Acrylate modified polyurethane resin for leather finish and preparation method thereof

A technology of polyurethane resin and acrylate, which is applied in the direction of coating, etc., can solve the problems of limitation and difficulty in increasing solid content, and achieve the effects of fast reaction speed, excellent adhesion, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

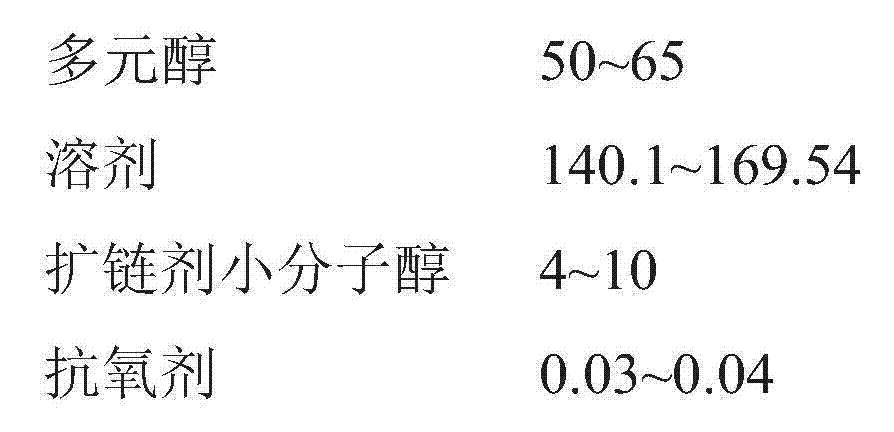

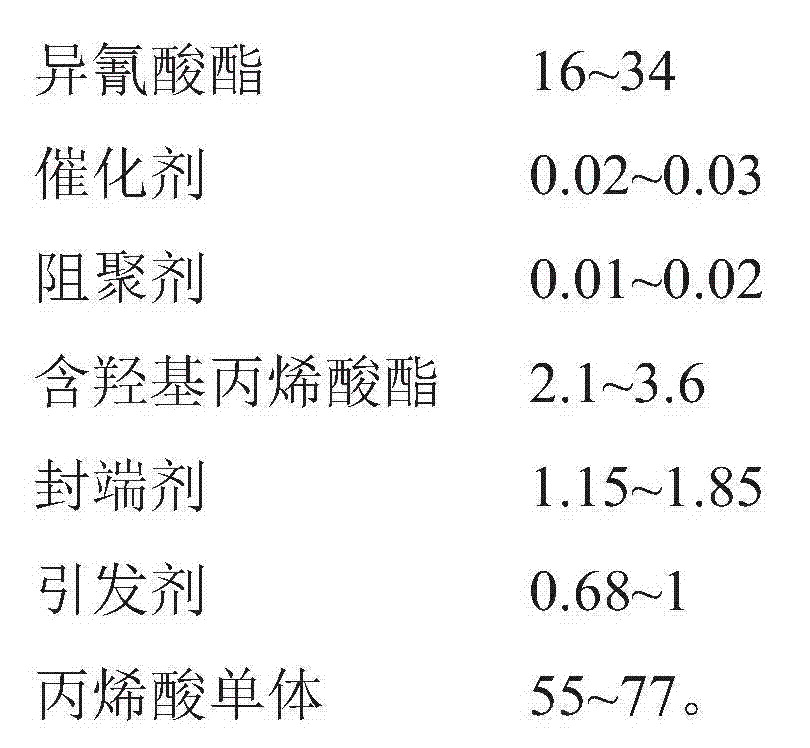

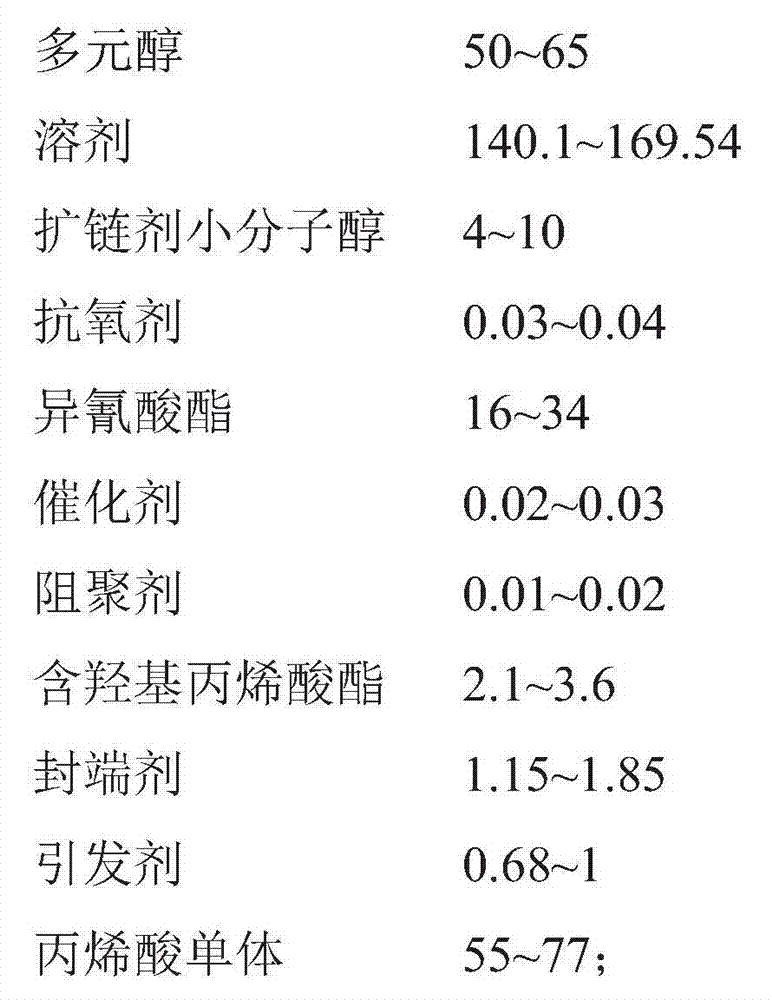

[0032] Embodiment 1: The acrylate-modified polyurethane resin for leather finishing provided in this embodiment is prepared from the following components in parts by weight:

[0033]

[0034] Described polyol is polyester polyol or polyether polyol, wherein, described polyester polyol is the polyol of adipic acid series, and described polyether polyol is polyoxypropylene glycol, poly Any one of oxypropylene triols, or a combination of two of them.

[0035] The solvent is a combination of one or more of ketones, benzenes, and esters; the chain extender small molecule alcohol is ethylene glycol, propylene glycol, methyl propylene glycol, 1,4 butanediol A composition of one or more of them; the isocyanate is a composition of one or two of toluene diisocyanate and isophordione diisocyanate.

[0036] Described antioxidant is the composition of one or both in 2,6-di-tert-butyl p-cresol, antioxidant 1010; Described catalyst is dibutyltin dilaurate, stannous octyl ester, , one or...

Embodiment 2

[0051] Embodiment 2: the acrylate-modified polyurethane resin for leather finishing provided by this embodiment, and the preparation method, its components and steps are basically the same as in Example 1, except that:

