Diamond tool bit slope grinding device

A diamond cutter head and grinding technology, which is applied in the direction of grinding driving device, grinding workpiece support, grinding machine tool parts, etc., can solve the problems of low production efficiency and inability to meet social needs, and achieve high production efficiency and structure Compact, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

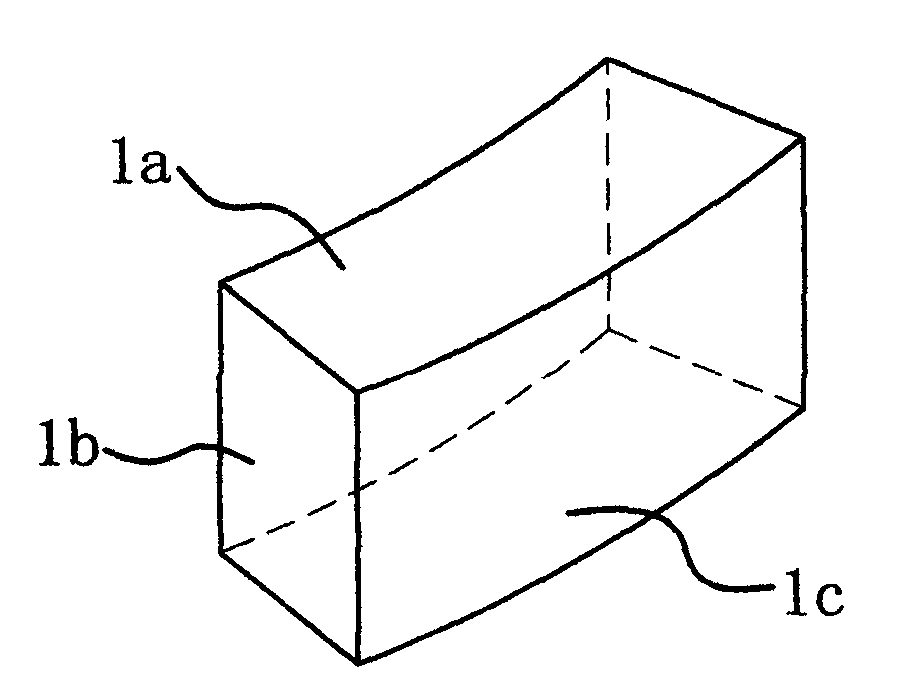

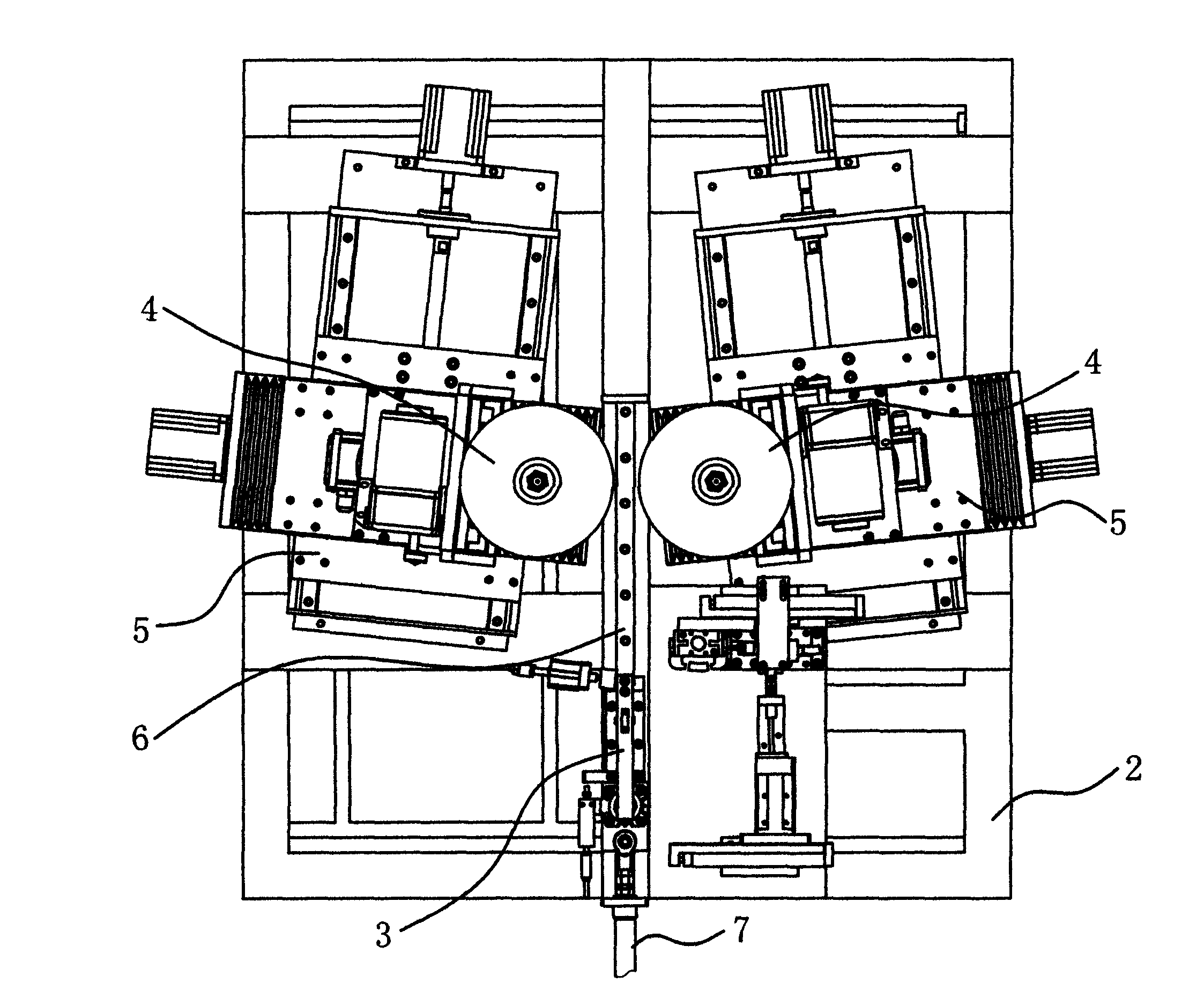

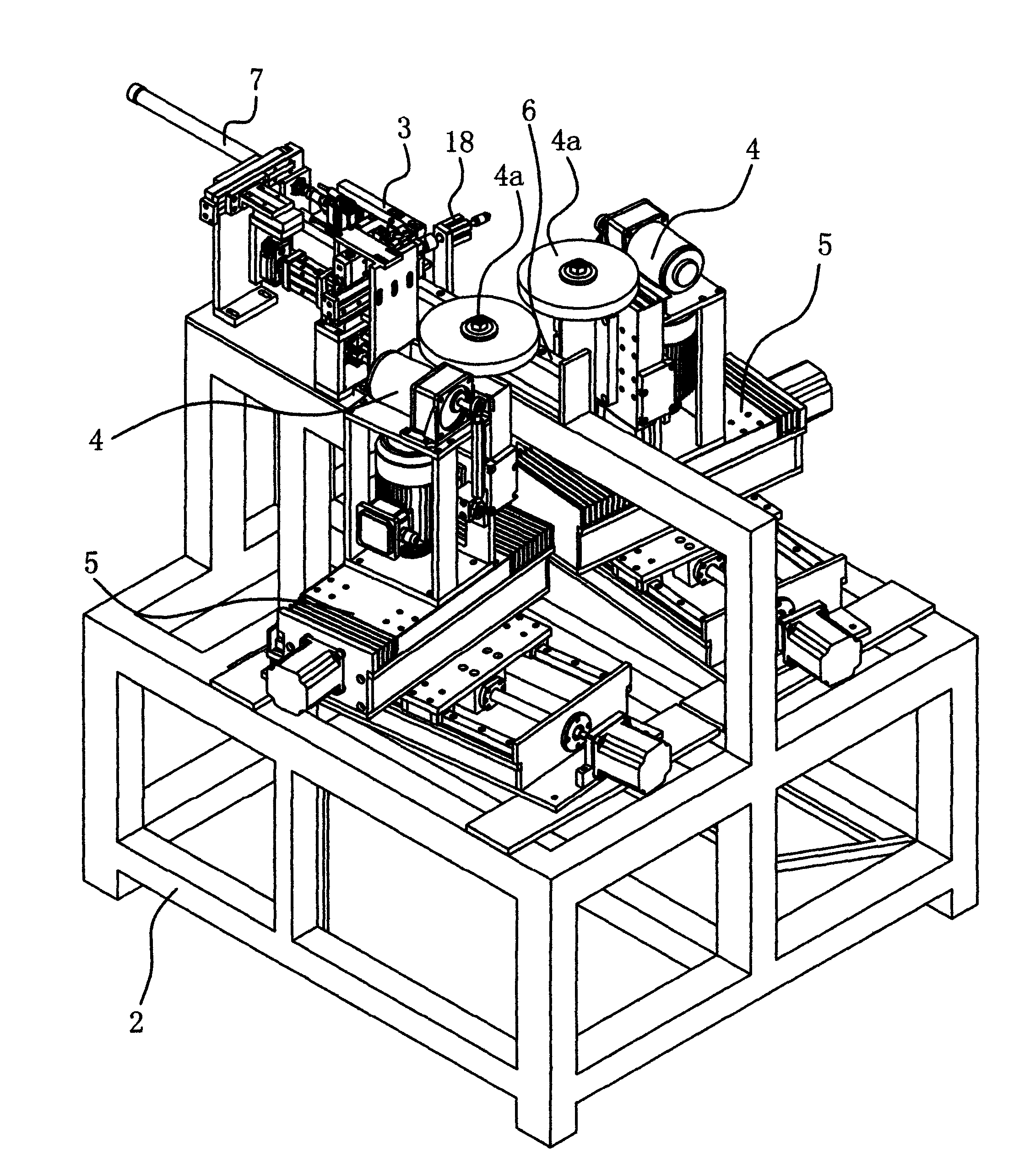

[0036] The diamond cutter head inclined surface 1b grinding device includes a frame 2 , a fixture 3 , a grinding mechanism 4 and a feeding mechanism 5 .

[0037] The clamp 3 is arranged on the frame 2 for clamping the diamond bit 1 . In order to facilitate grinding, after the diamond cutter head 1 is clamped, the cutter face of the diamond cutter head 1 faces upward, the bottom face faces, the