Method for deep purification and efficient recovery of trace phosphorus in biochemical tail water

A deep purification and biochemical technology, applied in chemical instruments and methods, water/sewage treatment, neutralized water/sewage treatment, etc. The effect of low cost, lower operating cost and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

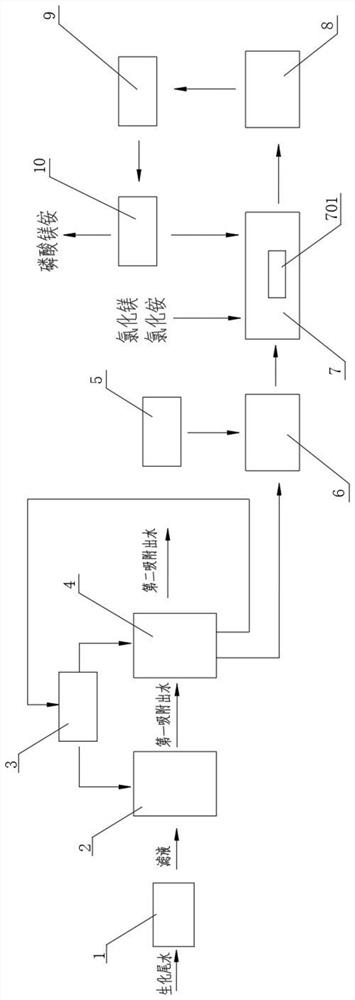

Method used

Image

Examples

Embodiment 1

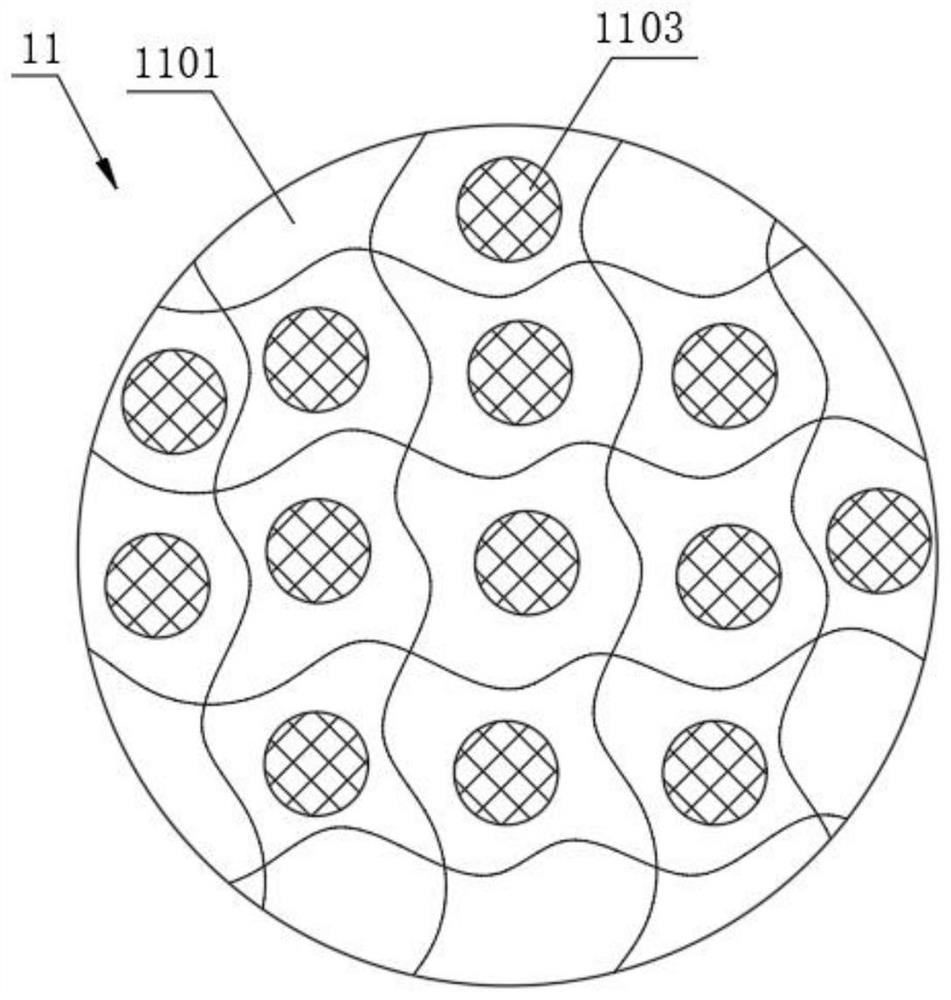

[0051]Pass the sewage with TP concentration of 2.47mg / L and COD of 43.5mg / L through a quartz sand filter to obtain a filtrate with SS≤5mg / L; the filtrate is introduced into the first adsorption tower 2, and the first The adsorption device is filled with ultra-highly cross-linked polystyrene (developed and produced by Nanjing University) modified with dimethylamine groups on the surface to obtain the first adsorption effluent with COD≤15mg / L; the first adsorption effluent is introduced into the second adsorption tower 4 , into the second adsorption tower 4 filled with resin-based nano-zirconia (developed and produced by Nanjing University), the resin-based nano-zirconia is the D201 resin 11 loaded with HZO nanoparticles 1103 in the channel 1101, obtained after the second adsorption device absorbs The second adsorbed effluent with TP concentration ≤ 0.1 mg / L and the second adsorbed effluent is discharged.

