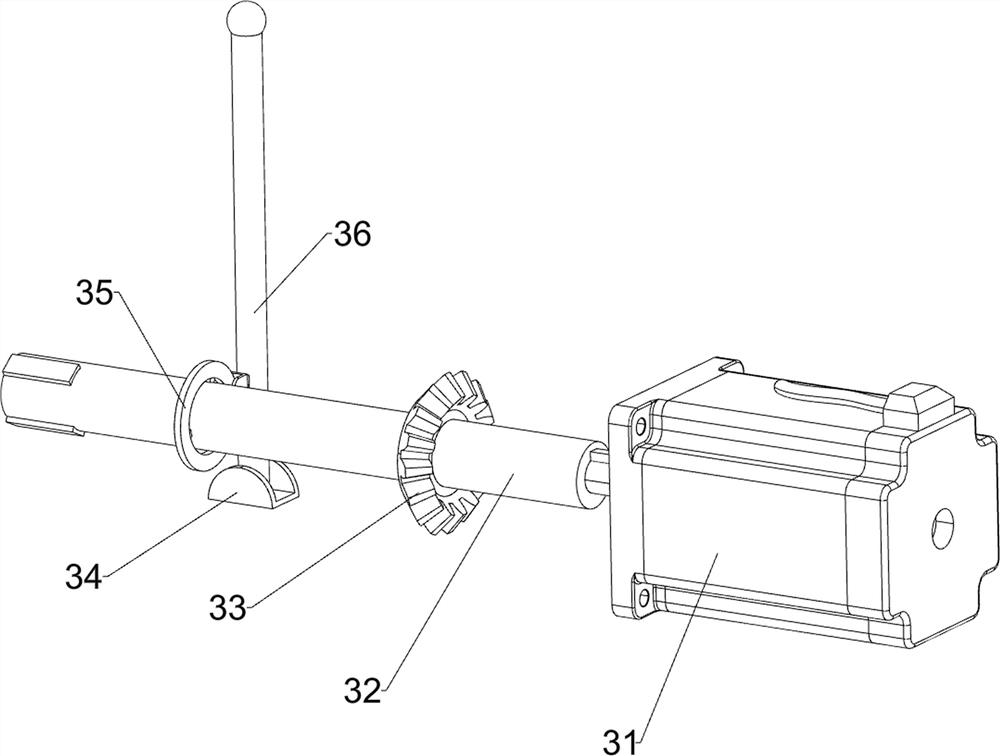

[0028]A device for storing bottled water, such asFigure 1 to Figure 7As shown, it includes a mounting frame 1, a right bracket 101, a left bracket 102, a round telescopic rod 103, a square telescopic rod 104, wheels 2, a power assembly 3, a clamping assembly 4, a lifting assembly 5 and a rotating assembly 6, and the mounting frame 1 is slidably mounted on the right front side of the right bracket 101, the left front side of the mounting frame 1 is slidably mounted on the left bracket 102, the upper side of the right bracket 101 and the upper side of the left bracket 102 are rotatably connected with a circle A rectangular telescopic rod 103, a square telescopic rod 104 is connected between the middle of the right bracket 101 and the middle of the left bracket 102, the front and rear sides of the lower part of the right bracket 101 and the left bracket 102, and the lower left and right sides of the mounting frame 1 are all rotatable There are wheels 2, a power assembly 3 is installed ...

Embodiment 2

[0039]On the basis of Example 1, such asfigure 1 withFigure 8 As shown, the guide assembly 7 is also included. The guide assembly 7 includes a guide rail 71 and a slider 72. The upper right side of the left bracket 102 is fixedly connected to the guide rail 71 by screws, and the left side of the left arc ring 48 is connected to the slider 72. The slider 72 cooperates with the guide rail 71.

[0040]When the arc ring 48 rotates with the bottled water to make the bottled water stand upside down, the arc ring 48 continues to move upwards, and the slider 72 will contact the guide rail 71 to ensure that the bottled water stands upside down perpendicular to the ground, preventing the barrel The offset of the water filling leads to inaccurate placement and damage to the water dispenser.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com