inner side faces outward, and the two inclined surfaces 1b are located outside the fixture 3 . In order to improve the positioning accuracy, the bottom surface of the diamond bit 1 has been ground and machined. The fixture 3 includes a base 3a, a support block 3b for holding the bottom surface of the diamond cutter head 1 is fixed on the base 3a, a pressing rod 3c is hinged on the base 3a, and one end of the pressing rod 3c is connected with a pressing force for mortgaging the diamond cutter face. Block; the base 3a is inherently connected with the other end of the pressure rod 3c and c...

Embodiment 2

[0049] The difference between this embodiment and the embodiment is that the base 3 a of the clamp 3 is fixed on the frame 2 ; other structures are the same, and will not be described redundantly here.

Embodiment 3

[0051] Compared with the embodiment, the present embodiment also has the following structure: the frame 2 is provided with a fifth linear guide rail 8 vertically arranged with the fourth linear guide rail 6, and the slider of the fifth linear guide rail 8 is provided with a first pneumatic clamp Head 9, the frame 2 is provided with a feeding cylinder 10 which is connected with the first pneumatic chuck 9 and can drive the movement of the first pneumatic chuck 9; The clamp 3 avoids the avoidance cylinder 11 of the movement track of the first pneumatic chuck 9 , and the third drive assembly 7 and the clamp 3 are connected through the avoidance cylinder 11 .

[0052] The diamond bit 1 is first clamped by the first pneumatic chuck 9 . Specifically, the first pneumatic chuck 9 is clamped on the two inclined surfaces 1b of the diamond bit 1 . In order to facilitate the placement of the diamond bit 1 clamped by the first pneumatic chuck 9 into the fixture 3 , the clamp 3 is driven t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com