[0052] An acrylate-modified polyurethane resin for leather finishing, which is prepared from the following components in parts by weight:

[0053] Polyoxypropylene diol: 65g, toluene and the mixture of toluene and butyl acetate: 148g, 1,4 butanediol: 10g, antioxidant 1010: 0.04g, toluene diisocyanate: 34g, dibutyltin dilaurate: 0.03g, hydroquinone: 0.01g, hydroxypropyl acrylate: 2.88g, n-butanol: 1.56g, azobisisobutyronitrile: 1g, acrylic acid monomer: 77g, and the acrylic acid monomer is methacrylic acid A mixed liquid of 73 g of methyl ester and 4 g of acrylic acid.

[0054] The preparation method of the aforementioned acrylate-modified polyurethane resin for leather finishing, which comprises: weighing the aforementioned components in parts by weight;

[...

Embodiment 3

[0057] Embodiment 3: The acrylate-modified polyurethane resin for leather finishing provided by this embodiment, and the preparation method, its components and steps are basically the same as those in Embodiment 1 and 2, except that:

[0058] An acrylate-modified polyurethane resin for leather finishing, which is prepared from the following components in parts by weight: polyoxypropylene triol: 50g, toluene: 145.1g, a mixed solution of 1,4 butanediol and ethylene glycol : 7.88g, of which, 1,4-butanediol 5.4g, ethylene glycol 2.48g, 2,6-di-tert-butyl-p-cresol: 0.03g, toluene diisocyanate: 26.1g, dibutyltin dilaurate: 0.03 g, hydroquinone: 0.01g, hydroxypropyl methacrylate: 3.6g, n-butanol: 1.85g, azobisisobutyronitrile: 0.84g, acrylic acid monomer: 60g, wherein the acrylic monomer is formazan A mixed liquid made of 54.8 g of methyl acrylate and 5.2 g of acrylic acid.

[0059] The preparation method of the aforesaid acrylate-modified polyurethane resin for leather finishing com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com