Ceramic green body injection molding machine and molding method thereof

A technology of injection molding machine and ceramic body, applied in ceramic molding machines, auxiliary molding equipment, molds, etc., can solve problems such as production efficiency and product cost not achieving ideal results, product damage, etc., and achieve ingenious structural design and high efficiency. , the effect of fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

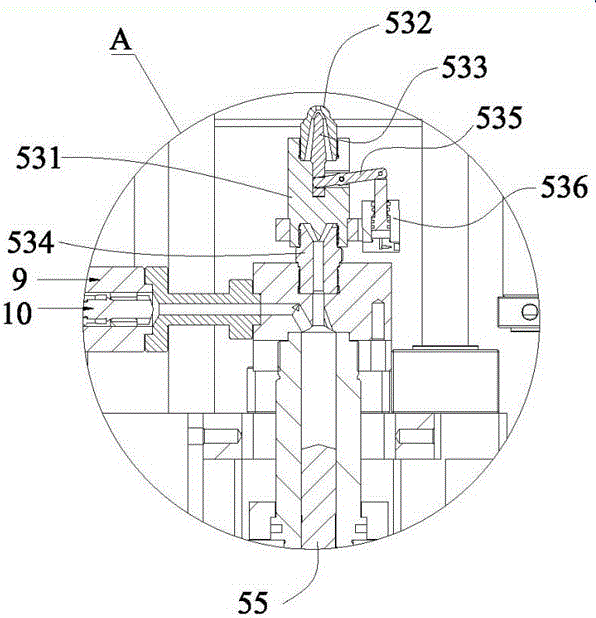

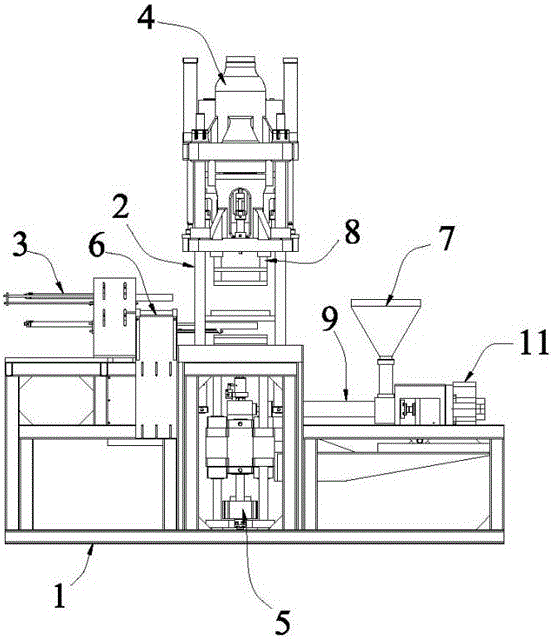

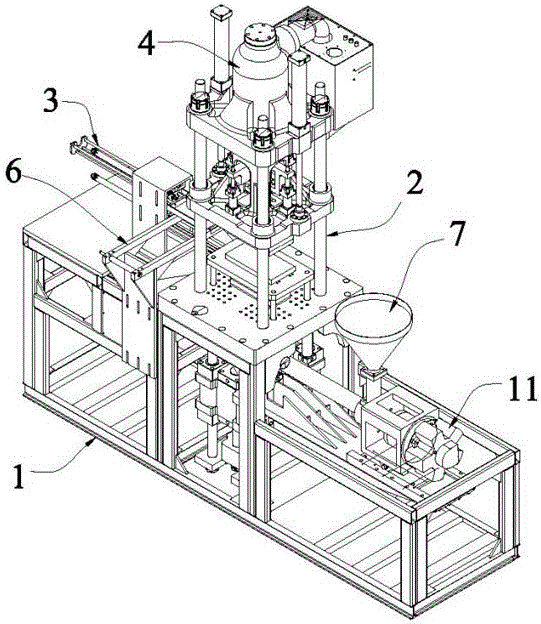

[0032] Examples, see Figure 1 to Figure 5 , a ceramic body injection molding machine provided in this embodiment, which includes a frame 1, a bracket 2, a manipulator 3, a direct pressure mold opening and closing device 4, a material injection mechanism 5, a product conveyor belt 6, a hopper 7, a molding Mold 8, plasticizing barrel 9, screw rod 10 and plasticizing motor 11, said bracket 2 is arranged vertically in the middle of frame 1, said forming mold 8 is located on bracket 2, said direct pressure type mold opening and closing device 4 It is arranged on the top of the bracket 2, and can drive the forming mold 8 for mold opening or closing. The injection mechanism 5 is arranged at the bottom of the frame 1 corresponding to the lower position of the forming mold 8, and the stop of the injection mechanism 5 The retroreflection nozzle presses against the feed port of the forming mold 8, the plasticizing barrel 9 is horizontally arranged on the frame 1, one end of the plastici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com