[0052] Stop importing the first adsorption effluent to the second adsorp...

Embodiment 2

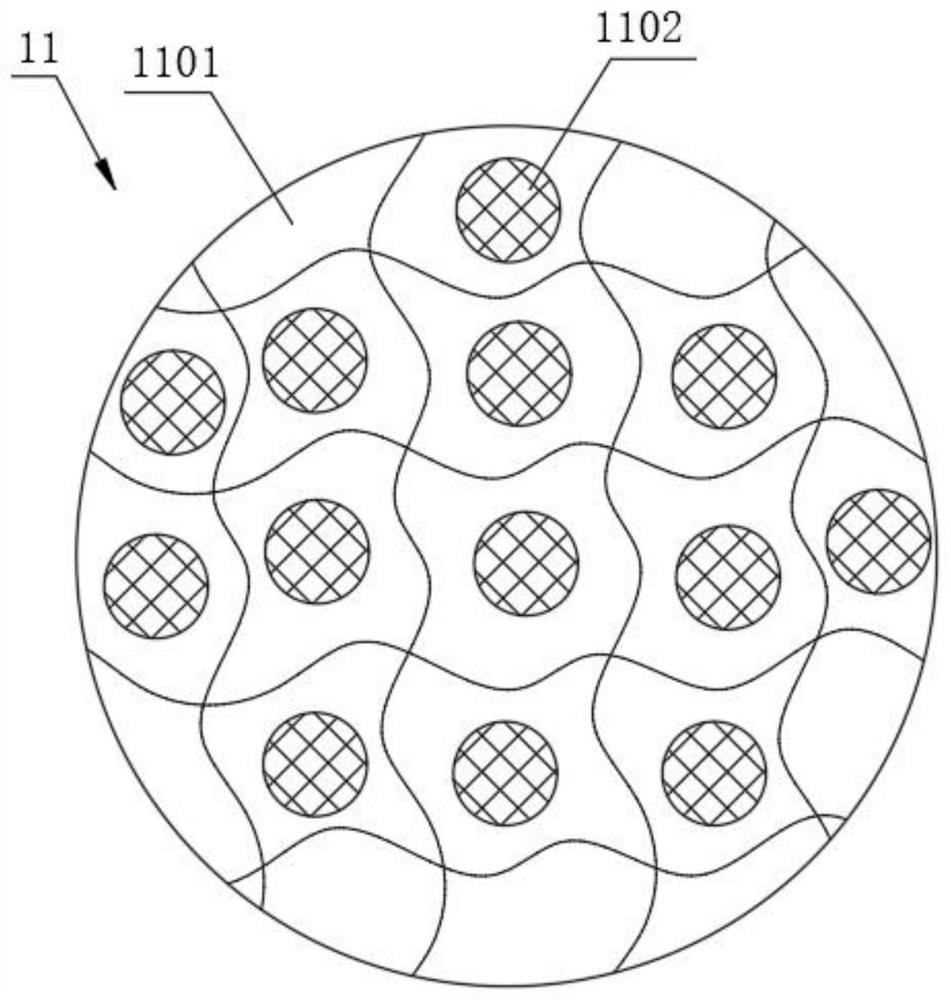

[0055] Pass the sewage with TP concentration of 4.38mg / L and COD of 56.3mg / L through a quartz sand filter to obtain a filtrate with SS≤5mg / L; the filtrate is introduced into the first adsorption tower 2, and the first The adsorption device is filled with ultra-highly cross-linked polystyrene (developed and produced by Nanjing University) modified with dimethylamine groups on the surface to obtain the first adsorption effluent with COD≤15mg / L; the first adsorption effluent is introduced into the second adsorption tower 4 , into the second adsorption tower 4 filled with resin-based nano-iron oxide (developed and produced by Nanjing University), the resin-based nano-iron oxide is the D201 resin 11 loaded with HFO nanoparticles 1102 in the channel 1101, obtained after adsorption by the second adsorption device The second adsorbed effluent with TP concentration ≤ 0.1 mg / L and the second adsorbed effluent is discharged (). .

[0056] Stop importing the first adsorption effluent to ...

Embodiment 3

[0059] Pass the sewage with TP concentration of 1.25mg / L and COD of 35.6mg / L through a quartz sand filter to obtain a filtrate with SS≤5mg / L; the filtrate is introduced into the first adsorption tower 2, and the first The adsorption device is filled with ultra-highly cross-linked polystyrene (developed and produced by Nanjing University) modified with dimethylamine groups on the surface to obtain the first adsorption effluent with COD≤15mg / L; the first adsorption effluent is introduced into the second adsorption tower 4 , import the second adsorption tower 4 and be filled with resin-based nano-lanthanum oxide (developed and produced by Nanjing University), the resin-based nano-lanthanum oxide is the D201 resin 11 loaded with HLO nanoparticles 1104 in the channel 1101, obtained after the second adsorption device absorbs The second adsorbed effluent with TP concentration ≤ 0.1 mg / L and the second adsorbed effluent is discharged.

[0060] When the TP concentration of the second a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com